5.5 Production planning

Introduction

Managing the supply chain and stock (inventory) levels are important operations management responsibilities.

- Main conflicting elements:

- Cost minimization - to remain competitive

- Consistent and reliable supply of products - to satisfy customer demand.

Supply chain: every business that comes into contact with a particular product for example, the supply chain for most products will be all the businesses manufacturing parts for the product, assembling it, delivering it and selling it.

Stock (inventory) control - the difference between JIT and JIC

- Stock (inventory): materials and goods required to allow for the production and supply of products to the customer.

- Just-in-time (JIT) stock control: stock-control method that aims to avoid holding stocks by requiring supplies to arrive just as they are needed in production and completed products are produced to order.

- Just-in-case (JIC) stock control: stock management strategy that businesses use when they hold a high level of stocks because there is a risk of “stock-out”.

Forms in which manufacturing businesses will hold stocks:

- Raw materials and components will have been purchased from outside

suppliers. They will be held in stock until they are used in the production process. - Work in progress: at any one time the production process will be converting raw materials and components into finished goods and these are “work in progress”.

- Finished goods: having been through the complete production process goods may then be held in stock until sold and despatched to the customer.

- Raw materials and components will have been purchased from outside

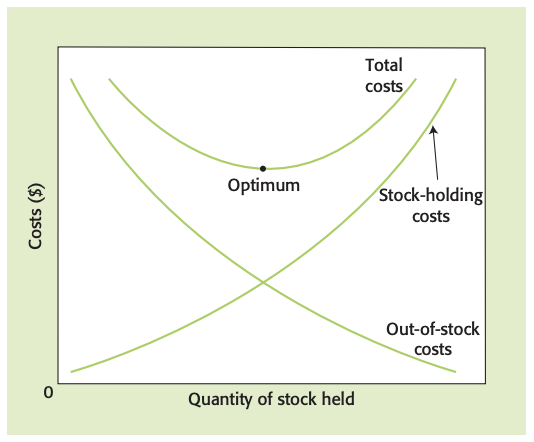

Stock-holding costs

Costs associated with stock-holding:

- Opportunity cost: working capital tied up in stocks could be put to another best alternative use. The capital might be used to pay off loans, buy new equipment or pay off suppliers, or could be left in the bank to earn interest.

- Storage costs: stocks have to be held in secure warehouses. They often require special conditions, such as refrigeration. Staff will be needed to guard and transport the stocks, which should be insured against fire/theft.

- Risk of wastage and obsolescence: if stocks are used or sold rapidly as expected, then there is an increasing danger of goods deteriorating or becoming outdated. This will lower the value of such stocks.

Costs of not holding enough stocks:

- Lost sales

- Idle production resources

- Special orders could be expensive

- Small order quantities

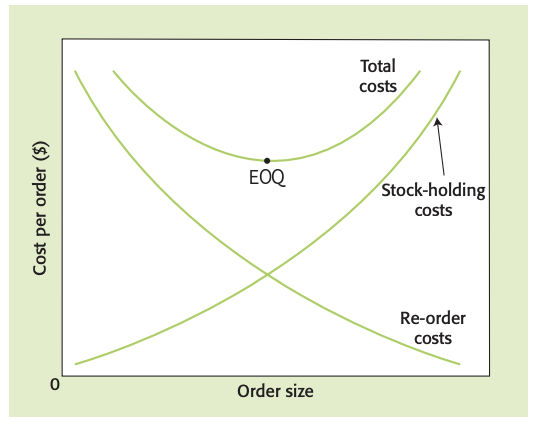

Optimum order size

Economic order quantity (EOQ): optimum or least-cost quantity of stock to re-order taking into account delivery costs and stock-holding costs.

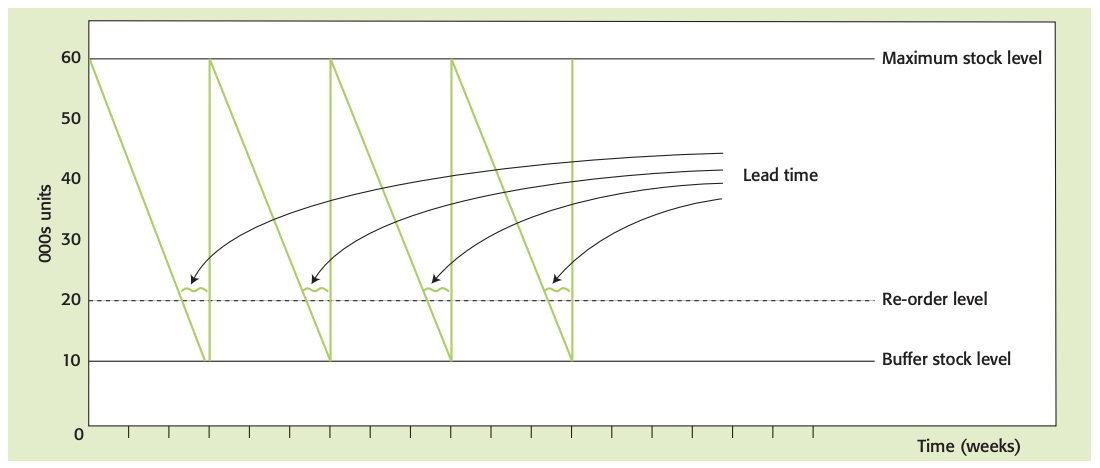

Stock control charts

Buffer stocks: minimum stocks that should be held to ensure that production could still take place should a delay in delivery occur or production rates increase.

Re-order quantity: number of units ordered each time.

Lead time: normal time taken between ordering new stocks and their delivery.

Re-order stock level: level of stocks that will trigger a new order to be sent to the supplier.

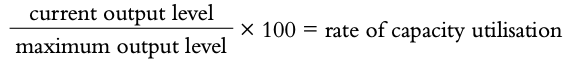

Capacity utilization

Capacity utilization: proportion of maximum output capacity currently being achieved.

Excess capacity exists when the current levels of demand are less than the full capacity output of a business - also known as spare capacity.

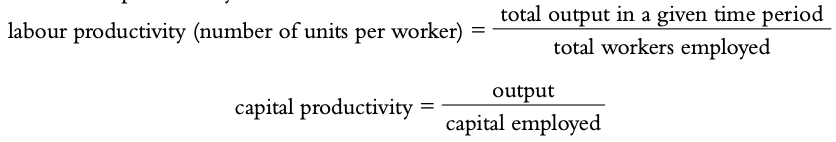

Productivity: ratio of outputs to inputs during production, e.g. output per worker per time period.

Level of production: number of units produced a during a time period.

Ways in which productivity levels could be increased:

- Improve the training of employees to raise skill levels

- Improve worker motivation

- Purchase more technologically advanced equipment

- More effective management