engineering 2023 | prelims

1/165

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

166 Terms

moment and couple (formula)

M=Fd

concurrent

all acting through the same point

friction (definition)

the resistance to motion of two bodies in contact

coefficient of friction (definition)

the ratio of the frictional force present and the normal reaction of the two surfaces in contact

friction (formula)

F=μN

influences on friction

mass/normal reaction

type of material

pascal’s principle

the liquid spreads to fill up to the edges of a container

the increase in pressure is evenly spread through the liquid

a small force (in a small container) can be turned into a larger force (in a larger container)

shear stress

the tendency to cause deformation along the planes parallel to the imposed stress

liquids and shear stress

cannot support shear stress

deform and take the shape of the container

solids and shear stress

may deform elastically, but generally maintain a fixed form and volume

hydrostatic pressure applications

hydraulic braking systems → use hydraulics to amplify the force applied on the brake pedal to clamp the discs to stop the wheels

work (definition)

occurs when a force causes motion

forces do work

measured in joules (J)

work (formula)

W=Fs

energy (definition)

the measure of it’s capacity to do work

types of energy

mechanical, potential, kinetic, chemical, electrical, heat, atomic

potential energy

a measure of the object’s ability to do work due to a specific position

kinetic energy

energy an object possesses due to motion

amount of kinetic energy a body possesses = the amount of work required to bring it to rest

law of conservation of energy

energy can be neither destroyed nor created, rather transformed from one form to another

power (definition)

the rate at which work is done

measured in watts (W)

6 types of simple machines

lever, screw, wedge, inclined plane, pulley, wheel and axle

lever

consists of a rigid bar that rotates around a fulcrum

applying one force on one end amplifies the output force

examples of levers

scissor, wheelbarrow, hammer

inclined plane

sloping surface that allows the movement of an object up/down

examples of inclined planes

ramp, slide, roof, funnel

wheel and axle

consists of a circular wheel attached to a shaft (axle)

when force is applied to the wheel, the axle rotates

examples of wheel and axles

bicycle, doorknob

wedge

used to split or hold objects in place

consists of a sharp pointed edge

examples of wedges

shovel, zipper, knife

screw

an inclined plane wrapped around a cylindrical post

when rotated, moves through solid material

useful for holding objects together or lifting them

examples of screws

lightbulbs, corkscrew

pulley

a wheel with a groove to hold.a rope

pulling one end allows the lifting of objects vertically

examples of pulleys

elevator, flagpole

1st order lever

fulcrum in the middle

MA and VR >, <, = to 1

2nd order lever

load in the middle

MA and VR > 1

3rd order lever

effort in the middle

MA and VR < 1

1st order levers in the body

neck muscles to keep your head up

triceps when pulling a load

2nd order levers in the body

lifting your heel up

3d order levers

biceps when holding an object

mechanical advantage (definition)

a measure of the benefit in using simple machines (usually levers)

the higher the MA, the more efficient

MA (formula)

MA = load/effort

mechanical disadvantage

E > L

what does it mean if the fulcrum is closer to the load

less effort needed

velocity ratio (defintion)

the ratio of the distance moved by the effort compared with the distance moved by the load

the higher the VR, the greater distance the user must move

VR (formula)

VR = length of effort arm / length of load arm

finding the VR in pulleys

count the number of ropes excluding the load rope

efficiency (formula)

η = MA/VR

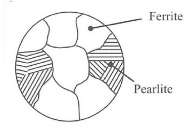

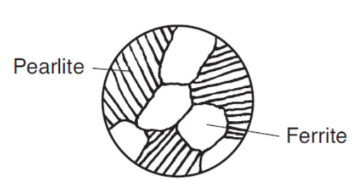

hypo-eutectoid steel

hypo-eutectoid steel (carbon)

0.2%

hypo-eutectoid (properties)

high ductility, malleability and weldability

what happens when carbon content in steel increases?

strength and hardness increases

ductility and weldability decrease

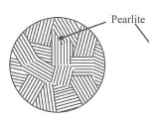

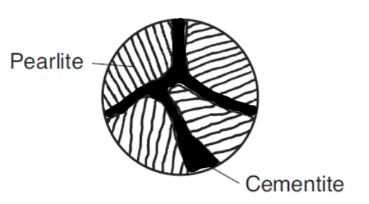

eutectoid steel

eutectoid steel (carbon)

0.8%

eutectoid steel (properties)

good toughness and high tensile strength

high production

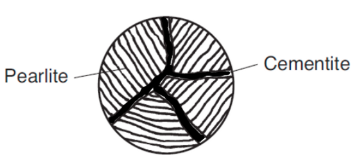

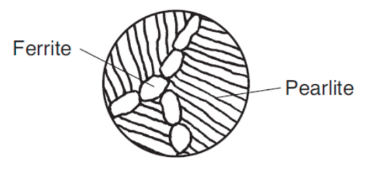

hyper-eutectoid steel

hyper-eutectoid steel (carbon)

1.2%

hyper-eutectoid (properties)

good wear resistance, toughness and hardness

austenitestructure

FCC

denoted as solid grey sections

austenite

forms when liquid steel first starts to cool

does not exist below 723 degrees

dissolves up to 2% carbon

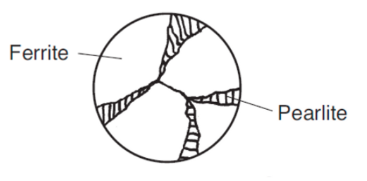

ferrite structure

BCC

denoted by white sections

ferrite

as the steel cools, the austenite will turn into ferrite

very small amount of carbon (0.025%)

ferrite properties

soft and ductile

cementite structure

ferrite doesn’t absorb much carbon, so the rest of the carbon joins with the remaining iron to form cementite

denoted by solid black cracks

cementite properties

hard and brittle

increases the hardness of the steel

lowered ductility and toughness

pearlite structure

layers of ferrite and cementite

a lamellar structure (layered)

denoted by striped sections

pearlite properties

hard and strong

not tough

order of steel formation

austenite, ferrite, pearlite, cementite

dead mild steel

dead mild steel (carbon)

0.07 - 0.15%

dead mild steel (properties)

highly ductile and elleable

capable of withstanding a large amount of cold working

dead mild steel (uses)

chains, revets, wire, nails

used in production of solid tubes where cold deformation is required

high carbon steels

high carbon steels (carbon)

0.55 - 0.9%

high carbon steels (properties)

high strength

high wear resistance

high carbon steels (uses)

saws, drills, high-tensile tubes

chisels, hammers

mild steels

mild steels (carbon)

0.15 - 0.25%

mild steels (properties)

very weldable

does not harden when quenched

mild steels (uses)

most common type of steel

structural steels, screws, machine parts, car bodies, gears, shafts, levers

tool steels (ultra high steels)

tool steels (carbon)

0.9 - 1.6%

tool steel (properties)

high tensile strength

excellent wear resistance and hardness

tool steel (uses)

drills, taps, knives, files, wires, axes

medium carbon steels

medium carbon steels (carbon)

0.25 - 0.55%

medium carbon steels (properties)

good tensile strength

medium carbon steel (uses)

connecting rods, shafts, axles, springs, wire ropes

martensitic steel (structure)

forms in steels when steel is quenched form an austenite structure

martensitic steel (properties)

high hardness and tensile strength

less corrosion resistion

martensitic steel (uses)

cutlery, surgical instruments, wrenches

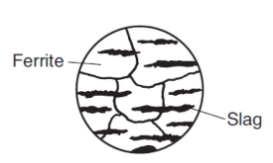

wrought iron

wrought iron (carbon)

less than 0.1% carbon

1-2% slag

mix of silicon, sulphur and metal oxides

slag (definition)

waste left over when pure iron is extracted from its ore

wrought iron properties

tough but malleable

ductile, easy to weld and resistant to corrosion

has a unique grain appearance when broekn open, from the slag peices

wrought iron (uses)

has been widely replaced by steel, as mordern iron is more stronger

remains only for use in ornamental ironwork

used be be used in horseshoes and railways

wrought iron (manufacture)

it is worked into shape rather than being poured into a mould like cast iron

cast iron vs wrought iron

- wrought iron is more corrosion resistance

- cast iron is less malleable and more brittle

- wrought iron is worked with tools, cast iron is melted an casted

cast iron vs steel

- cast iron has more carbon than steels

what happens as carbon content in steel increases?

strength and hardness increase

ductility and weldability decrease

cast iron (carbon)

2-4%

why is cast iron a desirable engineering material?

relatively cheap

high compressive strength and rigidity

easily machined

good fluidity, flows wwell in castings