Experiment 1 - Bonus

1/7

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

8 Terms

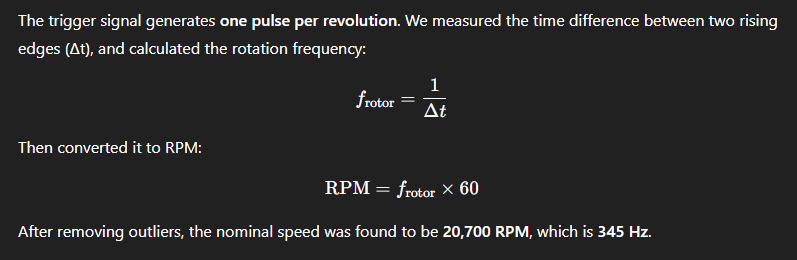

Q1: How did you determine the rotor speed from the trigger signal?

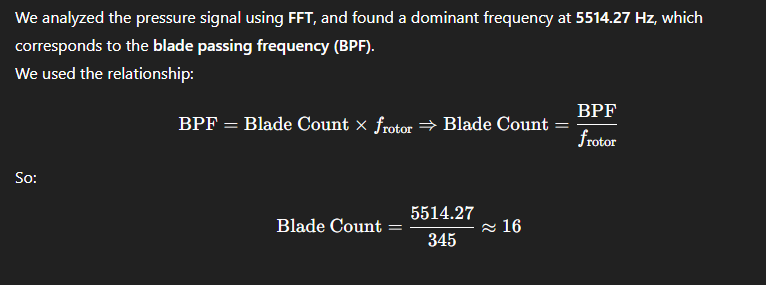

Q2: What is the blade passing frequency and how did you use it to estimate blade count?

Q3: Why does the blade passing frequency appear as a peak in the pressure spectrum?

As each rotor blade passes by a pressure sensor, it creates a periodic disturbance in the flow field (small shock or vortex).

This happens once per blade per revolution, and leads to a strong periodic signal at BPF.

The FFT captures this periodicity as a dominant spectral peak, which is useful for health monitoring and diagnostics.

Q4: How did you identify the frequency of rotating stall?

We computed a time–frequency spectrogram of the pressure signal.

Between 3–4 seconds, a low-frequency component around 183.11 Hz became prominent.

This frequency is interpreted as the rotating stall frequency — the rate at which stall cells move circumferentially around the annulus.

Q5: What physical phenomenon causes a low-frequency signal during rotating stall?

Rotating stall occurs when flow separates in parts of the compressor, forming one or more stall cells (regions of low momentum).

These cells rotate slower than the rotor and generate periodic pressure fluctuations detectable by probes.

The low frequency (much lower than rotor speed) reflects the stall cell rotation, not the blade rotation.

Q6: How did you determine when stall began?

We monitored the energy in the stall frequency band (typically 300–600 Hz).

Using an empirical threshold, we tracked when the energy suddenly increased.

Stall onset was identified at 2.847 seconds, when energy rose in that frequency range — indicating transition from stable to unstable flow.

Q7: Why is detecting stall onset important in compressor applications?

Early detection of stall:

Helps prevent rotating stall from growing into full surge, which can damage the engine.

Enables active control systems to stabilize the flow.

Extends component life and improves safety.

Monitoring stall onset is a key part of health management in jet engines and turbomachinery.

Q8: What does it mean that stall frequency is lower than rotor speed?

Stall cells move much slower than the rotor — for example:

Rotor frequency = 345 Hz

Stall frequency = ~183 Hz

This confirms that stall is not tied to blade motion but to instabilities in the flow field.

This behavior is well-documented in literature and used to distinguish stall from blade-related phenomena.