Ch3 - 4 Energy

1/95

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

96 Terms

Geology

Joint adn Fault Lines: earth curst break and fractures in joints where the fault lines form that split crust

Drilling seeps (instruments)

1920

Torsion balance - measure the gravitational acceleration at the Earth's surface

Seismology - measure earthquakes by their magnitude, energy release and intensity

Vibroseis - Vibration used to create wavetrain.

Gravitometer - measures variations in the Earth's gravitational field

Magnetometer - measuring magnetic forces, especially the earth's magnetism

Wireline log - a continuous measurement of formation properties ran on a wire

Sampling/coring - sample or cylindrical piece of subsurface material

4 crucial characteristics in Resovoir

Source of hydrocarbon, POROUS (void space in rock), PERMEABLE (movement of flow), TRAP

Hydrostatic Pressure

Important aspects are weight of fluid and MD

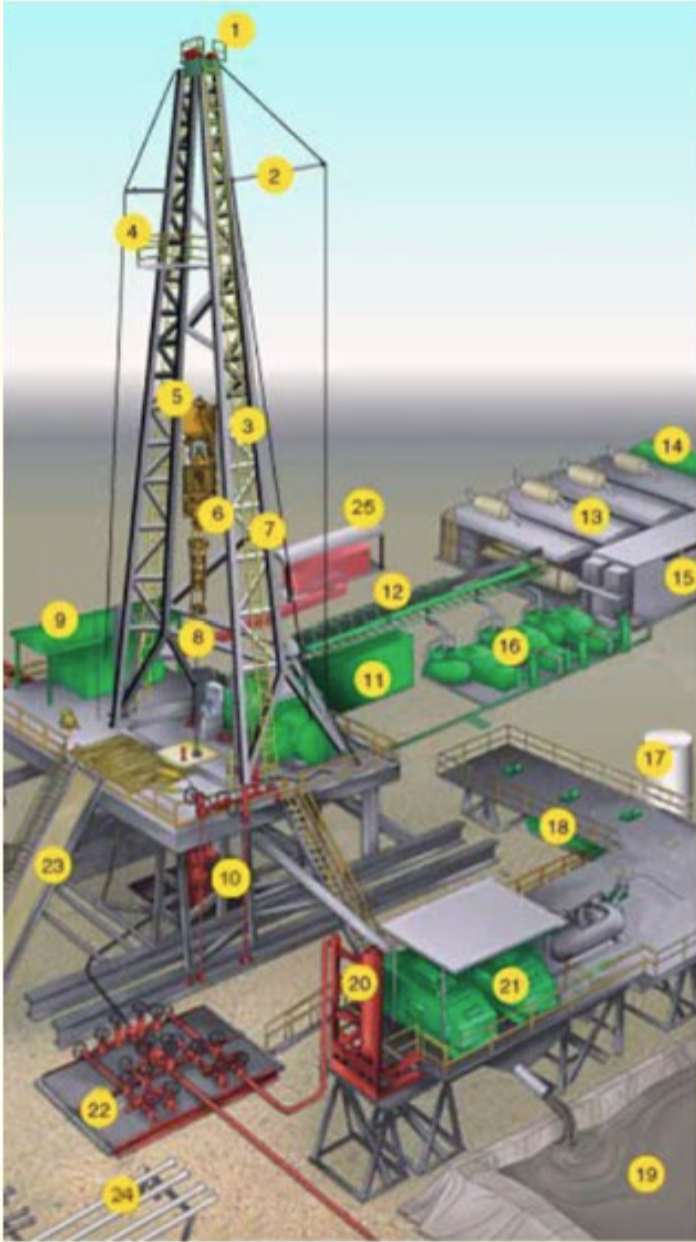

2 Main Requirements for Rotary Rig

Rotation and Circulation

Derrick Must have these systems

Power system

Hoisting system

Rotary system

Fluid circulating system

Well control system

Data acquisition system and monitoring system

Latest development (Walking ability, developed for PAD Drilling)

Types fo Derrick and Masts

Cantilever

Folding

Telescoping

Bootstrap mast

Substructure

gives space between well floor for well control system/equipment (BOP)

Drill string

The bit is attached at the end of the drill string at the bottom of the well, or hole. The drill string connects the bit to the handling equipment at the surface of the rig (is composed only of the drill pipe and tool joints)

Drill pipe

special pipe with thread and shoulder end connections, called tool joints that is used to connect the drill bit to the surface and transmit drilling fluid to the bit.

Drill collars

thick-walled steel pipes placed at the bottom of the drill string to provide weight for the bit and keep tension in the drill string.

WOB

Weigth on bit

ROP

Rate of Penatration of the formation

TIH

Trip in hole

TOOH

Trip out of hole

BR

Bit Run (when to change bit)

Power system

Gas or Diesel generators

Hoisting System

Kelly Drive

This method is Cheap / Slower limitation is the length of the kelly

and the potential for rotation issues. It involves using a square or hexagonal tool to transmit torque to the drill bit.

Some specs

Top Drive

A drilling system that allows for the rotation of the drill string from the top of the derrick, improving efficiency and reducing the risk of issues associated with traditional rotary systems. Less connections and quicker tripping times.

Components:

• A – Elevator

• B – Bail or Link

• C – IBOP (both manual and pneumatic operated)

• D – Rotating Head

• E – Top drive motor

• F – Dolly Track

• G – Hook

• H – Travelling Block

Other important components

Civil

wireline

Casing

Cementing

The Circulating System

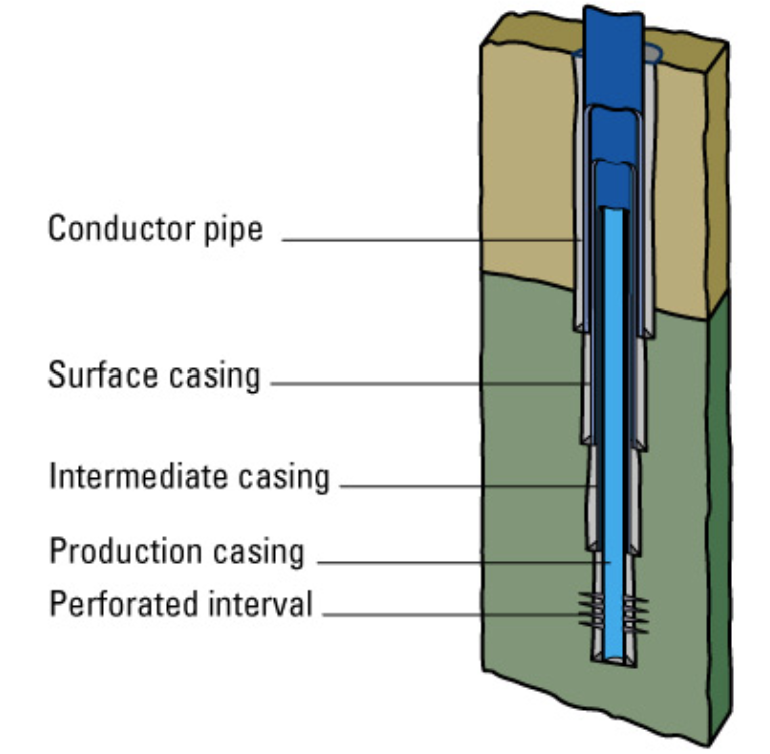

Casing

Prevents formation walld to cave in

Prevents crossflow

Well Control Systems

BOP: A device used to control the flow of fluids from a well during drilling, completion, and workover operations. (Temporary: have rams and kill/choke lines)

Wellhead: there for the life of well in celluar and monitores anulus

Drill stem

whole drill from swivel to bit

BOP Accumulator 3

Side of the rig use prevent a blow out (hydrolic powered system)

Type of Rams

Blind and Shear Rams

Pipe Failures

Pure fatigue (Cycling loading in the hole)

Notch fatigue (from setting slips)

Corrosion fatigue (Critical for weld section of hte

tool joint on welded pipe vs Forged Pipe)

Drill collars

thicker more weight between drill pipe and bit

Pendulum effect

Defined as the tendency of the drill stem to hang in a vertical position due to the force of gravity. The heavier the pendulum, the stronger is its tendency to remain vertical and the greater the force needed to cause the drill stem to deviate from vertical

BHA

(bottom hole assembly) lower portion of the drill string, from the bit, bit sub, a mud motor, stabilizers, drill collars, heavy-weight DP, crossovers for various thread forms.

MWD

Measure While Drilling (mud telemetry)

LWD

Logging while Drilling (Geosteering near bit)

2 Main category of bits

Rolling cutter bits and Fixed cutter bits

KOP

Kick of point (direction changes)

TVD

True vertical Depth

TD

Target Depth

MD

Measure depth

Inclination

departure from vertical

Azimuth

Depature from magnetic north

Spider Plot

used to survey area

Different Method of deviating the wellbore

Whipstocks

Jetting

Rotary BHA adjustable stabilizer

Traditional Motor

Rotary steerable assy

Positive Displacement Motors

only the bit and rotar can move

Bent Housing

Orient the direction in which the bit is going to travel

Dogleg severity

measure of the amount of change in the inclination, and/or azimuth of a borehole, usually expressed in degrees per 100 feet of course length (low=small)

Rotary Steerable

No more sliding and has an adjustible tool face thru Mud Telemetry

Wireline Operations

Delivery method for tools on a wire through trucks

Run it before you case (survey area)

Case tool wireline (diff)

Perforating guns could work

Cementing

Create Zonal Isolation • Protect Useable Water • Provide Structural

Support for Casing • Protect Casing from Corrosion • Isolate Casing Seat for

Subsequent Drilling

Rig crew

Company man (onsite manager)

Rig manager (rotating schedule)

Derrickman

motorman

Floorman

Prep for stimulation

Tubing head installed, then valve, Clean up, Xmas tree

Stimulation

ensure the hydrocarbon are able to flow in the well bore

Frac

Artifcal lift (pump jack, Electrical submersible pumping (ESP), gas lift, plunger)

Fishing operations

when something falls into pipe (junk) and needs to be fished out

First Offshore

Socali in late 1800s

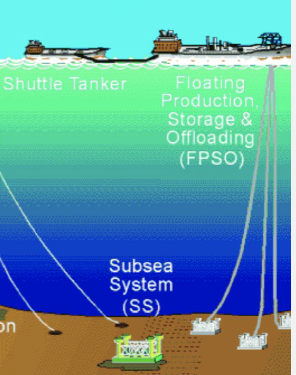

FP

Fixed platforms

CT

Compliant Tower

TLP

Tension Leg Platform

Mini-TLP

Mini-tension Leg Platform

SP

SPAR Platform

FPS

Foating Production systems

FPSO

Floathing Production storage and offloading

SS

Subsea system

Barges

brings well to surface for a dry well

Submersible

leveraging large bottles but same concept of a parge

Jack up

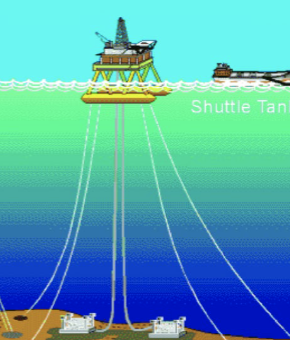

Have legs sumerge in sea floor for about 500ft

Semi Sub

Floating units > 500

column-stabilized

Subsea Wellhead

LMRP

Lower Marine riser package allows for quick disconnect of the marine rise

Heave Compensation

helps with sea movements and keeps the drill and piping sationary (passive, active, and both)

SubSea BOP

Same concept but bigger/heavery and has LMRP and lower stack with valve controls

Marine Riser

cylindrical pipe connecting a subsea wellhead

Biggest diff from Onshore and Offshore

Econmics, Time fram, Tech diff, Storage and transport

FEED

Front end Enngineering design

EPC

Engineering Procrment Construction

Green Field

Conceptulize what to do in new terretory (first one)

Brown Field

Planning in prexisting area (been drilled at)

FID

Final Investment Deciscions

ROV

Remote operated vehicle

Flow Assurance

Ensures mesaures in case there is issues like frozen methane in piping due to extreme temp changes in sea

Mudmar, suction pile

Prevent offshore structures from sinking into seabed

subsea equipment

Vertical Subsea Tree

valves in a vertical bore

Advantages:

• Vertical trees require only one time BOP nipple down.

• No wireline plug to be removed from a tree for a well intervention program.

• Better for fields that don’t expect to do workover or have small chance of doing the workover

• Simpler and cheaper to change a vertical tree when compared to a horizontal tree

• Disadvantages:

• If the workover operations such as recompletion, changing tubing, installing extra downhole tools, etc. are required, a vertical tree must be removed in order to install BOP on top of the well.

Horizontal Subsea tree

valves in a horizontal configuration

Advantages:

• Better for fields that expect to do workover quite often because a tree does not need to be removed.

• Can have a larger bore tubing

• Lower total height of a tree

• Disadvantages:

• Less flexibility for operation if the delivery of a tree is delayed.

• Two runs for subsea BOP and riser are required

• Completion string must be removed if replacement of a tree is needed.

• Two wireline plugs (crown plugs) must be removed before starting any well intervention program. There have been several cases when people have faced a lot of difficulty for removing the plugs. This can lead to extra time and cost forthe operation

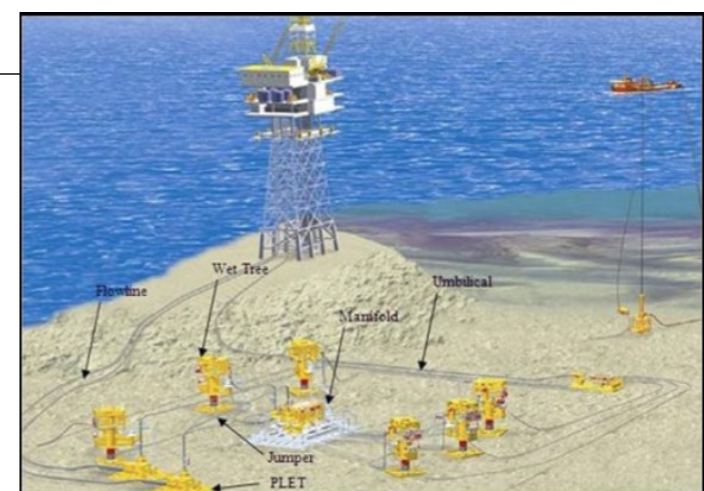

Manifold

Structure w/ valves and pipework designed to commingle and direct produced fluids from multiple wells into one or more flowlines

Jumpers

short pipe connector that is used to transport production fluid between two subsea components

Umbilical Systems (UTA)

bundled arrangement of tubing, piping, and/or electrical conductors in an armored sheath that is installed from the host (umbilical termination assembly)

Subsea Flowlines

pipelines used to connect a subsea wellhead with a manifold or the surface facility

FLNG

Floating Liquefied Natural Gas

FSRU

FLoating Storage Regasification Unit (stores LNG)

Production Riser

portion of the flowline that resides between the host facility and the seabed adjacent to a host facility

PLET

Pipline ends and In line termination: subsea structures designed to attach the pipeline end and then lowered to the seabed in the desired orientation

PLEM

Pipeline end manifold

HIPPS

High integrity presuure protection system

CIU

Chemical injection unit

SDU

Subsea Distribution unit (hydrolic and electircal control system)

Riser Tensioner

type of heave compensator