Reservoir Fundamentals KNW1

1/84

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

85 Terms

porosity

ratio of pore volume to bulk volume

phi = Vp/Vb => 0<phi<1

pore throat factors & responsibilities

determines permeability

their number, size & distribution controls:

resistivity

flow

capillary force

porosity factors

size

shape

distribution (sorting)

arrangement (packing)

permeability

capacity of a porous material for transmitting a fluid controlled by the size of the pore throats & capillaries [mD]

1mD = 10e-15 m2

Darcy law

description of single-phase flow in porous media

q_darcy = phi*velocity = -k//µ (pressure gradient-rho*g)

permeability tests

core flooding in lab

pressure transient test for field

reservoir velocities

volumetric flux: discharge of a volume per time Q=dV/dt [m3/s]

darcy velocity: the velocity of porous medium would be an open volume q=Q/A [m/s]

interstitial velocity: the actual velocity of a fluid element as the fluid moves through the pore space in the porous medium v=q/phi [m/s]

permeability upscaling

changing from the micro to continuum scale via porosity REV

- flow parallel to the layers → arithmetic avg: k_avg = ∑kihi/∑hi

- flow perpendicular to the layers → harmonic avg: k_avg = ∑Li/∑(Li/ki)

wiener bounds

The effective property of a heterogeneous media is bounded between harmonic and arithmetic averages.

fluid pressure

the weight of the fluid column above the reservoir depth

pfl = p0+rho*g*z p0+G*z

density order of a reservoir fluids

water>oil>gas

fluid contact tests

fluid pressure regimes

fluid densities from formation samples

capillary pressure data from core samples

seismic survey

total pressure of reservoir

weight of the formation rock & fluids

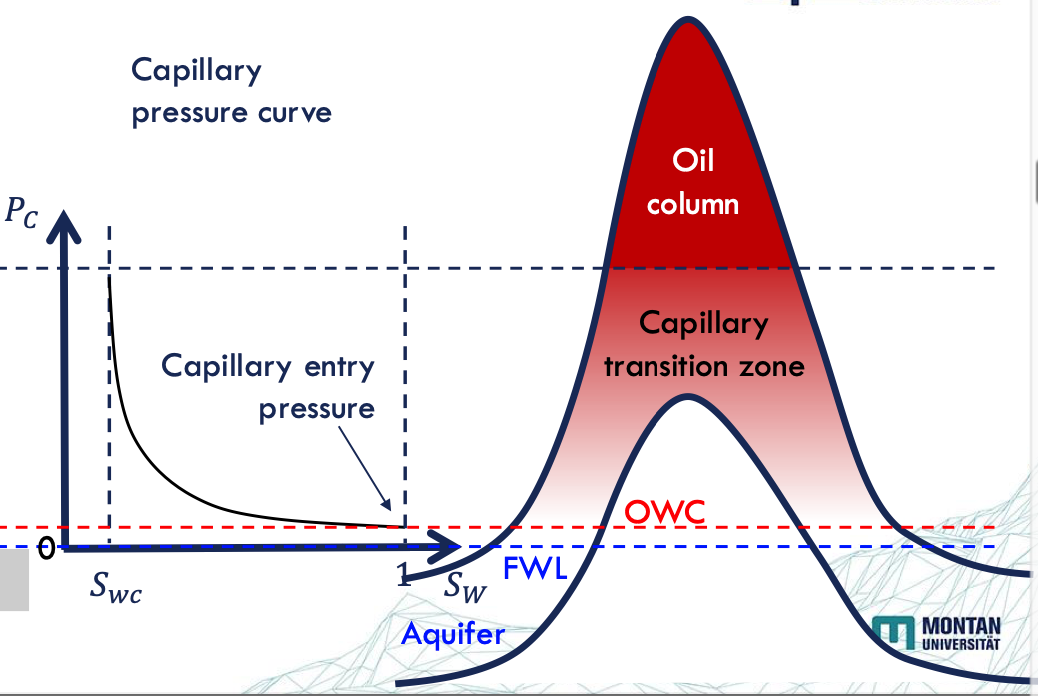

transition zone factors

rock structure

heterogeneity

total pore volume

volume of fluid filled pores

Vp=Vw+Vo+Vg

fluid saturation

the proportion of each fluid within the total pore volume

Si = Vi/Vp => Sw+So+Sg=1

fluid saturation of heterogeneous formation

saturation varies through the layers thus we go with the avg saturation

So,avg = ∑phi*hi*Soi/∑phi*hi

capillary rise

a competition between the capillary force & gravity

p_c = p_g

(2*sigma(F1F2)*cosø)/r = rho*g*h

PVT experiment

recombine crude oil & gas in the right proportions

control pressure by Hg-pump pressure gauge at const. temp →injected Hg acts as piston controlling the volume in the pressure cell

main parameters of reservoir volume

solution gas oil ratio Rs=Vgs/Vos [scf/stb]

oil formation volume factor Bo=Vor/Vos [rb/stb]

gas formation volume factor Bg=Vgr/Vfg [rb/scf]

Vgs=Vsg+Vfg

Vsg = volume of solution gas

Vfg = volume of free gas

Vos = volume of oil surface cond.

Vor = volume of oil res. cond.

fluid types

incompressible → liquids under pressure maintenance conditions c = 0

slightly compressible → liquids under pressure depletion conditions c = const

compressible → gases & supercritical fluids under pressure variation c(p)

compressibility by volume & density

fractional changes in volume due to unit change in pressure [psi-1]:

cv = - 1/V * ∂V/∂p

cp= 1/rho * ∂rho/dp

![<p>fractional changes in volume due to unit change in pressure [psi<sup>-1</sup>]: </p><p>cv = - 1/V * ∂V/∂p</p><p>cp= 1/rho * ∂rho/dp</p>](https://knowt-user-attachments.s3.amazonaws.com/2f453d7f-e1ae-45de-b389-9a4c5b8fabdd.png)

surface (stock tank) pT-condition

p = 14.696 psi

T = 60°F =15,556 °C 16°C

ideal gas EOS

low pressure pV = nRT

high pressure pV = ZnRT

compressibility z factor parameters

gas composition

temp

pressure

sensible heat

changes the temp of a substance w/o changing its state

latent heat

changes the state of a substance w/o changing its temp

water recharge

a doublet system w/ a hot producer and a cold re-injector:

injection into a single-phase liquid water region: increase or maintain pressure

injection of cold water into two-phase (steam-water) reservoir: decrease pressure & temp until condensation

injection of cold water into a superheated steam zone: increase pressure as long as no two phase zone develops

solubility

the ability of a substance to be dissolved in the solvent

increases w/ pressure

decrease w/ increasing temp & salinity

miscibility

the ability of one substance to dissolve in another substance forming a homogenous solution (usually liquid)

critical locus

the max pressure at which two phases can exist

cumulative gas volume formula

F = ∑Vg

expansion factor formula

E = Vg/Vm,g

compressibility z-factor formula

Z = p/psc Tsc/T 1/E = 35.37 p/ET

shrinkage factor formula

cbs = Vo in the separator/Vo at BP

GOR

the ratio of gas to oil produced at stock-tank cond.

GOR = Vg/Vo in the separator

Derivation of Field Relevant Parameters

flash (FE): liberation process in reservoir

differential (DLE): liberation process around well → same as flash experiment starts at bp pressure and after each step, gas is removed from the cell by const pressure Hg-injection

oil formation volume factor

Bo = Vo/cbf [rb/stb]

![<p>Bo = V<sub>o</sub>/c<sub>bf</sub> [rb/stb]</p>](https://knowt-user-attachments.s3.amazonaws.com/3edc7a68-7f8d-4549-bcd6-6480ffc48207.png)

solution gas oil ratio

the solubility of natural gas in crude oil depending on temp, pressure & composition of o&g

Rsi - Rs = 5.615F/cbf [scf/stb]

![<p>the solubility of natural gas in crude oil depending on temp, pressure & composition of o&g</p><p>R<sub>si</sub> - R<sub>s</sub> = 5.615F/c<sub>bf</sub> [scf/stb]</p>](https://knowt-user-attachments.s3.amazonaws.com/8ed0704d-3c97-4aa9-994b-efd03d56d7ff.png)

gas formation volume factor

Bg = 1/ 5.615E [rb/scf]

![<p>Bg = 1/ 5.615E [rb/scf]</p>](https://knowt-user-attachments.s3.amazonaws.com/e9a74ceb-b52b-44cd-a31c-66c1e8a345f8.png)

Apparent molecular weight formula

Ma = ∑yiMi

Volume at standard conditions formula

RTsc/psc

gas density formula

rho = m/V = pMa/ZRT

specific volume formula

v = V/m = ZRT/pMa = 1/gas density

gas expansion factor formula

Eg = 1/Bg

gas formation volume factor

Bg = Vres/Vsc = 0.02827 ZT/p [ft3/scf] = 0.005035 ZT/p [rb/scf] = 351.64 ZT/p [m3/sm3]

gas specific gravity formula

gamma g = rhogas,sc/ rhoair,sc = Ma/Mair = Ma/28.96

critical pT formula

pc = ∑yipci

Tc = ∑yiTci

reduced pT formula

pr = p/pc

Tr = T/Tc

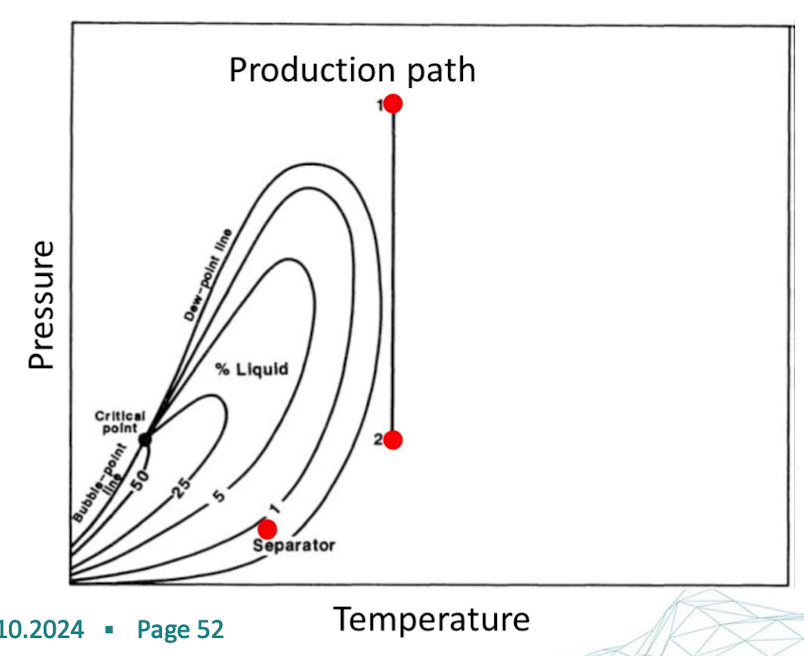

quality lines

determines the percentage of liquid & gas at the given PVT conditions

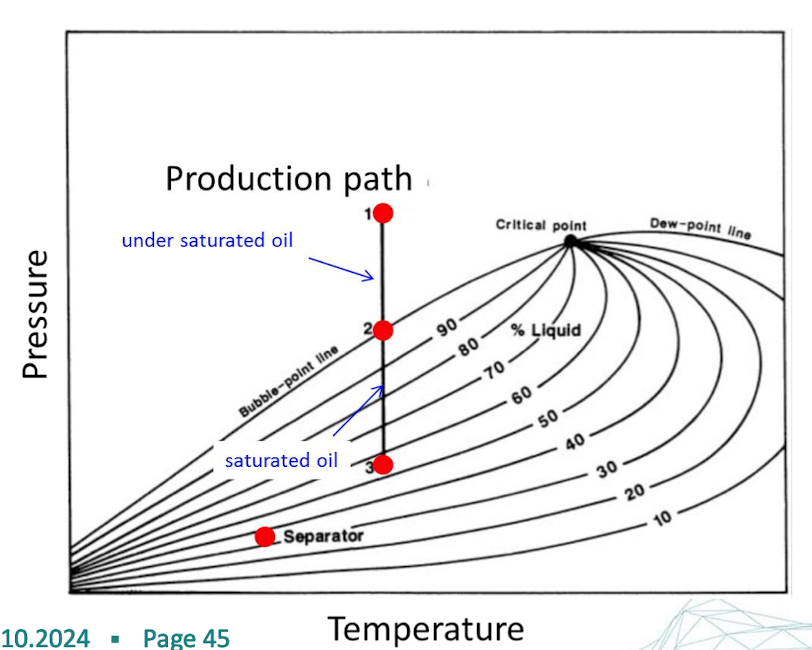

black oil reservoir

includes large, heavy, nonvolatile molecules

covers a wide temp range

aka low shrinkage crude oil or ordinary oil

brown to dark green color

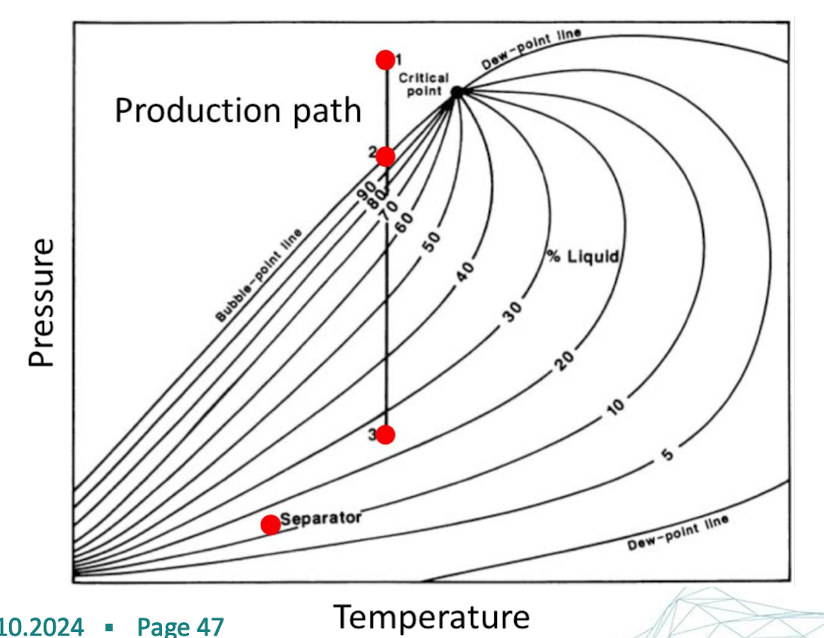

volatile oil reservoir

more intermediate molecules (ethane to hexane)

smaller temp range

Tc closer to the Tres

release large amount of gas in the reservoir

lower amount of oil in the separator

aka high shrinkage crude oil or near critical oil

Tc >Tres

greenish to orange color

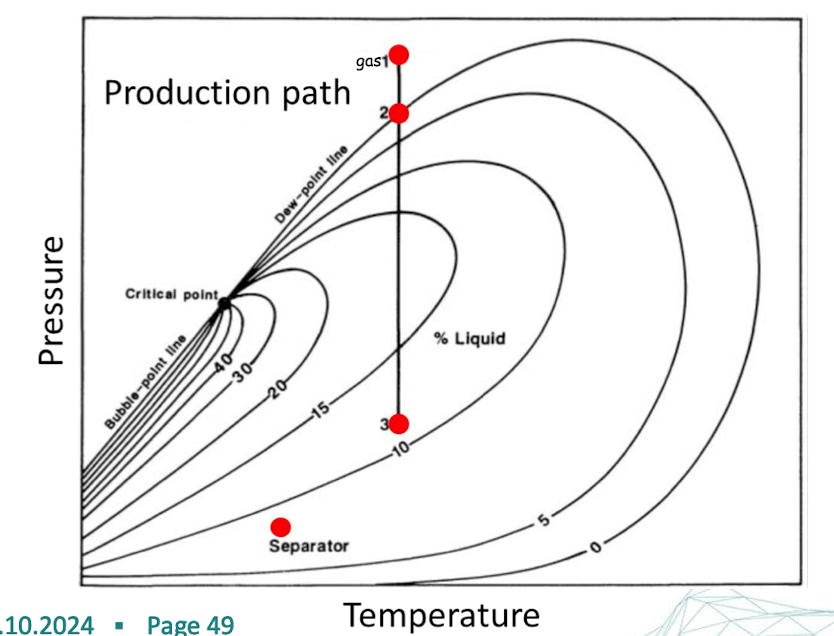

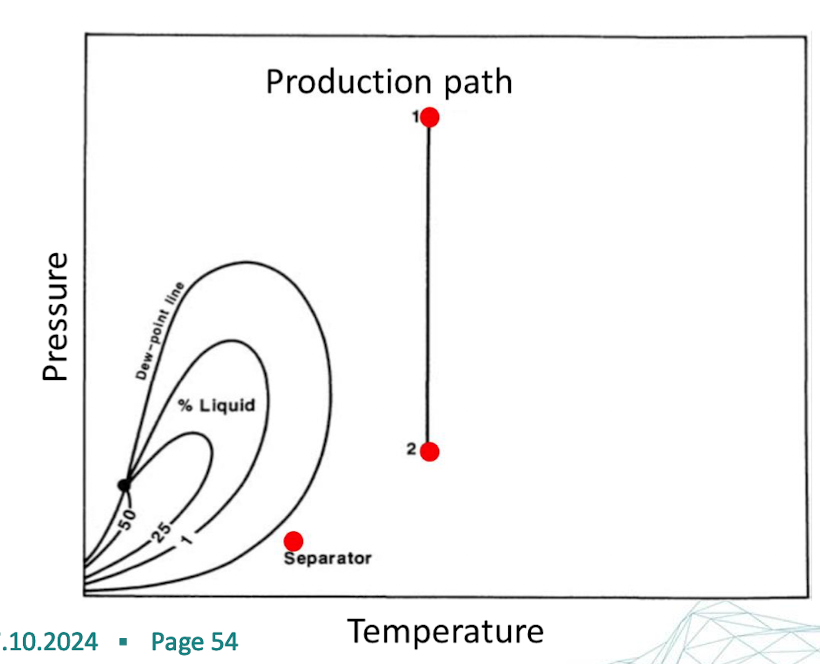

retrograde gas reservoir

Tc<Tres<Tct

fewer heavy HC

smaller temp range

reservoir is initially in gas phase & as the pressure decreases below the dew point, liquid condenses

translucent or slightly coloured

aka gas condensate

wet gas reservoir

The hydrocarbon mixture exists as a gas in the reservoir and two-phase in the surface

Tres>Tc

translucent

smaller HC molecules

entire envelope is below Tres

dry gas reservoir

The hydrocarbon mixture exists as a gas both in the reservoir and in the surface since it doesn’t have enough heavier molecules to form liquid in the separator or field

Tres>Tc

primarily methane w/ some intermediates

separator flash expansion

stimulates the surf separation conditions of reservoir fluid

PVT cell is connected to a separator system

the separator maintains a fixed pT-condition that mimics surface facility conditions

the bp oil is then flashed through the separator system to stock tank conditions

FCM process

injecting a primarily slug that is miscible w/ the crude oil

material balance

Keep track of mass and be able to convert form reservoir to surface conditions to predict recovery & determine the principle res drive mechanism

oil volume

Vo = V*NG*phi*Soi

total oil volume at sc

N = V*NG*phi*Soi/Boi

connate water

water naturally trapped in rock pores due to capillary force → lowest in-situ water saturation

water expansion formula

cw = -1/Swc ∂Swc/∂p due to pressure & effective pore pressure decrease

pot aquifer model

assumes the gas field is in contact with an aquifer, which responds instantly to any decline in reservoir pressure (maintaining pressure) used for

rel. slow production

small aquifers

well connected & high permeable aquifers

reservoir tank model

describes the effective volumetric properties

Oil production formula

N - Np = V*NG*phi*So/Bo

Rf = Np/N = 1 - (Boi*So)/(Bo*Soi)

gas production formula

G - Gp = V*NG*phi*Sgi/Bg

Rf = Gp/G = 1 - (Bgi/Bg) = 1- (pZi/piZ)

Water drive gas res formula

G - Gp = (V*NG*phi*Sgi/Bg)-(We/Bg)

Gp = G(1-(Bgi/Bg)) + We/Bg

Rf = Gp/G = (1 - (Bgi/Bg))+ Bgi(1-Swc-Sgr)/Bg(1-Swc) = 1 - (Bgi*Sgr)/Bg(1-Swc)

Water influx formula

We = Wc∆p = W(Cø+Cw)∆p = Vinv*phi(1-Swc-Sgr)

material balance formula

F = N(E0 + mEg + (1+m)Er) + We = N(Bo-Boi+Bg(Rsi-Rs)) + mNBoi((Bg/Bgi)-1) + (1+m)NBoi(cø+SwcCw/1-Swc)∆p + Wc∆P

m = Vgc/Voc

main drive mechanism

gas cap drive

water drive

solution gas drive

combined drive = gas cap + water

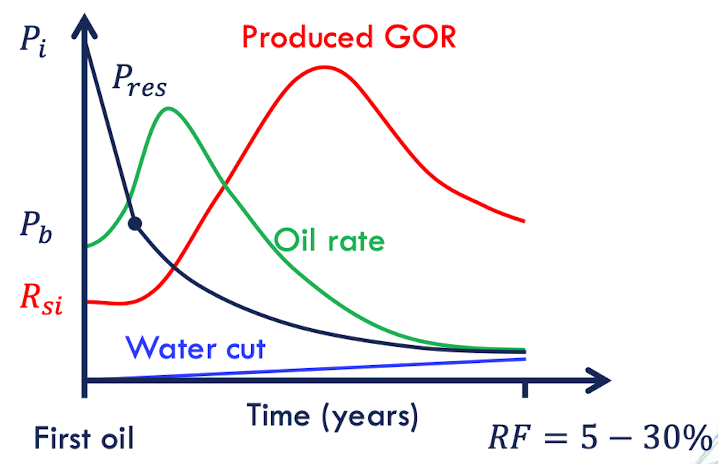

Solution gas drive MBE conditions

energy source: evolved solution gas expansion

RF = 5-30%

m = 0

Cg »Cw => Cw & Cø =0

W = 0

F = NE0

Np(Bo+Bg(Rp-Rs)) = N(Bo-Boi+Bg(Rsi-Rs))

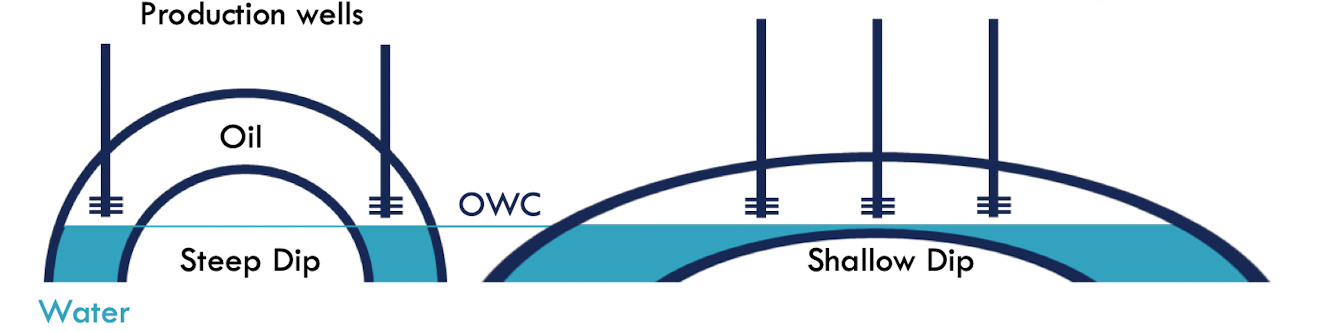

gas solution drive well placement

artificial lift at early stages

steep dip: wells in down dip but not too close to WOC to form a secondary gas cap

shallow dip: well as low as possible to keep was from secondary gas cap

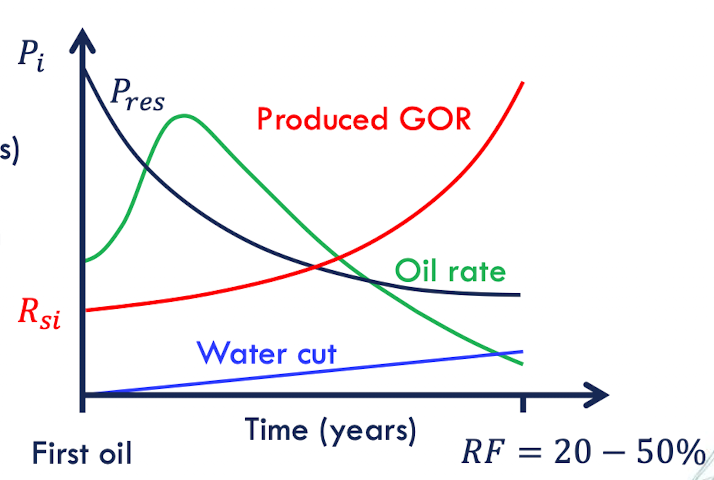

Gas cap drive MBE conditions

Energy source: gas cap & evolved solution gas expansion

RF = 20-50%

Cg »Cw => Cw & Cø =0

W = 0

F= N(E0+mEg)

Np(Bo+Bg(Rp-Rs)) = N(Bo-Boi+Bg(Rsi-Rs))+mNBoi(Bg/Bgi -1)

gas cap well placement

higher recover w/ gas driving oil downwards => to avoids the problem of extensive gas production:

Well completions near the bottom of the oil column

horizontal wells low in the oil column

wells should be placed far away from gas cap w/ long life time

types of aquifer

confined/ excxpansion: The aquifer is bounded by impermeable rock so that the reservoir and aquifer together form a volumetrically closed unit. parameters:

compressibility of aquifer water & matrix

relative size of aquifer to HC accumulation

unconfined/ artesian: The reservoir rock outcropped at one or more places where it may be refilled by surface water.

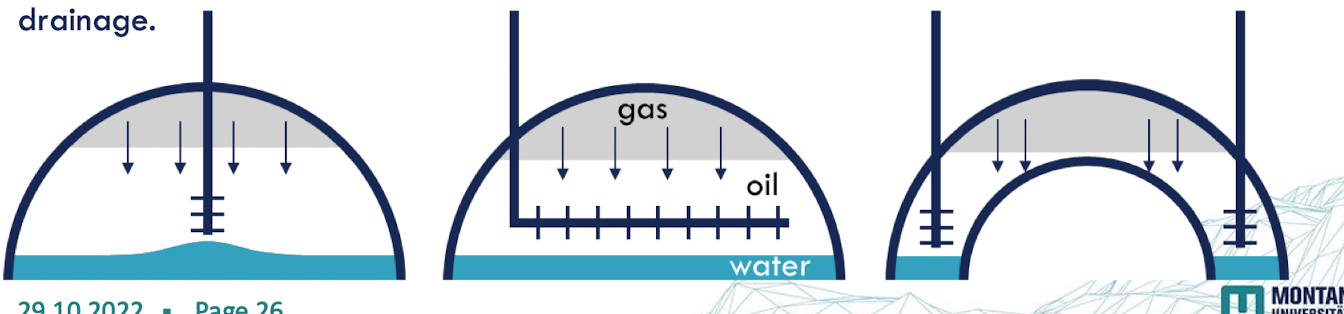

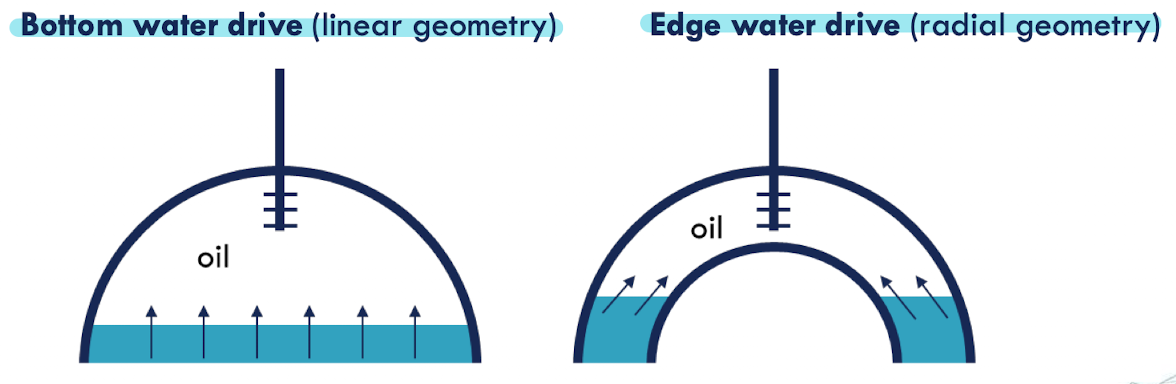

water drive type

bottom water drive → linear geometry

edge water drive→ radial geometry

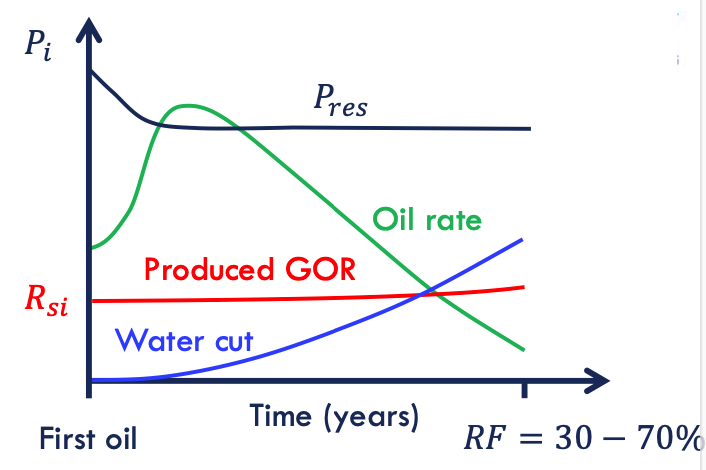

water drive MBE conditions

Energy source: aquifer expansion

RF = 30-70%

Cg »Cw => Cw & Cø =0

m = 0

SwcCw=0

F= NE0 + Wc∆p

Np(Bo+Bg(Rp-Rs)) = N(Bo-Boi+Bg(Rsi-Rs))+Wc∆p

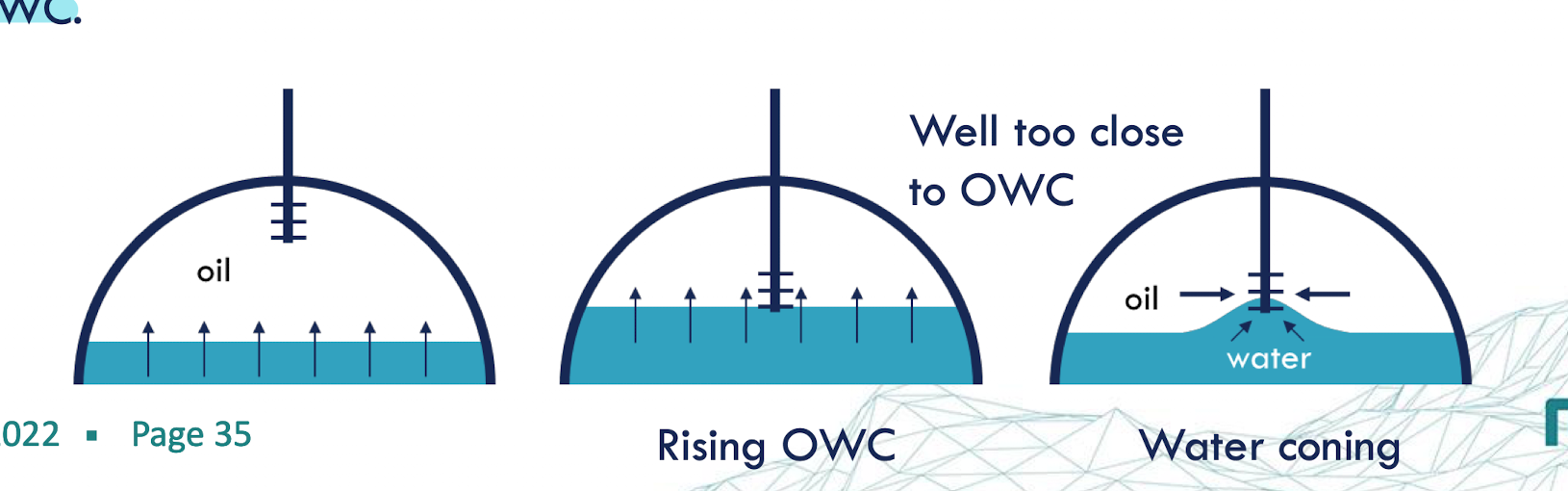

water drive well placement

there is an early water breakthrough due to water coning & viscous fingering => well should be perforated high in the oil zone to maximise distance to WOC

combined drive

m = 0

Rp-Rs = 0

W = 0

Rs = 0

SwcCw =0

F =N(E0+Er)

NpBo = N(Bo-Boi)+NBoi(Cø/1-Swc)∆p

Z-factor

describes the deviation of a gas from ideal gas law

Z = Vactual/Videal

solution drive

oil reservoirs that don’t initially contain free gas but develop free gas on pressure depletion. applies when the pressure drops below the BP

water cut

the ratio of water produced compared to the volume of total liquids produced from an oil well

natural drive mechanism

pressure différence between the reservoir & the surf

secondary gas cap

formed by migration of librated gas to the top by buoyancy → weak drive mechanism

depends on:

permeability

permeability aniostrophy

dipping angle

gravity drainage

a type of reservoir drive mechanism caused by the difference in densities of oil & gas & gas segregation → weak and slow mechanism

depends on steepness of the reservoir