MSE 175 Exam 1 Combined

1/37

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

38 Terms

radial cleavage, macro

chevron cleavage, macro

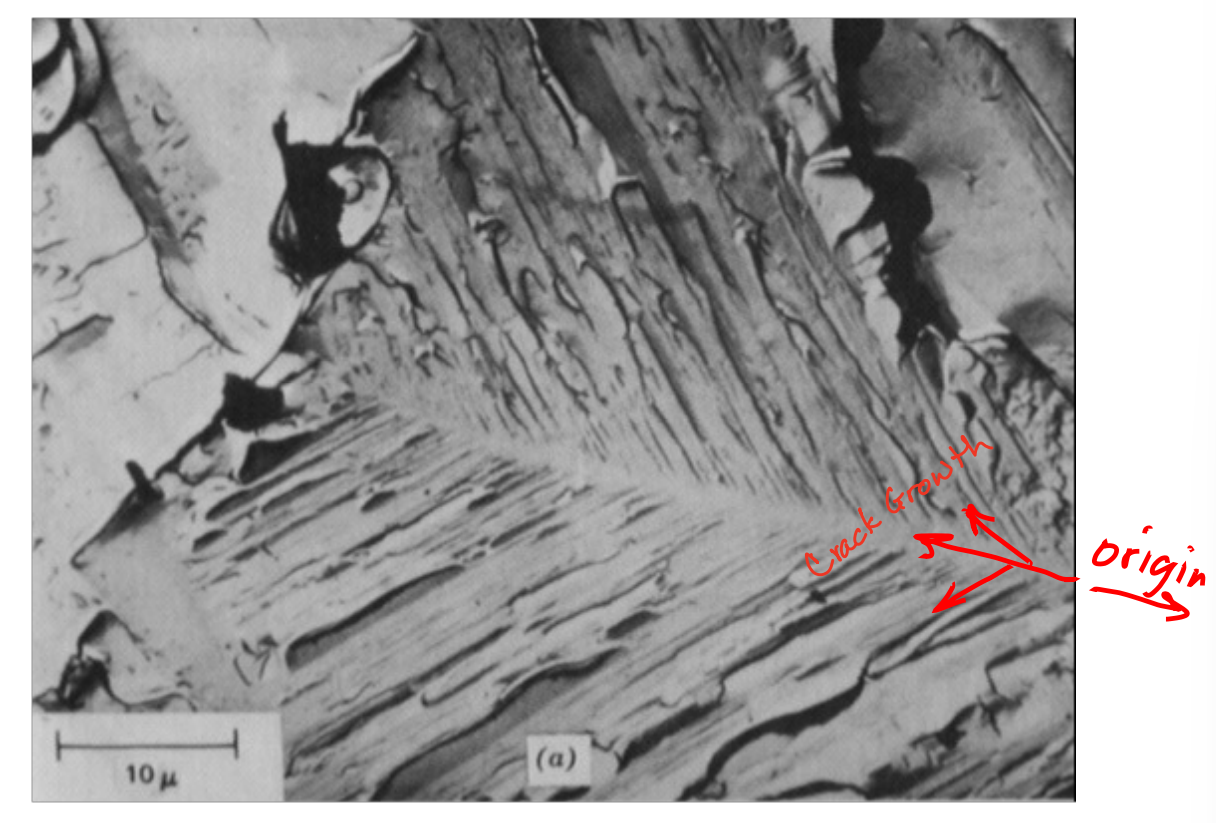

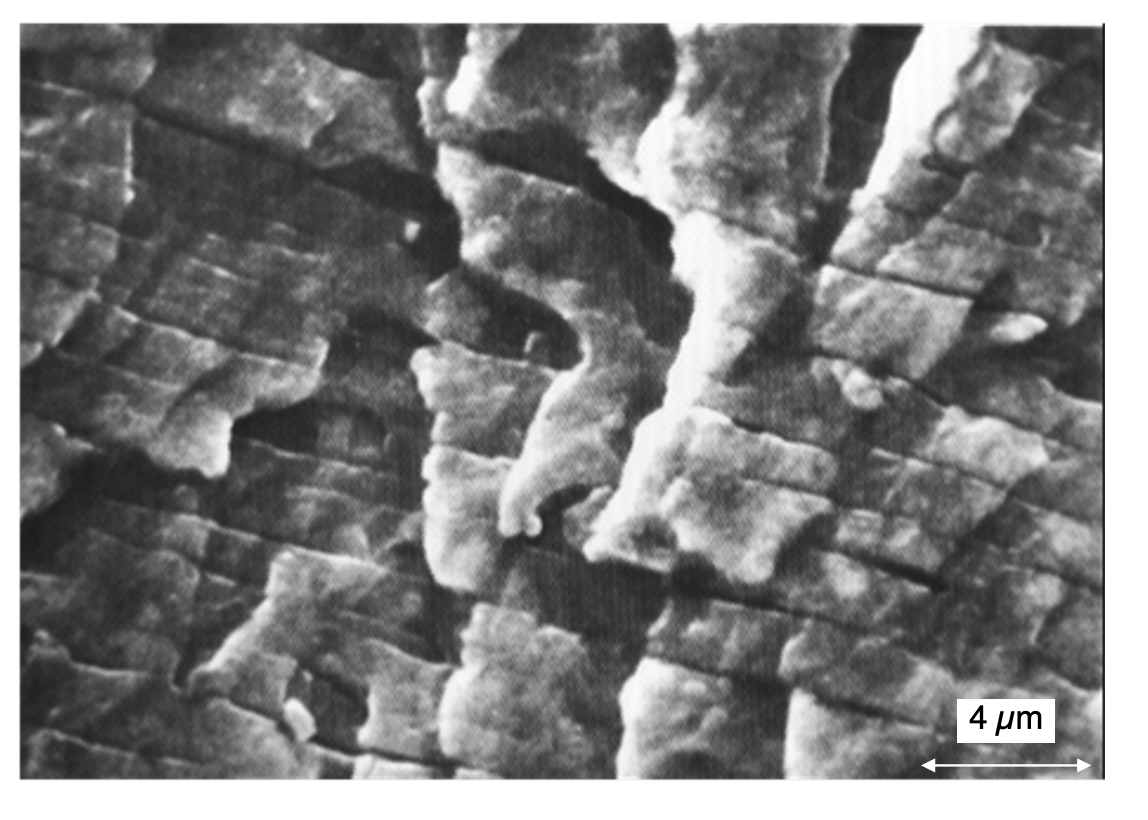

river cleavage, micro

tongue cleavage, micro

feather cleavage, micro

river cleavage & deformation twins

wallner cleavage, micro

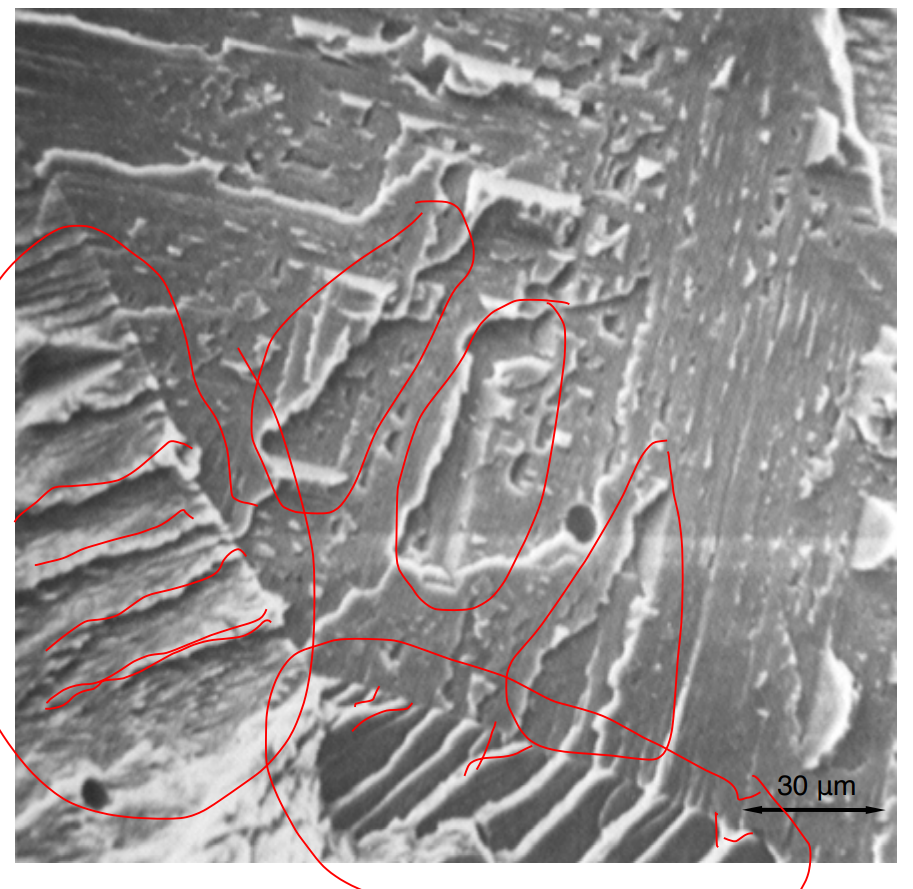

quasi-cleavage

transgranular interaction with grains?

goes through the grain

intergranular interaction with grains?

goes along grain boundaries

faceted fracture surface

usually because impurity segregation

weakened forces at grain boundaries

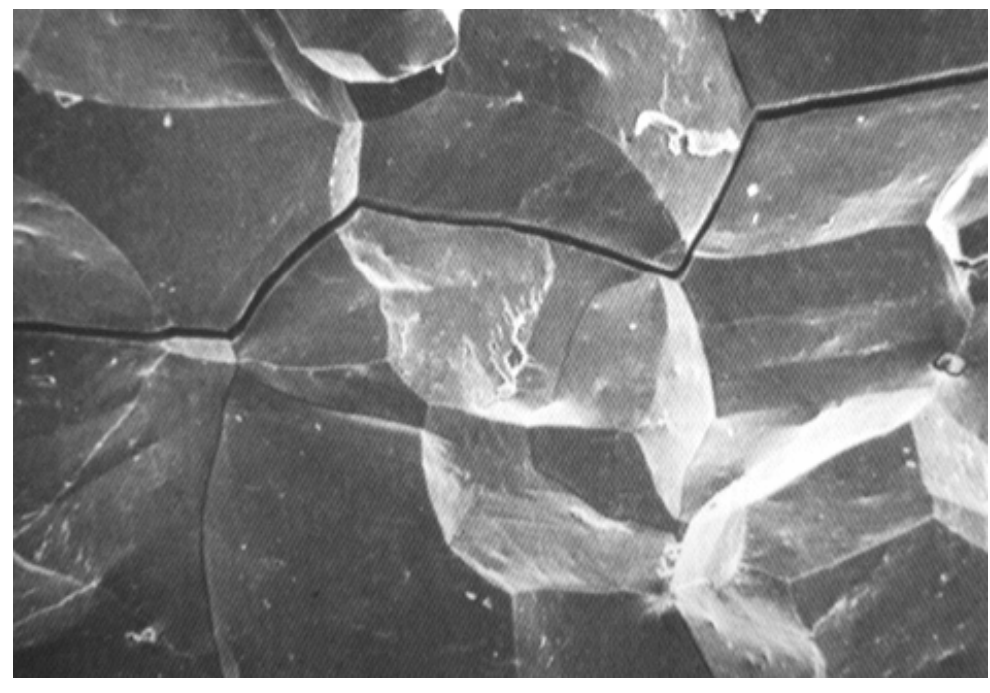

brittle intergranular fracture

crack growth along favored crystallographic planes

(river, feather, tongues, wallner, herring)

brittle cleavage/transgranular fracture

macroscopically flat

fracture surface is shiny to the naked eye (metals)

fracture supersedes any sizable plastic deformation

brittle fracture

intergranular fracture by impurity segregation

intergranular fracture by over heating

What is K_IC?

fracture toughness, material property

What is K_I?

Stress intensity factor

Brittle fracture occurs when..

K_I >= K_IC

Modes of fracture mechanics

Opening

Shear

Tearing / aAnti-plane sheare

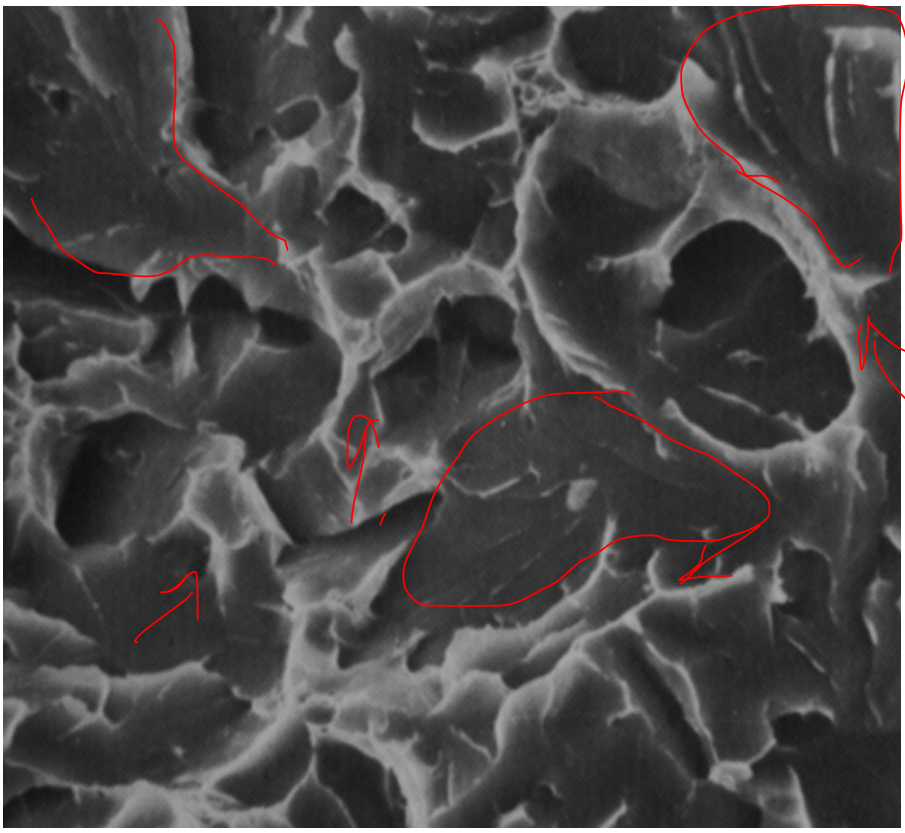

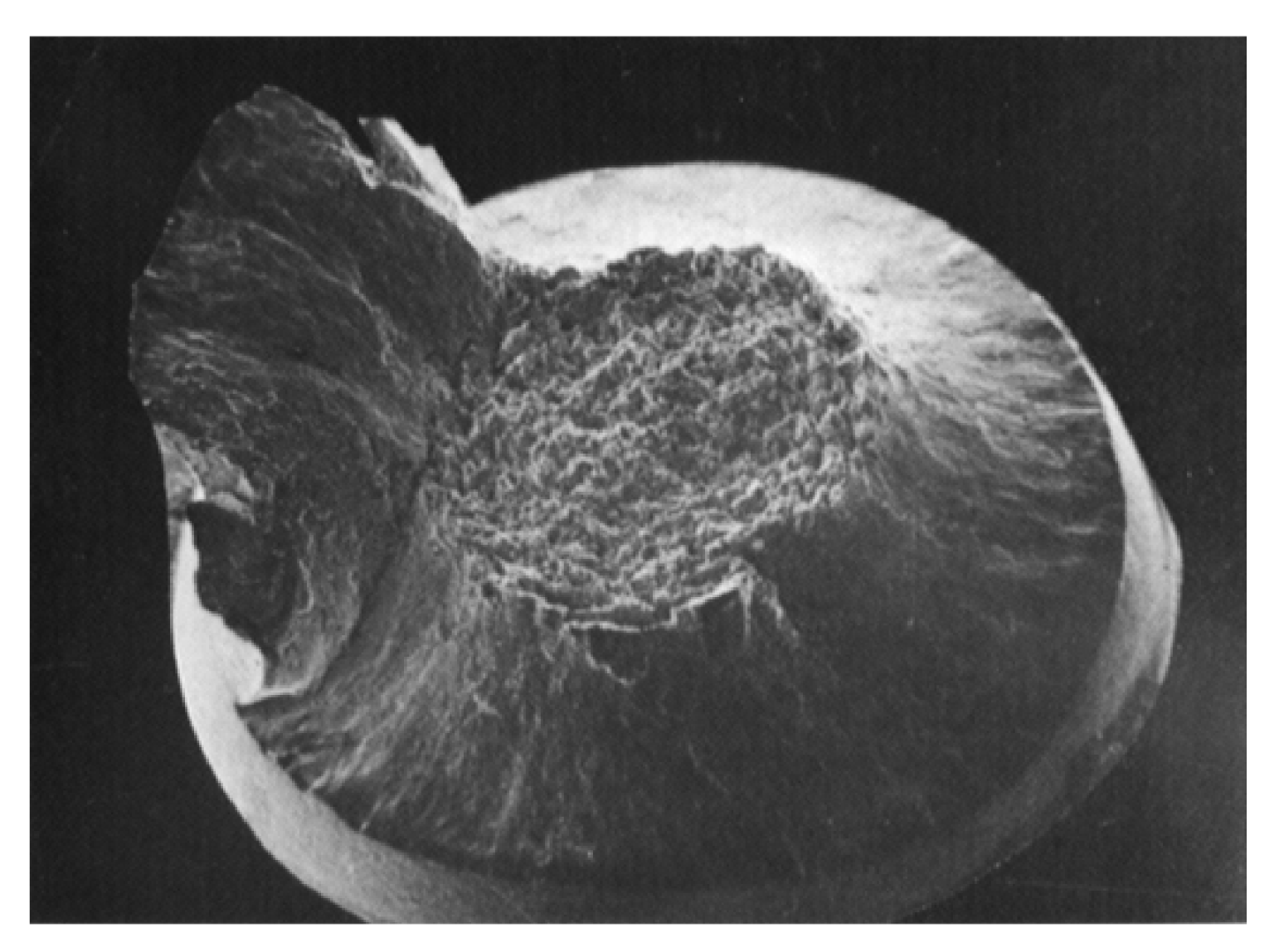

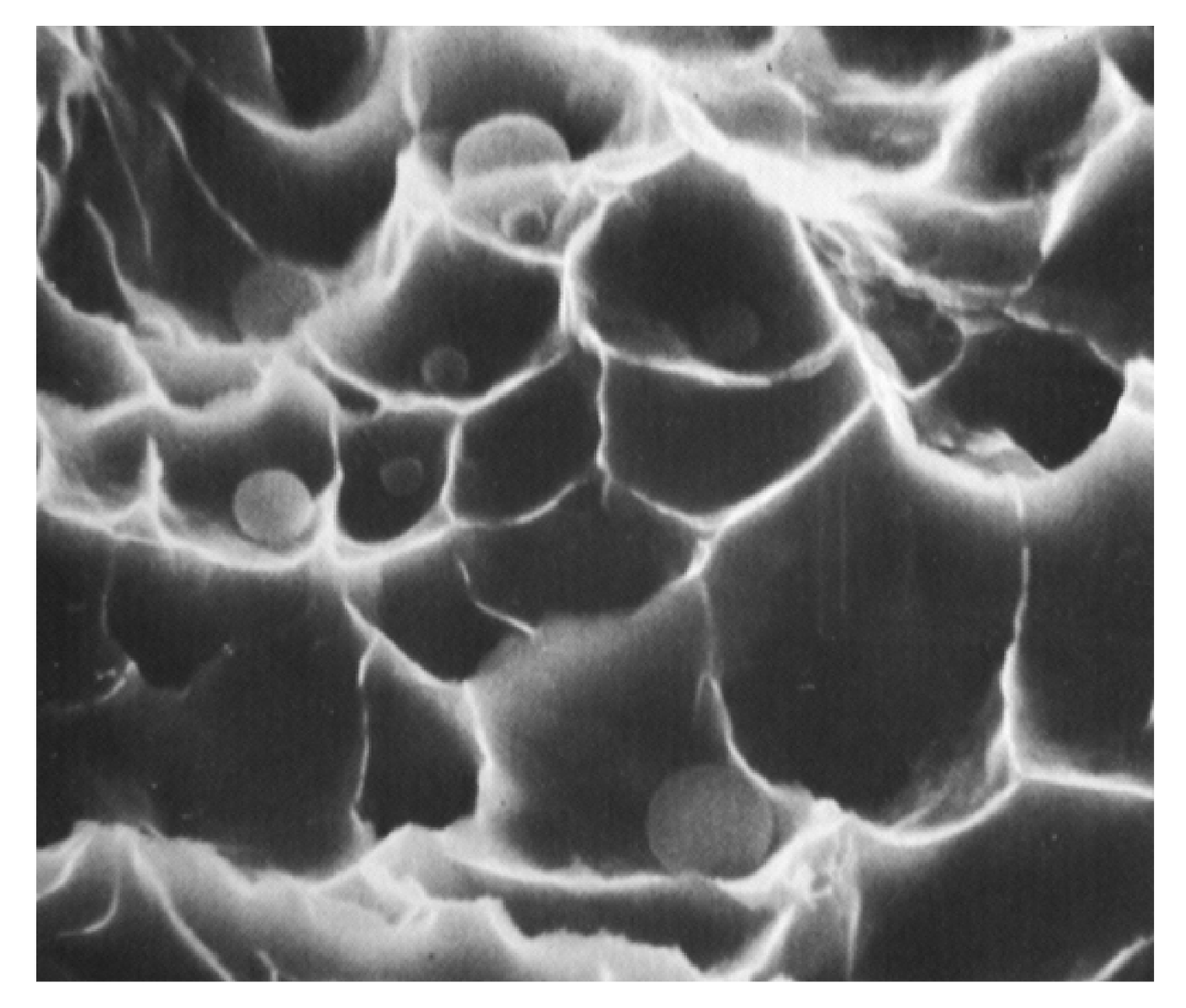

Cup-and-Cone Ductile Rupture

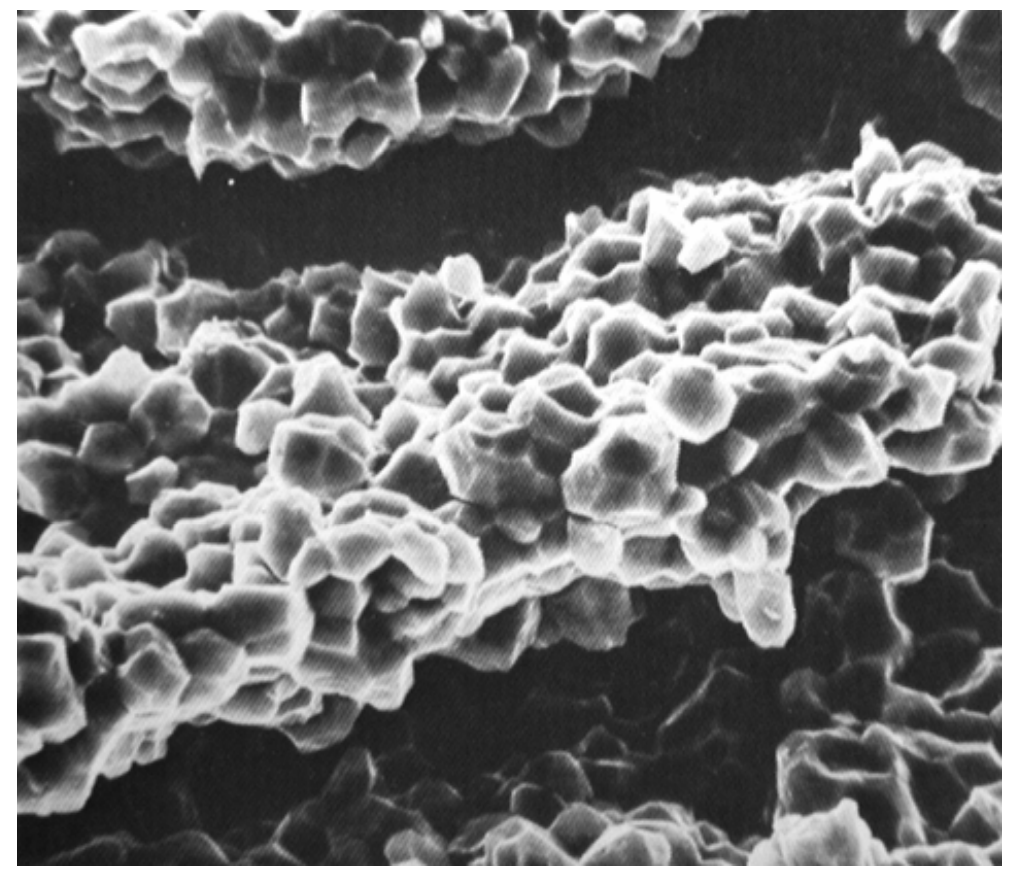

Ductile Rupture - Skewed Dimples

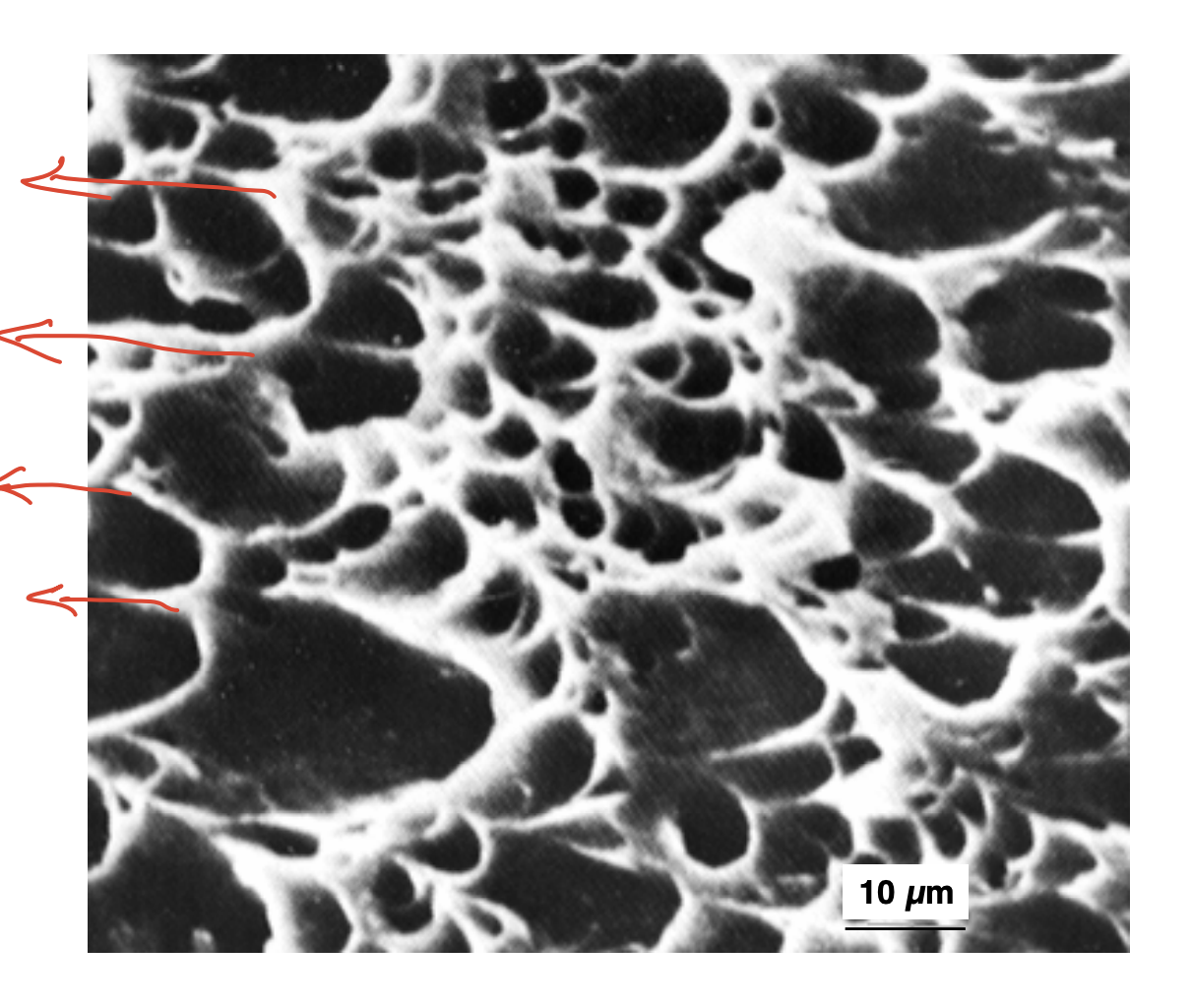

Silicate Inclusions in Carbon Steel

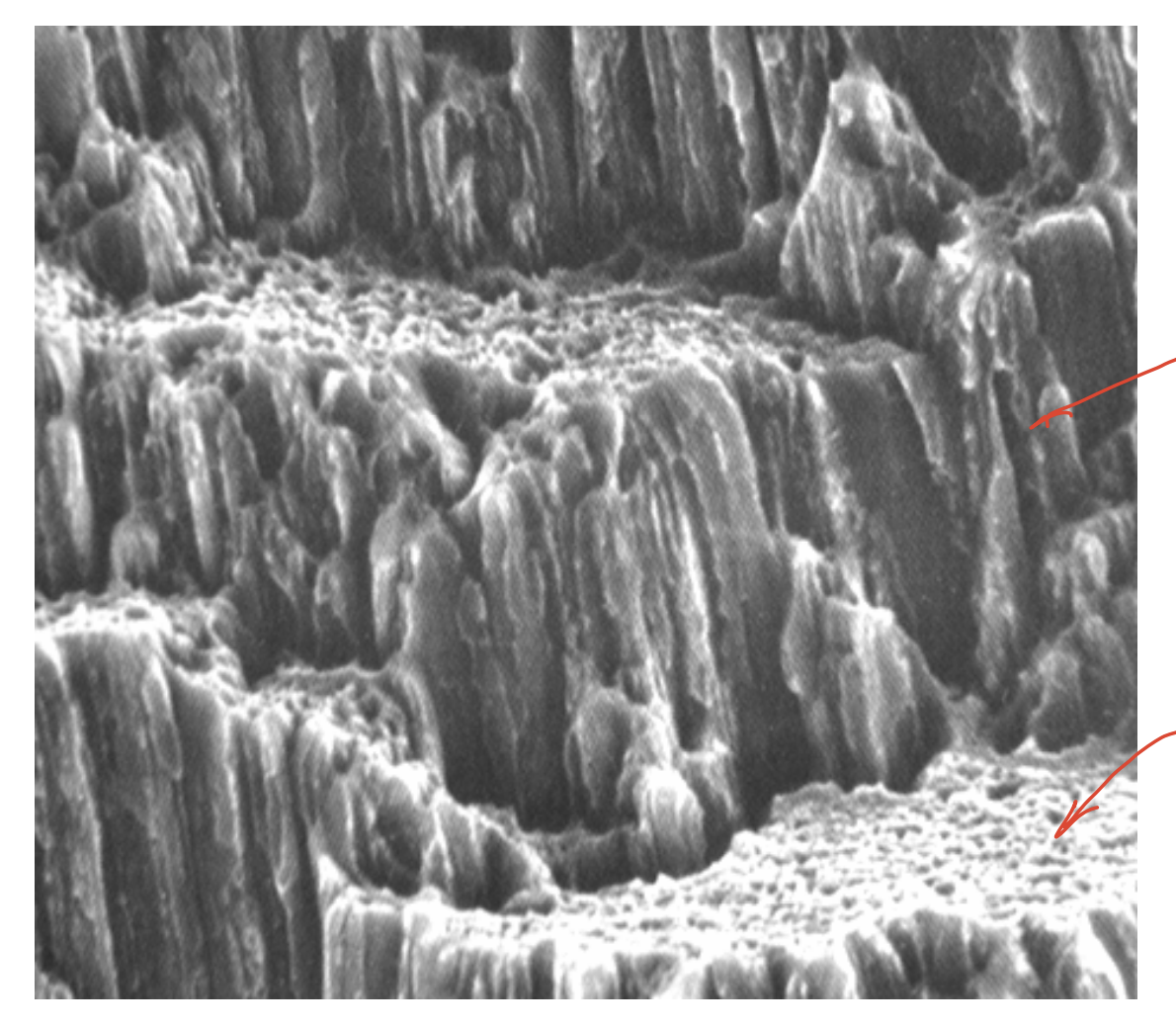

Ductile Rupture (Steel Wire, Fibrous Fracture) —> On the flat horizontal surface (dimples) & vertically the elongated grain boundaries are visible

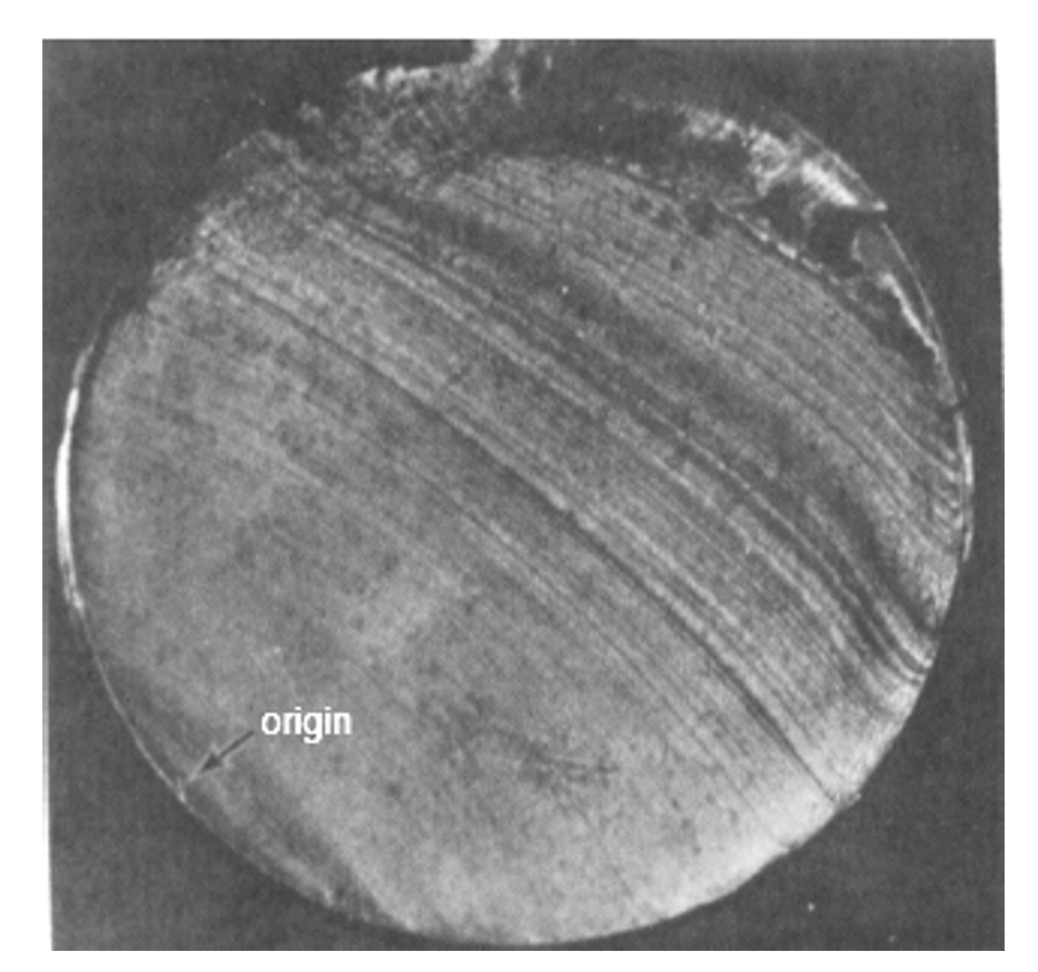

Fatigure - Macroscopic Beach Marks

Low Cycle Fatigue - Microcracks in the External Surface (Microcracks & Slip Bands - extrusion/ intrusion pairs)

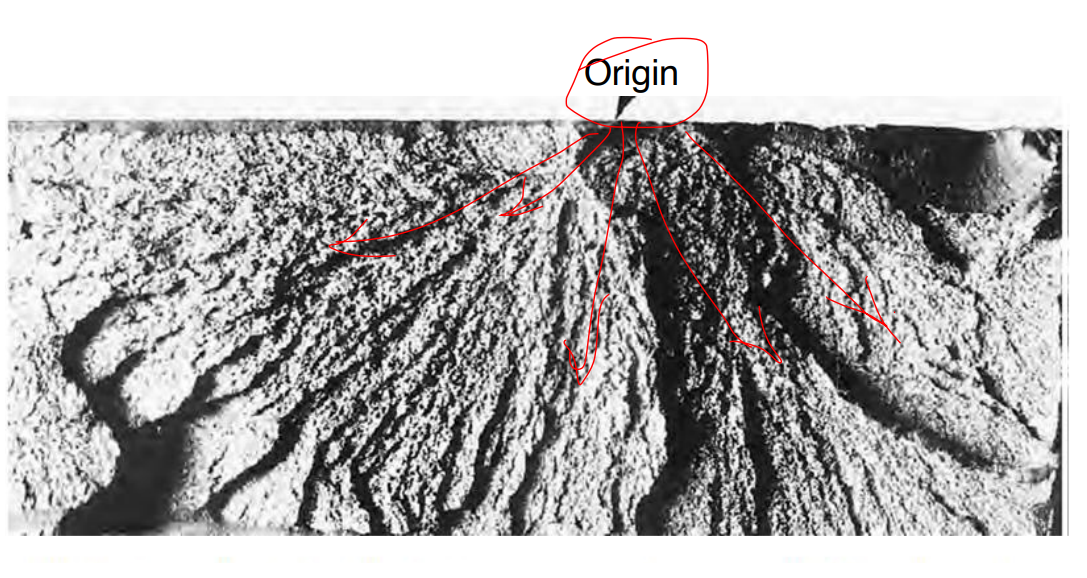

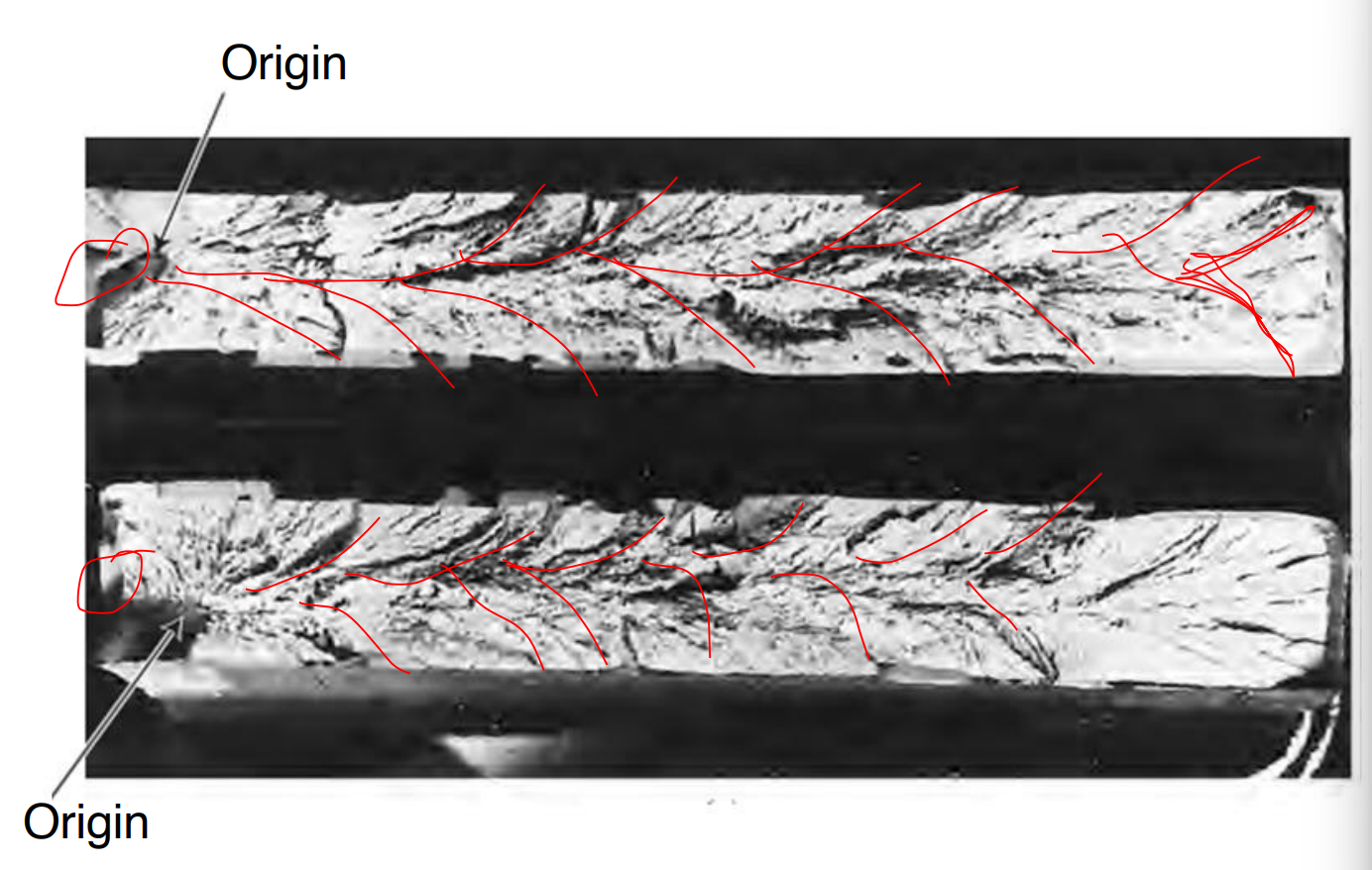

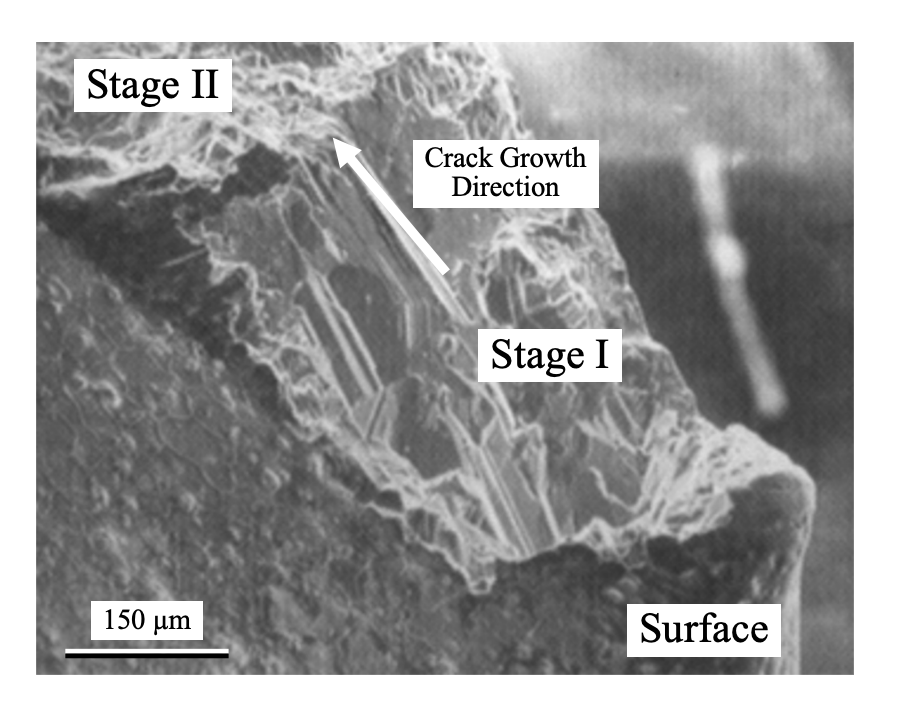

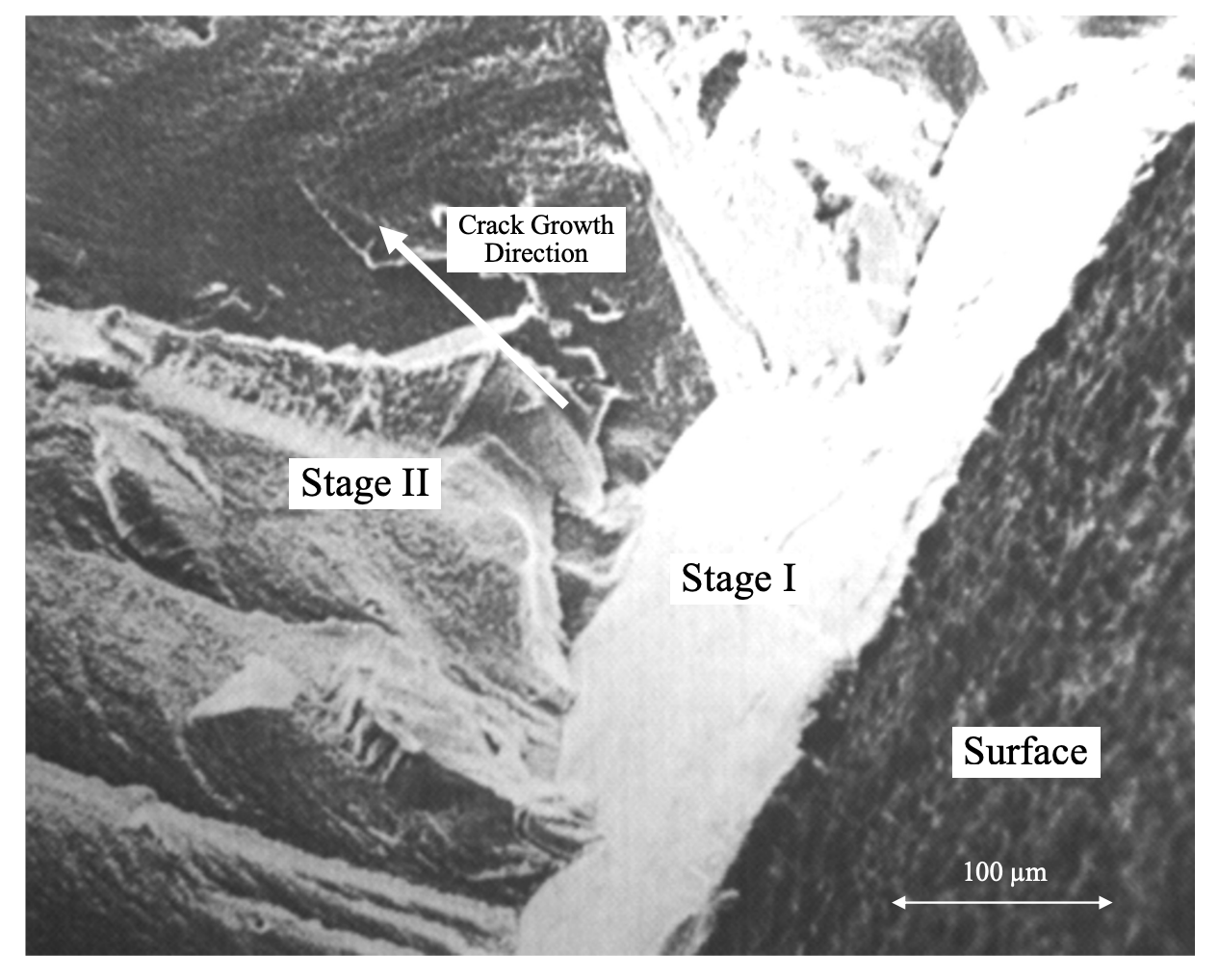

Fatigue: Crack Origin

Fatigue: Crack Origin

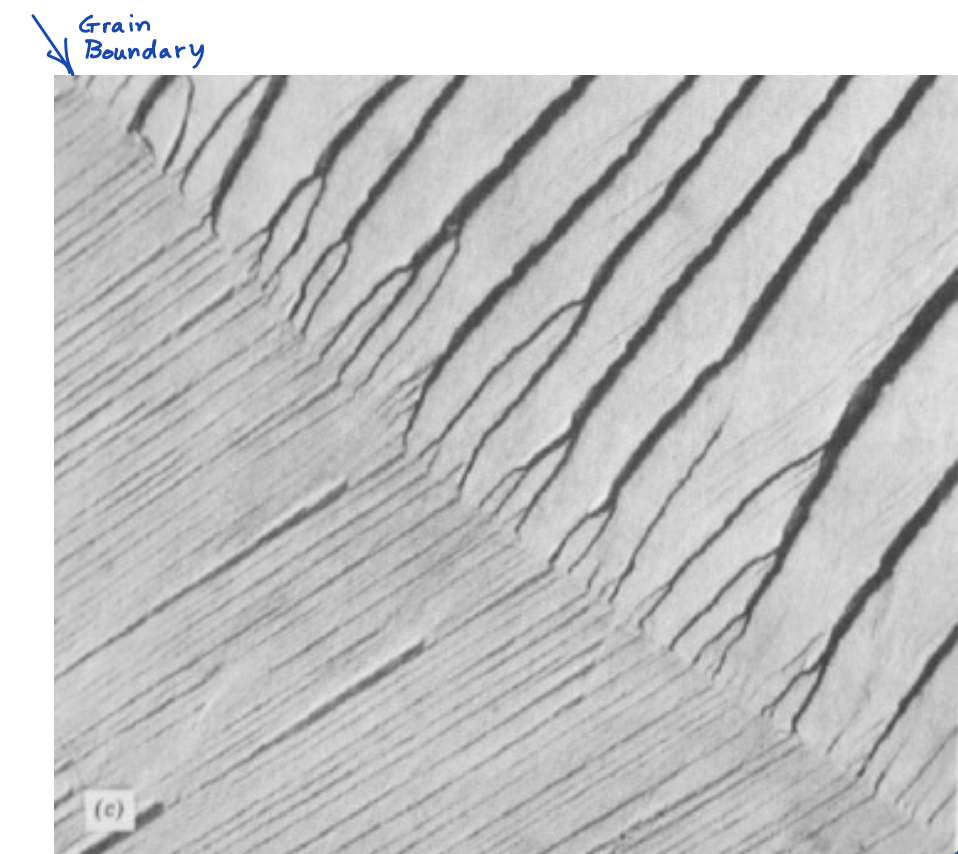

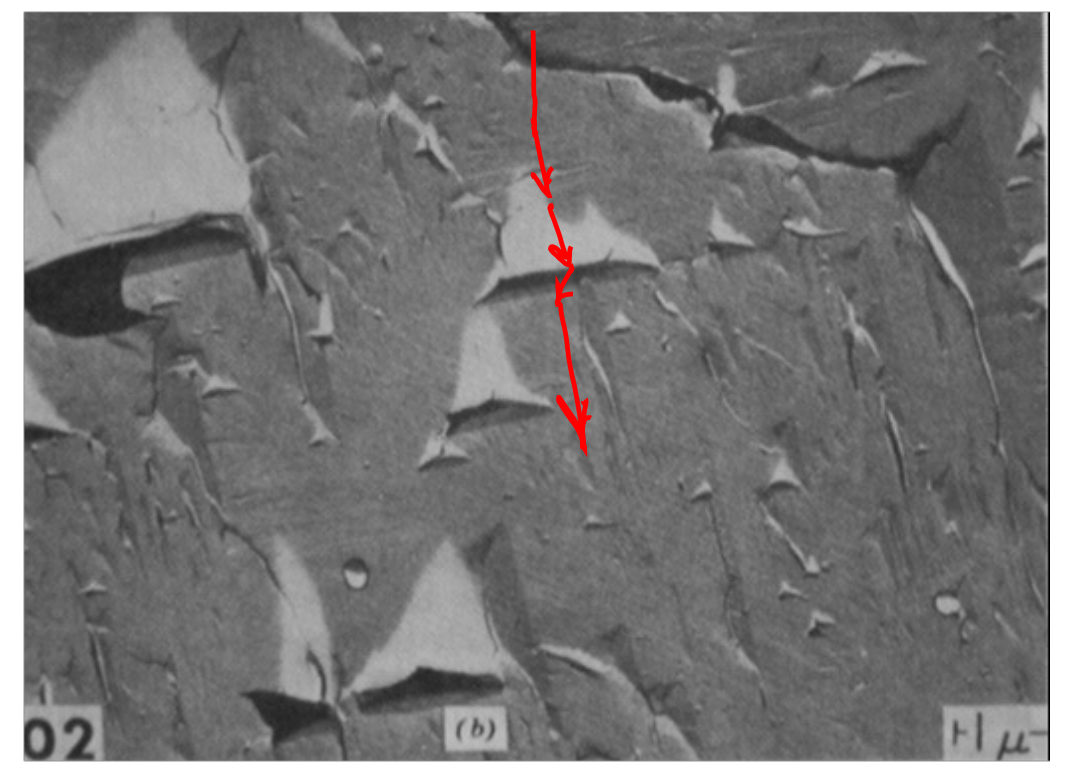

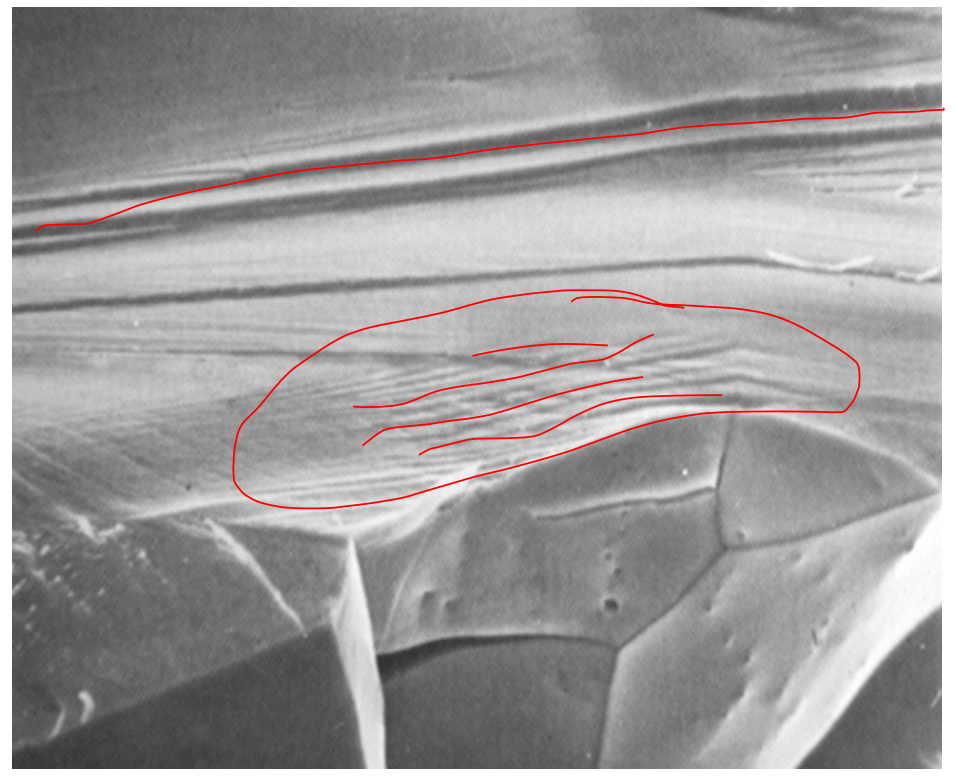

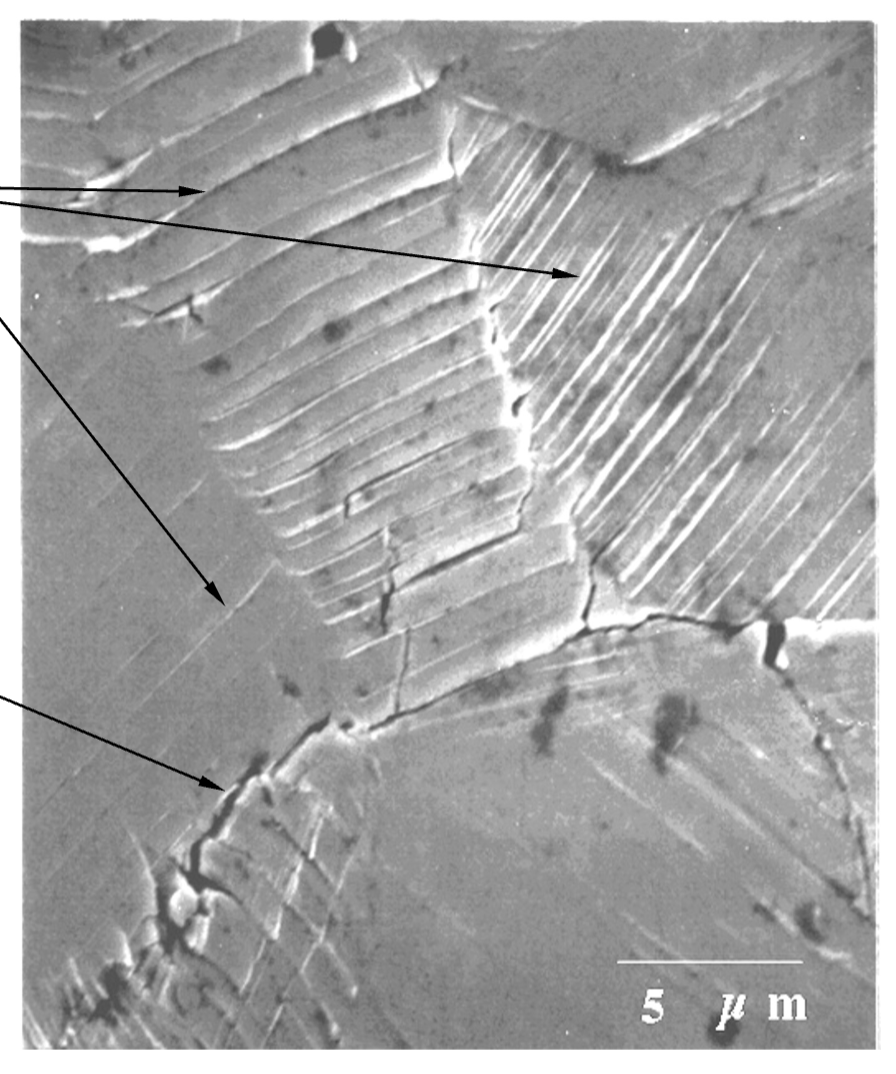

Fatigue: Slip Lines

Fatigue: Slip Lines

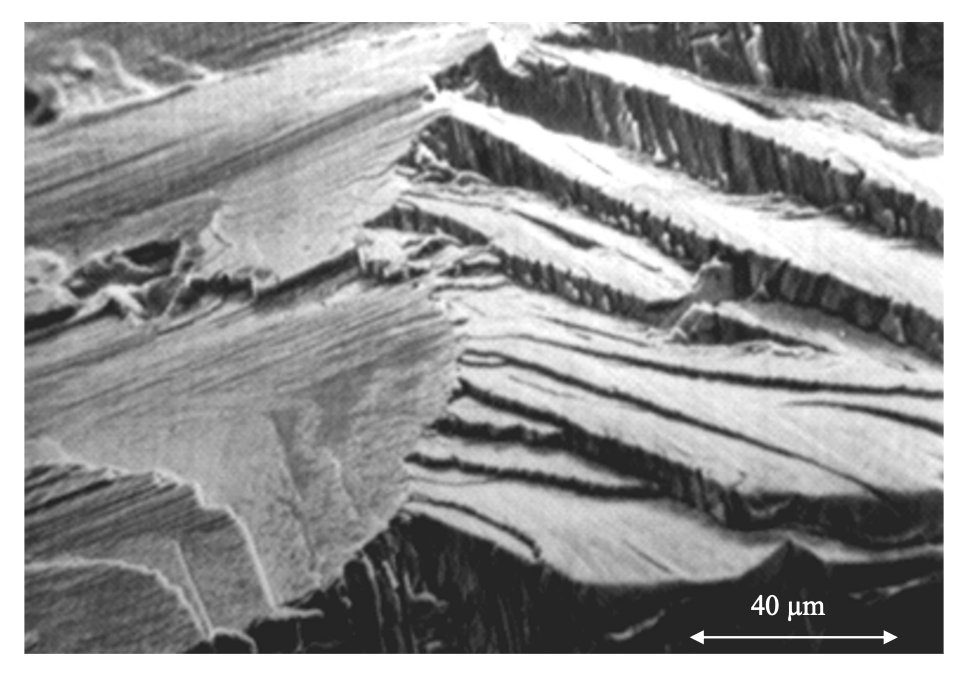

Fatigue: Feather Pattern

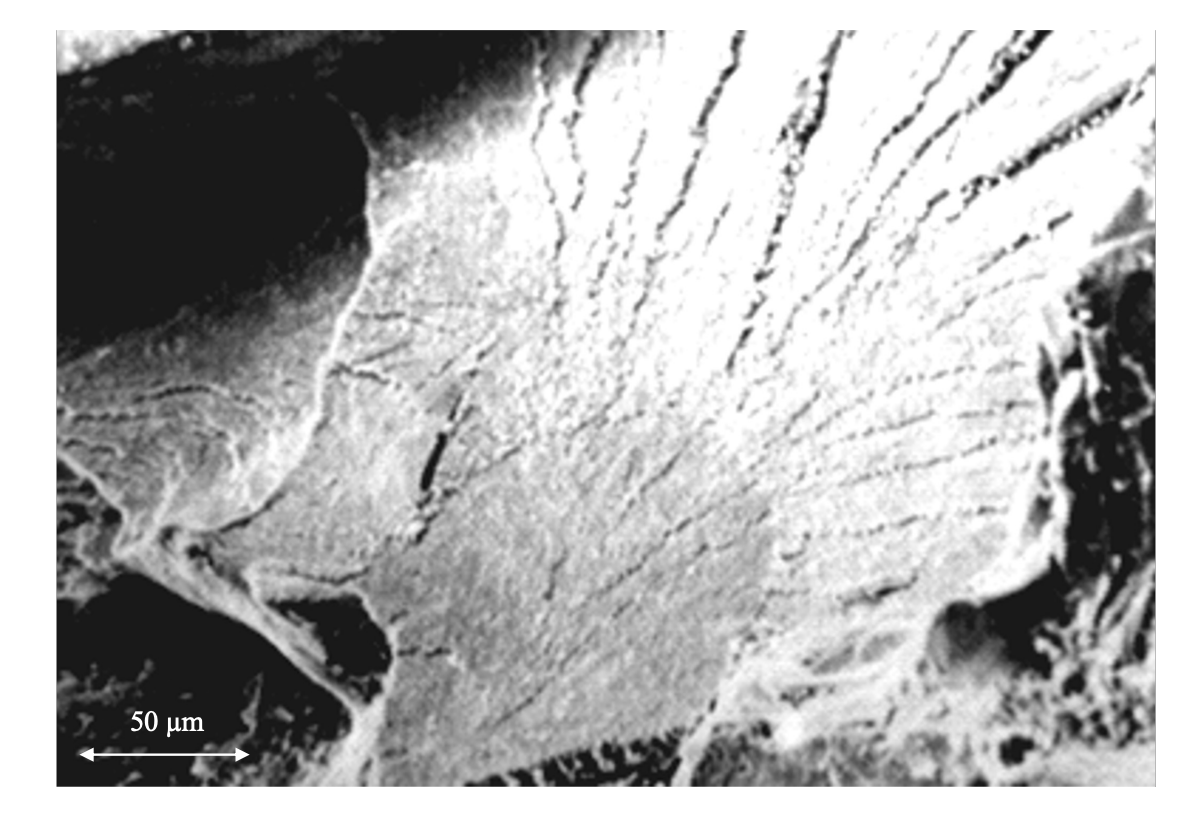

Fatigue: River Pattern

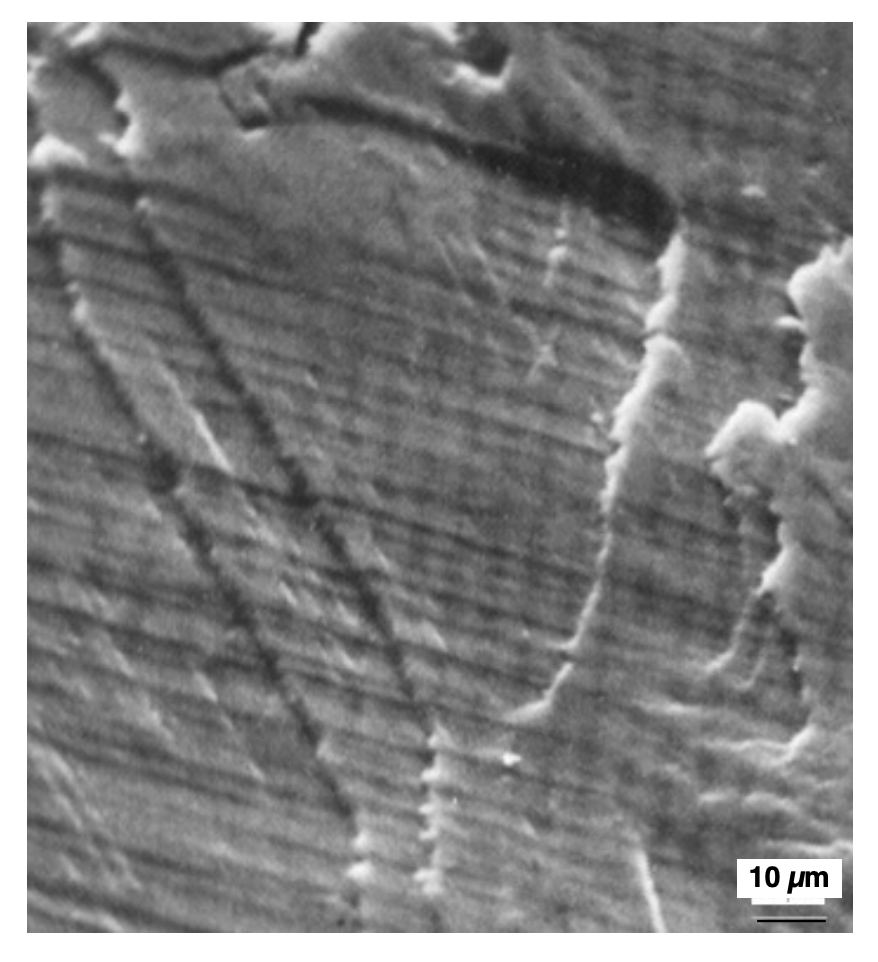

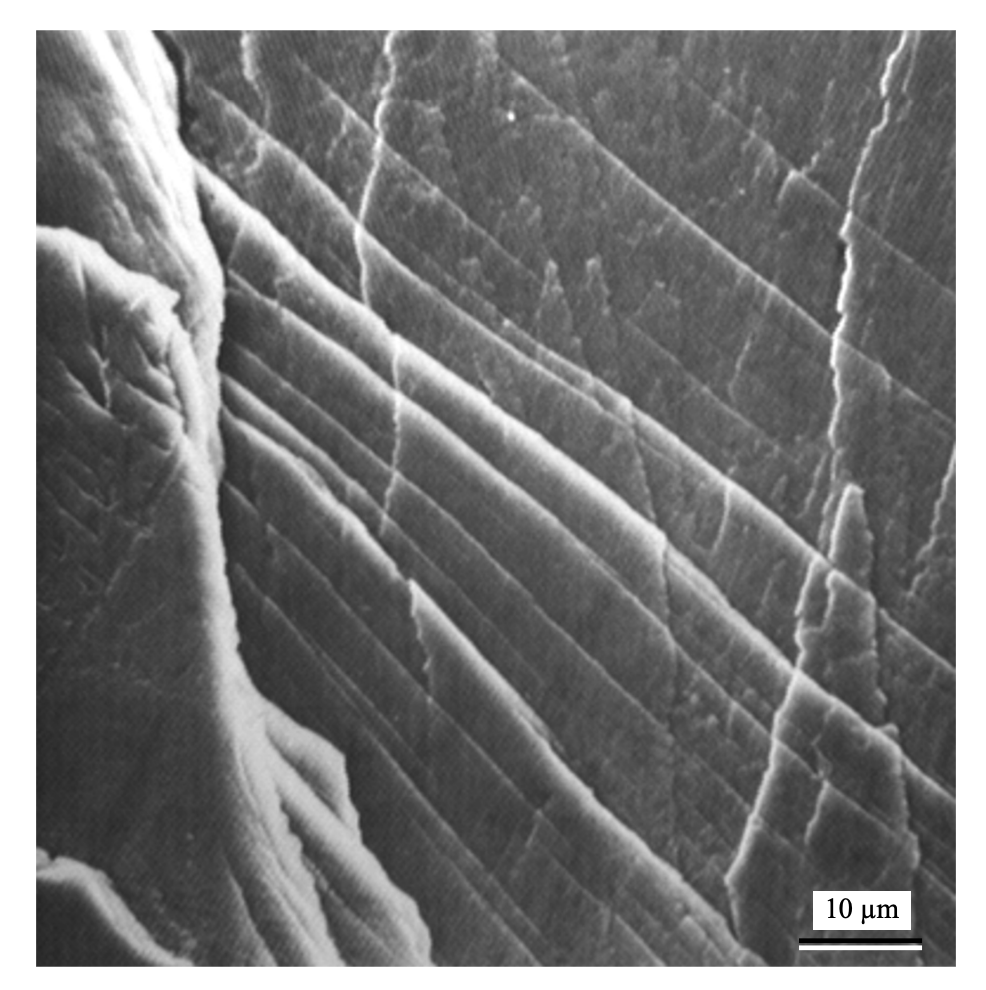

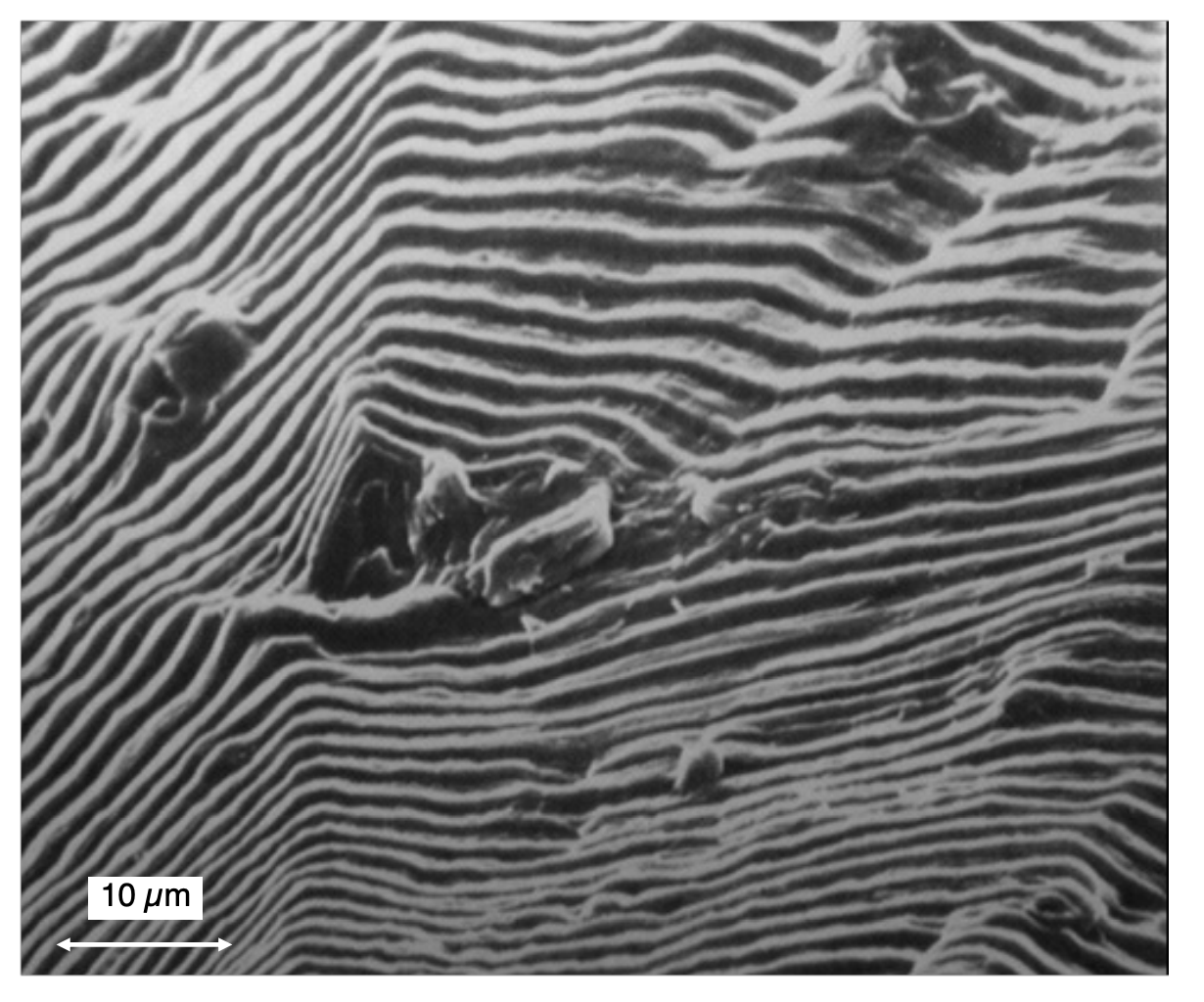

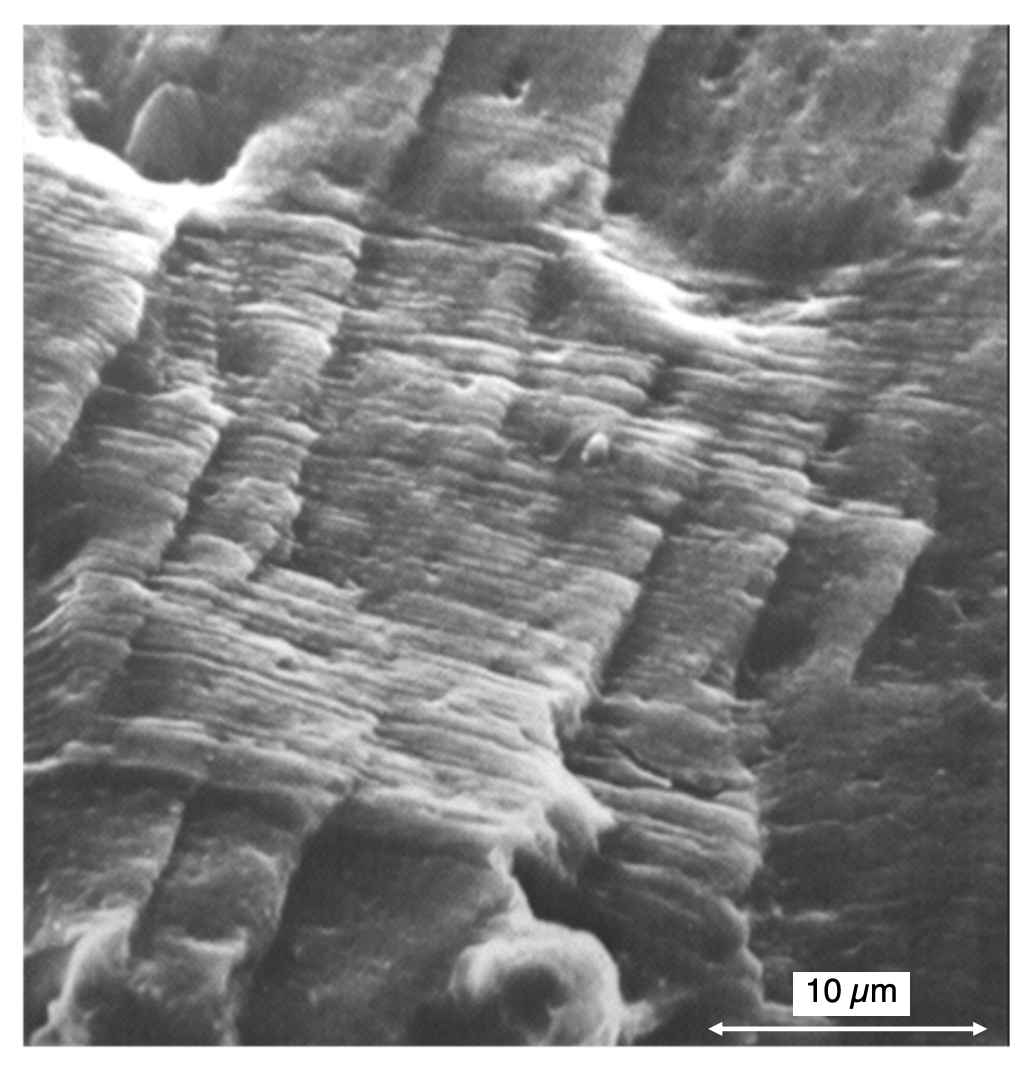

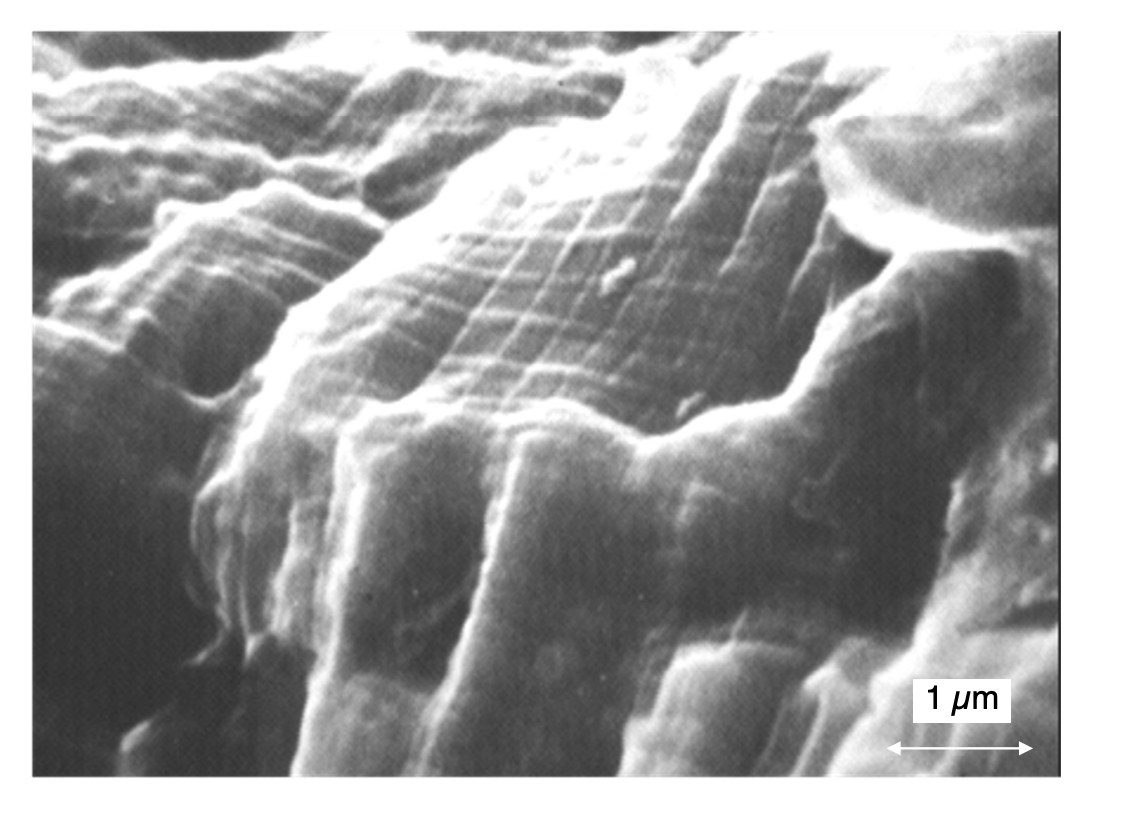

Fatigue: Striations

Fatigue: Striations (transitions in load amplitude)

Fatigue: Brittle Cracking (titanium alloy casting)

Fatigue: Brittle Cracking (pearlitic cast iron)

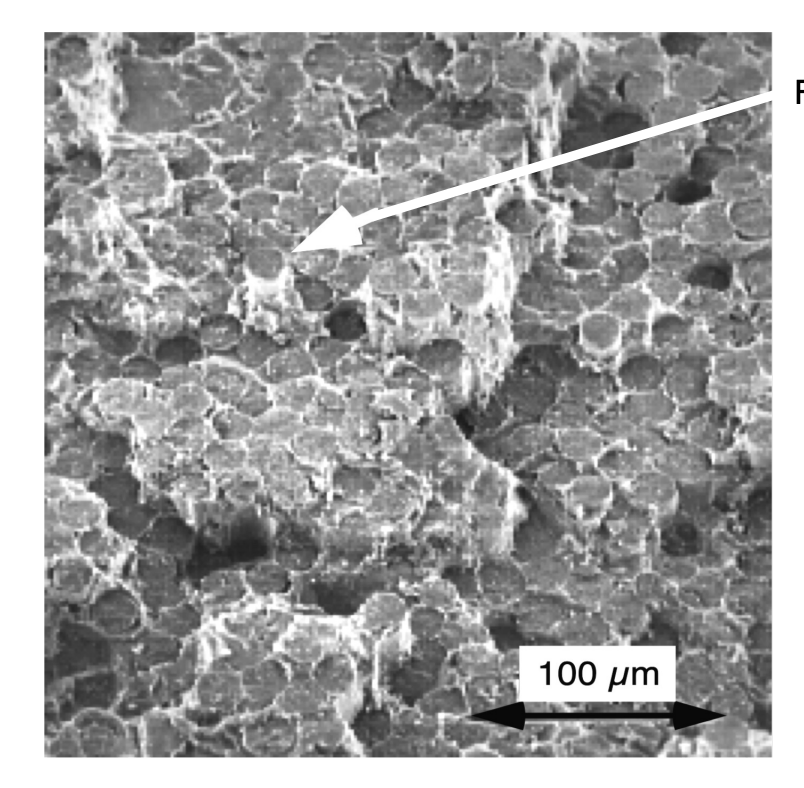

Fatigue: Brittle Cracking (continuous alumina fiber reinforced Mg alloy) & Visible Fiber Pullout

Ductile Rupture

• Facilitated by microvoid growth and coalescence

• Microvoids tend to nucleate at particulates

• Fracture surface is characterized by dimples with shear ridges

• Height of the ridges is indicative of the ductility of the material

• Orientation of the ridges is indicative of the stress state

Fatigue Failure

Four stages:

1) crack initiation (may be circumvented by preexisting defect)

2) Stage I crack growth along a slip band (may be circumvented by pre-existing defect)

3) Stage II crack growth by alternating slip that produces striations.

4) Catastrophic fracture (ductile rupture or quasi- cleavage)