Processing Prowess

1/196

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

197 Terms

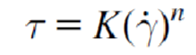

Processing cycle

Definition of Materials Processing

Materials processing is the series of steps that converts as starting materials into functional form with controlled structure and properties.

Three approaches to Material Processing

1) Forming

2) Additive

3) Subtractive

Melt Process

A melt is poured or forced into a mold, through a die, or onto a surface. As it cools, it solidifies into the shape. The melt can also be shaped further before it solidifies. Results in constant cross section

Solid Processes

formation of 3D shapes or constant cross-section shapes by plastically deforming a solid using mechanical stress (e.g., with a die or roll), or by shaping solids through subtractive machining processes.

Powder Processes

Form 3D shapes by filling a die or mold with powder and applying uniaxial or isostatic pressure, optionally with heating. Post-processing such as sintering is typically required for densification, and many additive processes also use powders.

Dispersion and Solution Processes

Forming 3D shapes, sheets, or coatings from a dispersion of particles in a liquid or a polymer solution. Solidification usually occurs as the liquid is removed, such as by drying.

Vapor Processes

transforming vapor into a solid using methods like evaporation, sputtering, or chemical vapor deposition. Subtractive processes then define 2D regions and, with repetition, build 3D structures.

Do we typically change the composition of starting materials

No, only major expectations is manufacturing thermosets

Common Metal Processing steps (non-powder)

1) Extraction of Metal through ore

2) Formulated composition into alloys

3) Melt and cast into standard shapes

4) Solid deformation operations into smaller shapes

5) machining in 3D shape + post-processing

Common Metal Powder Processing steps

1) Extraction of Metal through ore

2) Make into powder

3) compacted into a shape or added in 2D layer

4) Sintering

5) machining in 3D shape + post-processing

Advanced ceramics

aluminum oxide (alumina, Al2O3), silicon dioxide (GLASS, silica, SiO2 ), silicon nitride (Si3N4)

Traditional ceramics

composed of clay materials

Common Ceramic process (non glass)

1) ceramic powders extracted or chemically synthesized

2) Compacted into shape or suspended and molded

3) Sintering

4) Post Process Thermal treatment

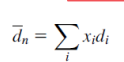

Common glass process

1) ceramic powders and minerals

2) Melting

3)Molding + Blowing or Flowing

4) Post process thermal treatment

Common thermoplastic process

1) Get pellets, particles, etc

2) Extrusions or molding

3) Cutting or machining

Common thermoset process

1) Monomers and curing agents (resins)

2) Flow resin and curing agents into mold

3) Solidify in mold and cool

4) machining

What characteristics do the starting materials affect?

1) properties and performance of final product

2) The processing steps

How to read steel metal grades

1st number shows the class of steel (2000 for nickel steels)

2nd number is a significant composition

3rd and 4th are C wt% *100

Why are most metals starting materials originate from ores?

It is thermodynamically stable for most metals to oxidize

Extractive Metallurgy

Processes to remove metal from ore, always involves crushing and separating first

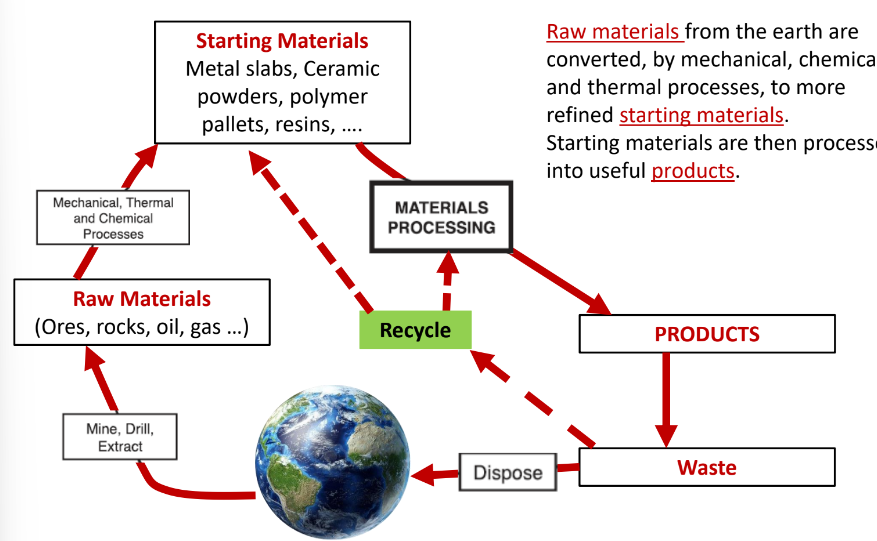

Pyrometallurgy

uses heat to reduce metal compounds in ores with rxn with carbon at high temps, with strict control over temperature and atmosphere. Iron is example

Hydrometallurgy

extracting metals from aqueous solutions by leaching, purifying, and depositing the metal, often using ion replacement or bubbling hydrogen reduction at low temperatures. Example: Copper is extracted by adding iron to a copper sulfate solution and Cu precipitates out

Ion replacement

one ion in a solution is replaced by another ion to precipitate out as a pure metal

Bubbling Hydrogen reduction

Hydrogen gas is bubbled through a metal ion solution, reducing the ions to solid metal, which then precipitates out.

Electrometallurgy

use electrical energy to convert metallic ions into metals. Ions are leached from ore in aqueous solution or molten salt, then electrolysis is used to form the metal. Aluminum is an example

How is scrap metal used in metal processing?

Scrap metal is added at various stages of metal production. It offers economic and environmental benefits. Controlling its composition can be challenging.

2 most common form of iron ore

magnetite (Fe2O4) and hematite (Fe2O3)

Pig Iron Production

1) Add Coke, Iron Ore, and Limestone to the blast furnace

2)coke reacts to O2 to generate CO and heat

3) CO reduces the ore which completes at 1600 C.

How is coke made

Coal undergoes pyrolysis (heating without oxygen)

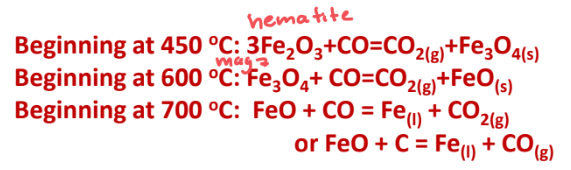

Role of Limestone

Acts as a flux, decomposes to CaCO3 which reacts and removes SiO2 from iron melt and forms slag

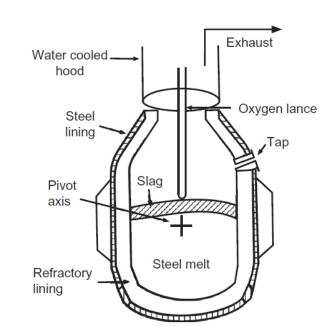

Basic Oxygen Furnace (BOF)

1) Pure O2 blown into molten pig iron, scrap (~30% )and flux

2)O2 reacts with C to lower C content and other impurities to make slag

3) slag is removed

4) Excess Oxygen will need to be removed later

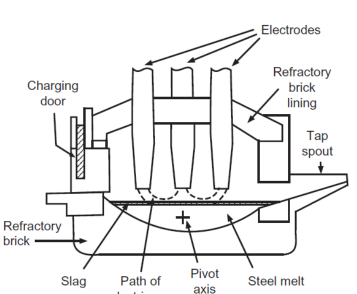

Electric Arc Furnace (EAF)

1) Graphite electrodes melt pig iron and scrap by passing a large current through the charge

2) O2 is added to oxidize impurities

3) Lime flux is added near the end

Which is better EAF or BOF

EAF because it can use more scrap which is cheaper and better for environment

Ladle Metallurgy

1)Remove from furnace into ladle

2) Refine chem by adding deoxidants to remove O2 and make slag

3)Remove slag and ingot or continuously cast

Overall Steel Process

1) Make pig Iron from iron ore and coke at 1600 C

2) Use BOF or EAF to remove impurities with O2

3) Use Lime and other fluxes to remove impurities in slag

4) Pour into ladle and remove excess O2

5) Cast into ingots or continuously cast into smaller shapes

Main source of Al

Bauxite

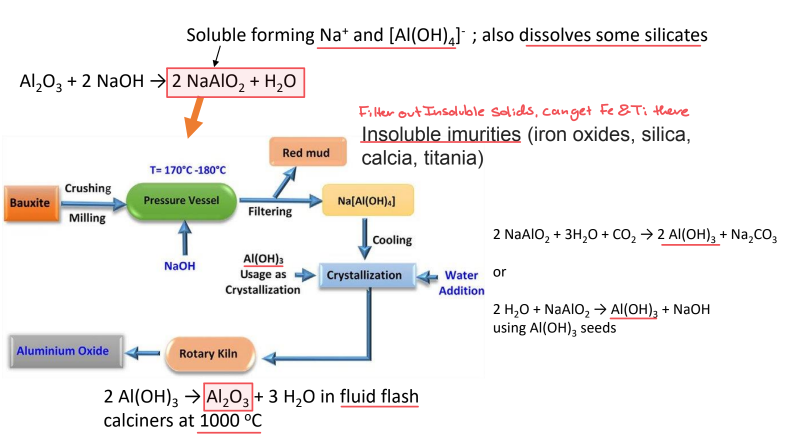

Bayer Process

1) Crush Bauxite

2) Add NaOH to dissolve Al2O3 into NaAlO2

3)FIlter out insoluble impurities

4)Cool and added with Al(OH)3 crystals to precipitate aluminum hydroxide (Al(OH)₃) from the solution.

5) Heat Precipitates to remove water and make alumina (Al2O3)

Hall-Heroult Process

Continuous Process

1) Alumina dissolved in dissolved in a mixture of cryolite (Na3AlF6), aluminum fluoride (AlF3), and a little fluorspar (CaF2) at about 940 C.

2) Carbon Anodes reduce the Al ions to metal Al and some CO and more CO2 are released

3) Liquid Al is dense and collects at the bottom to be removed

Why is recycling Al important

Hall-Heroult Process is energy intensive and releases lots of CO2

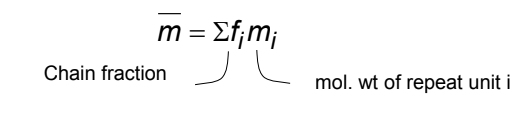

Estimating size of irregular paticle

1)equated to the diameter of a sphere that has the same volume

2) the diameter of a sphere that has the same projected area

Sieving

Weight Distribution, Powder is passed through sieves with progressively smaller openings. The powder retained on each sieve is weighed to determine the PDI

Microscopy

Number distribution, Size and shaped observed, but time consuming

Sedimentation by X-ray absorption

Weight distribution, Sedimentation rate under gravity varies with particle size. X-ray adsorption measures particle concentration at specific locations over time

Laser Difraction

Volume distribution, Laser light diffraction from particles in a liquid is measured to determine size. The spatial distribution of diffracted intensity is proportional to size

Photon Correlation Spectroscopy

Number distribution. Suspension of particles in a liquid is light with coherent light, and the scattered light is measured. The Brownian motion of small particles modulates the scattered intensity, which is related to particle size.

List of Metal Powder Processes

Mechanical Methods

Melt Atomization

Oxide Reduction

Chem and electrochem processes

Powder processing with Mech Methods

Can be made from chips and shavings, but hard to do with ductile materials

Melt Atomization

A stream of liquid metal is broken up (atomized) by gas or water jet into droplets that solidify into particles as they cool.

Oxide Reduction

High-purity, size-controlled metal powders are made by heating ceramic powders in a reducing atmosphere to convert them into metal powders.

Chemical and Electrochemical Processes

Metal powders may be formed by precipitation due to chemical or electrochemical reduction of aqueous salt solutions.

Ways to get alloyed powders

Prealloyed powder

Admixed powders

Bonded powder

How to tailor PDI

Sieve

Blend - add 2 diff sizes

Comminution - Mill

Additives - Add binders etc

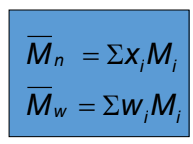

Get average diameter size

4 ways to make ceramic powders

Mineral Process

Chemical Solution Process

Solid State Reaction Process

Gas Phase Process

Ceramic Powder Mineral Process

Mined materials like clay and quartz are crushed and processed to remove impurities and standardize particle size. Advanced ceramics, such as zirconia and alumina, undergo further purification and processing

Powder Chemical Solution Processes

Inorganic chemicals are dissolved in water or organic solvent to produce metal oxides thru precipitation, gelation, or evaporation. Then heated to produce final oxide powder

Ceramic Powder Solid State Reaction

Multicomponent ceramic oxide compositions can be prepared by solid state reaction of materials created by mineral-based or chemical solution processes.

Ceramic Powder Gas Phase Process

Gases or vapors as one or more of the reactants. Metal Chloride vapor and water vapor heated in a reactor or passing gas over solid reactant.

Comminution

Reducing particle size and break agglomerates thru crushing,millimng and grinding

Bigger parilces break up first due to more flaws

Ceramic Additives

- Binders (to bind particles to each other)

- Dispersants (to prevent particles from clumping together and dispersed

- Surfactants (reduces surface tension)

- Deflocculants (to scattered particles in suspension)

Glass starting material

Glass formers: SiO2, B2O3

Flux: salt cake (Na2SO4) to lower melting point and viscosity

Other glass modifiers: limestone (CaCO3) for chemical stability and durability (positive charged modifiers)

Glass process

A continuous process to final product

Why is viscosity of glasses important

Determines how easily the glass can be made, modifiers are added to dcrese viscosity

Chain growth polymerization

involves three steps: initiation, propagation, and termination

Step growth polymerization

involves the reactions of two chemically different monomers

The two species are typically difunctional (i.e., they can react at both ends) so that chains grow as reaction proceeds.

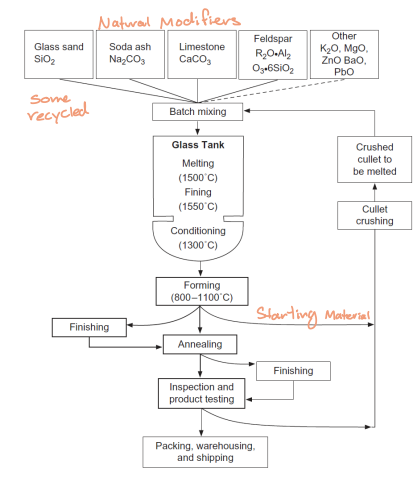

Number Average and Weight Average Formula

Average molecular weight formula

Thermoplastic starting materials

pellets, granules, flakes and powders

Thermoset starting materials

mixes that contain prepolymers or oligomers (low molecular weight polymers) as well as hardeners, curing agents, or initiators.

Bulk Polymeriztion

Reactants are combined with initiators in a controlled vessel to synthesize polymers, mainly through chain addition reactions. The process yields high-purity polymers but poses challenges in controlling temperature, molecular weight, and managing increasing viscosity during mixing.

Solution Polymerization

Solvent is used to dissipate heat during polymerization, with all components dissolved in the solvent. This method has a lower yield than bulk polymerization and requires solvent removal afterward.

Suspension Polymerization

A liquid is used to remove reaction heat, with reactants suspended as droplets. Additives maintain small droplet sizes, resulting in small polymer beads that are later formed into larger pellets. However, purity is lower due to the use of these additives.

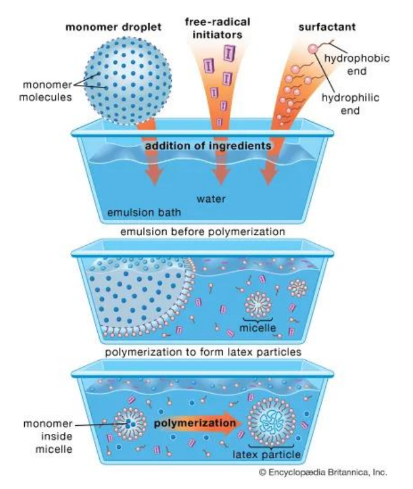

Emulsion Polymerization

Water is used as a medium for monomer droplets and initiator in suspension polymerization. Surfactants stabilize the droplets and form micelles. The monomer diffuses into micelles and reacts with a water-soluble initiator, forming solid polymer particles suspended in water, known as latex, used in paints and adhesives.

How to make Low density PE (LDPE)

High pressure bulk polymerization, high temp and pressure are used to increase the MW. Also lots of initiator is used to create many small chains which lowers density b/c it cant crystalize

Gas phase fluidize bed process

Makes both HDPE and LLDPE. Ethylene gas is fed into a reactor packed with catalyst and polymer particles to create reactive sites and polymerizes

DIfferent stages of resins

Stage A resins - no crosslinking

Stage B resins - partly polymerized

Stage C resins - fully crosslinked

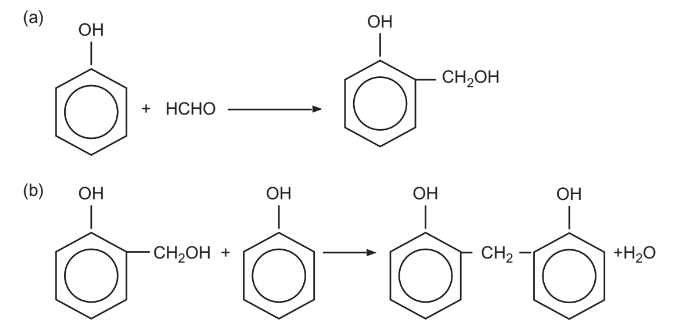

Phenolics

(a) The reaction between phenol and formaldehyde to form a hydroxymethyl substituted intermediate

(b) condensation reaction between phenol and hydroxymethyl substituted intermediate to make phenol

Resoles

One step

Liquid or solid resins made from phenol and formaldehyde oligomers (B stage).

Capable of reacting without additional additives.

Produced in small quantities with a limited shelf life.

Novolacs

Formed under conditions that produce low molecular weight polymers without reactive hydroxymethyl groups.

Water by-product is continuously removed.

Cannot form crosslinked polymers without a curing agent (2 step)

Have an infinite shelf life

3 steps in every melt process

Flow

Shape definition

Shape retention

Materials that use melt processes

Metals - most common method

Glasses

Thermoplastics

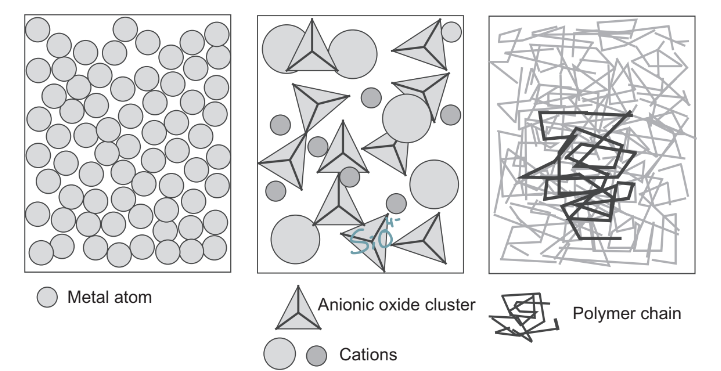

Models of melts for each material class

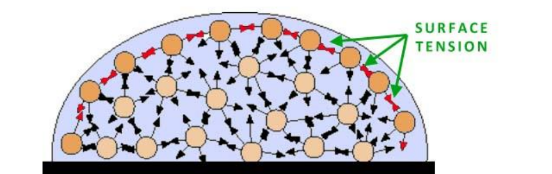

WHat causes surface tension

Surface molecules are more strongly attracted to their neighboring molecules in the liquid due to fewer molecules in the adjacent vapor phase.

This imbalance in forces at the liquid's surface results in surface tension.

Equivalent to surface energy/interfacial energy

Forms spherical shape to minimize energy

Do molten metals have the higher surface tensions

Yes because they have have stronger bonds (shon by Higher Tm)

Relation between Surface tension and bond strength

Stronger bonds lead to higher surface tensions

Contact angle

The contact angle is the angle formed at the interface between a liquid droplet and a solid surface.

It indicates the wettability of the surface: smaller angles represent better wetting, while larger angles indicate poor wetting.

What usually happens to surface tension as temp increases

Usually decreases (weaken bonds)

Do larger or smaller bubbles have a larger internal pressure

Smaller

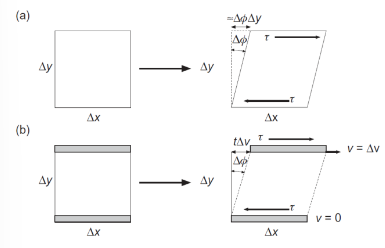

Laminar Flow

Sliding of layers with infinitesimal thickness relative to adjutant layer, no mixing

Turbulent flow

Irregular motion with fluctuation in velocity, promotes mixing

Fundamental difference between solid and liquid

Ability to withstand a shear stress, liquids can not

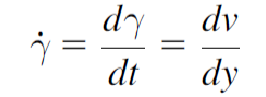

Shear strain rate

Can use velocity because top plate is moving with speed v while the bottom plate is stationary

Viscous heating

Viscous heating occurs when a liquid is sheared, increasing its internal energy due to work done on it.

If no heat exchange with the surroundings occurs, the liquid’s temperature rises due to friction

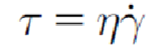

Viscosity

Viscosity is a measure of a fluid's resistance to flow and deformation.

It quantifies internal friction within the fluid, determining how easily it can move.

Relationship between shear stress and strain rate (newtonian)

Shear thinning

is when a fluid's viscosity decreases with increasing shear rate.

This means the fluid flows more easily when subjected to higher stress or agitation

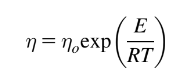

Viscosity’s relationship with temperature

Decreases with increasing temp

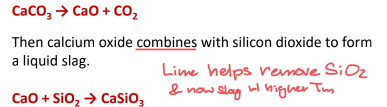

Non-Newtonian Fluid

fluid whose viscosity changes with the applied shear rate or shear stress.

Equation for non-Newtonian fluids