Instruments - OPD Lab

1/78

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

79 Terms

HANDLE OR SHAFT

Part grasped in the operator’s hand.

Usually straight.

It is smooth, knurled, and/or serrated for better instrument control

SHANK

Connects the handle to the blade or nib.

Smooth, round, tapered, and contrangled.

Have one or more bends to avoid the tendency to twist in use where force is applied.

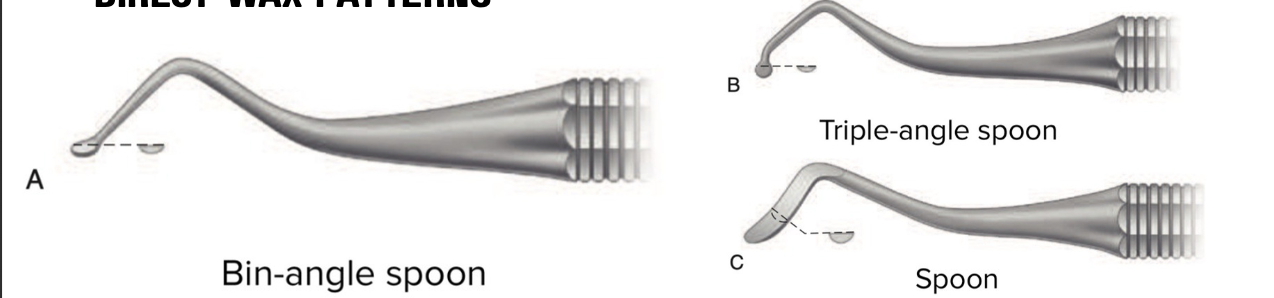

Shank Angles

Straight

Mon-angle (one)

Bin-angle (two)

Triple-angle (three)

Contra-angled

BLADE OR NIB

The working part of the instrument, begins at the last angle.

CUTTING: Blade

NON-CUTTING: Nib

The end of the Nib, or working surface, is known as FACE

Function

Manner of Use

Design of the Working End

Shape of shank

BLACK’S CLASSIFICATION SYSTEM BY INSTRUMENT NAME

categorized instruments by:

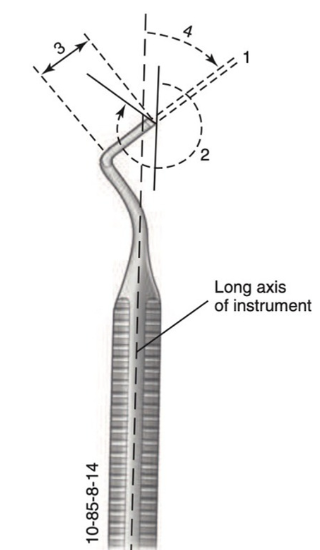

3-number code: WLA

Width of the blade (tenths of an MM)

Length of the blade (MM)

Blade Angle (relative to the long axis of the handle in clockwise centigrade or hundredths of a circle)

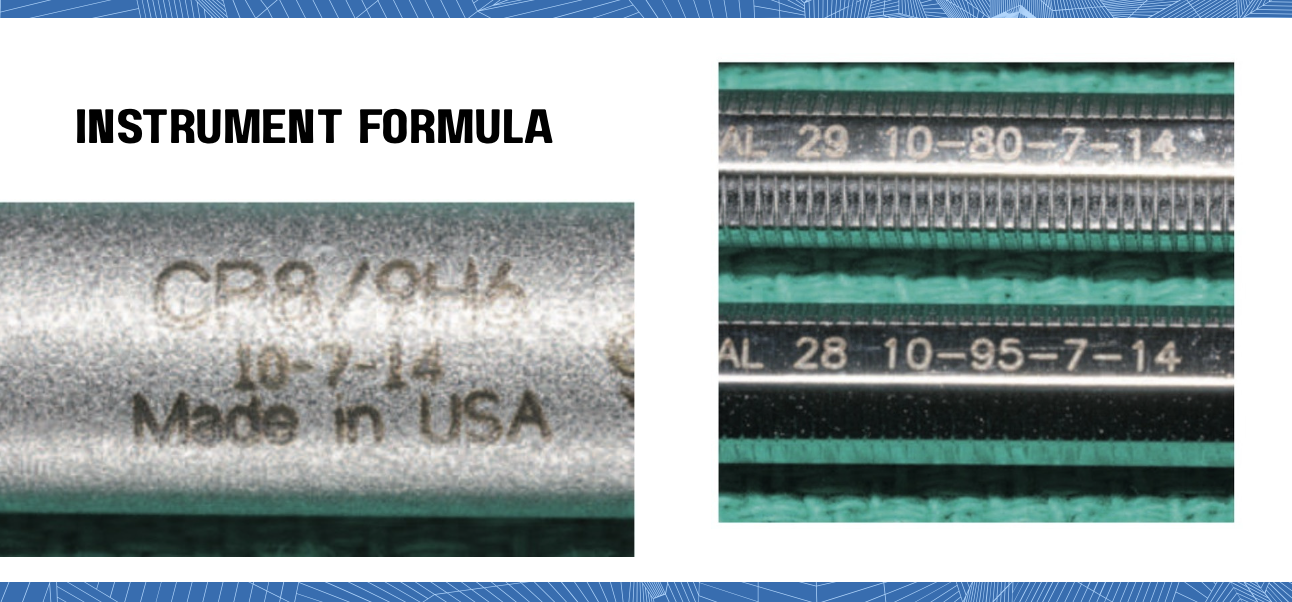

What’s the instrument formula? - 3-number code:

4-number code: WCLA

Width of the blade (in tenths of a mm)

Cutting edge angle (degrees centigrade) Instrument is positioned so that this number always exceeds 50.

Length of the blade (in mm)

Blade Angle (relative to the long axis of the handle in clockwise centigrade or hundredths of a circle) Instrument is positioned such that this number is always 50 or less.

360

The centigrade angle is expressed as a percent of _____ degrees

e.g. 85 = 85% x 360 degrees = 306 degrees

e.g. 14 = 14% x 360 degrees = 50.4 degrees

Explain how to solve for the angle

Interpret:

e.g. 85 = ?

e.g. 14 = ?

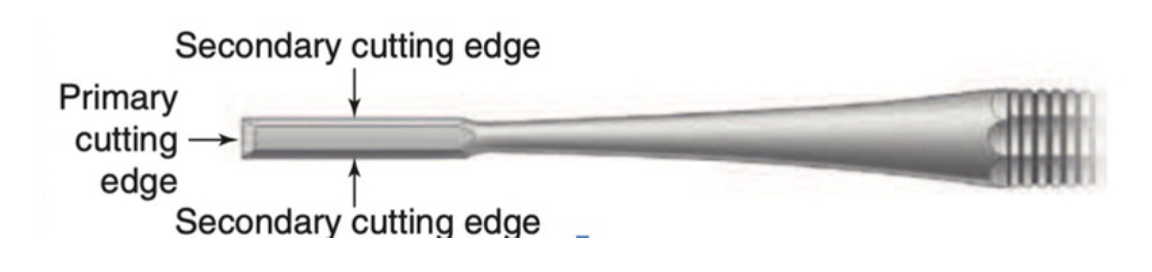

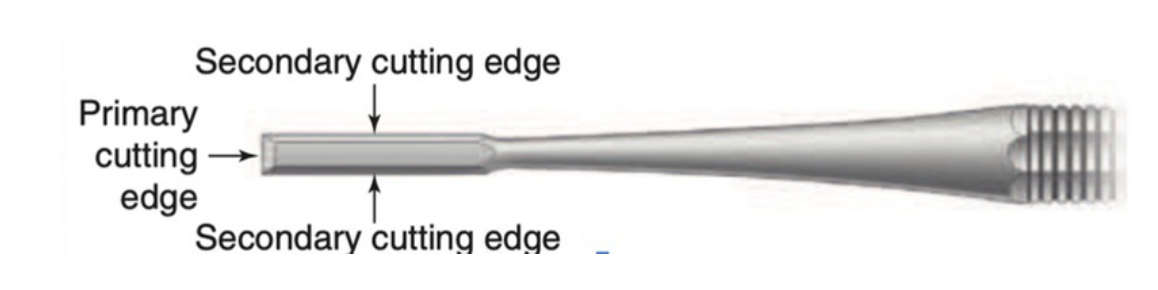

PRIMARY CUTTING EDGE

BEVELS

Single bevel on the end of the blade

SECONDARY CUTTING EDGES

BEVELS

Two additional BEVELS extending from the primary edge.

spoon excavator

gingival margin trimmers

enamel hatchets

What are single-beveled instruments?

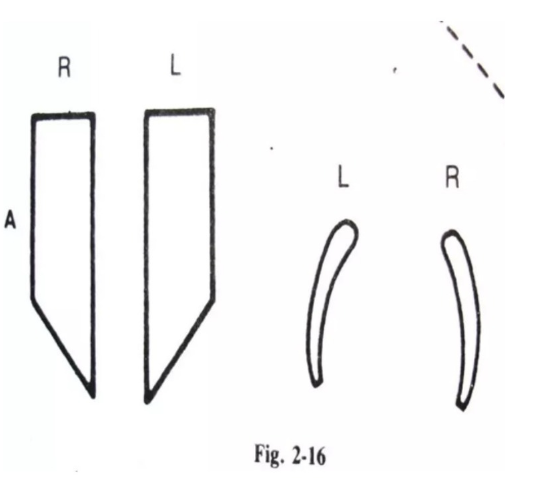

If bevel is on the right - RIGHT INSTRUMENT - moved from right to left

If bevel is on the left - LEFT INSTRUMENT - moved from left to right

RIGHT and LEFT BEVELS

(Single-beveled instruments: spoon excavator, gingival margin trimmers, enamel

hatchets)

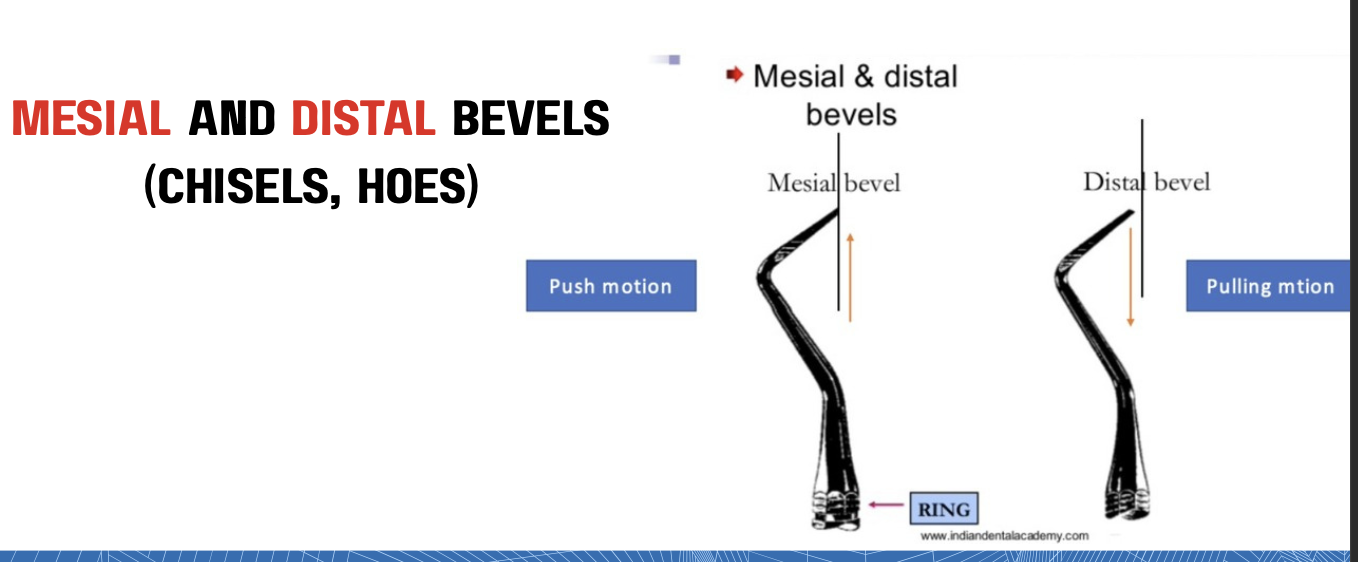

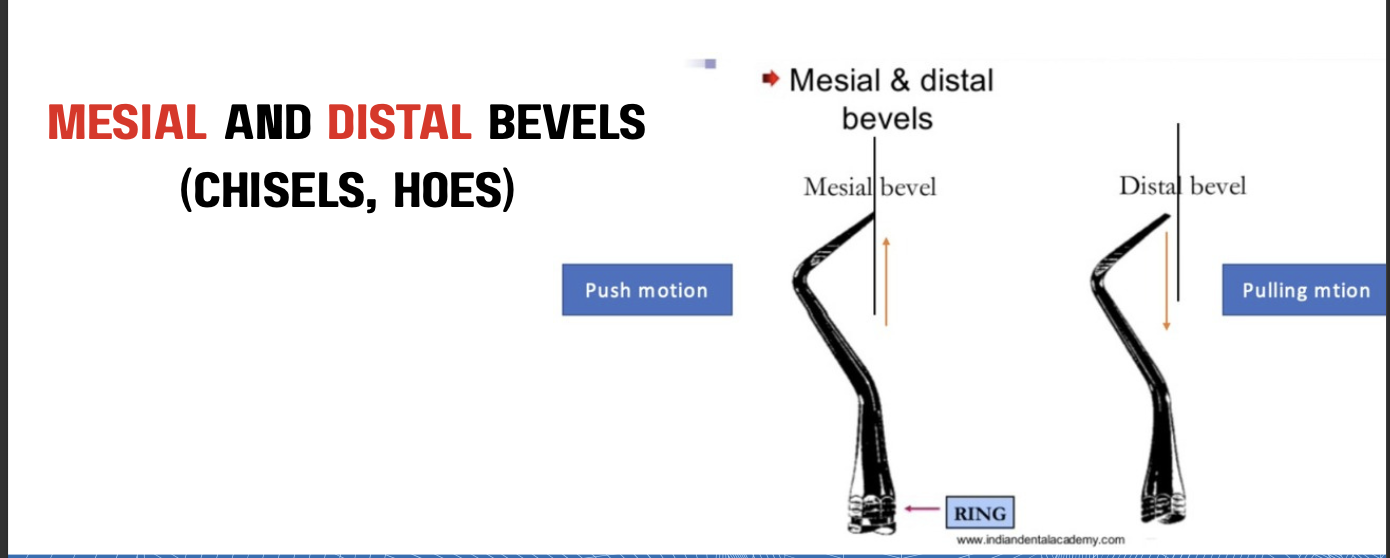

Chisels

Hoes

MESIAL and DISTAL BEVELS - EXAMPLES

DISTAL BEVEL

If primary bevel is not visible - ?

MESIAL or REVERSE BEVEL

If primary bevel is seen - ?

Excavators

For removal of carious tissue, refinement of the internal aspects of the preparation

Establishment of correct anatomical restoration

Ordinary Hatchets

Hoes

Angle Formers

Spoons

Examples of Excavators

Excavators - ORDINARY HATCHETS

Primarily on anterior teeth for preparing retentive areas

Sharpening internal line angles, particularly for direct gold restorations.

Excavators - HOES

For planing tooth preparation walls and for forming line angles.

Commonly used in Class III and V preparations to ensure removal of unsupported enamel

Excavators - ANGLE FORMERS

For sharpening line angles and creating retentive features in dentin in preparation for gold restorations.

Also used when placing a bevel on enamel margins.

Excavators - SPOON EXCAVATORS

For removing soft carious tissue and carving amalgam or direct wax patterns

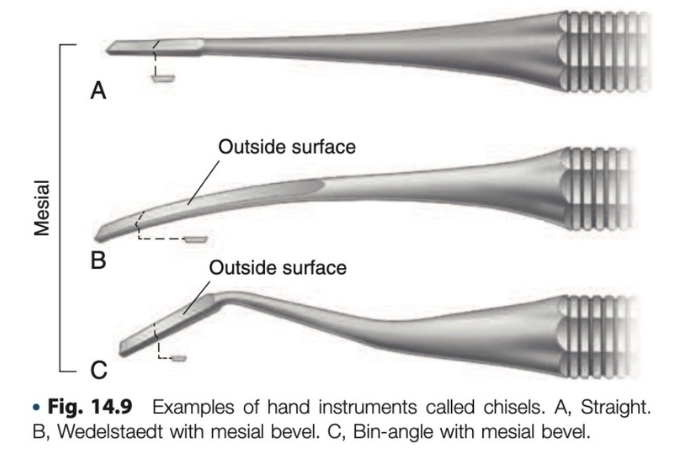

CHISELS

Intended primarily for cutting enamel

Straight, slightly curved or bin-angle

Enamel hatchets

Gingival margin trimmers

KINDS OF CHISELS

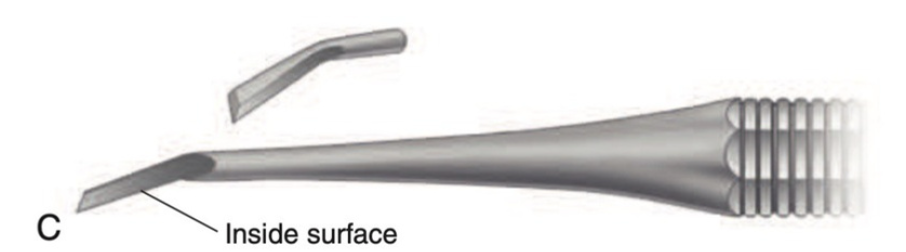

CHISELS - STRAIGHT, SLIGHTLY CURVED, OR BIN-ANGLE

Force used is essentially a straight thrust or a pushing motion.

For bin-angle and Wedelstaedt (slightly curved) chisels.

Blades w/ distal bevel used to plane a wall that faces the blade’s inside surface.

Blades w/ mesial bevel used to plane a wall that faces the blade’s outside surface.

CHISELS - STRAIGHT, SLIGHTLY CURVED, OR BIN-ANGLE

CHISELS - ENAMEL HATCHET

Used for cutting enamel and comes as right or left types for use on opposite sides of the preparation.

CHISELS - GINGIVAL MARGIN TRIMMER

Used to eliminate unsupported enamel on gingival walls of proximal preparations.

Knife

File

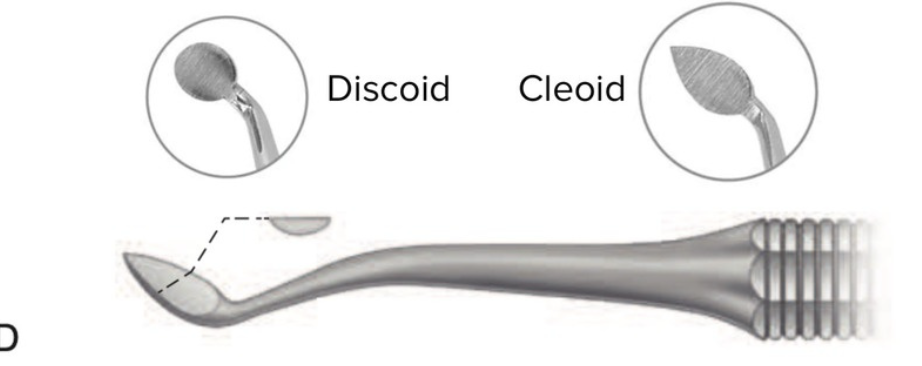

Discoid-cleoid

OTHER CUTTING INSTRUMENTS - Used for trimming restorative material rather than cutting tooth structure

OTHER CUTTING INSTRUMENTS - KNIVES

Finishing knives, amalgam knives, or gold knives

Used for trimming excess restorative material on the gingival, facial, or lingual margins of a proximal restoration.

Trimming and contouring the surface of a Class V restoration

OTHER CUTTING INSTRUMENTS - FILES

May also be used to trim excess restorative material and are particularly useful at gingival margins

Push/pull instrument

OTHER CUTTING INSTRUMENTS - DISCO-CLEOID

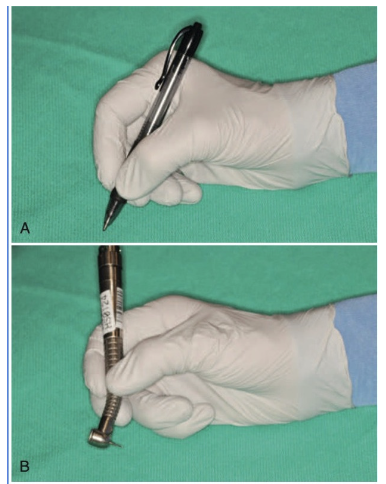

1. MODIFIED PEN GRASP

2. INVERTED PEN GRASP

3. PALM-AND-THUMB GRASP

4. MODIFIED PALM-AND-THUMB GRASP

What are the instrument grasp techniques?

MODIFIED PEN GRASP

Permits the greatest control of the instrument

The tip of the ring finger is placed on a nearby tooth surface of the same arch as a rest.

INVERTED PEN GRASP

Used mostly for tooth preparations employing the lingual approach on anterior teeth

PALM-AND-THUMB GRASP

Rest is provided by supporting the tip of the thumb on a nearby tooth of the same arch or on a firm, stable structure.

MODIFIED PALM-AND-THUMB GRASP

Usually employed in the area of the maxillary arch and is best adopted when the dentist is operating from a rear-chair position.

RESTS

To steady the hand during operating procedures.

GUARDS

Hand instruments or other items used to protect soft tissue from contact with sharp cutting or abrasive instruments

DENTAL HANDPIECE

Powered rotary cutting instrument

Air-driven and electric motor-driven

2 technologies of dental handpiece:

High / ultrahigh speed

200,000 rpm

40,000 rpm

Electric handpiece motors operate up to

Quieter than air-driven handpieces

Cut with high torque

Offer absolute control over rotary instrument revolutions per minute (rpm)

Offer a single motor with multiple attachments (straight or contra-angle type)

ADVANTAGES OF ELECTRIC HANDPIECES

LOW-SPEED CUTTING

ineffective, time consuming, and requires a relatively heavy force application

Heat and vibration are the main sources of patient discomfort

For cleaning teeth, caries excavation, and finishing and polishing procedures.

HEAT AND VIBRATION

are the main sources of patient discomfort

For cleaning teeth, caries excavation, and finishing and polishing procedures.

Diamond and carbide cutting instruments remove tooth structure faster and with less pressure, vibration, and heat generation

Types of rotary cutting instruments needed is reduced because smaller sizes are more universal

Better control and greater ease of operation

Instruments last longer

Patients less apprehensive

Increased operation efficiency

ADVANTAGES OF HIGH RPM

LASER EQUIPMENT

A crystal or gas is excited to emit photons of a characteristic wavelength that are amplified and filtered to make a coherent light beam.

AIR-ABRASIVE CUTTING

Not generally accepted for tooth preparation

Only helpful for stain removal, debriding pits and fissures before sealing, and micromechanical roughening of surfaces to be bonded.

Shank, Neck, and Head

Parts of a dental bur/instrument

Shank –

the part that fits into the handpiece

Neck –

connects the head to the shank

Head –

the working part of the instrument

Head size

Head shape

Bladed/abrasive (dental burs and diamond abrasive instruments)

HEAD DESIGN CLASSIFICATIONS:

BURS

All rotary cutting instruments with bladed cutting heads

Used for:

→ Tooth preparation

→ Finishing metal restorations

→ Surgical removal of bone

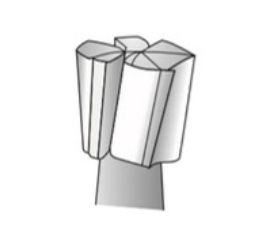

ROUND BUR

INVERTED CONE

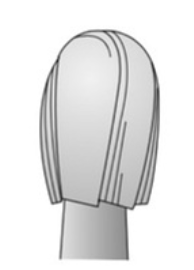

PEAR-SHAPED

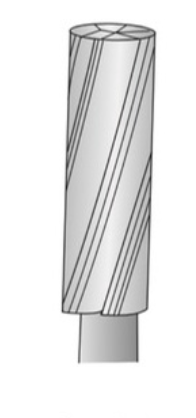

STRAIGHT FISSURE

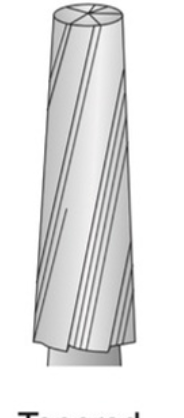

TAPERED FISSURE

Ranges from 12 to 40 blades.

Finishing Bur Blades

The bur head should be as symmetrical as possible.

Bur Head Symmetry