MATERIAL PROPERTIES AND THEIR UNITS, GENERAL PROPERTIES, STRESS-STRAIN CURVE

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

18 Terms

Density, ρ (Units: kg/m3, lb./ft3

• is the mass per unit volume. We measure it today as

Archimedes did: by weighing in air and in a fluid of

known density.

Price, CM (Unit: $/kg , $/lb.)

• spans a wide range, can fluctuate, and they depend on

the quantity you want and on your status as a “preferred

customer” with your chosen vendor. Despite this

uncertainty, it is useful to have an approximate price in

the early stages of material selection.

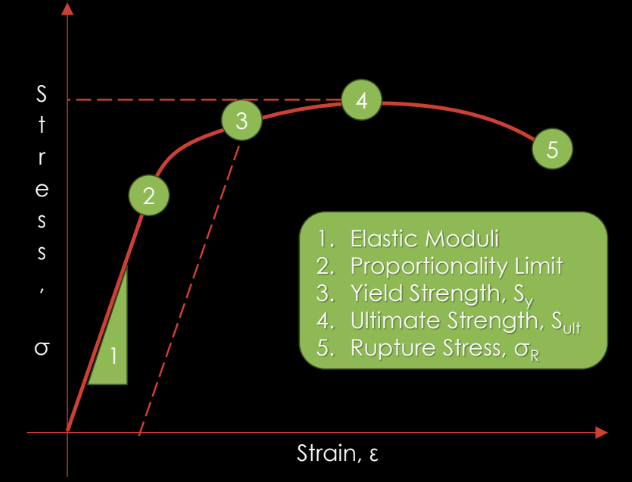

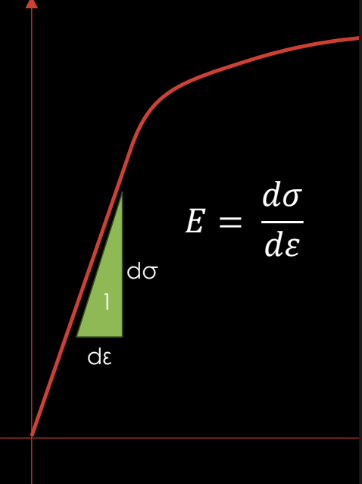

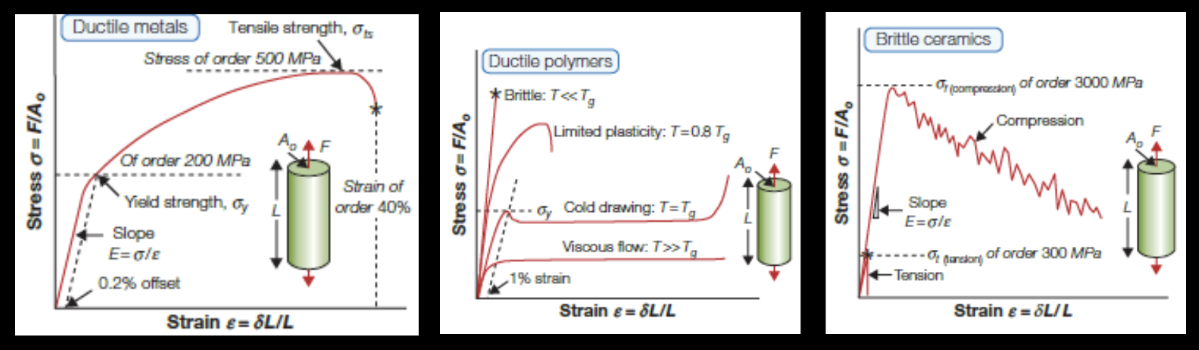

1. Elastic Moduli

2. Proportionality Limit

3. Yield Strength, Sy

4. Ultimate Strength, Sult

5. Rupture Stress, σR

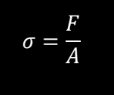

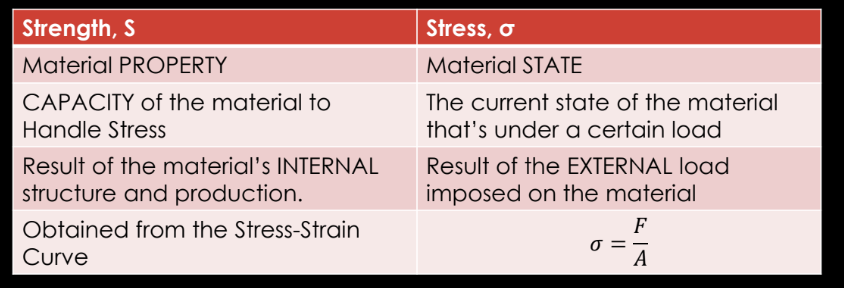

STRESS, σ

The force per unit area the specimen experiences

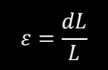

STRAIN, ε

The amount of deflection

an object experiences once stress is

applied relative to the original state

of the object.

Young’s Modulus, E

ELASTIC MODULI

Describes response to tensile or compressive loading

Shear Modulus, G

ELASTIC MODULI

Describes response to shear loading

Bulk Modulus, K

ELASTIC MODULI

Describes the response to hydrostatic pressure.

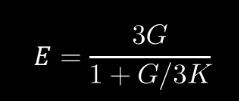

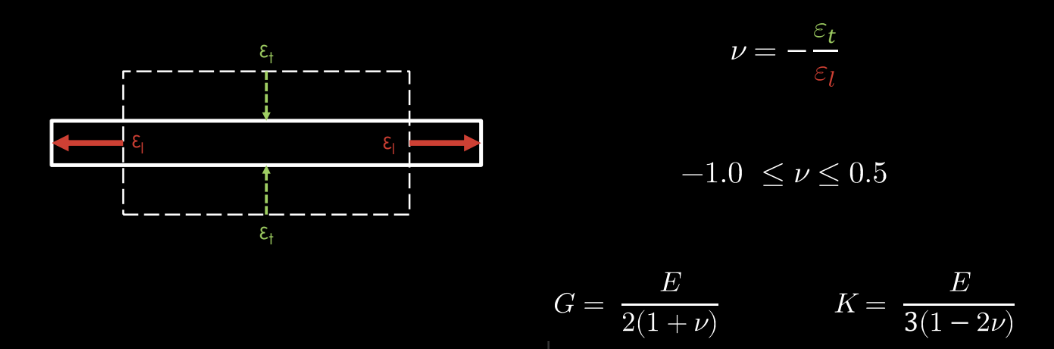

ELASTIC MODULI

Young’s Modulus, E

Shear Modulus, G

Bulk Modulus, K

ISOTROPIC

The Three Moduli are related in the following:

materials whose properties remain the same when tested in

different directions.

POISSON’S RATIO

Poisson’s ratio is “the ratio of transverse contraction strain to longitudinal

extension strain in the direction of the stretching force.”

STRENGTH

• The Strength of a solid, Sf

, depends on the material.

• The Capacity of the material to handle stress.

• The stress required for a material for something interesting to occur in that

material.

• For DUCTILE Materials: Yield Strength – Sy or Ultimate Strength – Sult

• For BRITTLE Materials: Ultimate Strength – SUlt

• Units

• SI – Pa (N/m2), kPa, MPa, GPa,

• EE – psi, ksi,

STRENGTH VS. STRESS

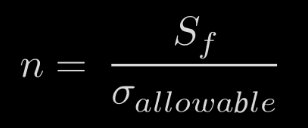

FACTOR OF SAFETY

• We want to design a component to withstand its

operating environment to be able to function

and to be able to function for a certain life.

• The performance criteria and the determination

of what is failure is typically determined by both

the design engineer and the program that

they're working on.

• So, what engineers do is they calculate

something called a factor of safety and what a

factor of safety does is it acts as a safeguard to

failure and it gives you a certain amount of

margin.

σ allowable

This is the maximum stress

that is set by the design

engineer that the

component must hold.

Sf

This is the Strength of the

material the component

is designed.