Metal alloys for fixed appliances

1/45

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

46 Terms

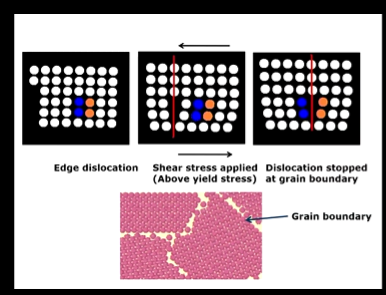

What are dislocations?

Imperfections within metals, all metals will have these imperfections

e.g a missing plane of atoms - line defect

applying a shear stress above the yield stress - permanently deforming the metal through movement of a dislocation from one plane to another within the crystal until it reaches a grain boundary where it cannot move anymore - so dislocations stack up at the grain boundary -

while deforming a metal you are increasing the density of dislocations - which makes it harder to deform the metal as you have to move extra deformations

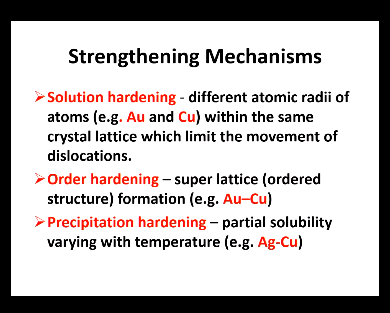

Give examples of strengthening mechanisms? (7)

Baseline: Increasing the dislocations within the metal, making it harder as well as decreasing the ductility

Work (strain) hardening (Cold working): application of shear stresses produces more dislocations, hinders movement, more difficult to deform

Forging: Drawing wires/rolling sheets

Bending: Denture clasps/orthodontic appliances

Burnishing: Amalgam/Gold inlays

Heating treatments:

Solution hardening - Different atomic radii of atoms (e.g Au and Cu) within the same crystal lattice limit the movement of dislocations (dislocations cannot move as you are creating obstacles)

Order hardening: Super lattice - heating gives energy and time for atoms to rearrange each other to give an ordered structure formation (only one phase)

Precipitation hardening - partial solubility varying with temperature, as temp goes down another phase will precipitate so dislocation will not move beyond this (2 phases)

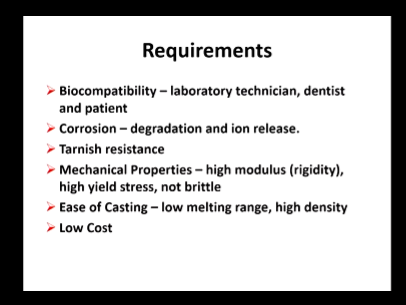

Requirements of metals and alloys? (6)

Biocompatible - lab tech, dentist and pt

Corrosion - degradation and ion release

Tarnish resistant - change in colour

Mechanical properties - high modulus and yield stress, not brittle

East of casting - low Mp and high density (easier to flow and remove any air)

Low cost

modulus means

Classification of metals used?

High noble: more than or equal to 60% noble metal, of which 40 or more needs to be gold

[Au, Pt, Pd, Rh, Ru, Os, Ir] (silver is not considered a metal alloy because it corrodes and tarnishes in the oral environment)

Noble - must contain at least 25% noble metal

Predominantly base metal - contain < 25% noble metal

![<p><strong>High noble:</strong> more than or equal to 60% noble metal, of which 40 or more needs to be gold</p><p>[Au, Pt, Pd, Rh, Ru, Os, Ir] (silver is not considered a metal alloy because it corrodes and tarnishes in the oral environment)</p><p><strong>Noble</strong> - must contain at least 25% noble metal</p><p><strong>Predominantly base metal</strong> - contain < 25% noble metal </p>](https://knowt-user-attachments.s3.amazonaws.com/5521bb9b-71c9-4e7a-b9dd-954743e253b1.png)

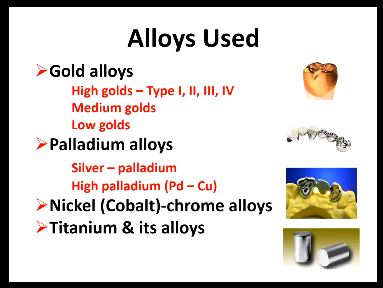

What are alloys used in Fixed pros?

Gold alloys:

- High gold - type 1,2,3 and 4 (discussed in removable pros)

- Medium and low gold

Palladium alloys:

- Silver-palladium

- High palladium (Pd-Cu)

Nickel (cobalt) - chrome alloys

Titanium and its alloys

High gold alloys

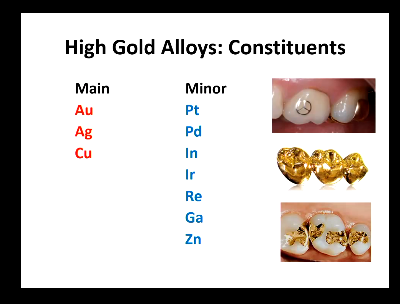

what are the main (3) and minor (7) constituents?

Main: Au, Ag, Cu

Minor: Pt, Pd, Ir, Zn, In, Ga, Re

Why is Ag added, what can it do?(4)?

Solution hardening

Precipitation hardening

Whitens

Reduces tarnish resistance

What does Cu add? (3)

Lowers Mp

Solution hardening

Order hardening (providing more than 11% Cu)

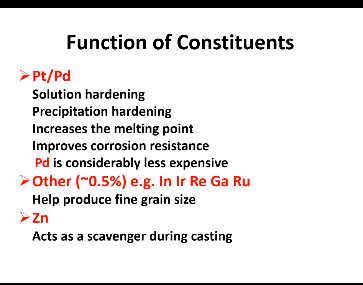

Pt/Pd functions? (4)

which is cheaper?

Solution hardening

Solution precipitation hardening

Increases Mp

Improve corrosion resistance

Pd is considerably less expensive

Function of Zn?

Acts as a scavenger during casting

In, Ir, Re, Ga Ru? function? (1)

Help produce fine grain size

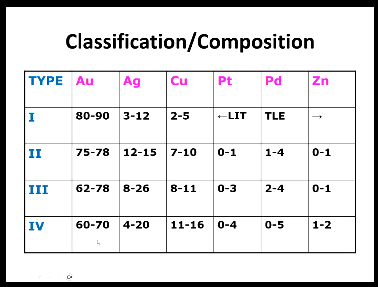

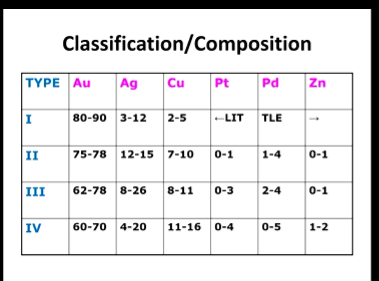

High gold types composition?

All the additions of metal form what with Au? (gold)

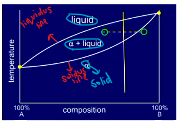

What does Pt and Pd addition cause in the graph which requires what?

All additions form solid solutions with Au

Pt and Pd increase the solidus/liquidus gap so type 3 and 4 need homogenisation (the metal is more likely to be a mix of solid/liquid as a result)

Overall, are gold alloys easy to cast?

and why? (3)

Easy to cast

Low casting temperature

Low shrinkage (1-4%)

High density

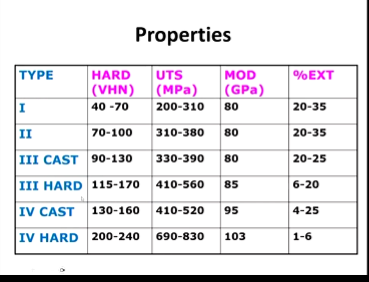

What is the trend in properties as you increase in type

As you increase in type, higher properties

Only type 3 and 4 have Cu > 11% so order hardening is possible hence why type 1 and 2 don’t have order hardening

hard stronger than cast

Type 1 alloys:

Yield stress?

what strengthening mechanisms can oyu do to this?

uses?

Low (this means it can be deformed more easily)

Burnished - improve marginal fit and increases hardness (cold working)

small, well supported inlays where forces are low

Type 2 alloys:

Yield stress?

Strengthening mechanism?

Uses?

Improved properties over type 1, higher yield stress

can still be burnished

used for larger inlays, not in thin sections

Type 3 alloys?

Can they be hardened?

Bonding to adhesive resins?

Can they be burnished?

Yields stress?

Can be hardened (because of the Cu >11%)

Difficult to burnish

High yield stress

Heat to 44 degrees for 10 minutes produces CuO layer which bonds to adhesive resin luting agents

Uses of type 3 alloys?

Inlays/onlays

Full crown and short span bridges

Cast posts and cores

Type 4 alloys

Yield stress?

uses?

can be it used for inlays?

Very high yield stress

High stress situations, partial dentures and clasps, long span bridges

Cannot be burnished so not suitable for inlays

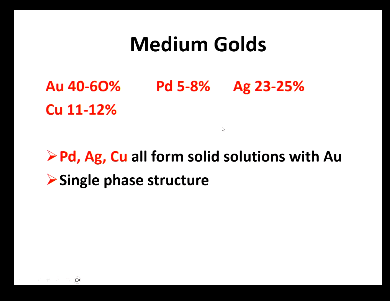

Medium golds:

Composition: (4)

phases?

Au, Pd, Ag, Cu

The added metals all form solid solutions with Au

Single phase structure

Low gold:

Composition: (5)

What colour can they be depending on metal composition?

Phases?

Au, Pd, Ag, Cu, In

Low gold are white

Cu-free low golds containing In are yellow

2 Phases

Ag-Au and Pd-In

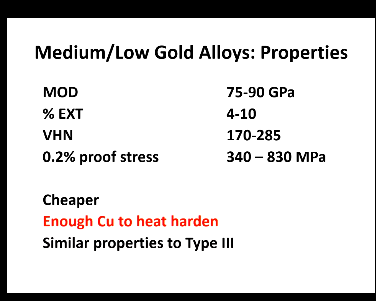

Medium/Low golds alloys

price and properties compared to High gold alloys?

Cheaper

Enough Cu to heat harden

Similar properties to type 3 gold

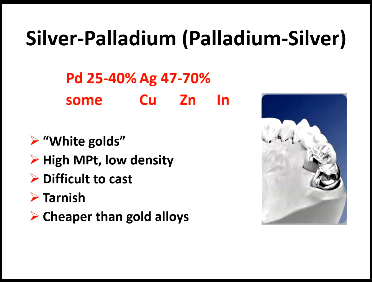

Silver-palladium alloys can be known as?

Composition (5)

Properties?

White gold

Pd, Ag, some Cu, Zn, In

difficult to cast, low density and high Mpt

Tarnish (silver, Pd increases corrosion resistance?)

Cheaper than gold alloys

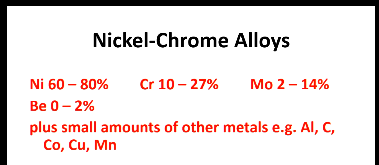

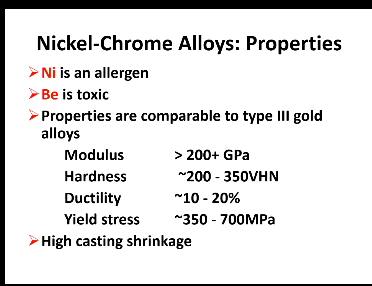

Nickel chrome alloys

Composition: (9)

Ni, Cr, Mo, Be

Small amounts of: Al, C, Mn, Cu, Co

Ni adds what?

Cr adds what?

C?

Ni - strength and hardness

Cr - hardens by solution hardening, corrosion resistance through a passive oxide layer

Must limit C/ carbide precipitation for strength

Downsides of Ni and Be?

Ni - an allergen so could use Co

Be - toxic

Properties of Ni-Cr alloys are comparable to what type of high gold alloy?

Type 3 gold

Disadvantage of Ni-Cr alloys?

High casting shrinkage

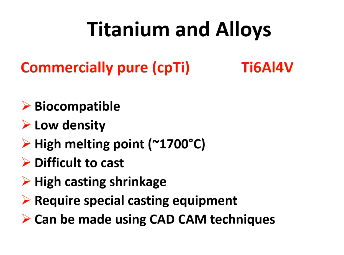

Titanium:

2 types?

Commercially pure and alloy TiAl4V

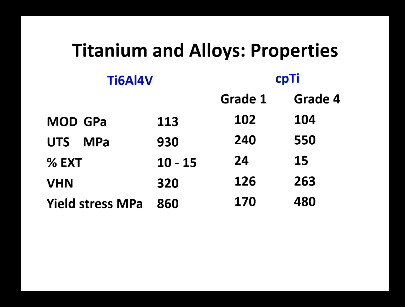

Titanium and alloys properties? (7)

Biocompatible, can be made using CAD/CAM techniques

Low density, high Mpt, difficult to caste, high casting shrinkage, require special casting equipment

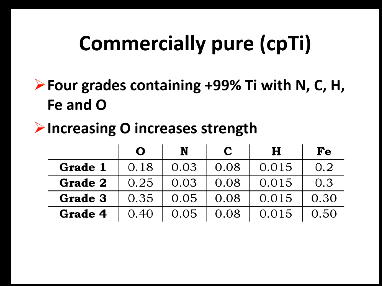

Other elements found in commercially pure Titanium and grades

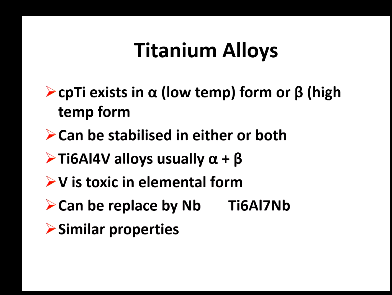

Commercially pure Titanium exists in what 2 forms

Alpha - low temp

Beta - high temp

In Titanium alloy, what stabilises either phase?

Titanium alloys usually have a mix of alpha and beta

V is toxic in elemental forms and can stabilise

Or V can be replaced by Nb which can also stabilise

Hardness of cpTi and Alloys comapred

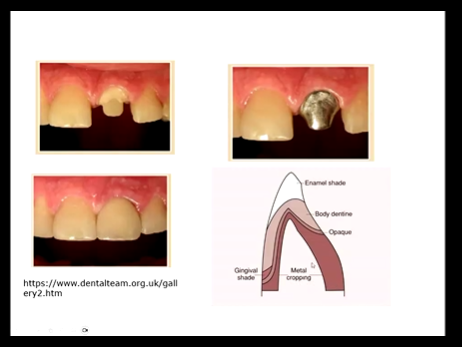

PFM?

Porcelain fused metal alloys

Additional requirements of metals in PFM?

Good bond to porcelain

Must not act adversely with the porcelain

Melting range > firing temperature of porcelain

Coefficient of thermal expansion slightly greater than of the porcelain

Low creep or sag (high temp and weight - the metal will permanently deform)

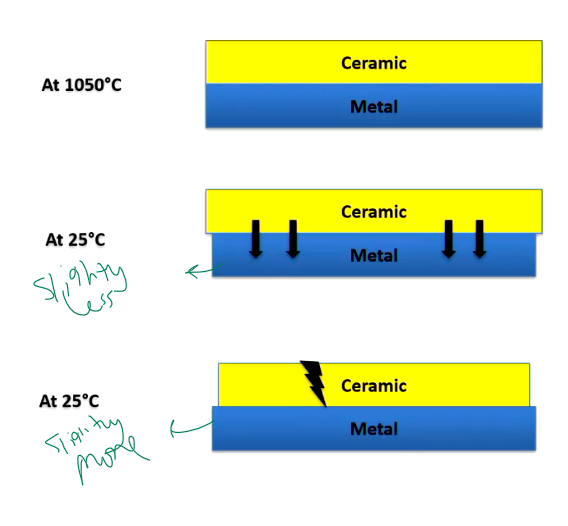

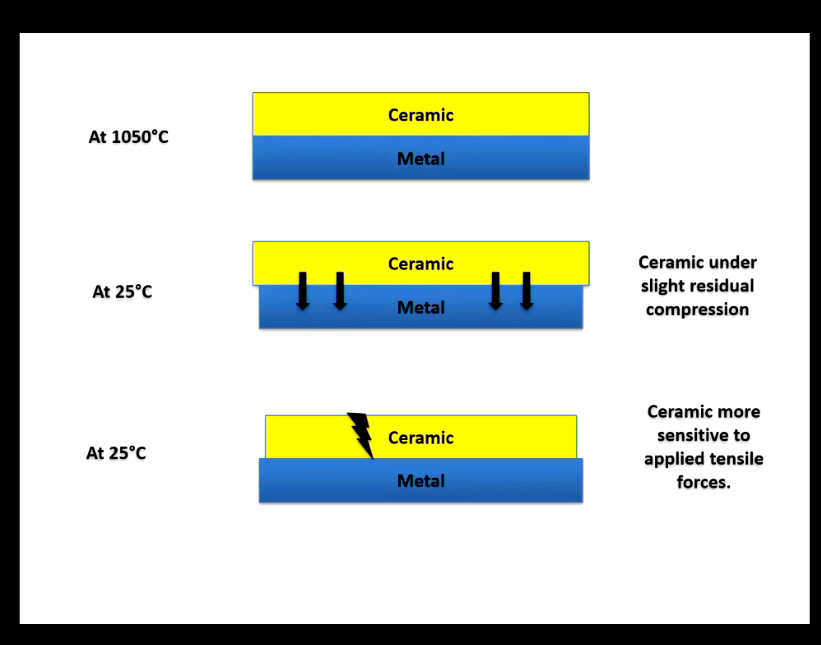

Explain the important of thermal coefficient?

Metal will contract a little more than ceramic, so all forces inwards so ceramic is under slight residual compression (one of the bonding mechanisms of p to m)

Ceramic is under tensile forces, forces are outwards, ceramics are more sensitive to applied tensile forces

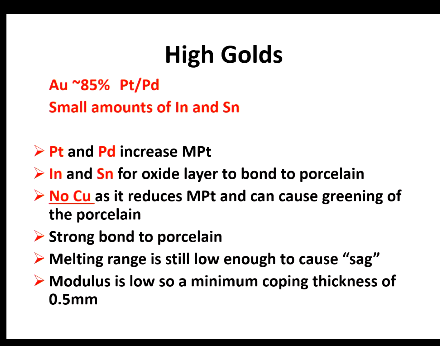

High golds metals used in PFM

What do Pt/Pd DO?

In and Sn?

Cu?

bond to porcelain?

Melting range still causes what?

minimum thickness of coping?

Pt/Pd increase Mpt

Form oxide layer to bond to porcelain

Cu is not include as it reduces Mpt and can cause greening of the porcelain

Strong bond to porcelain

Melting range is still low enough to cause sag

Modulus is low to a minimum coping thickness of 0.5mm

What is a metal coping?

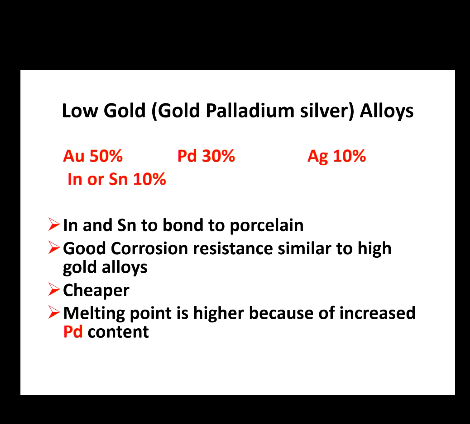

Low gold alloys (Gold, palladium silver) alloys:

What 2 elements allow for bonding to porcelain?

corrosion resistance, similar to?

cost?

Mpt and what element?

In and Sn to bond to porcelain

High corrosion resistance similar to high gold alloy

Cheaper

Melting point is higher because of increased Pd content

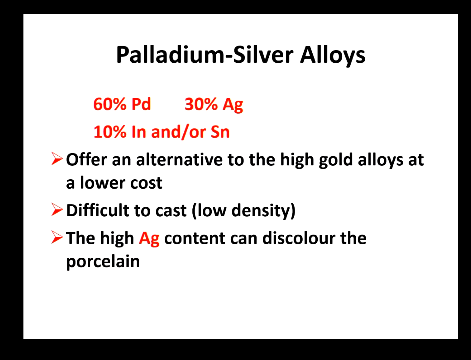

Palladium silver alloys

Cost compared to high gold alloys?

castability?

High silver content can cause what?

Offer an alt to high gold alloys at lower cost

Difficult to cast - low density

High Ag content can discolour the porcelain

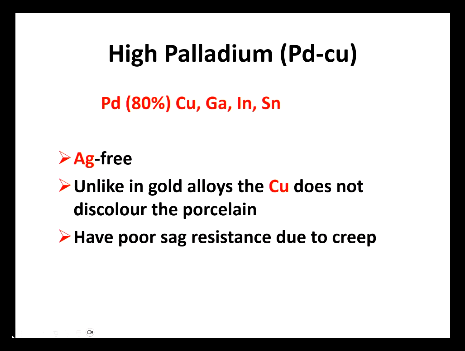

High palladium (Pu-Cu)

is what free?

Cu in this acts differently to when it is in gold how?

creep?

Silver free

Unlike in gold, the Cu does not discolour the porcelain

have poor sag resistance due to creep

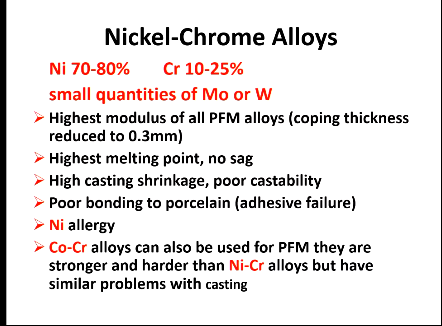

Ni-Cr

Has the highest what compared to other PFM alloys?

coping thickness

melting point

sag

castability?

bonding to porcelain

problem?

alt?

Highest modulus of all PFM alloys

0.3 mm

Highest

No sag

High casting shrinkage, poor

Poor bonding to porcelain - adhesive failure

Ni allergy

Co-Cr alloys can also be used for PFM - stronger and harder than Ni-Cr but still have similar problems with casting

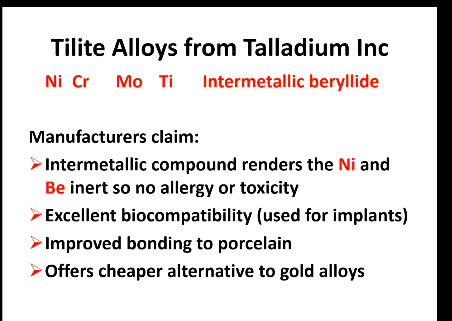

Tilite alloys from Talladium Inc?

manufacturer claims?

Intermetallic compound renders the Ni and Be inert so no allergy or toxicity

Good biocompatibility

good bonding to porcelain

cheaper to gold alloys

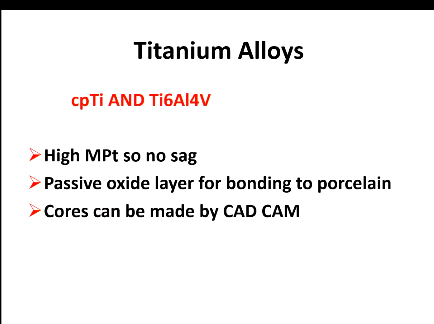

Titanium alloys - cpTi and Ti6Al4V?

Mpt?

sag?

bonding to porcelain?

how can cores be made?

Highest Mpt so no sag

Passive oxide layer for bonding to porcelain

cores can be made by CAD/CAM