Ch3 product design and process selection

1/30

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

31 Terms

product design

compaies decide on the unique characteristics and fetaures of their product

process selection

companies develop the process necessary to produce the designed product

what do product design and process selection affect

the product quality, cost, manufacturability and customer satisfaction

1) idea development

customers, competitors, suppliers

market research

benchmarking

reverse engineering

early supplier involvement

R&D

2) product screening

operation : study the impact on the resources needed

marketing : study the sales potential of the firm

finance : study the requirements and their return

break-even analysis

compute the amount of goods a company would need to sell to cover its fixed and variable costs

3) preliminary design and testing

technical specifications are developed

prototypes are built

prototypes are revised based on test results

4) final design

final specifications are translated into manufacturing instructions

design for manufcature (DFM)

guidelines to follow in order to produce a product easely and profitably

minimize parts

design parts for different products

use modular design

avoir tools

simplify operations

on what is design for manufacture based

→ simplification : limited number of parts and features

→ standardization : common and interchangeable parts

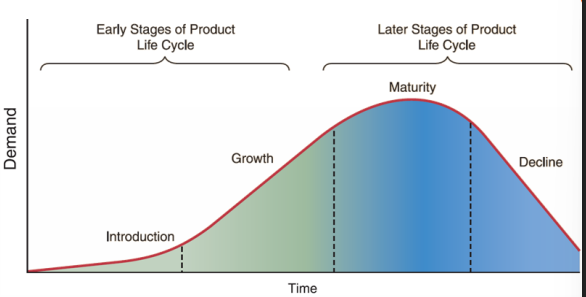

product life cycle

stages that products pass through in their lifetime, characterized by changing product demands over time

→ the expected lenght of the life cycle determines the profitability relative to initial invesments

concurrent engineering

simultaneously design of products and process in multifunctions teams, instead of traditional over the wall approach

more efficient

cheaper

faster

team aproach

remanufacturing

using components of old products in the production of new ones

envionmental benefits

costs benefits

types of processes :

intermittent operations

repetitive operations

types of processes : intermittent operations

→ variety of products in lower volumes

products have different processing requirements

products do not follow a stanard route through the facility

labor intensive (skilled workers)

volume directly tied to number of orders

project process and batch process

types of processes : repetitive operations

→ one or a few products in high volumes

products are standardized

resources are organized in a line flow

capital intensive (faclities, automation technology)

volume based on forecasts of demand

line porcesses

continuous processes

what does a process flowchart do

shows the sequence of steps from inputs to outputs

process flow chart analysis

how to imrpove the design of the process

examples of design consideration

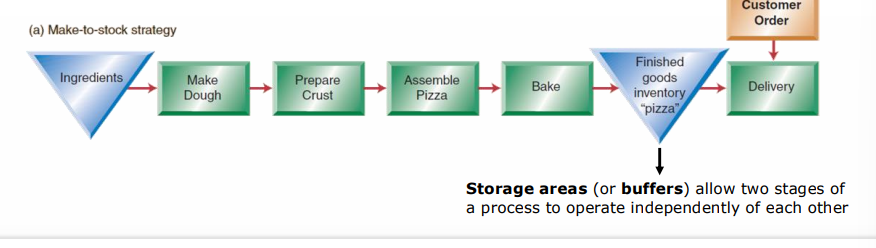

make to stock strategy

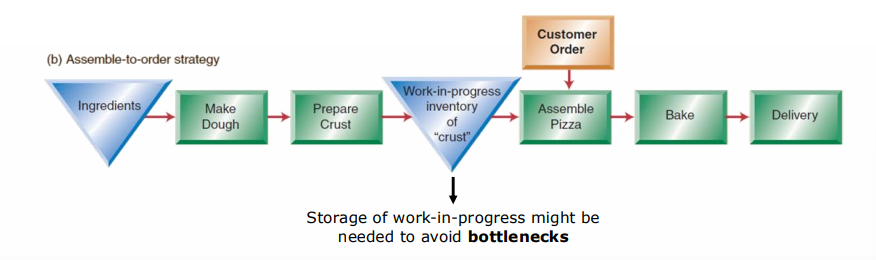

assemble to order startegy

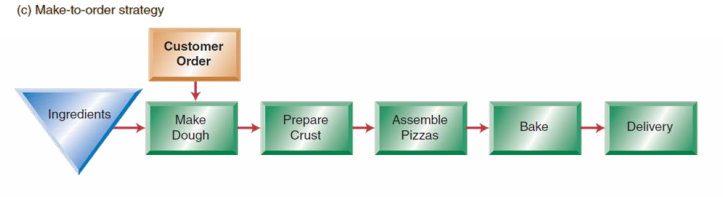

make to order strategy

make to stock strategy

standardized products for immediate sale

storage areas (or bufffers) allow two stages of process to operate independently of each other

assemble to order strategy

standard components which are combined to customer specifications

storage of work-in-progress might be needed to avoid bottelnecks

make to order strategy

products to custiomer specifications, produced after the order is received

process performance metrics : throughput time

average amount of time product takes to move through the system

process performance metrics : process velocity

= throughput time / value-added

a measure of wasted time in the system

process performance metrics : productivity

output / input

a measure of how well a company uses its resources

process performance metrics : utilization

= time a resource used / time a resource available

the proportion of time a resource is actually used

process performance metrics : efficiency

= actual output / standard output

measures performance relative to a standard

techology decisions

technological advancements enable the development of new processes and fatser, better and cheaper production

information technology

automation

E-manufcaturing

design

specifies what customers should experience

shoudl meet or exceed customer expectations

→ need for quality management to ensure consistency and reliability

design : service package / bundle

= tangible aspects + sensual benefits + psychological benefits

three approaches to differ service design

replacing people by technology :

reduces the uncertaintu of the service

cuts costs

gettting the customer involved

allows faster and cheaper service

control by the customer increases satisfaction

providing high customer attention

personal relationship with customers at higher cost