Lecture 13_Six Sigma (DMAIC Define)

1/7

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

8 Terms

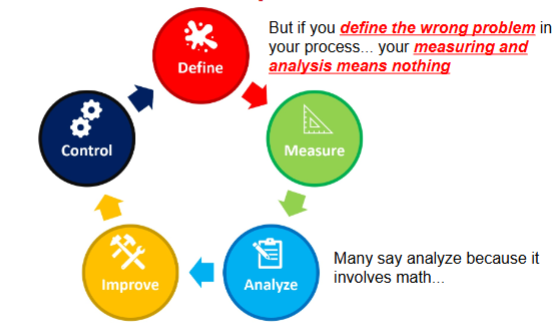

Which is the most difficult step in DMAIC?

Defining the problem – Pareto Rule

• Defining does mean just calling out the problem

Wrong definition: People prefer Pepsi over Classic Coke..

Correct definition: People prefer Pepsi over Classic Coke

because of the sweeter taste.

You need to identify the root cause to define

the problem fully.

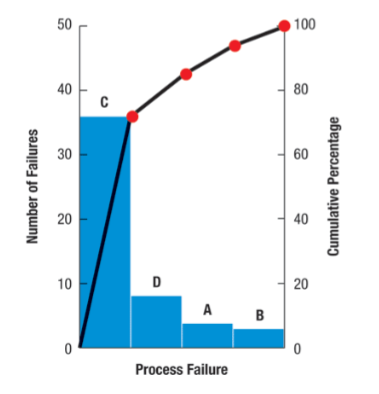

Pareto Rule: 80% of the problem comes from

one similar root cause (20% of all causes).

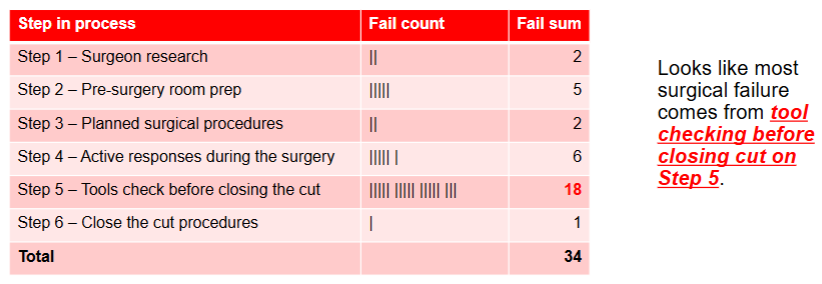

Tools to get to Root Cause – Checksheet

• Core problem: Surgical failure

• Make a checksheet:

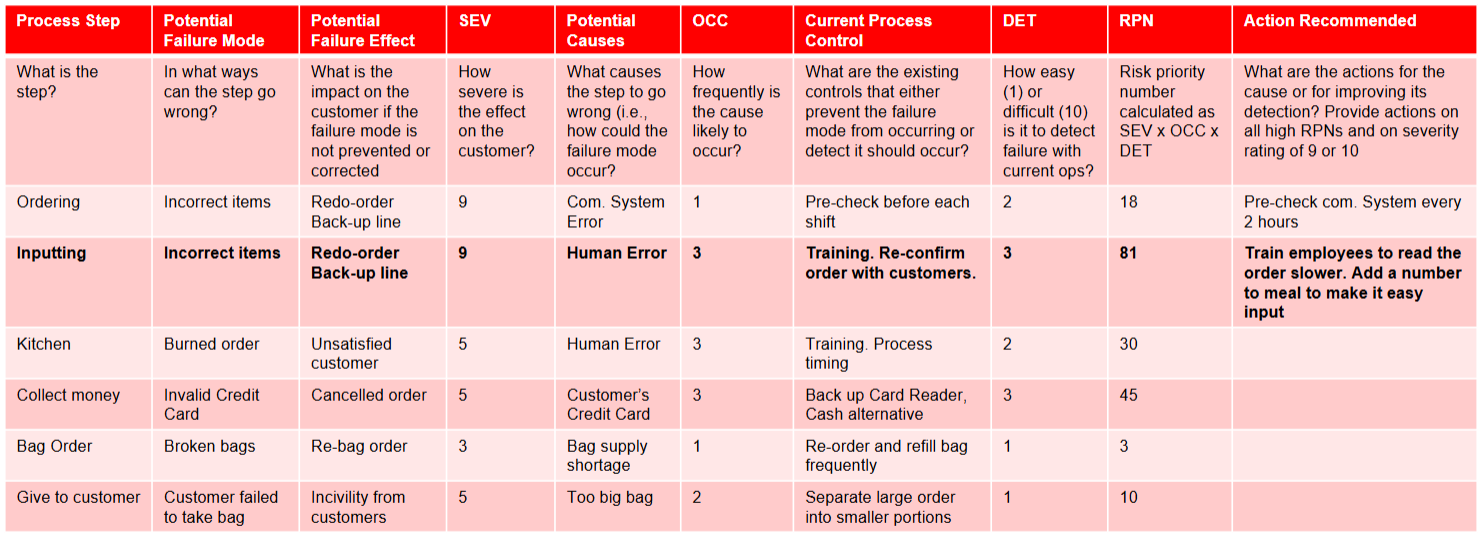

Tools to get to Root Cause – FMEA

Failure Mode and Effects Analysis/ Problem: Long line at Drive-through

Tools to get to Root Cause – Fishbone Diagram

And more complex approaches to Root Cause

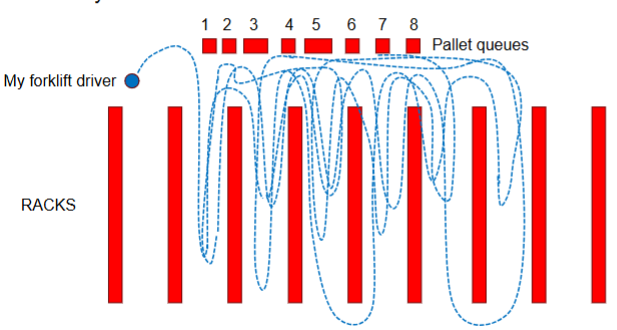

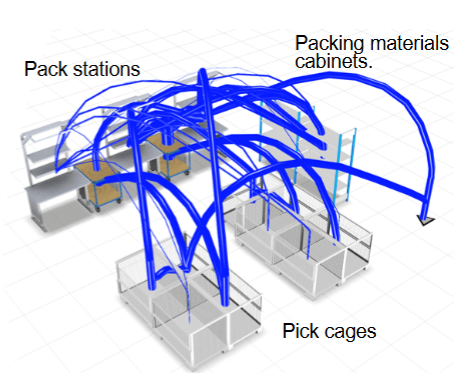

Tools to get to

Root Cause –

Spaghetti Map

• Every movement counts

• You can draw every detail

movement to identify

unnecessary movement and

identify the root cause of the

problem.

If the packer has to come to the materials cabinet too many times, it may slow

down the packing processes

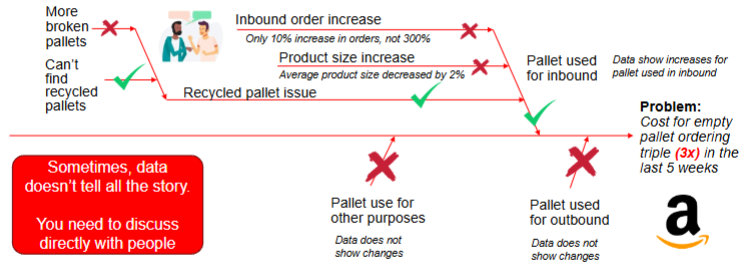

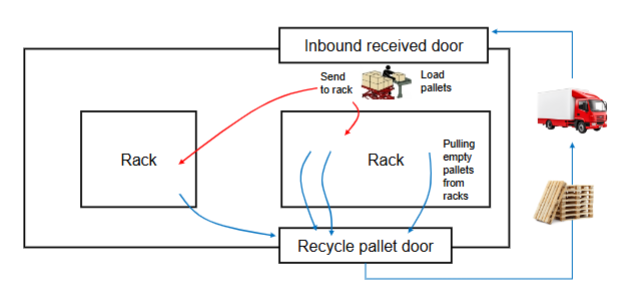

Tools to get to Root

Cause – Spaghetti Map

Pallet stow time takes too long...

Descriptions of the process:

• Product inbounded →

Palletized

• Shipped to stow queue (put

away)

• Stower put away the pallet in

the closest empty space they

see.

If you look at these

racks, it is difficult and

unsafe to drive a

forklift and look for

empty space at the

same time

So... Amazon HQ

came up with DPS

(Directed Pallet Stow)

The stower can scan

the pallet, and the

scanner assigns them

to an empty bin...

IT DIDN’T WORK...

Tools to get to Root Cause – Spaghetti Map

Why didn’t DPS Hi-tech solution work?

Notes:

• M-shaped pattern looking

for empty bins

• Pallets 3 and 5 were

skipped because they are

overhanged pallets –

Floor level only.

Discuss with stowers:

• Pallet heights can’t fit

middle-level spaces

• Level-2 spaces need to

be heavier pallets for rack

stability (You don’t want

the rack to fall on people)