L7- Point defects + dislocation density

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

Examples of point defects intrinsic

Intrinsic defects:

Vacancies

self-interstitials

What are the ranges of defects and changes in microstructure plastic deformation produces?

point defects

changes in grain shape, orientation and/or distribution

increase in dislocation density

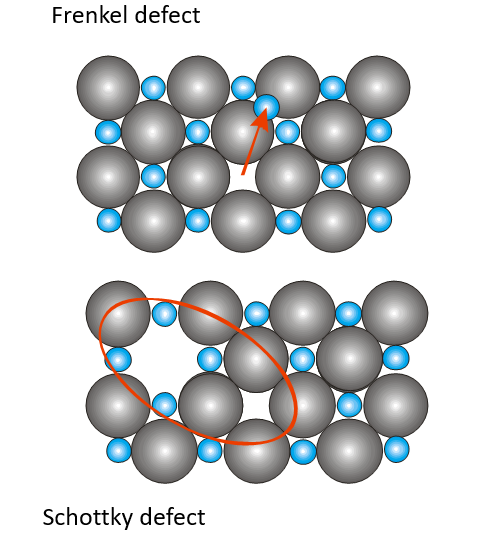

Point defects in ionic crystals:

Frenkel defect

Schottky defect

occur in pairs in ionic materials to maintain charge neutrality

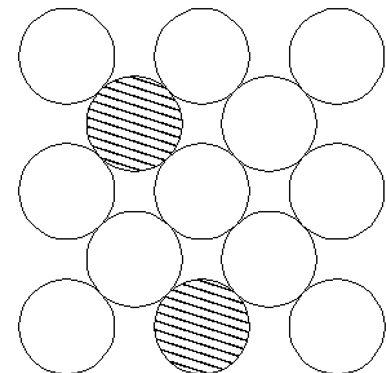

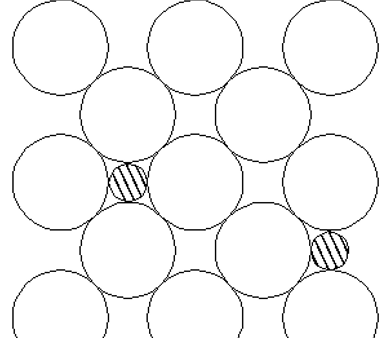

Examples of point defects extrinsic

solid solution atoms

substitution

interstitial

*point defects are associated with strain field

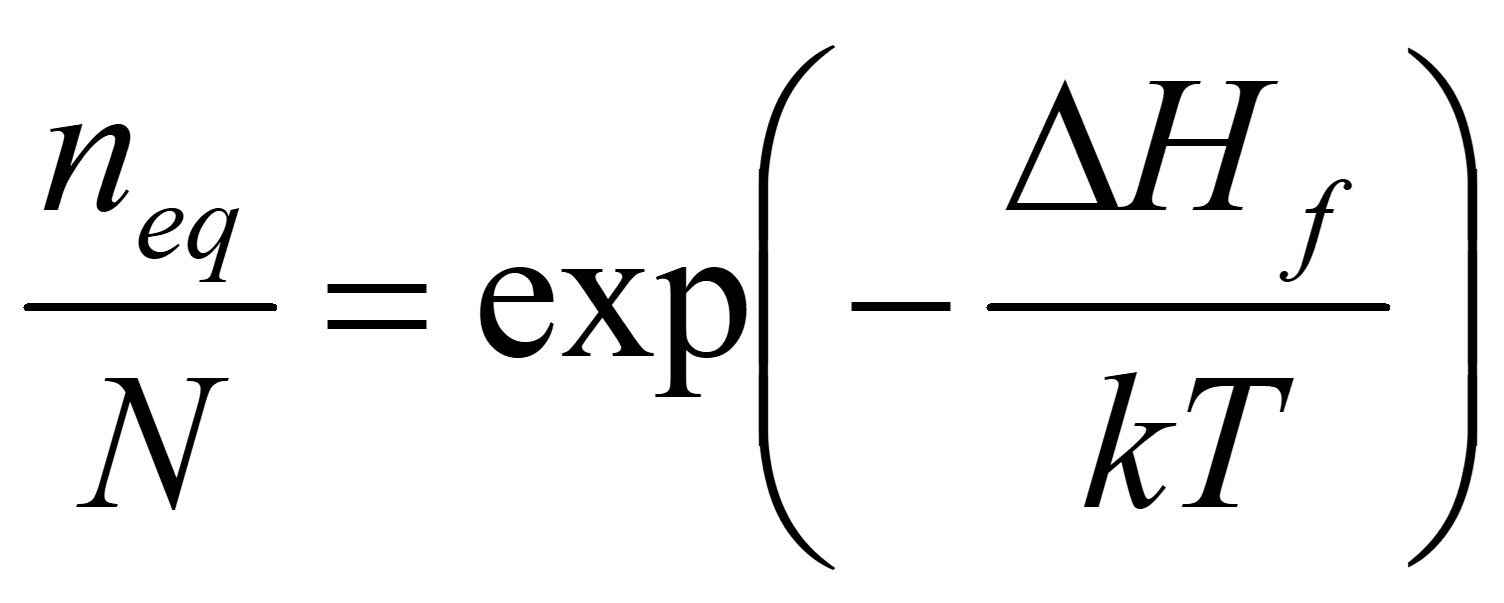

Equation for equilibrium concentration of vacancies:

N = no. atoms

neq = no. vacancies at equilibrium

ΔH f= Energy of formation of 1 vacancy site

Where can point defects be absorbed ?

grain boundaries

surfaces

dislocations

Point defect properties:

mobile, particularly interstitials

can also form aggregates in the case of vacancies these would result in voids

Properties of substitutional solutes:

•low diffusivity, solute atoms fixed

•atoms randomly distributed

•dislocations sample solute atoms

•resistance to flow function of atom size mismatch + solute concentration

Properties of interstitial solutes:

•high diffusivity, solute atoms concentrate

•segregate to dislocations

•low concentration of solute has disproportionate effect in pinning dislocations

Effect of impurities on lattice :

generates σ by distorting lattice

σ creates barrier to dislocation motion

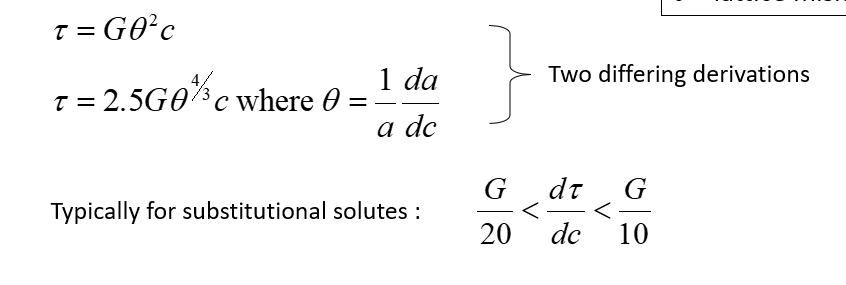

What does strengthening due to substitutional solutes depend on?

size difference between solute + matrix atoms

solute concentration

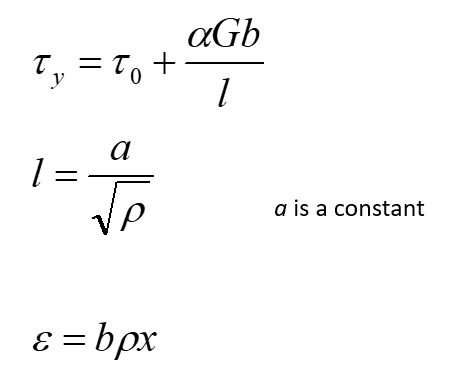

Substitutional solutes formulae

a – lattice parameter

c – concentration

θ– lattice mismatch

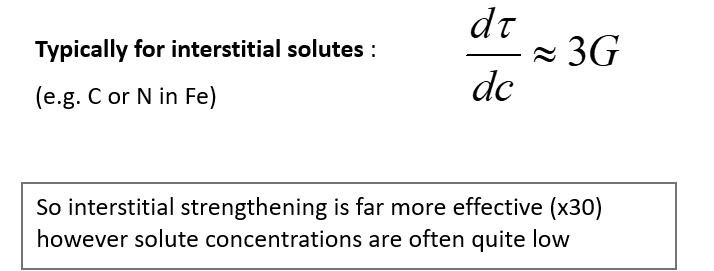

What does strengthening due to interstitial solutes depend on?

tetragonal stress fields that inhibit the mobility of both edge and screw dislocations

Segregation of solutes to dislocations

Why do interstitial solutes have high diffusivity

Interstitial solutes, such as C, O, N, and H, have high diffusivity due to their small atomic mass and ability to occupy small gaps in the lattice.

solutes strengthen materials by segregating to dislocations, reducing energy by filling space in the tensile region, but needing ↑ stress to free the dislocation from the solute/ forcing it to diffuse with the solute atom.

Disadv of work hardening as a strengthening mechanism:

loss in ductility

necking + loss of ability to resist cracking

How to tell if an interaction is favourable ?

If dislocation burgers vector, b decreases

⇒ decrease in E = ½ Gb2

so favourable (Frank’s Rule)

Why do most materials work harden?

1.Dislocations are bound to encounter each other

2.These encounters produce sessile debris

3.This debris makes deformation harder

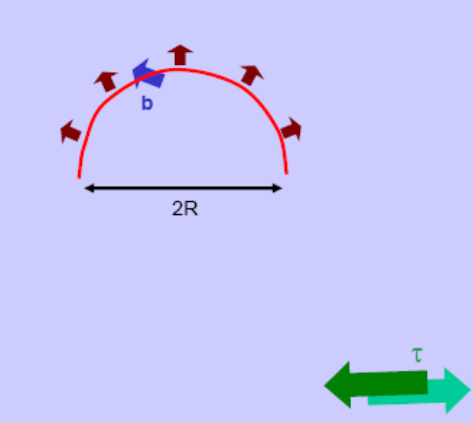

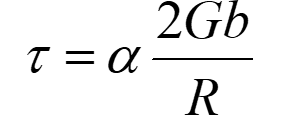

Stress to operate Frank Reed source

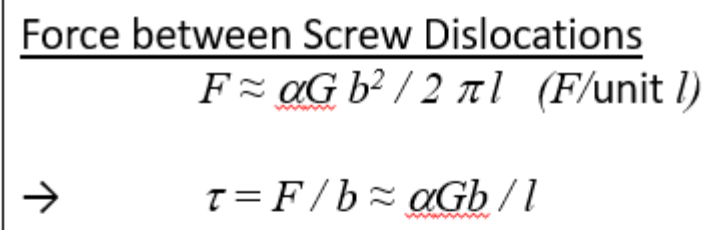

Force between screw dislocations

l = distance between 2 dislocations

Taylor’s model of dislocation hardening assumptions:

yield strength increases with increasing density of obstacles

density of obstacles increases with increasing dislocation density

dislocation density increases with plastic strain

Taylor’s model equation:

x = glide distance / distance moved by dislocations

ρ = dislocation density