[02-PRELIMS-ANALYSIS-LAB] BOTTLE AND CLOSURE INSPECTION

1/43

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

44 Terms

Yes

Are bottles a primary packaging?

Physical Evaluation

Visually check the presence of bottle defects.

Critical

Major

Minor

What are the three (3) physical evaluations for defects in primary packaging?

Critical Defects

Physical Evaluation:

Prevents the glass bottle from performing their intended function of safely holding the product causing danger to consumers.

Major Defects

Physical Evaluation:

Make handling of the bottle difficult (ex. durability).

Minor Defects

Physical Evaluation:

Adversely affect the appearance but not the function of the bottle.

Vernier Caliper

Measure the height and diameter of bottles.

Closures

A device that seals a bottle to protect its contents. They can be caps, lids, plugs, or liners.

Biological

Shallow CT

Roll On

Brandy Cork

Pry Off

Pilfer Proof

What are the six (6) types of closures?

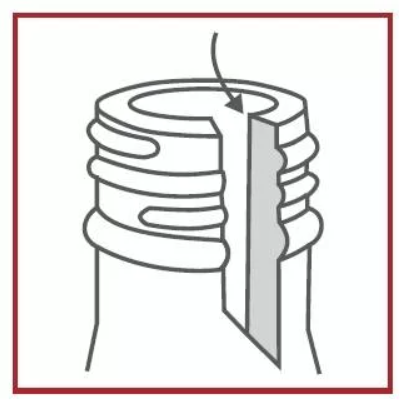

Continuous Thread

The CT in “Shallow CT” stands for?

Biological

Identify what type of closure:

Shallow CT

Identify what type of closure:

Roll On

Identify what type of closure:

Brandy Cork

Identify what type of closure:

Pry Off

Identify what type of closure:

Pilfer Proof

Identify what type of closure:

Finish

Neck

Body

Bottom

What are the four (4) parts of bottle?

Finish

Parts of Bottle:

Top of the container above the neck ring parting line.

Neck

Parts of Bottle:

Part which extends from the parting line to the curve at the base of the ____.

Body

Parts of Bottle:

Main part which holds the product.

Bottom

Parts of Bottle:

Part of the container on which it stands when upright.

Bird-Swings and Spikes

Critical Defect:

Long thin strands of glass inside the bottle would probably break off when bottle is filled.

Overpress

Critical Defect:

Small ridge of glass has been formed on the sealing surface of the finish.

Filament

Critical Defect:

Hair-like string inside the bottle.

Split

Critical Defect:

An open crack staring at the top of the finish (top) and extending downward.

Poor Distribution

Critical Defect:

Uneven thickness of glass.

Soft Blister

Critical Defect:

A thin walled bubble in glass.

Cracks

Critical Defect:

Partial fractures.

Pinhole

Critical Defect:

Any opening causing leakage.

Chipped Finish

Critical Defect:

Pieces broken out of the top edge in the manufacturing process.

Contamination of foreign materials

This occurs when unintended substances are present in the product or its packaging, potentially compromising quality and safety.

Mismatch

Major Defects:

When the bottle and its closure do not fit properly.

Fin

Major Defects:

A thin, raised edge of excess glass on the bottle surface.

Out of round finish

Major Defects:

A pinch, flattened, or oval finish.

Stone

Major Defects:

Small inclusion of nonmelted material.

Rocker Bottom

Major Defects:

Warped bottoms which makes bottle unstable when placed on a flat surface.

Sunken (Dropped Shoulder)

Minor Defects:

Shoulder not fully blown, sagged after blowing.

Tear

Minor Defects:

A small crack or split in the bottle that does not affect its overall integrity.

Washboard

Minor Defects:

A wavy condition of horizontal lines in the bottle.

Heeltap

Minor Defects:

Heavy glass on one side of the bottom.

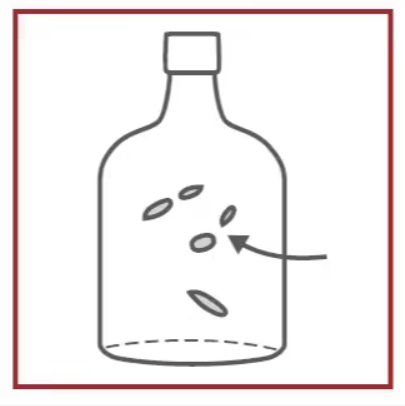

Seeds

Minor Defects:

Small bubbles in the glass.

Critical Defects

Defects that can cause serious harm or product failure and make the item unsafe for use.

Major Defects

Defects that affect product functionality or quality but are not immediately dangerous.

Minor Defects

Defects or small imperfections that do not significantly affect product performance or safety.