Chapter 9 - Layout Strategies

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

18 Terms

What is the strategic importance of layout decisions?

Layout decisions determine long-run operational efficiency and help establish competitive priorities such as capacity, processes, flexibility, cost, quality of work life, customer contact, and company image.

Name the six types of layouts in operations management.

Office layout

Retail layout

Warehouse and storage layout

Fixed-position layout

Process-oriented layout

Work-cell layout

What are the key objectives of retail layout design?

To maximize profitability per square foot by increasing customer exposure to products and strategically placing high-draw, impulse, and high-margin items.

Describe the fixed-position layout and its challenges.

In fixed-position layout, the product remains stationary while workers and equipment come to the site. Challenges include limited space, different materials at various stages, and dynamic volume requirements.

What is cross-docking in warehouse layouts?

Cross-docking involves moving materials directly from receiving to shipping without storage, requiring tight scheduling and advanced shipment notifications via barcodes or RFID.

What is random stocking in warehouse layouts?

It involves the random assignment of stocking locations using automatic identification systems (AIS) and effective information systems to maximize space efficiency.

What is customizing in warehouse layouts?

Customizing involves performing value-added activities at the warehouse, such as assembly of components, loading software, repairs, and customized labeling/packaging.

Describe the fixed-position layout and its challenges.

In fixed-position layout, the product remains stationary while workers and equipment come to the site. Challenges include limited space, different materials at various stages, and dynamic volume requirements.

What is an alternative strategy in fixed-position layouts?

An alternative strategy involves completing as much of the project as possible off-site in a product-oriented facility.

What is the main goal of process-oriented layouts?

To minimize the costs of material handling by arranging work centers based on the flow of materials or people, suitable for low-volume, high-variety production.

What are work-cell layouts?

Work-cell layouts reorganize people and machines into groups to focus on producing a single product or a group of related products.

What are the advantages of work-cell layouts?

Reduced work-in-process inventory

Less floor space required

Reduced raw material and finished goods inventory

Increased equipment utilization

Enhanced employee participation

What is the main goal of process-oriented layouts?

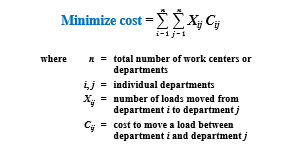

To minimize the costs of material handling by arranging work centers based on the flow of materials or people, suitable for low-volume, high-variety production.

Process Orientated Layout Minimize cost calculation

Fabrication line

Builds components on a series of machines

Assembly line

Puts fabricated parts together at a series of workstations

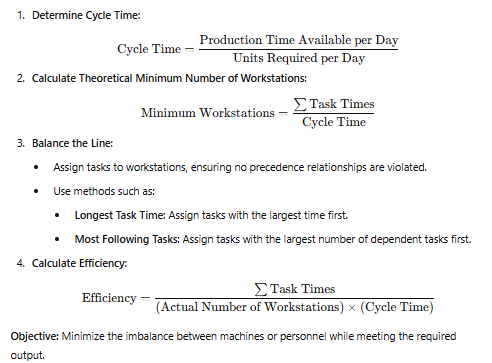

What is assembly-line balancing?

It aims to minimize the imbalance between machines or personnel while meeting required output by determining cycle times, calculating the minimum number of workstations, and assigning tasks efficiently.

How to calculate assembly-line balancing minimum workstation?