ADDITIONAL: SPRINGS

1/14

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

15 Terms

Springs

IS DEFINED AS AN ELASTIC BODY, WHOSE FUNCTION IS TO DISTORT WHEN LOADED AND TO RECOVER ITS ORIGINAL SHAPE WHEN THE LOAD IS REMOVED.

USES OF SPRINGS

cushion/absorb/control energy

apply forces

control motion by maintaining contact

measure forces

store energy

Helical Springs

Wire coiled in the form of a helix and is intended for compressive or tensile loads. Corss-section of the wirte may be circular, square or rectangular

Closely Coiled

Spring is coiled so close that the plane containing each turn is nearly at right angles to the axis of the helix and the wire is subjected to torsion. Helix angle is usually less than 10 degrees.

Open Coiled

there is a gap between the two consecutive turns, as a result of which the helix angle is large

Inactive Coils

part of the coil which is in contact with the seat and does not contribute to spring action.

Active Turns

turns which impart spring action

Conical / Volute Springs

Special applications where a telecopsing (spring with a spring rate that increases with the load is desired)

Helical and Sprial Type

Two Types of Torsional Springs

Helical Type

used only in applications where the load tends to wing up the spring and are used in various electrical mechanisms.

Spiral Type

is used where the load tends to increase the number of coils and when made of flat strip are used in watches and clocks.

Laminted / Leaf Springs

consist of a number of flat plates of varying lengths held together by means of clamps and bolts

Dics / Belleville Springs

Consist of a number of conical discs held together against slipping by a central bolt or tube. These springs are used in applications where high spring rates and compact spring units are required.

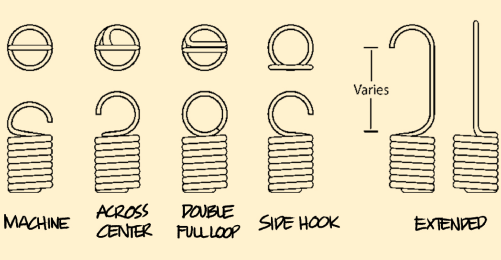

End Connection of Tension Springs

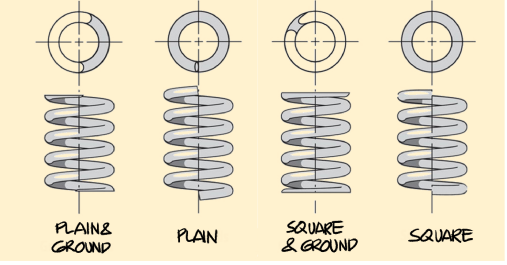

End Connection of Compression Springs