PTE Injection Molding

1/107

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

108 Terms

Parts of a molding machine

Tie bars

Mold

Controller

Nozzle

Barrel

Heater Bands

Hopper

Screw Motor

Hydraulic Valve

Moveable Platen

Stationary Platen

Screw Position Indicator

Thermolator

Conditions to start mold cycle

Doors / Safety guards shut

Soak time complete

Mold in open position

Ejectors back

Screw at or beyond injection start position

Injection carriage forward w/nozzle in contact with mold

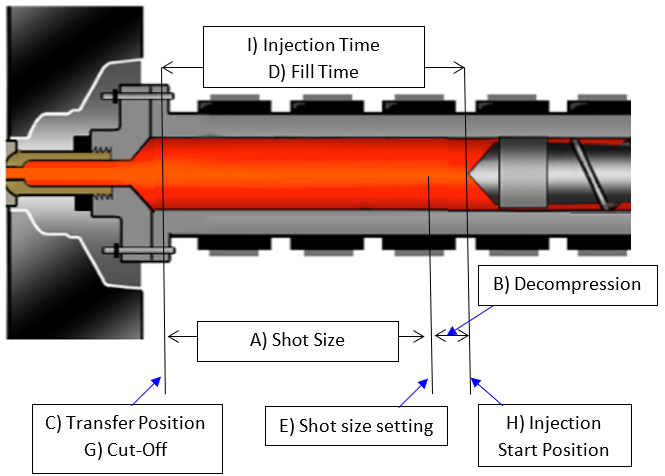

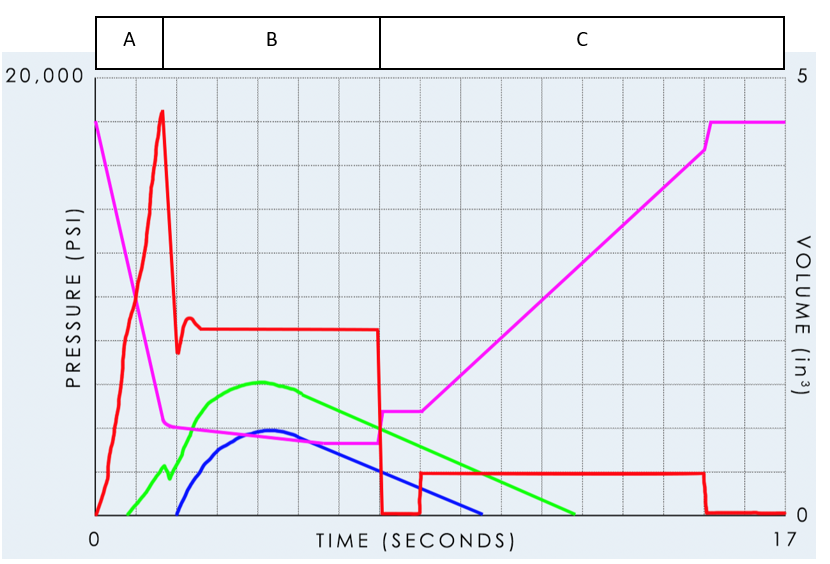

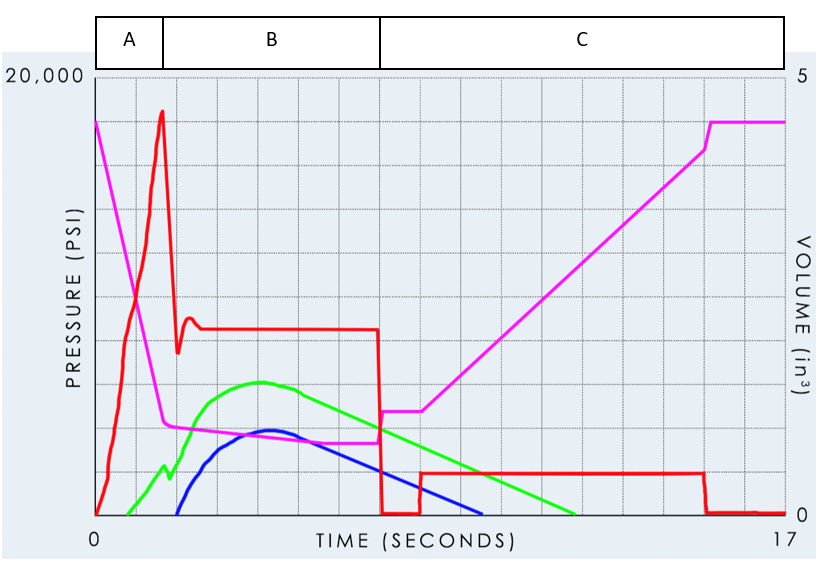

Label pressure output graph

X-axis = Time (seconds)

Fill time

Pack time

Pack Pressure

Injection pressure at transfer

Y-axis = pressure (psi) hydraulic or plastic

3 functions of molding machine injection unit

Heating (melts plastic)

Conveying (injections plastic)

Injecting (Pressurizes plastic)

Molding cycle phases

Mold close

1st stage filling

2nd stage pack and hold

Cooling —> Screw recovery delay, screw recovery, decompression

Mold open

Ejectors forward

Ejectors back

Why is pack pressure often limited in electric machines

High pressures requires high torque on the motor which could result in overheating and burning out the motor.

Why are 2-stage injection units often thought to be more precise

Screw does not reciprocate so heat history is more consistent

Plunger is less mass than a plasticizing screw so less overtravel

No check ring (eliminates variability)

Disadvantage: separate unit creates lots of bulk/length to injection unit so greater pressure loss through nozzle. Longer color changes.

3 zones of injection molding screw

Feed zone (deepest flight depth)

Compression zone - Most of the work done here. Squeezes pellets against barrel wall while rotating driving heat to melt plastic

Metering zone (shallowest flight depth. Fully flowable state to build shot)

Total injection forward time for a PARALLEL controller?

Injection time 6 sec

Pack time 4 sec

Actual fil time 1.3 sec

6 seconds

= Total screw forward time

Total injection forward time for a SERIES controller?

Injection time 6 sec

Pack time 4 sec

Actual fil time 1.3 sec

5.3 seconds

= set injection time limit

4 reasons sprue might stick to A side

Nozzle housing misaligned with sprue bushing (undercut to pull through tip)

Nozzle orifice larger than sprue diameter so can’t break free from nozzle tip

Incorrect sprue puller design

Sprue not cooled enough

Need 1in3/sec per cavity and going to 8 cavity mold. How does this impact choice of melt delivery system REGARDING PROCESS?

Hot or cold would need to support 8 in3/sec total. Cold would have bigger shot volume to maintain same vol flow rate so fill time would be longer

Need 1in3/sec per cavity and going to 8 cavity mold. How does this impact choice of melt delivery system REGARDING MACHINE?

Shot size vs machine capacity. Hot runners with small shot volume will lose process control. Cold runner with large shot volume may use all capacity

Minimum/maximum mold height and machine maximum daylight

Need larger screw diameter. One key factor regarding machine’s ability to mold based on larger screw diameter?

Machine max injection pressure. Screw diameter increase = injection pressure decrease which could interfere with parts ability to fill

Explain relationship between volumetric flow rate and larger screw diameter

Larger screw = increase volumetric flow rate = decreases mechanical advantage (intensification ratio)

Same force applied to a larger cross sectional area lowers plastic pressure capability and mechanical advantage

This lowers the injection pressure capacity

What force is clamp tonnage trying to overcome?

Must be greater than force acting on parting line of mold. Trying to overcome pressure needed to fill a specific part geometry/cross sectional area of cavity

Existing mold design and gate location cannot change. What 2 other factors will influence amount of clamp tonnage?

Material viscosity

Packing pressure

2 different parts with hot runner and same projected area onto parting line. Same material. Why might required clamp tonnage be different for the 2 parts?

Part thickness/geometry different for each of the parts

Material viscosity is different

Pressure distribution in the cavity — different gate location could lead to different flow lengths/pressure gradient during packing/filling

Experience lower injection pressure at transfer.

What changed in material?

Pressure in cavity?

Size of part?

Clamp tonnage?

Decreased

Increased

Increased

Increased

What is the recommended delta T for cooling systems?

<5°F or <2°F for critical dims

Identify nozzle tips

Full internal taper

General purpose

Nylon (reverse taper)

4 considerations when selecting nozzle

Material type/style

Length

Spherical radius

Orifice diameter

3 critical drying parameters

Residence time

Drying temperature

Dew point

Reasons why material might not be dry in desiccant dryer

Desiccant worn out or contaminated

Poor air flow

Wet desiccant at startup

Air flow not dispersed evenly within dryer

Bad moisture measurement

Blower motor turned backwards

2 concerns with a color change of same base material

Color package could impact nucleation

Colorant could have different viscosity

2 benefits of vacuum dryer

Decreased drying time (water boils out at lower temperature = faster and lower energy)

Reduces energy consumption

Why would using 87% of machine’s shot capacity lead to inconsistent processes?

Shorter residence time could risk unmelted pellets moving into compression zone of barrel leading to damage. Pellets could make it into part

How to improve chance of consistent parts if using 87% of machine shot capacity

Increase rear/midzone barrel temperatures to get heat in sooner/pre-heat the resin

Move to press with larger shot capacity

Put in 2-stage machine with plunger instead of reciprocating screw

New screw design

Within a family of materials, the higher the crystallinity the BLANK the melting point

Higher

Between families of materials, the most crystalline materials have the BLANK melting point

Lowest

Nylon 4/6 to Nylon 6/6 melt temperature should be BLANK

Decreased

Nylon 6/6 to Nylon 6 melt temperature should be BLANK

Decreased

Recommended temperature range for feed throat

130°F - 180°F

Avoids condensation but low enough to avoid binding from sticking/clumping

Running PVC material. What is one critical item of the screw you should review before you begin molding parts

Compression ratio. Different materials have different tolerances to shear heat which could lead to degradation

Explain how it might be possible to run above moisture limit and remain below 40% increase in MFI threshold for degradation

Lower residence time and lower melt temperature can tolerate some excessive moisture

Does AMORPHOUS or SEMI-CRYSTALLINE materials have a longer feed section in a screw. Why?

Semi-Crystalline. Take more energy to melt. Longer feed section will give more time for the material to melt before the compression zone

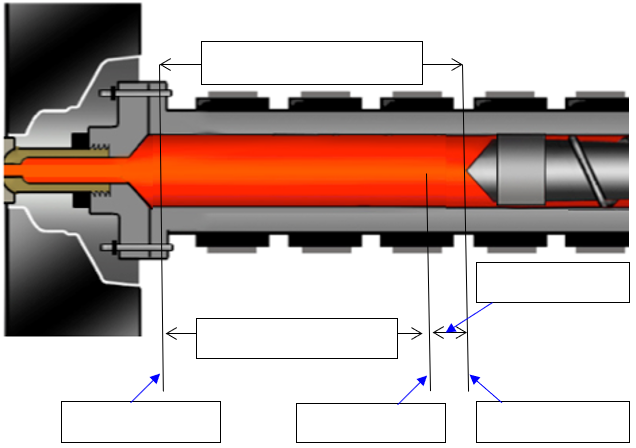

Label where the following are

Shot size

Decompression

Transfer Position

Fill Time

Shot Size Setting

Suck Back

Cut-off

Injection Start Position

Injection Time

Theoretical Fill Time

= (Injected Volume) / (Volumetric Flow Rate Q)

OR

= (Injected Volume) / (Area * Injection speed)

Using Q, r, and Viscosity describe behavior of Hagen-Poiseuille graph

Slow fill times - thick frozen layer, viscosity increases = higher pressure. Very little shear thinning and shear heating

Medium fill times - viscosity decreases due to shear heating = lower pressure. Frozen layer decreases. Reductions in viscosity and frozen layer outweigh the increase in flow rate.

Fast fill times = Reductions in viscosity and frozen layer no longer outweigh the increase in flow rate

2 reasons why you may not want to begin your Fill Time Scan at max machine injection speed

Material degradation from over shearing

Damage the mold

Pressure limited at this speed

3 items to determine why fill time is no longer decreasing with faster speeds in Fill Time Scan

Achieved machine pressure limit

Met injection pressure limit

Machine cannot achieve set speed

Why not start at slowest speed during Fill Time Scan?

The faster you go, you gain momentum then the screw over travels and pushes more material into the mold (not safe for mold)

3 reasons to adjust transfer position during Fill Time Scan

Can see almost entire part every time to assess part filling and cosmetics

Better indication of mold, machine, and material capability

Less risk of parts sticking and mold damage. Can check for sticking at 95%

Adjust transfer will take place on next shot. Adjusting shot size setting may cause an error when it picks up the shot.

2 key factors to consider when setting injection pressure limit

Machine delta P

Normal viscosity variation

What is Delta P? Why is it important?

Machine’s pressure drop (Difference between set injection pressure limit and peak pressure during injection).

Important to understand so you’re not pressure limited without knowing it. Prefer mold to stop when there’s an issue instead of keep going until machine limit is hit.

Simulation pressure greater than reality. Nozzle accounted for. Why?

Simulation doesn’t account for screw overtravel which can cause different perceived 95% full parts. Simulation fills to 99% every time. Reality it does not.

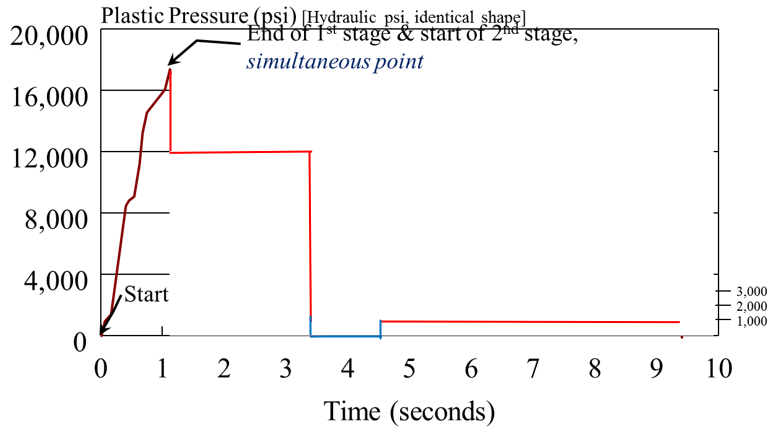

Complete graph for pack and hold, cooling, screw delay and recovery

Pack P 12,000 for 2.5 seconds

1 second screw delay

Back pressure 750 psi

Screw recovery ends at 9.5 seconds at 200 RPMs

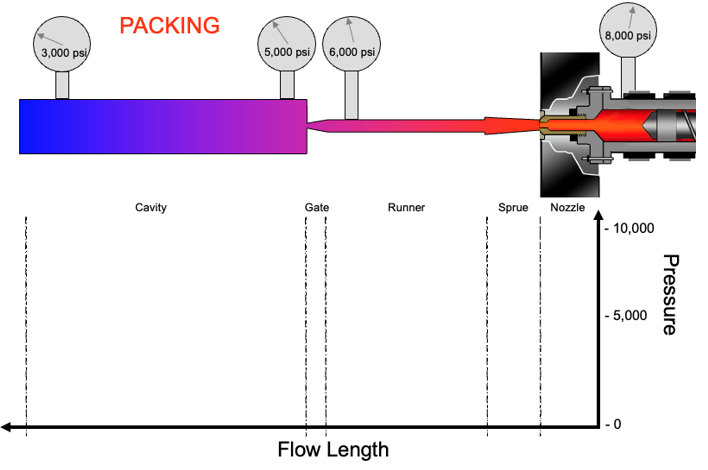

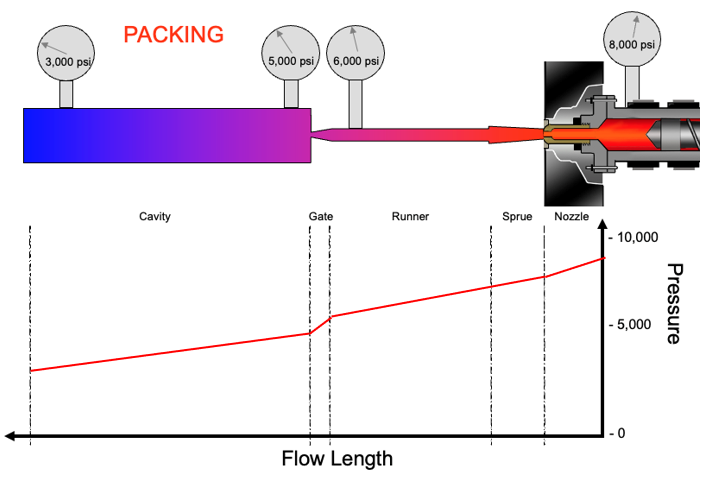

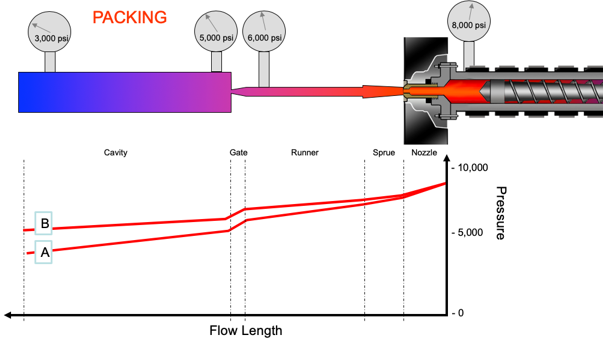

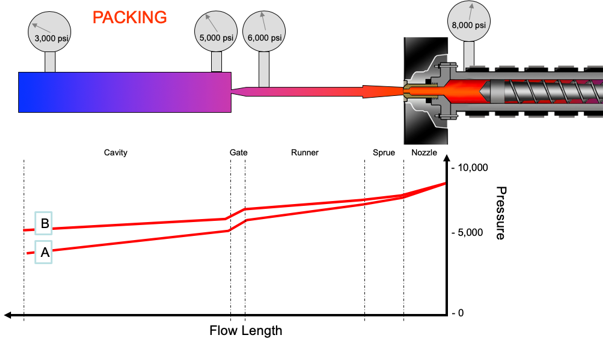

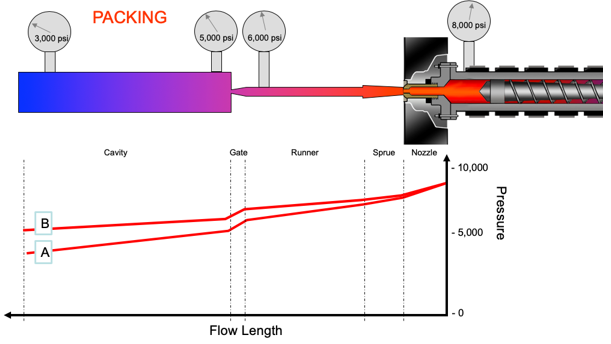

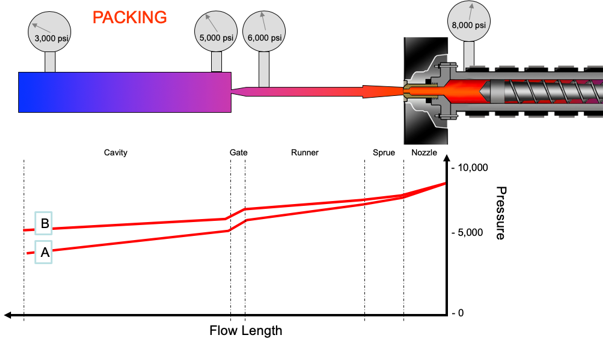

Draw pressure vs flow length line during pack and hold

Why would you run WITHOUT gate seal?

Relieve pressure and minimize stress at the gate which can be a failure point. May get better part performance if relieve pressure. May have more uniform shrink or reduce the shrink/warp.

Why would you run WITH gate seal?

Pressurize cavity to prevent material flow out which could lead to sink or voids.

2-Cavity mold artificially balanced for filling by tweaking a runner diameter feeding one of the cavities. Why might variations in cavity pressure exist between cavities during packing?

Weight balancing ensures cavities are filled to the same % full at the same time but they are not evenly packed out. Different pressure drops to each cavity so imbalanced packing which will lead to one cavity just packed out and the other one with flash/sticking

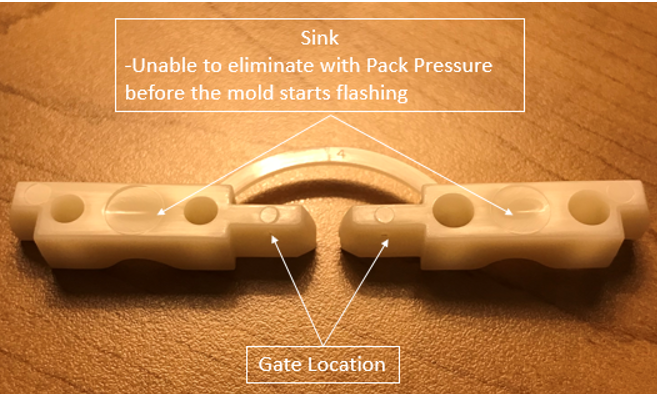

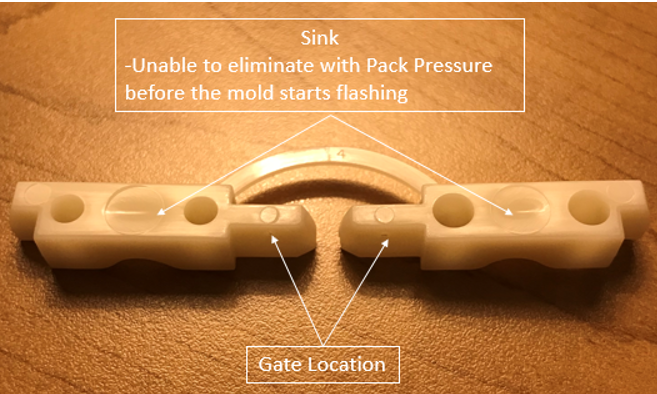

Sink on parts can’t eliminate with pack pressure without flash. Root cause related to PROCESS?

Low cushion

Pack velocity limited

Clamp tonnage set too low or not enough available

Pressure removed before gate was sealed

Sink on parts can’t eliminate with pack pressure without flash. Root cause related to MOLD?

Gate location on thin wall - Move

Gate too small and freezing before pack done

Ejector pin mark - no cooling & in thick area

Mold damage leading to flash before pressure

What studies are completed in the workbook?

Fill time scan

Pressure drop study

Pack pressure scan

Pack time scan

As you increase pack pressure to find the “Highest Acceptable Pack Pressure” you notice that as the pack pressure increases it is having no effect on the molded parts. What could cause this to happen?

No cushion left. Safe startup shot size calculations help prevent this.

When is gate seal on graph?

Part weight no longer gets heavier - go to next point even if weight increase looks small

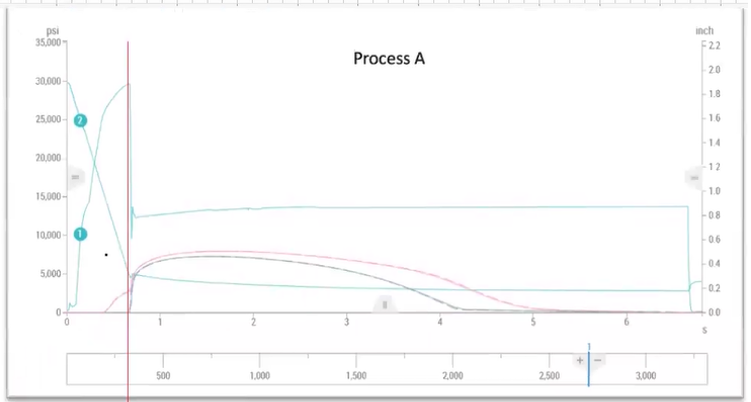

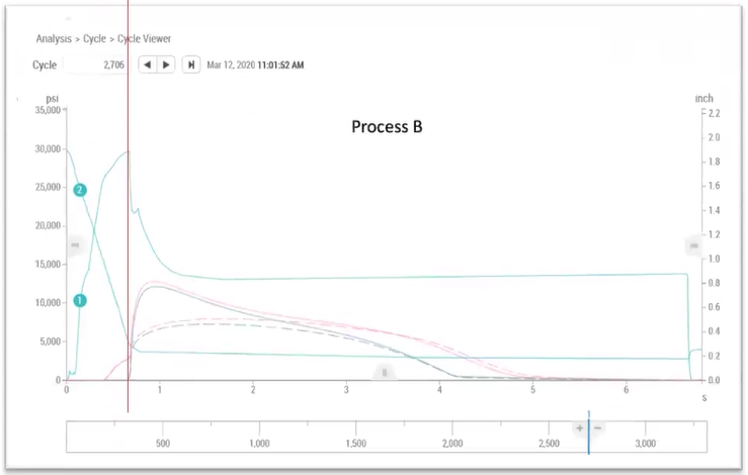

What changed to cause pressure gradient B?

Viscosity decreased

Why didn’t pressure at the nozzle change?

It’s a setpoint

How to adjust process to match B to A at end of cavity?

Decrease pack and hold time.

Can decrease injection speed and melt temperature to adjust viscosity but these can have significant side effects

When changing process to match B to A, what values from process sheet would you match?

Cavity pressure output

Fill only part weight

Critical dimensions

What is underdamped? What will the parts be like?

Pressure drops below set point

Parts will be under packed, lighter, smaller, sink, voids

What is overdamped? What will the parts be like?

More pressure during transfer so see more pressure in cavity

Parts will be over packed, heaving, larger, flash, stick

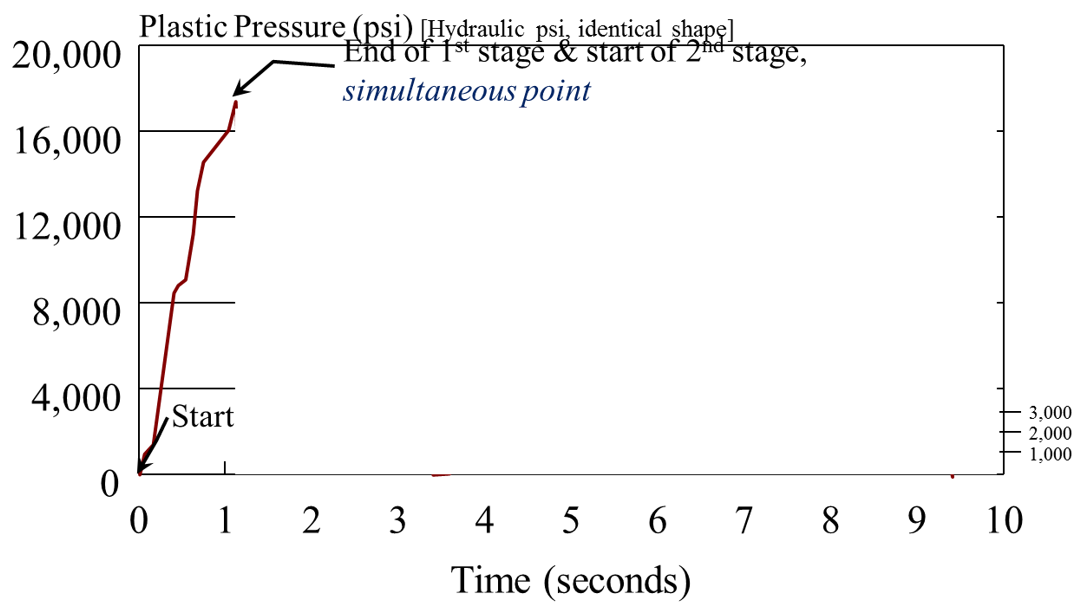

How to tell if plastic or hydraulic pressure on graph?

Hydraulic will be 2-3,000 psi or less

Plastic will be greater

List 3 things happening in region C

Cooling

Screw Recovery

Suck back

Screw Delay

Describe what is happening with screw position over time

Turn 90°

Injection rate (slope)

Transfer position screw moves forward to pressurize/compensate for material shrinkage

Remove pack/hold pressure so screw springs back due to material compression

Delay to allow pressure to bleed off

Recover rate (slope)

Suck back to start position

If viscosity increases, how does FILLING pressure react?

Increase

If viscosity increases, how does CLAMP TONNAGE react and why?

Decrease

Lower cavity pressure

How to address an increase in viscosity?

Manipulate of compensate for viscosity

Easier to compensate

Manipulate: Inject faster (should have already studied) or raise barrel temperature (increase likelihood of degradation, increase cooling time/cycle time, takes time to raise temp)

Compensate: Decrease transfer position slightly and increase pack/hold pressure. Match cavity pressure, part weight, and/or critical dimensions —> Viscosity UP = Pressure to fill UP = Compression of material UP = screw bounce UP = fill cavity less during filling

Explain why flow grouping root cause is either shear or steel variation

Delta P = (8 Q l n) / (pi r4)

8 & pi are constants

Q is controlled by machine

l, n, and r are the remaining variables which are related to shear or steel

What mold design characteristics determine number of flow groups

Number of cavities

Number of gates

Runner layout (balanced?)

Part geometry relative to gate

Comparing data BETWEEN flow groups, what are you looking for?

Rheological variations

Comparing data WITHIN A flow group, what are you looking for?

Steel variations

Within a group should receive about the same melt properties

# Flow groups =

# Total cavities / # cavities in FG 1

# Regions =

= cavities in FG 1

2 reasons to fill 80% visually during mold balance analysis?

Reduce flow front hesitation effects

Avoid overfilling the cavity skewing the analysis

2 reasons to ignore recommendation to fill 80% visually during mold balance analysis?

Terminate flow before living hinge (flow front hesitation)

May need more than 80% to eject the part out especially in stripper plate so don’t have to dig each part out.

What are the risks to collecting shot weights directly out of a hot runner manifold without shooting into the cavities themselves?

Safety (purging hot material)

Damage to hot runner system causing a leaking issue

Damage to face mounted gate inserts due to excessive pressure behind them - Resulting force could blow the insert out of the mold

Reviewing flow grouping analysis data and it indicates parts in the region to the right of the sprue are heaving. What should you consider?

Hot sprue? What kind of tip? Ported could have inconsistencies

Is data average or just one shot?

Shot to shot consistency?

If consistent, verify runner sizing, venting

4 PLASTIC VARIABLES

Plastic melt temperature

Plastic cooling rate and time

Plastic pressure gradient

Plastic flow rate

5 process outputs

Recovery time

Cycle time

Pressure at Transfer

Cushion

Fill time

Why monitor recovery time?

May indicate worn screw or barrel

Screw turns until it hits shot size setting so material in barrel is sheared differently which can change melt temperature

Why monitor cycle time?

Process consistency

Why monitor cushion?

Shot size consistency

Short shot if low

Flash if high

Check ring issues

Why monitor fill time?

1st stage flow rate setting consistency

Why monitor pressure at transfer?

Assesses viscosity shifts (moisture, new lot of resin, heater band out, etc.)

Submitted parts are too small. What outputs and settings should you evaluate?

Outputs

Cushion (shot size consistency)

Transfer pressure (viscosity shift)

Cavity pressure sensors (if available)

Mold temperature

Settings

Pack pressure

Transfer position (still correct?)

Mold temperature

Moisture content

Other

Flow rate

Nozzle

Cooling circuits hooked up correct and correct flow rate

Cycle time varying 1-2 seconds over 30 shots with 30% regrind. What outputs and settings should you evaulate?

Outputs

Recovery time (regrind sizing)

Cycle time

Settings

Back pressure (may not feed material properly)

Feed throat temperature

Other

Regrind composition/degradation/sizing

Feed throat actual temperature - needs to be cleaned?

Mold open/close time (machine issue)

Hydraulic Pressure - Machine or Plastic Variable?

Machine

Velocity (in/sec or mm/sec) - Machine or Plastic Variable?

Machine

Fill Time - Machine or Plastic Variable?

Plastic

Shot Size (mm, cm, in) - Machine or Plastic Variable?

Machine

Shot Size (mm3, cm3, in3) - Machine or Plastic Variable?

Plastic

Barrel Temperatures - Machine or Plastic Variable?

Machine

Plastic Temperatures - Machine or Plastic Variable?

Plastic

Machine or Plastic Variable?

Hydraulic Pressure

Pressure in the Nozzle

Velocity (in/sec or mm/sec)

Fill Time

Shot Size (mm, cm, in)

Shot Size (mm3, cm3, in3)

Barrel Temperatures

Part Temperature

M

P

M

P

M

P

M

P

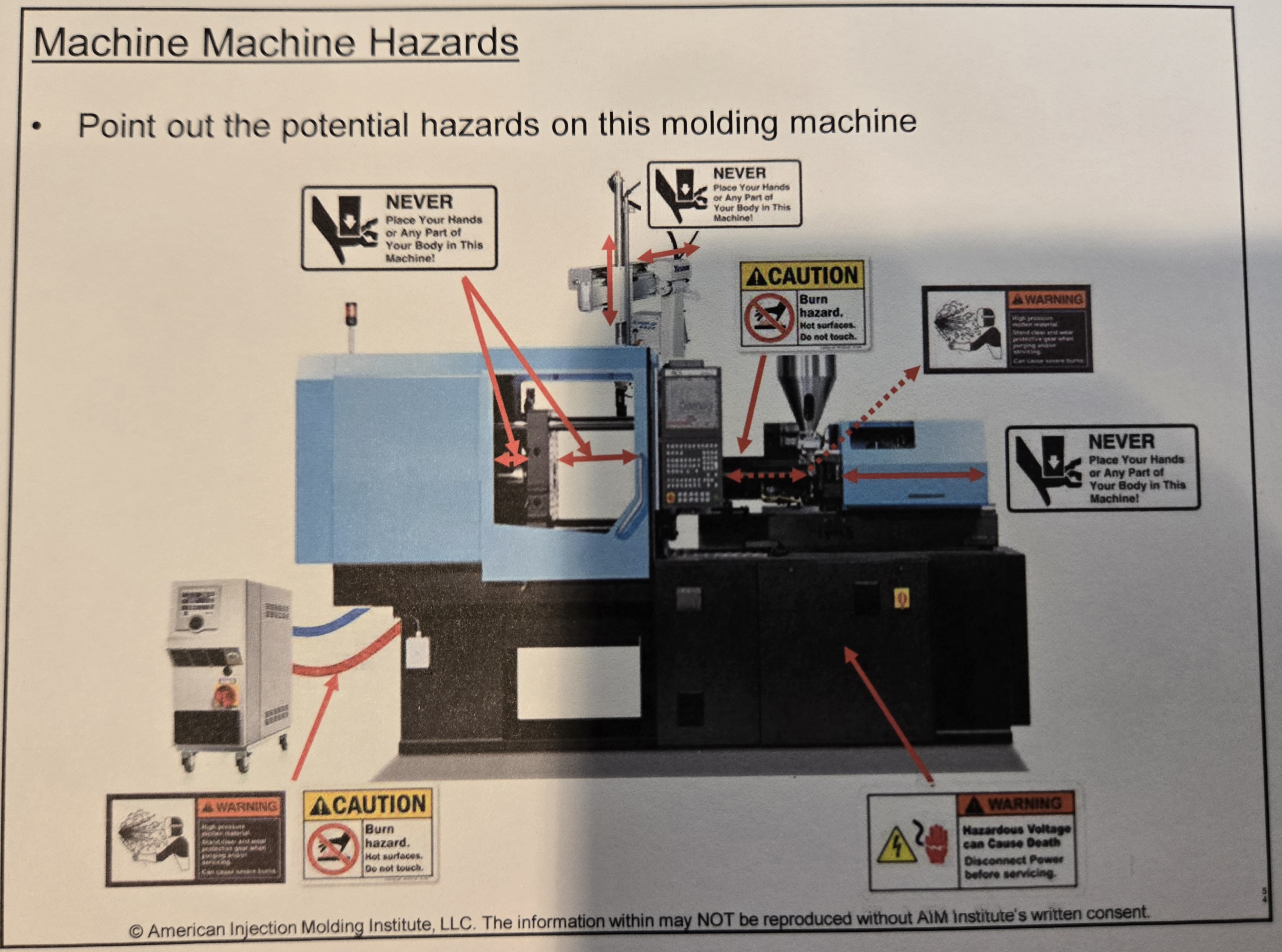

Identify potential hazards on this molding machine

Never place your hands or any part of your body in this machine

Caution Burn hazard. Hot surfaces. Do not touch.

Warning high pressure

Warning hazardous voltage can cause death

How are tie bars used to allow the clamp force to be maintained on the mold

As the moveable platen comes forward and applies clamp force, the force is transmitted to the stationary platen which forces the tie bars to stretch ever so slightly so the clamp force is applied to the mold face.

Advantage and disadvantage of reciprocating screw

Advantage: Single parrel. Plasticizing & plunger in one unit = less bulk = less pressure drop

Disadvantage: All pellets may not receive same heat history. Check ring is a wear item that needs to seal or you could have an inconsistent shot and run out of cushion. Mass of screw to move forward can over travel when it goes to transfer

Ejection stroke vs Mold open stroke

Ejection - enough to push part out (subtract wall thickness)

Mold open - 2.5*Part height + sprue height above part