Textiles - Final Exam

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

59 Terms

Mercerization

Fabric finish that uses sodium hydroxide for cotton yarns or fabrics to increase the lustre and dyeability.

Gray Goods

Refers to fabric as it comes off the loom, knitting machine, or whatever machine made it, before it is bleached, dyed, or otherwise finished.

Durable Finish

Fabric finish that may last for the life of the product, but its effectiveness diminishes with use or age. (Ex: wrinkle resistance).

Crocking

Color transfers to another fabric from rubbing together.

Renewable Finish

Fabric finish that can be applied by the consumer or reapplied by the dry cleaner.

Permanent Finish

Fabric finish that lasts the life of the item.

Bleeding

Loss of color in water or other solutions; may color other fabrics present.

Overprinting

Fabrics that have first been dyed and then printed.

Converted Goods

Fabrics that have received wet, or finishing treatments, such as bleaching, dyeing, or embossing.

Temporary Finish

Fabric finish that lasts until the item is washed or dry-cleaned the first time.

Migration

Color movement to adjacent areas or fabrics; (red and white striped shirt).

Colorfastness

Refers to resistance to change in any color characteristic or to transferring color to another object.

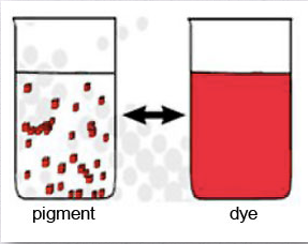

Pigments

Insoluble color particles that are held on the surface of a fabric by a binding agent (glue). Does not have affinity for fiber.

Dyes

An organic compound that is water or other carrier soluble. Has affinity for fibers.

Pigments do not have an affinity for fibers so they are kept on with a binding agent while Dyes do have an affinity for fibers.

What is the difference between pigments and dyes?

Prefiber Dyeing

Fiber Dyeing / Stock Dyeing

Yarn Dyeing

Piece Dyeing

Product Dyeing

What are the five processes of dyeing?

Prefiber Dyeing

Color is added with the dope before it is extruded into a fiber.

Fiber dyeing/Stock dyeing

Color is added to loose staple fibers before yarn spinning.

Yarn dyeing

Color is added after the fibers have been spun into yarns.

Piece dyeing

Color is added to a bolt or roll of fabric.

Product dyeing

Color is added after the fabric is cut and sewn into the finished product.

Resist Printing

Blocks color absorption on different parts of the yarns or fabrics.

Batik

Tie-dye

Ikat

Screen Printing

Stencil Printing

What are the different methods of resist printing?

Textile Fiber Products Identification Act of 1960.

The percentage of fiber content listed in order of predominance by weight (generic fabric names).

Name of the manufacturer or the company’s RN #

Country of origin

What is TFPIA?

Permanent Care Labeling Regulation of 1972

Required accurate, permanently attached and legible label or tag that contains regular care information and instructions

Label must state:

Washing method

Water temperature

Drying method

Drying temperature

Ironing temperature

Procedures to be avoided

If multiple care methods are appropriate for the product, the manufacturer is not required to list them all on the label

Reversible garments are required only to have removable, not permanent, care labels.

If the care-label instructions are followed and some problem develops during care, the manufacturer is liable (Consumer should contact the Federal Trade Commision, FTC).

What is the Care Labeling Act?

The crockmeter is used for colorfastness tests that works by rubbing a square of white, bleached fabric against the fabric being tested, indicating how much dye will transfer due to crocking.

How does the Crockmeter work and what does it tell us about tested fabrics?

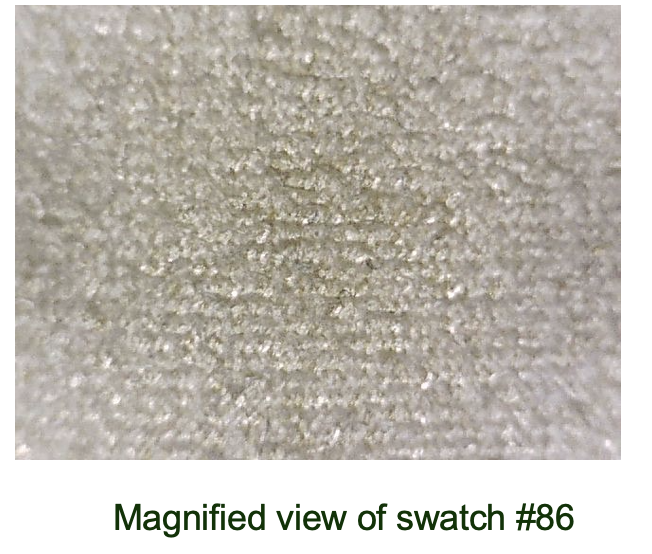

Spun Yarns

Yarns made from short staple fibers; all natural fibers except silk are staple fibers.

Filament Yarns

Yarns made from long filament fibers.

A natural, cellulosic fiber.

Cotton (Type of fiber)

A manufactured, regenerated fiber.

Rayon (Type of fiber)

A natural, protein fiber.

Wool (Type of fiber)

A natural, protein fiber.

Mohair (Type of fiber)

A natural, protein fiber.

Silk (Type of fiber)

A natural, cellulosic fiber.

Flax (Type of fiber)

A manufactured, synthetic fiber.

Acrylic (Type of fiber)

A manufactured, synthetic fiber.

Spandex (Type of fiber)

A manufactured, synthetic fiber.

Polyester (Type of fiber)

Warp (Wovens)

The yarns that run lengthwise (vertically) in woven fabrics.

Weft (Wovens)

The yarns that run crosswise (horizontally) in woven fabrics.

Wale (Wovens)

In a twill weave, each warp or weft yarn floats across two or more weft or warp yarns, forming a distinct diagonal line.

Warp (Knits)

Yarn is fed to the needles from the end, forming loops in the direction of the wales; vertical.

Weft (Knits)

Yarn is fed to the needles from the side, forming loops across a course; horizontal.

Wale (Knits)

A vertical column of stitches in knits.

Course

A horizontal row of stitches in knits.

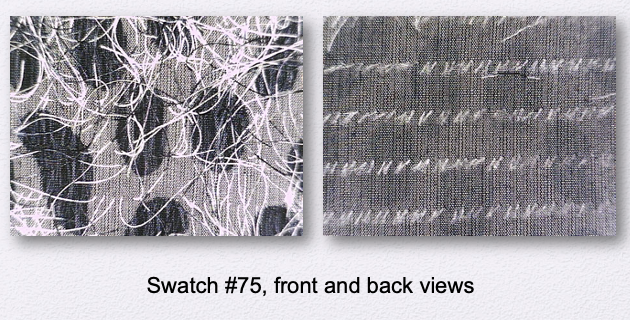

Embroidered

Fabrics decorated by hand or by machine with a surface-applied thread.

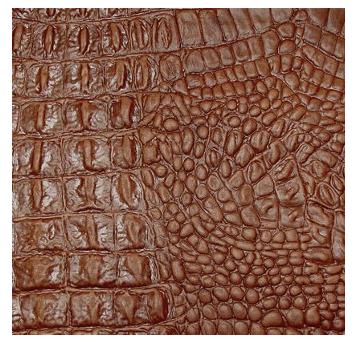

Embossed

Fabrics that produce flat or raised designs by passing through hollow, engraved metal calendar rolls.

Burnout

Fabrics produced by printing a chemical solvent on a blend fabric made of different fiber groups, dissolving one fiber to leave sheer areas.

Plisse

Fabrics converted by printing sodium hydroxide onto cotton lawn or printcloth gray goods, creating a striped appearance.

Sueded

A process for fine silky fabrics where the fabric is moved under rollers with abrasive paper to create a soft texture.

Flocked

A process where a fine natural or synthetic surface fiber is applied onto a base fabric.

Moiré

Fabrics that have a wood grain or watermarked appearance.

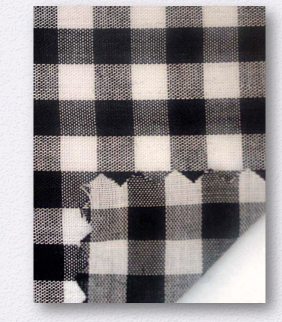

Yarn Dyed

Yarn that can be dyed in skeins, on cones, or wound on warp beams, used for structural designs like plaids and stripes.

Direct/Application Print

Color applied directly to the fabric in the desired pattern and location.

Batik

A hand process where hot wax is applied to fabric to create a design.

Overprinting

Fabrics that have been dyed first and then printed.

Duplex Print

Roller printing with a pattern on both sides of the fabric.

Glazed

Fabric passed through a finishing solution, partially dried, and calendered to polish the surface.

Prepared for Printing

PFP

Turns/Twists per Inch

TPI