U3 AOS 3: Operations

1/13

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

14 Terms

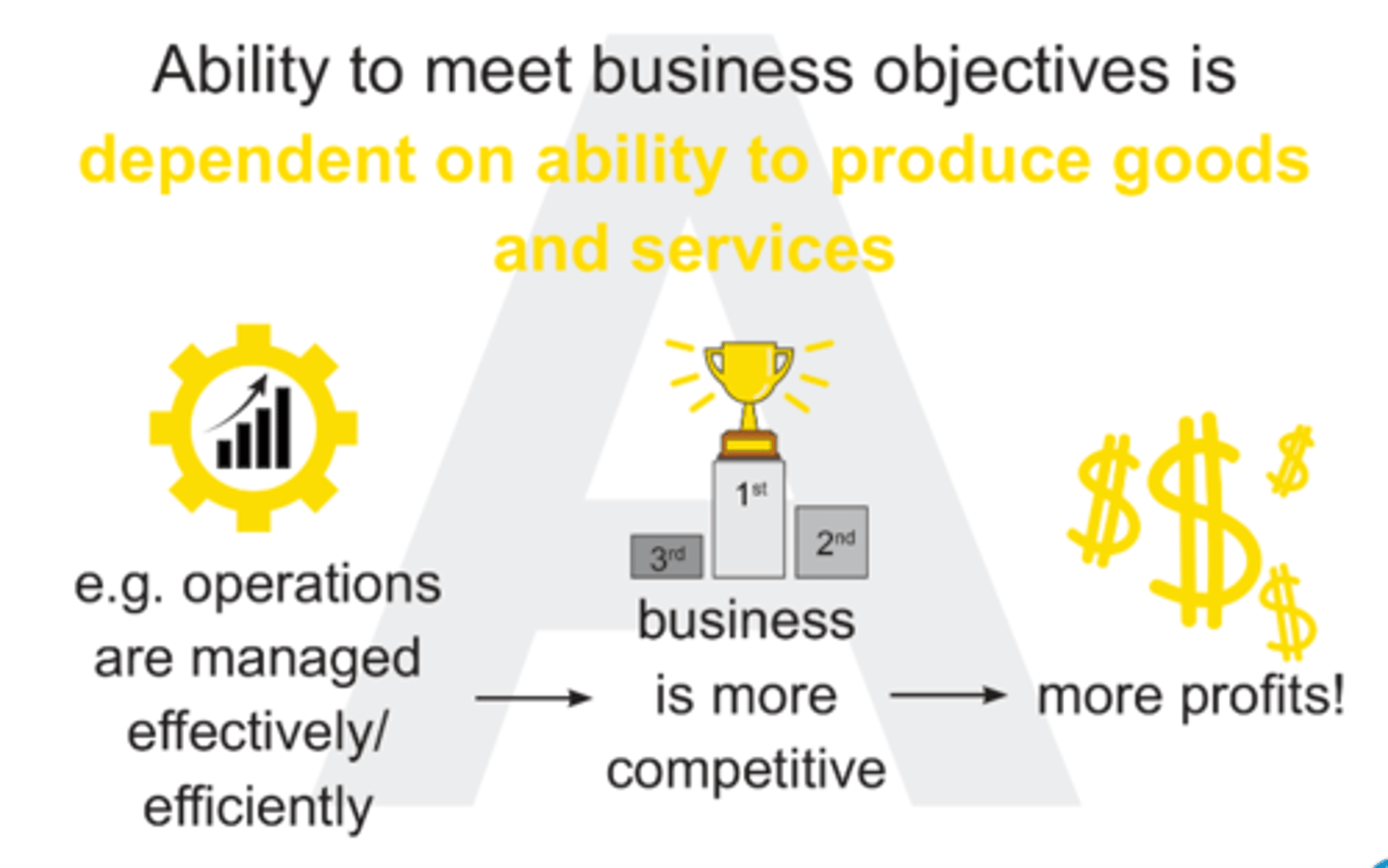

Why is operations management important for meeting business objectives?

What are the 3 differences between manufacturing and service businesses?

· Manufacturing outputs are tangible whereas service outputs are intangible

· Manufacturing outputs need to be stored whereas service outputs do not

· In manufacturing, production and consumption are not linked whereas in service, the consumer has to be present

(e.g. consumer doesn’t have to wear a t-shirt after buying, but person must be present for haircut)

What are 3 advantages and 3 disadvantages to implementing new technology in a business?

Advantages:

· Increased economies of scale (less input required for more output)

· Reduced costs once implemented

· Opportunity for staff to learn new skills

Disadvantages:

· Expensive

· May break which can disrupt the entire business

· May replace jobs, leading to downsizing/redundancies

Explain how CAD/CAM and AI can improve operational efficiency in a business.

CAD/CAM: used to test design and manufacturing options (prototypes), saving time/effort and allowing businesses to improve outputs before production

AI: minimises human error by completing tasks quicker and more precisely/consistently than human capability – business can increase quality without increasing human labour, thus saving money

Why are online services beneficial for the operations of a business?

· Increase in potential market share

(e.g. anyone with internet access, not just anyone near a physical store)

· Provide more info to consumers

(e.g. FAQs, returns policy, items frequently purchased together)

· Marketing opportunities

(e.g. sign up to email list for discounts)

· More reliability/trust for customers

(e.g. live customer service chats, contact info)

How does the material management strategy of MPS increase operational efficiency?

Materials production schedule (MPS)

MPS: lists quantity and delivery date of outputs with lead times for input delivery – ensures correct productive capacity

How does the material management strategy of MRP increase operational efficiency?

Materials requirement planning (MRP)

MRP: lists all inputs required, inventory counts, and lead times of suppliers – ensures correct quantity of inputs are delivered on time

How does the material management strategy of JIT increase operational efficiency?

Just in Time approach (JIT)

JIT: all inputs arrive just when needed for production (not sitting in stock waiting) – reduces storage costs and risk of waste

How does the material management strategy of Forecasting increase operational efficiency?

Forecasting: uses past trends to predict future sales – supply matches demand, increases production effectiveness, minimises waste

How do quality control, quality assurance, and total quality management improve operational efficiency?

· QC: internal checks to ensure outputs meet benchmarks – reduces defects and waste

· QA: external audit to set standards for the business – reliable/proactive way to ensure high quality output

· TQM: business-wide commitment to improving quality outputs – comprehensive strategy that prioritises quality and increases competitiveness

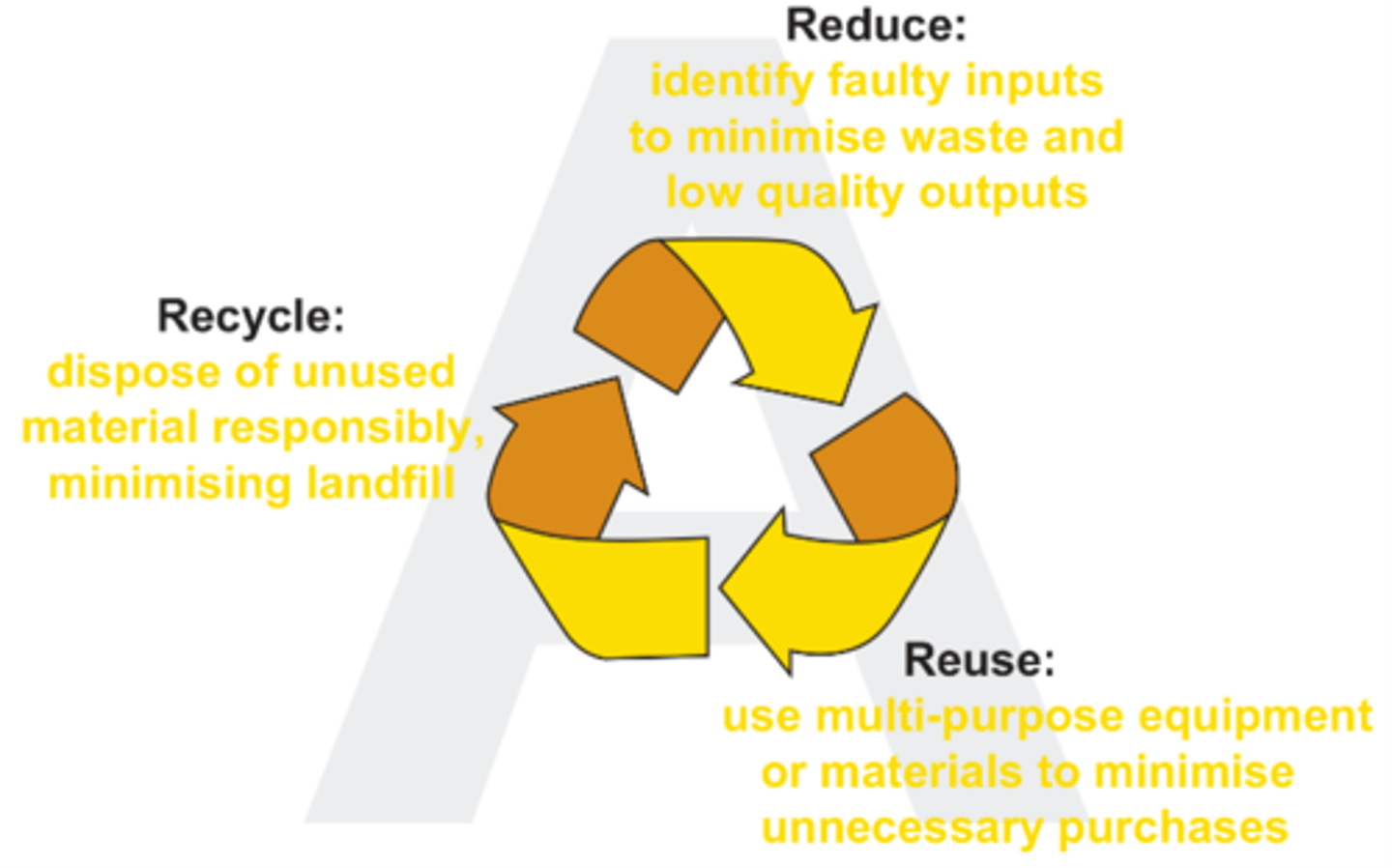

How can businesses employ the reduce, reuse, recycle method of waste minimisation?

What are the 4 principles of lean management?

1. Pull: avoid overproduction by not overestimating demand

2. One piece flow: reduce unnecessary wait time to make production more efficient

3. Takt: match rate of production to customer demand in a timely manner

4. Zero defects: aim to prevent problems early to reduce waste

What corporate social responsibility elements should be considered for inputs, processes, and outputs?

Inputs:

· Purchase from ethical, environmentally sustainable suppliers

· Pay suppliers on time

Processes:

· Decent pay and OH&S for employees, not exploiting cheap overseas labour

· Fair treatment of customers and competitors

Outputs

· Disposing of waste ethically

· Making outputs beneficial, reliable, safe, and not misleading

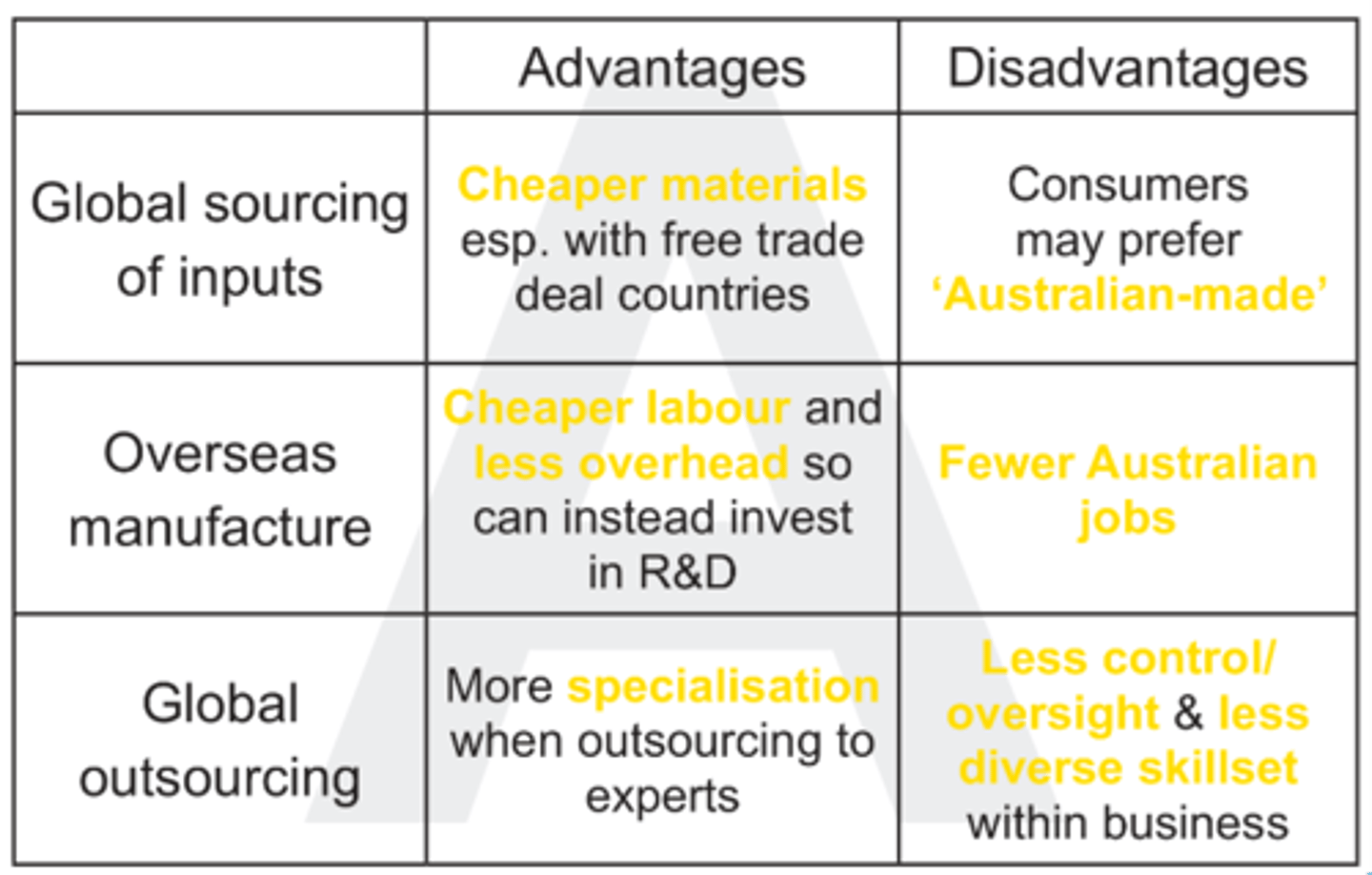

Global operations considerations.