MDA Chapter 35: Dental Handpieces & Accessories

1/77

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

78 Terms

Bur

all rotary instruments that have a sharp cutting head; made of steel or tungsten carbide; blades make up cutting surfaces; were originally made primarily of steel; use of steel burs on enamel caused bur to dull rapidly; tungsten carbide replaced in 1940s bc it is stiffer & stronger than steel and stays sharp longer; made in a variety of shapes & sizes; each bur has a name, a series of numbers for its shape, and a purpose

Console

freestanding cabinet that holds contents or control devices (ex. laser handpiece)

Dental Handpiece

an electrical instrument used to hold rotary instruments; most frequently used instrument in restorative dentistry; 2 types: low-speed & high-speed; sophisticated device; runs on air pressure

Flutes

blades on the working end of a finishing rotary instrument that resemble pleats

Laser Handpiece

has fiber optic cable that produces a laser light; uses laser beam to cauterize soft tissue or vaporize decayed tooth structure; like standard handpiece; laser comes from fiber optic cable extending from console

Mandrel

metal shaft on which a sandpaper disc or other abrasive materials are mounted; used because abrasive discs & wheels are supplied separately and are not attached to shank; attaches abrasives to dental handpiece; designed according to diff shank types; can be used on low and high speed handpieces

Rotary Instruments

parts or device that rotates around an axis; attached to the handpiece; operates at diff speeds to do different cutting, polishing, and finishing functions; 3 parts: shank, head, neck; hundreds of diff types w//diff uses; dentists have preferences & only use a few for most procedures;

Shank

part of bur that fits into handpiece; length varies according to function of bur and handpiece type; 3 styles: straight, latch-type, and friction-grip

Torque

twisting or turning force

Ultrasonic Handpiece

uses mechanical radiant energy of water and sound vibrations used to break down material/tissue; mainly used for scaling & root planing procedure; also used to remove bonding materials from tooth surface after removal of ortho appliances; has diff appliances for diff tooth surfaces and locations

How does the ultrasonic handpiece work?

attached to dental unit and powered by electricity; delivers pulsating spray of water; causes calculus & stain/bonding agent to break down for easier removal

What do a handpiece and attachment resemble?

A drill and bit; used to create an outline or finish a piece of wood like how handpieces create outlines for restorations and finishes restorations

When were rotary instruments first introduced to dentistry?

introduced to dentistry in 1940s; complemented hand instruments in cutting, grinding, and polishing procedures

What helped the design of dental rotary instruments advance?

the addition of electricity as a power source; advanced design & construction of handpieces

What did the first dental handpieces look like?

were operated by a long belt running over a series of pulleys; went back to the motor, continously moving inserted rotary instrument

What developments were made to handpieces and burs in the 1940s and 50s?

dev of tungsten carbide burs improved cutting and removal of tooth structure; studies revealed that burs performed better at higher speeds; air-driven turbine handpiece was introduced in the 1950s

round bur; used for initial entry into the tooth structure, extending preparation, retention, and removing decay

bullet bur

beveled cylinder bur

interproximal bur

wavy cylinder bur

needle bur

wavy taper bur

football bur

barrel bur

flame bur

double inverted cone bur

wheel bur

pear bur; used for initial entry into tooth structure and extending preparation

lens bur

round end cylinder bur

round end taper bur

modified chamfering bur

flat end taper bur

flat end cylinder bur

egg bur

inverted cone bur; used to remove decay & establish retentive grooves

straight fissure plain cut bur; used for initial entry into to tooth & forming internal walls of preparation

plain fissure cross-cut bur; used to help form internal walls of preparation

tapered fissure plain cut bur; used to help provide angles in walls of prepared tooth

tapered fissure cross cut bur; used to help provide angles in walls of prepared tooth

end cutting bur; used for initial entry into tooth structure and to create a shoulder for the margin of a crown preparation

How does a dental handpiece work?

motor component receptor is attached to a hose in the dental unit; when rheostat is pressed, compressed air enters back of handpiece; this rotates the turbine, which rotates rotary instruments; turbine does all the work; harder rheostat is pressed, the more air is supplied and the faster the rotary instrument runs

Low-Speed Handpiece

aka. straight handpiece, slow-speed handpiece; 10,000-40,000 rpm; most versatile handpiece; 3 versions that come w/attachments: straight handpiece, contra-angle handpiece, prophy low speed

Low-Speed Handpiece w/Straight Attachment

attachment slides onto motor & locks into place; mostly used for lab procedures; used for trimming & contouring custom trays, temporary & provisional appliances, and ortho appliances and trimming & relining removable partials & dentures

Low-Speed Handpiece w/Contra-Angle Attachment

attachment slides onto motor & locks into place; angle allows operator intraoral access w/easier adaption to tooth surfaces; uses latch-type locking system; holds latch-type rotary instruments, endo files, Prophy cups, and mandrels; used for removal of soft decay and fine finishing of cavity preparation, finishing & polishing restorations, coronal polishing & removal of stains, porcelain adjustments, and root canal treatment

Low-Speed Handpiece w/Prophy Attachment

used during polishing procedures to hold prophy cup & bristle brush; most common type is plastic disposable prophy angle; available w/rubber cup or bristle brush already in place

High-Speed Handpiece

used for majority of restorative procedures & specialty procedures in endodontics, fixed prosthodontics, & oral surgery; does not have attachments; uses rotary instruments (bur); operates on air pressure; can go 450,000 rpm

What is the high-speed handpiece used for?

removal of decay; removal of an old/faulty restoration; reduction of coronal portion of tooth in prep for crown/bridge; prep of outline & retention grooves for a new restoration; finishing & polishing of restorations; sectioning of a tooth during surgery

How is the high-speed handpiece cooled down?

high speed of bur generates frictional heat on tooth; can damage pulp; handpiece is designed to handle a water coolant system; tooth & bur are constantly sprayed w/cool water while operating; water spray also helps remove debris from tooth prep and allows better visibility

What method do all high-speed handpieces use to hold burs, stones, & polishing devices?

friction-grip method; different from low-speed handpieces; some older handpieces require bur-changing device

Fiber-Optic Light

high-speed handpieces have fiber-optic light placed in head; light ports near bur deliver proper amt of light directly onto operating sight

What are the benefits of using the laser handpiece?

treatment is painless, so no anesthesia; don’t have to wait for pt to get numb

What are the disadvantages of using the laser handpiece?

laser cannot be used on teeth w/restorations; laser procedures take longer

What precautions should one take when handling the laser handpiece?

don’t sharply bend/twist fiber-optic cable (could break & burn during use, injuring user/pt); don’t touch exposed cable (dirt & fingerprints can damage cable); don’t touch end of cable connector (connector contains small optical fiber that may degrade if contaminated); keep connecting parts clean

Air Abrasion Handpiece

delivers aluminum oxide particles through small probe at high pressure; removes diseased enamel, diseased dentin & restorative materials; doesn’t compromise healthy tooth structure; no local anesthesia use; shifting tooth preparations to a more conservative approach

How has the use of the air abrasion handpiece evolved?

introduced to dentistry in 1940s; designed to remove stains & tooth decay; not widely recognized by community and faded out of use; has been brought back as a pt friendly approach to restorative dental treatment

What is the air abrasion handpiece used for?

sealants, external stain removal, Class I - VI preparations, endodontic access, crown margins, preparation of tooth surface for cementation of cast restoration (crown, veneer)

Laboratory Handpiece

designed for dental lab; operators at up to 20,000 rpm; uses lab burs of various shapes & sizes; has more torque than intraoral handpieces; better suited to heavier pressure required for extraoral grinding & polishing proceddures

What is the cause of most problems w/handpieces?

improper cleaning & lubrication; inadequate cleaning before sterilization can cause debris to collect inside handpiece; improper cleaning solutions/techniques can shorten working life; debris can create wear; excessive lubrication just as damaging as inadequate lubrication; follow manufacturer’s directions or warranty can be voided

How should the sterilization of handpieces be handled?

handpiece is critical instruemnt and must be sterilized; require special consideration bc blood & saliva can be sucked into internal portions; some handpieces require lubrication before or after sterilization, some require both; wipe fiber optic light w/alcohol swab to remove excess lubricant (can dim light if stays on); follow manufacturer’s instructions for wrapping & sterilizing (autoclave or chem vapor) handpiece; wear PPE & use standard precautions dry before packaging to prevent corrosion; after sterilization, flush air & waterlines on hose for 30-60 sec

How should the precleaning of handpieces be handled?

use mild soap & water or only water to clean debris from external surface; some disinfectants can corrode handpiece; follow manufacturer’s instructions for cleaning in internal components (some say ultrasonic cleaning, some do not);

Sterilization Procedure Sheets

avoids errors in sterilization; helpful when getting handpieces from diff manufacturers or diff models; sterilization instruction may vary; also for when several team members are involved in process; use info in manufacturer’s instruction book

Straight Shank

long,straight shank used in straight-line attachments; fits into low-speed handpiece; held in place by mechanism in stright attachment

Latch-type Shank

has small groove at end; mechanically locks into contra-angle attachment; fits onto low speed handpiece

Friction-Grip Shank

short & smooth; has no retention grooves in end; held in high-speed handpiece by creation of friction that grips entire shank

Neck

narrow portion that connects shank & head

Head

cutting, polishing, or finishing portion; made in a large variety of sizes, shapes, & materials

What are burs used for?

preparing the tooth, excavating decay, finishing cavity walls, finishing restoration surfaces, removing old fillings, finishing crown preparations, separating crowns & bridges, adjusting & correcting acrylic temporary crowns

What does the shape of a bur describe?

the contour/design of the head

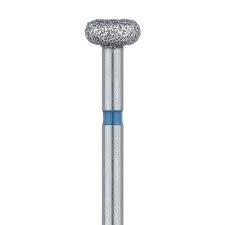

Diamond Rotary Instrument

included in standard restorative setup; cutting ability shortens preparation time and increases productivity; diamond burs have metal base w/flecks of industrial diamonds embedded into base and bonded w/metallic bonding material; shape/design varies according to dentist’s need

What are the most frequently used shapes for diamond burs and what are they used for?

round: provides access to pulp chamber for endo treatment, adjusts/shapes occlusal surfaces; flat end taper: reduces tooth structure during crown preparation; flame: reduces tooth structure during crown preparation, makes bevels in crown preparations; round-end taper: removes tooth structure, makes mechanical retention grooves; wheel: makes subgingival bevels in crown prep, adjusts/shapes occlusal surfaces, used for anterior crown prep; cylinder: smooths & finishes walls in tooth preparation

Finishing Rotary Instruments

looks like cutting bur; # of cutting blades (flutes) on working end is increased; the greater # of cutting surfaces, the greater the polishing/finishing capability; most commonly used are round, tapered, and flame-shaped

Abrasive Rotary Instruments

most varied rotary instruments; many types of abrasive material applied to many shapes to create flexible working surfaces; can be adapted to contour tooth/restoration; made in shapes ranging from discs & stones to points & strips

Laboratory Rotary Instruments

has longer shank & head than dental burs; easy to distinguish from dental burs; used in low-speed handpiece; used to cut & polish acrylic; acrylic bur is most commonly used; comes in diff shapes for specific uses

Grit

aka coarseness; diamond burs are made w/a range of grit; like sandpaper; range allows right grit to be chosen for each stage of restoration; diff grits can be identified through letter at end of bur number or color coded band; repeated use & sterilization causes diamond particle to debond, decreasing efficiency

Identifying & Attaching Dental Handpieces

(1 & 4) identify & attach the low-speed handpiece or high-speed handpiece to the dental unit, ensuring the receptors are aligned & the handpiece fits correctly onto the correct line; (2 & 3) identify & attach the contra-angle or prophy angle attachment onto the stretch attachment to the low-speed handpiece; ensure the attachment is locked

Identify & Attach Burs for Rotary Cutting Instruments

(1) identify specific burs by name & number sequence; (2 & 3) attach latch-type burs to the contra angle-attachment on low-speed handpiece or friction-grip bur to high-speed handpiece, ensuring that bur is locked in place; (4) attach abrasive discs to mandrel by screwing to tightenn or by positioning metal opening onto mandrel, ensuring disc is securely locked