Metal Bending Assessment - Metals Lecture

1/43

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

44 Terms

Metal (definition)

a chemical element that is lustrous, hard, malleable, heavy, ductile, tenacious, and usually a good conductor of heat and electricity

Alloy (definition)

combination of elements which exhibits the properties of a metal

alloying used to improve properties such as strength, ductility, hardness, wear resistances and corrosion resistance

All metals are _____.

crystalline

Metals crystallize into a regular arrangement of atoms called________.

space lattices

Cubic System (space lattice)

three contiguous edges of equal length and at right angles

Tetragonal (space lattice)

three contiguous edges, two of equal length, all at right angles

Hexagonal (space lattice)

three parallel sets of equal length horizontal aces at 120 degrees and a vertical axis

In molten form, metals are _________

non-crystalline

the temperature at which atoms begin to crystallize is called __________

its freezing point

Grain

each unit is called a grain

each grain is essentially a single crystal

size of grain depends on the temperature from which the metal is cast, the cooling rate and nature of the metal.

slow cooling - large grain

fast cooling - small grain

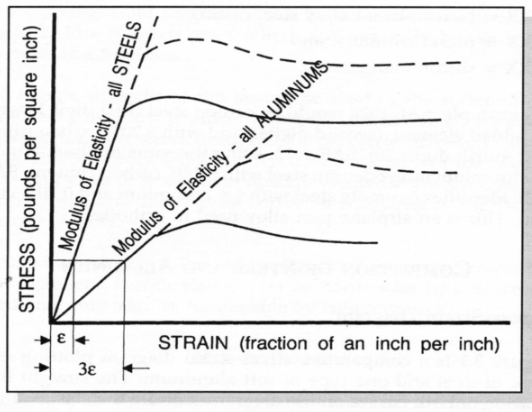

Slip planes (below elastic limit)

applied force distorts crystal lattice

remove force, crystal goes back to shape

Slip planes (above elastic limit)

force causes permanent displacement or slip

occurs in lattice on certain specified plane called slip planes (crystal slips without separation, plasticity)

lattice undergoes distortion, becomes highly stressed and hardened

slip planes tend to greatest concentration of atoms and be 45 degrees from applied force

slip is not confined to one set of planes during plastic deformation

Mechanical Properties of Metals

dependent on lattice structure

in general, cubic lattices are more ductile or workable materials

FCC - ductile through a wide temp range

CPH - good hardening by cold working

ability to shape and contour AL and stainless steel depend on plasticity

elasticity governs safe and use as load bearing members

Plasticity

Metals ability to be deformed beyond the range of elasticity without fracture resulting in permanent change in shape

for metals, plastic to elastic ratio is high

100:1

Permanent set as result of slip

further force means that the slip doesn’t happen along original slip plan indefinitely, it gets increased resistance to further motion therefore the slip now occurs along new parallel slip plane

as slip shifts from one slip plane to another progressively higher forces required to cause slip, metal has become work hardened

Actual strength of metals are a ______ of their theoretical strength

fraction

metal strength can be compromised by imperfections like. . .

flaws in regularity of crystal lattice

micro cracks in grains

shrinkage voids

nonmetallic impurities

rough surfaces

notches

Notches are great _______

weakeners

stress raisers and stress complicators, induce stress in many directions

deeper the notch and the sharper its root, the more of a stress problem it is

beware of notches from contouring instruments, grain boundaries

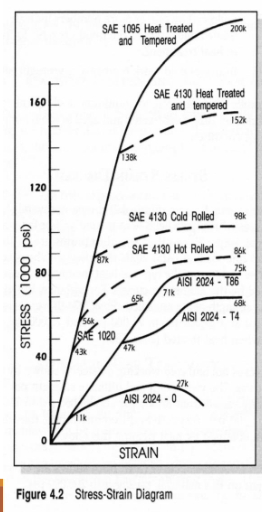

Types of steel and aluminum used in O and P applications

general designations can be misleading

terms don’t accurately describe the material

Carbon Steel

iron as pure as metal - too low strength and hardness for many applications

iron with added carbon

hardness and strength of carbon steel are directly proportional to amount of added carbon

manganese and small amounts of sulfur and phosphorous are also present in carbon steel

Alloy steel

adding other elements to carbon steel to achieve certain properties gives an alloy steel

general characteristics used to describe alloy steel properties

toughness - ability to withstand shock force

hardness - resistance to penetration an abrasion

ductility - ability to undergo permanent changes in shape without rupturing

corrosion resistance - the resistance to chemical attack of a metal under the influence of a moist atmosphere

Characteristics of Specific Alloys

nickel steels - increased toughness, easier heat treating, decreased distortion in quenching, increased corrosion resistance

nickel chromium steels - increased depth hardenability and abrasion resistance

molybendenum steels - greatest hardenability, increased high temp strength and increased corrosion resistance

chromium steel - increased hardening affect (can decrease carbon % and get a steel with high strength and satisfactory ductility)

Steel and Aluminum Alloys

vanadium steel - increaased refinement of internal structure of the alloy

silicon manganese steels - increased strength and hardness

Double and triple alloys have some characteristics of each

chromium molybendenum steels - excellent hardenability and satisfactory ductility

chromium nickel steels - good hardenability and satisfactory ductility

Stainless Steels

steel alloys with >3.99% chromium

AISI 3 digit grading system for types of stainless steels

austenitic - most common, cannot be heat treated, cold working increased properties, high nickel and chromium content, rapidly work harden (use sharp tools), highest corrosion resistance

martinistic - can be head treated to improve properties

ferritic - non hardenable by heat treatment and only slightly by cold working

SAE Number

4 digits

1st digit - type of steel

2nd digit - approximately % alloying element

3rd and 4th digits - % of carbon in 1/100’s of a percent

Comparison of Steel and Aluminum

Size, weight, and strength comparisons

aluminum 1/3 modulus of steel

aluminum ~ 1/3 weight of steel

AL more subject to fatigue failure than steel

Strengthening Aluminum and Steel

AL can be stronger than some steels (proper alloying, heat treatement or cold working)

still more subject to fatigue

Heat Treatment Purposes

increase or decrease hardness or tensile strength

relieve internal stresses due to hot or cold working

improve machinability

increase toughness

Techniques for steel

steel heated above critical range undergoes definite internal changes

if steel is slowly cooled from this elevated temp, internal changes will have to reverse themselves

if steel is cooled more rapidly, structure will be modified and mechanical characteristics altered

Heat treat cycle

normalized steel - returns to its original or normal internal structure

will have increased strength and hardness but decreased ductility than same piece annealed

annealed steel - relieve internal stresses and lower yield point for max ductility

Strengthening Aluminum and Steel

tempering - often follows quenching. Heat treated steel can be too brittle and hard. Tempering can make it softer more ductile and tougher

aluminum alloy - large increased in both yield and ultimate strengths when heat treated

steel alloy - effects of hot and cold working and heat treating

carbon steel - the difference between a carbon steel and a high carbon steel that has been heat treated and tempered

Strengthening Aluminum

tempering aluminum alloys is the major determinant of its strength, hardness, ductility, and other properties

some are tempered with heat treating, and others by cold working

temper designations are added to the four identifying digits

Preventing Failure

fatigue stress - fluctuating stressed lower than the ultimate stress of the material, but will cause after a number of cycles

this is called fatigue failure

Comparison of Fatigue in Aluminum and Steel

steel curve levels of at about 50% of its original stress

aluminum does not level off, more subject to fatigue failure

adding alloying elements can increase yield and ultimate stress but doesn’t change fatigue strength much

heat treating also doesnt’t change fatigue strength a lot

Minimizing Stress Concentraion

following practices help minimize stress concentrations in orthoses:

remove nicks and scratches by polishing

cap vice jaws that are checkered before clamping your workpiece

make sure contouring instruments have smooth curved surfaces

do not shape orthotic stirrups, uprights with a metal hammer

avoid abrupt changes in cross section

Overall what is the best way to minimize stress concentration due to bending?

avoid sharp bends

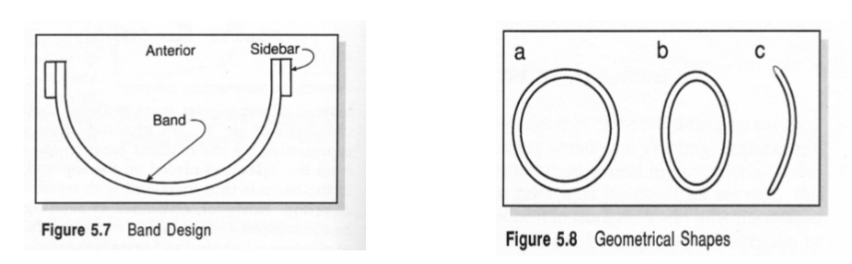

Orthotic bars are designed to be more _____________ (with knee locked) than M-L direction.

rigid in flexion

Titanium

titanium has strength comparable to steel while having a density of 56% steel but 60% greater than aluminum

double the strength of aluminum

better strength than steel, steel has better fatigue resistance

good biological compatibility

very resistant to corrosion

more expensive

Metals are highly __________ and crystallize into ______________.

crystalline, space lattices

Alloying steel is done to improve properties such as _____, __________, ________, ________________

toughness, hardenability, ductility, corrosion resistance

_______ is the major determinant of strength, hardness, and ductility for AL alloys.

Tempering

Aluminum is _____ density of steel, while steel has _______ the modulus of AL

1/3, 3x

Steel has a better _______ _________ than AL.

fatigue resistance

The best way to minimize stress concentrations in orthotic fabrication are:

prevent nicks, notches, large drilled holes, sharp contours