Reservoir KNW2

1/35

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

36 Terms

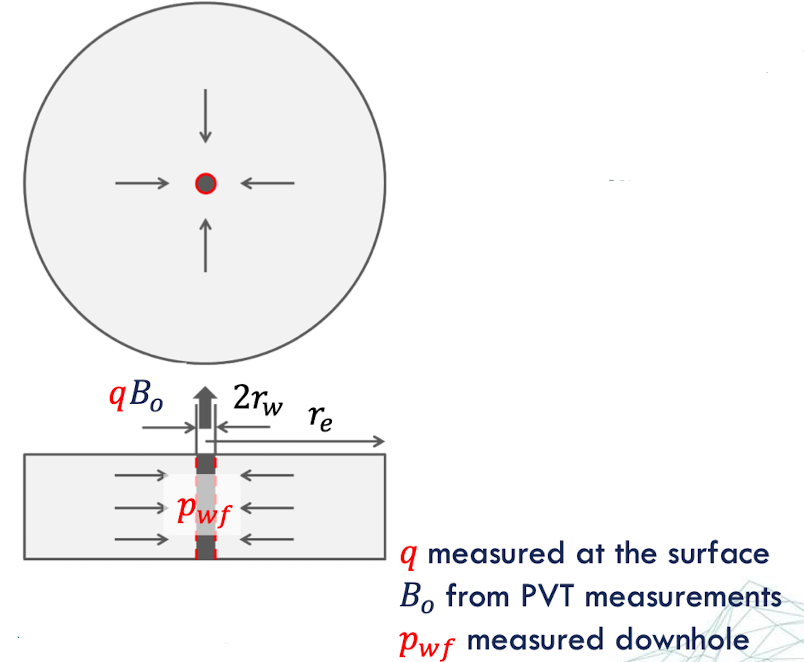

Production well assumptions

the reservoir is considered homogeneous in all rock properties & isotropic w/ respect to permeability

the well is completed & perforated across the entire formation thickness (quasi 1D)

the formation is saturated with/ a single fluid

partial différentiel equation factors

initial cond.

boundary cond.

const. terminal rate solution scenario

at a point in time at which the res., is at equilibrium pressure pi, the well starts producing w/ constant. rate q at the wellbore w/ radius rw

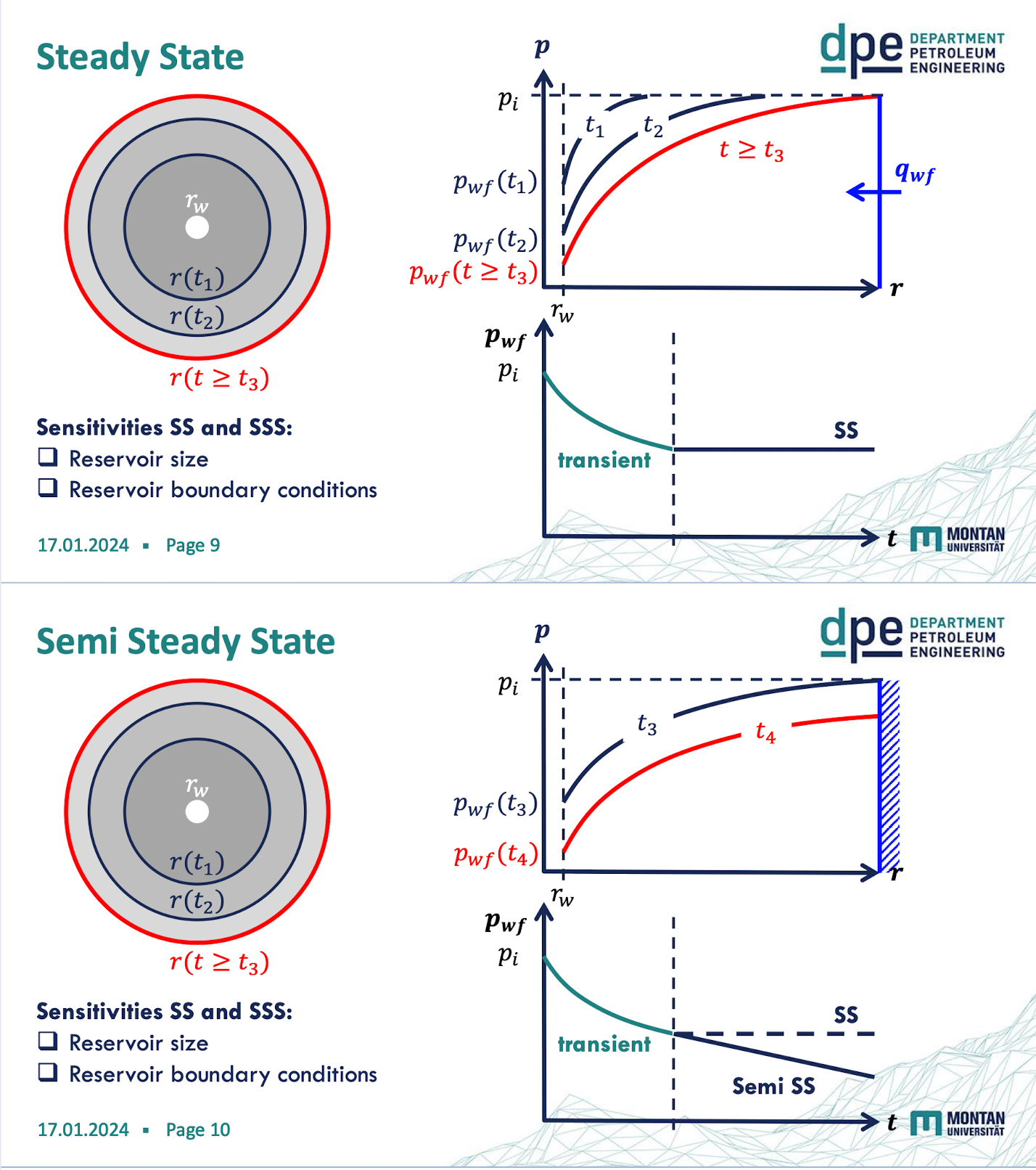

radial flow states

transient: infinitely acting res.

semi-steady state (SSS)

steady state (SS)

=> SSS & SS are stabilised flow cond.

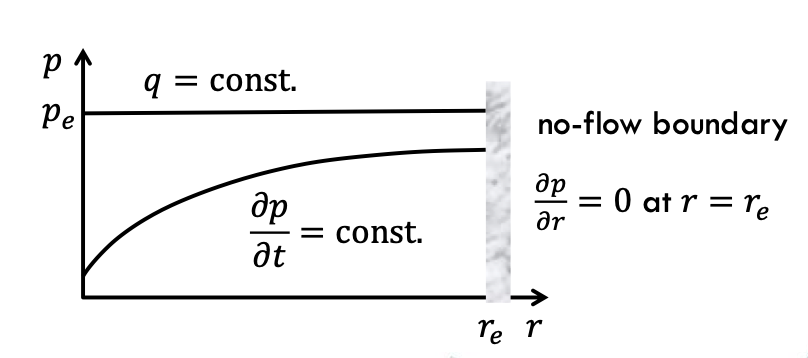

semi steady state

reservoir has closed/ solid boundaries, meaning there is no influx of fluid from the outside → production is changing pres

the pressure decline is proportional to the production rate and invers proportional to the reservoir size

applied to reservoir that is producing for a sufficient period of time such that the boundary effects are fully developed.

q = const.; ∂p/∂t = const; ∂p/∂r = 0 at r=re

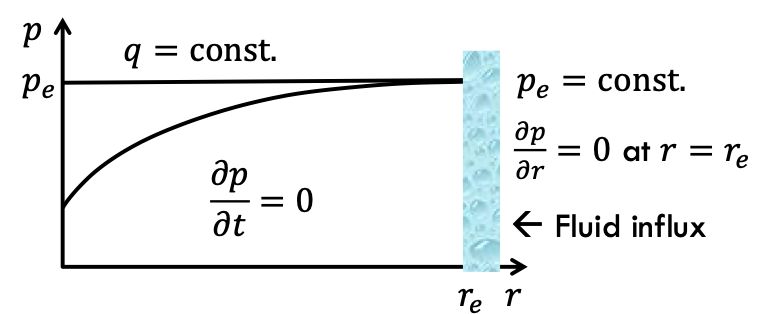

Steady state

influx from boundaries compensates for fluid loss from production

pe = const; q = const; ∂p/∂t = 0; ∂p/∂r = 0 at r = re

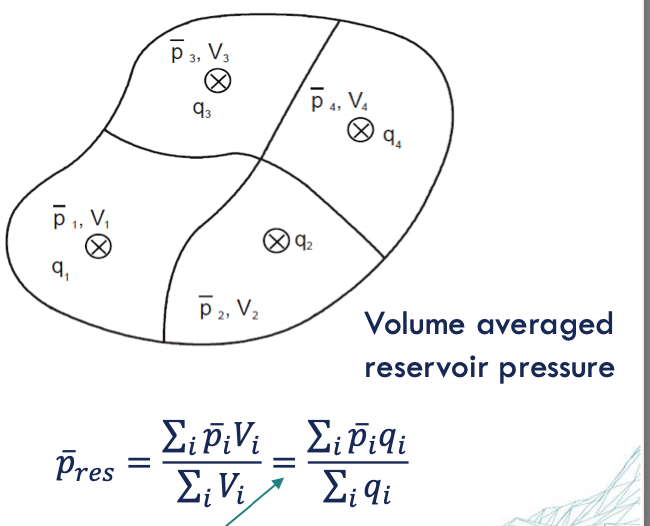

Dietz shape factor

considers the irregularities in the drainage area as each well have its own drainage boundary with the symmetry depending on the injection pattern and the geological settings.

proportional to the well’s production rate under SSS conditions

NOT the TRUE shape

cant obtain the orientation

superposition theorem

individual const. rate wells can be placed in any position at any time and each well will drain from within its own no flow boundary quite independently

pres = ∑piVi/∑Vi = ∑piqi/∑qi

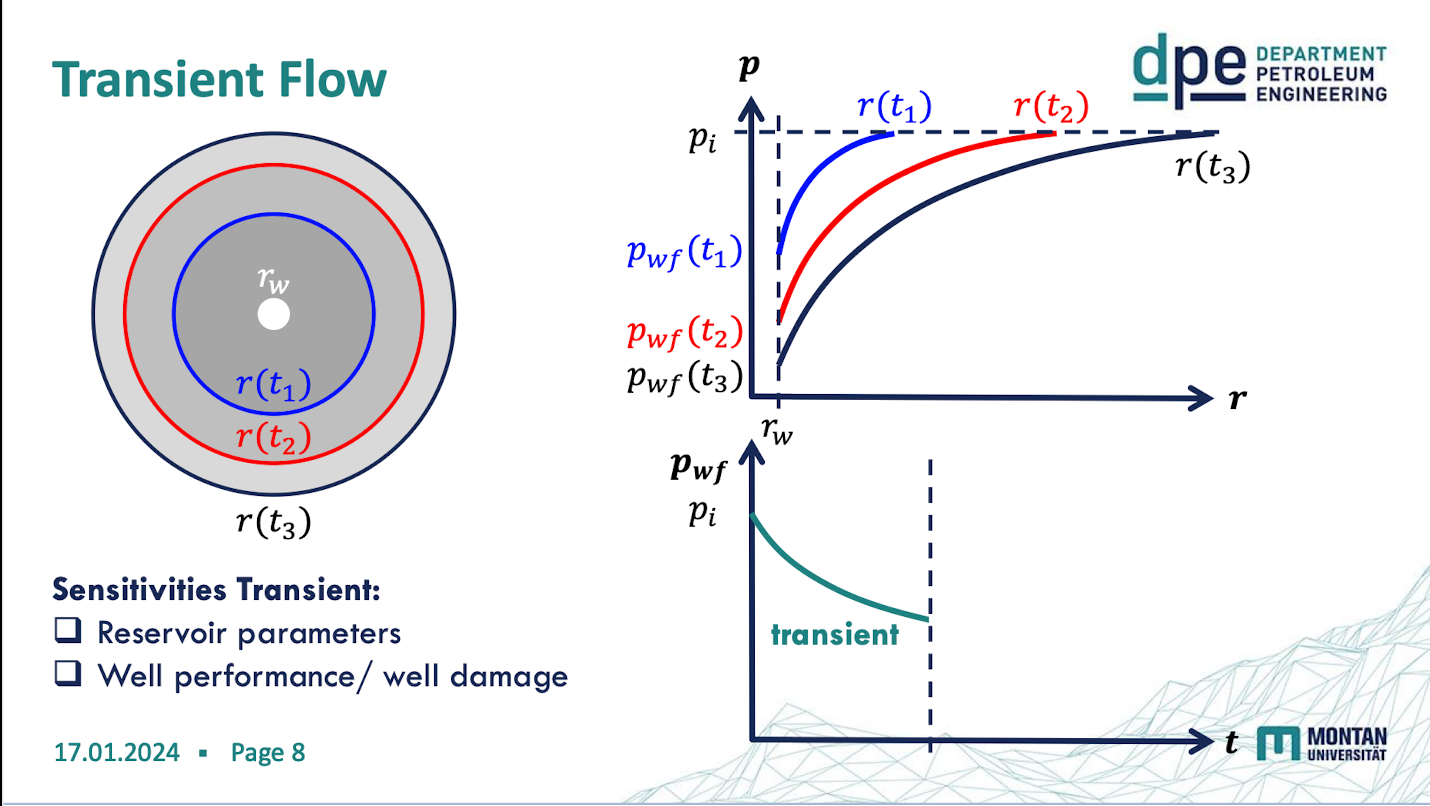

transient flow

the pressure disturbance travels into the field right after starting production & is not affected by the boundaries of the res.

p = pi at t=0 for all r → pbefore production = pi

p = pi at r=∞ for all t → ensures transient cond.: infinite reservoir

lim r ∂p/r = qµ/2πKh# for t>0 → line-source inner boundary cond.

well testing

the process of measuring the changes of production or injection rate and the downhole pressure under flowing cond. of the testing well, i.e. obtaining input or output signals of the system.

well testing objectives

Provides information about:

permeability

formation damage

productivity index

res. drive mechanism

basic res. geometries & other characteristics

well testing methods

wireline

drill stem (DST)

production test

Pressure Measurement Challenges

Pressure gauge limitations:

Gauge type

Applicable pressure range

Calibration status

Depth measurement errors:

Need for accurate true vertical depth

Corrections affected by uncertain fluid density in the well

Background noise:

Pressure variations from nearby producing wells

Interpretation assumptions

surface rate measurement

accuracy of converting reservoir to surface volumes, effected by conversion factors & exact hydrostatic head

production test process

Case off the hole

Run a production string

Perforate the zone of interest

Produce reservoir fluids at controlled rates for a desired period

Record reservoir pressure as a function of time

Take fluid samples (either downhole or at the surface)

=> basis of field appraisal & development decisions

drill stem test

carried out with a temporary completion using the drill stem as temporary conduit

Run DST tool into the wellbore

Set packer to isolate test zone

Open valve and allow initial flow

Close valve for pressure measurement

Open valve for main production period

Collect fluid samples

Close valve for final pressure readings

Remove tool from wellbore

=> used for low GOR for safety reasons

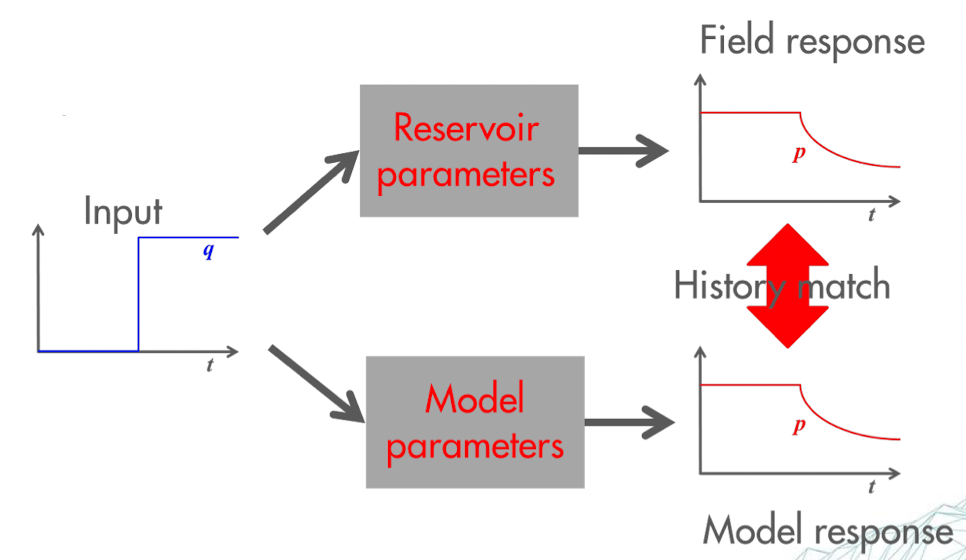

pressure transient analysis

creates a controlled disturbance (perturbation) in the reservoir and analyzing its response.

Perturbation: Create a change in the reservoir (by producing or shutting in the well)

Reservoir Mechanism: The reservoir responds to this change

Response: Measure the pressure changes over time (pressure transient)

Analysis: Interpret the pressure transient data to derive reservoir properties

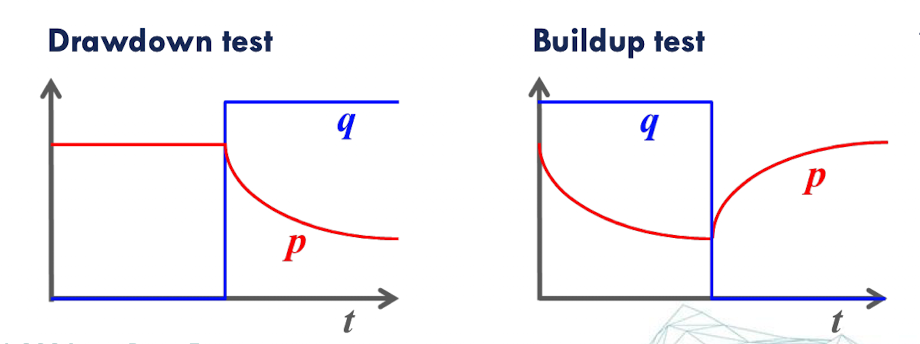

transient analysis test types

drawdown test: log-log plot

Input: Constant flow rate (well is opened to produce)

Output: Decreasing pressure over time

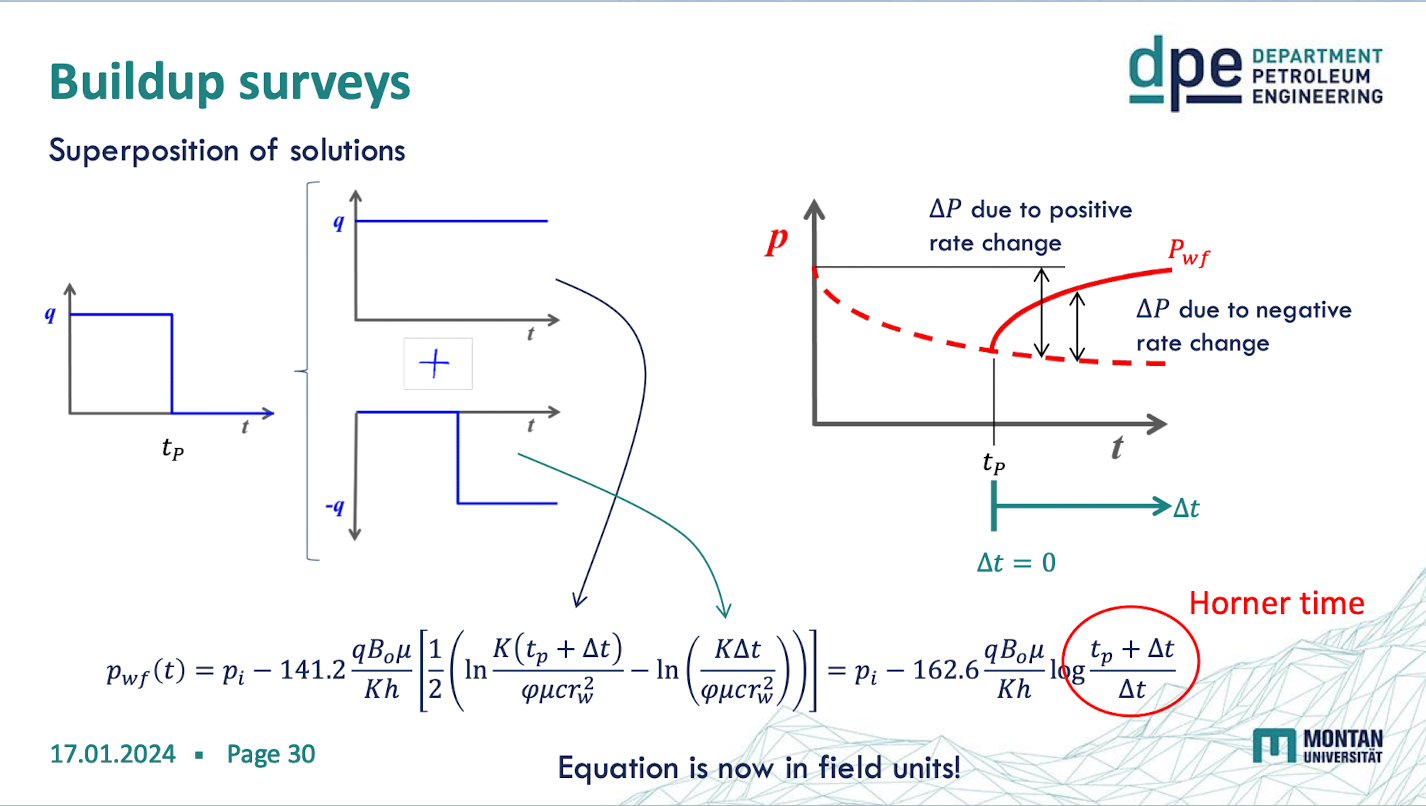

build up test: Horner plot (semi-log)

Input: Well is shut in (flow rate becomes zero)

Output: Increasing pressure over time

transient analysis approaches

comparison to analytical model: compares observed pressure and flow rate data to theoretical models

numerical history matching: uses computer simulations to match observed data

transient analysis output parameters

permeability

skin factor

drainage radius

productivity index

transient flow sensitivties

reservoir parameters

Well performance

well damage

radial flow method

the movement of fluid in a reservoir from the perimeter towards the bottom hole along radial directions in the horizontal plane.

SS & SSS flow sensitivties

reservoir size

reservoir boundary conditions

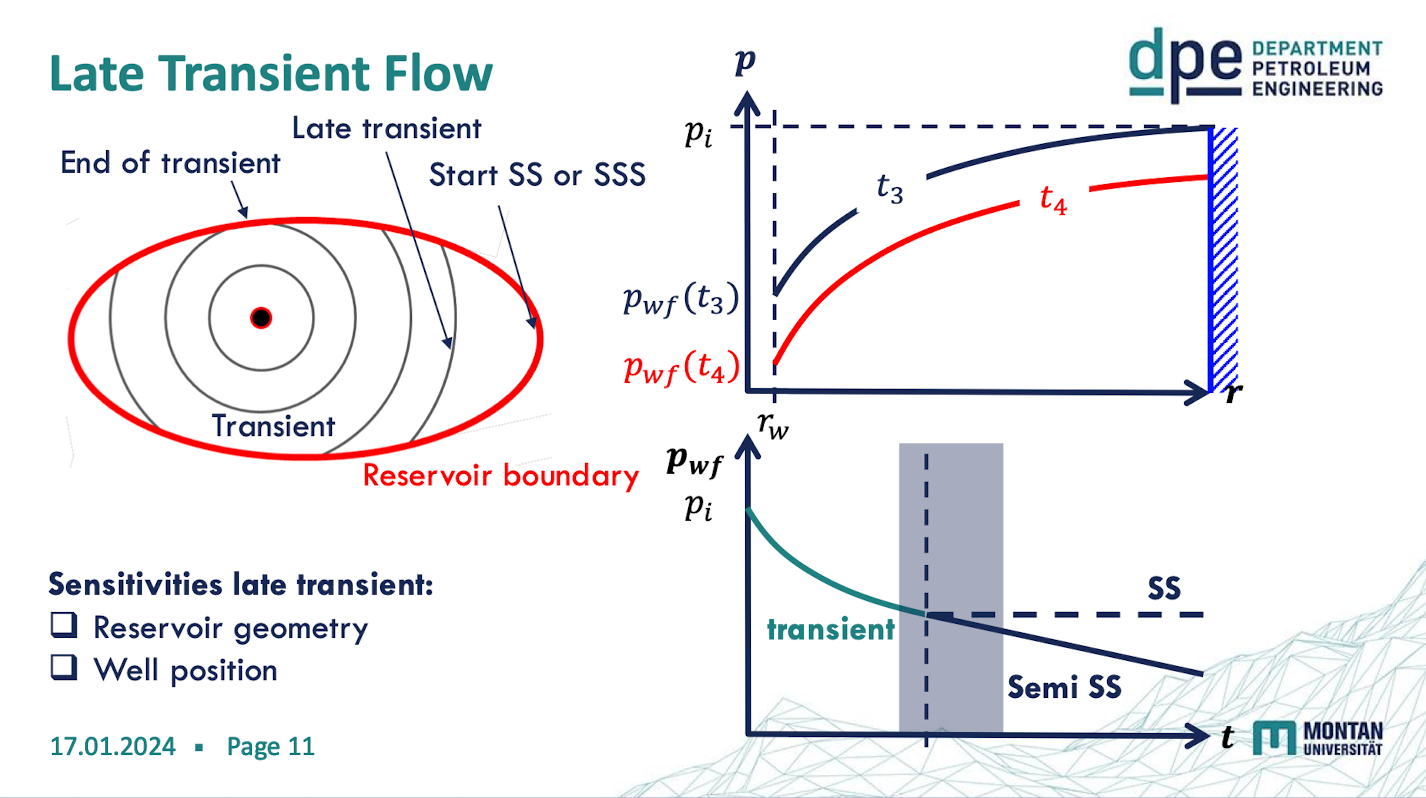

late transient flow sensitivties

reservoir geometry

well position

wellbore storage

the effect of fluid expansion or contraction within the wellbore itself, separate from fluid flow from the reservoir

wellbore storage causes

pressure decrease due to:

expansion of fluids in the well

changing liquid level in the well annulus

wellbore storage mechanism

When production starts or stops, there's a delay before the sandface flow rate matches the surface flow rate

During production, fluid in the wellbore expands as pressure decreases

During shut-in, fluid in the wellbore compresses

skin factor

damage zone around the production & injection wells caused by invasion of mud filtrate or cement during drilling / completion (a.k.a formation damage)

S>0: additional pressure drop → formation damage

S<0: improved wellbore cond. → well simulation

S=0: no changes in the well cond. → formation permeability

drainage radius

gives an estimate about the size if the reservoir

at the drainage radius: p(r,t>0) - pi = 0

max drainage radius: p(re, t) - pi = 0

productivity index

measures of the ability of the well to produce

PI = qtotal /(p-pwf) [stb/d.psi]

buildup survey benefits

less susceptible for noise from fluctuating production rates

cancel skin effects

buildup survey procedure

the well is producing for a certain time (pressure drawdown) and is then shut-in → the pressure builds up again

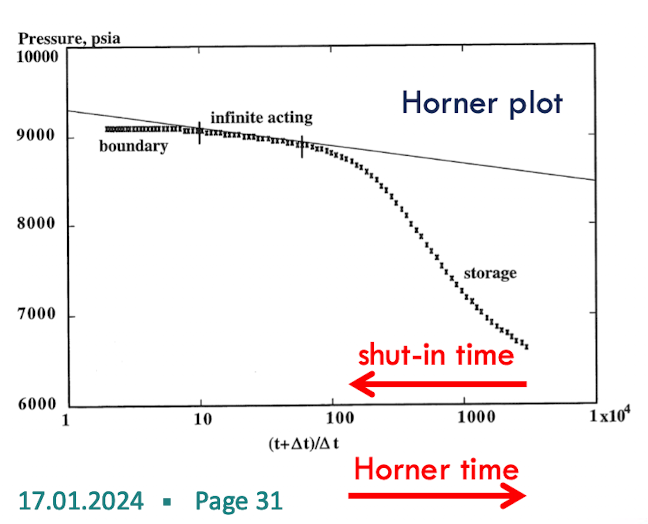

Horner plot

a semi-logarithmic analysis in which its time axis is read from right to left

Right side: Wellbore storage effects

Middle: Transient flow (straight line)

Left side: Boundary effects

Horner plot benefits

Complements drawdown data for verification

Usually provides cleaner data (less noise)

Transient flow appears as a straight line

Permeability calculated from the slope

Sequence of Flow Regimes in horizontal wells

Wellbore Storage and Skin Effects

Occurs immediately after production starts or stops

Early Radial Flow (in the yz plane)

Flow is radial in a vertical plane perpendicular to the wellbore

Linear Flow (in y direction)

Fluid flows linearly towards the wellbore

Late Pseudoradial Flow (in the xy plane)

Occurs when the pressure transient extends beyond the well's ends

elliptical flow

a transitional flow period that occurs between a linear or near-linear flow pattern at early times and a radial or near-radial flow pattern at late times