6.2.5 Organic synthesis

1/64

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

65 Terms

how to prepare organic compounds

reflux

distillation

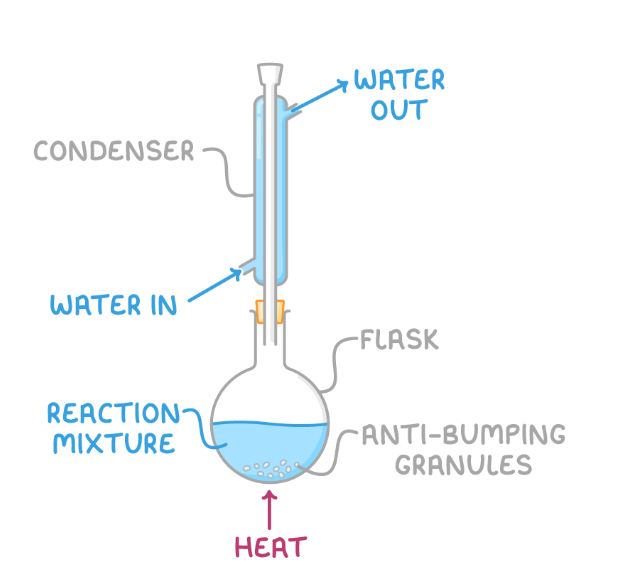

heating under reflux

Involves heating the reaction mixture in a round-bottomed flask equipped with a Liebig condenser.

As the mixture boils, vapours condense in the condenser and return to the flask, preventing the escape of reagents.

problem with reflux

a drawback of reflux is that desired products may undergo further reactions if heated for too long.

reflux apparatus

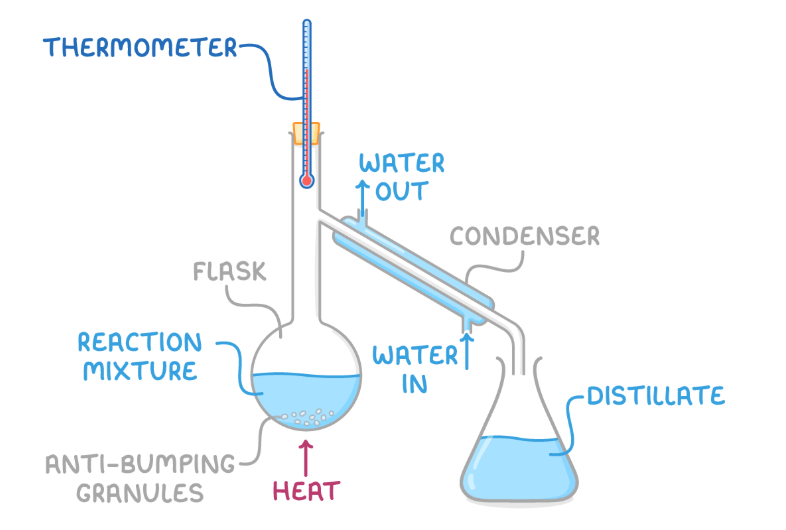

distillation

Involves gently heating the mixture so that components evaporate according to their boiling points.

This is particularly useful if the desired product has the lowest boiling point, allowing it to be selectively evaporated and condensed, thereby avoiding unwanted side reactions.

Distillation is most effective when the product's boiling point is lower than that of the reactants.

distillation apparatues

how to purify an organic solid

filtration under reduced pressure

recrystallisation

measurements of melting point

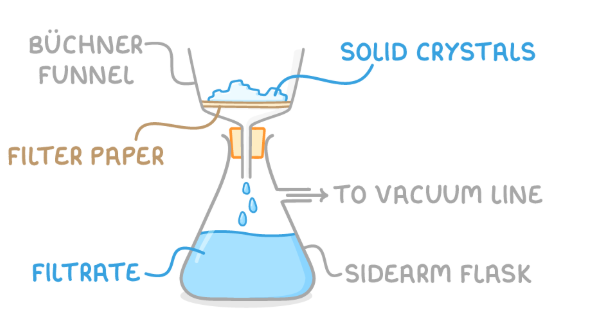

steps for filtering solids under reduced pressure

Transfer the reaction mixture into a Büchner funnel with a piece of filter paper. The funnel is positioned on top of a flask connected to a vacuum line.

Apply suction to quickly draw the liquid through the filter, leaving the dry solid on the filter paper while the filtrate containing liquid impurities is collected in the flask below.

filtration under reduced pressures

technique for separating a solid product from liquid impurities in a reaction mixture

filtration under reduced pressures apparatus

recrystallisation steps

Dissolve the impure solid in a minimal amount of hot solvent to create a saturated solution.

Allow the solution to cool slowly, which encourages the formation of pure crystals while impurities remain in the solution.

Filter the mixture under reduced pressure to collect the crystals, and wash them with a small amount of cold solvent to remove any residual impurities on the crystal surface.

Dry the purified crystals.

what should the ideal recrystallisaiotn solvent do

Fully dissolve the solid at high temperatures.

Promote crystallisation of the solid as the solution cools.

if solubility i to low when hot when recrystallising

The product does not fully dissolve, even upon boiling.

This prevents recrystallisation since crystals cannot form from a solution.

if solubility i to high when cold when recrystallising

The product remains dissolved in the cold solution.

Crystals fail to form, leading to product loss during filtration rather than impurity removal.

how cna you test purity

The melting point of a compound is a valuable indicator of its purity. Pure substances melt at precise temperatures, while impure substances melt over a range of temperatures.

how to determine melting pointof an organic solid

The melting point of a compound is a valuable indicator of its purity. Pure substances melt at precise temperatures, while impure substances melt over a range of temperatures.

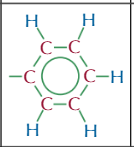

aromatic compounds functional group,properties and typical reactioms

stable delocalised ring of electrons,electrophilic substitution

haloalkane functional group,properties and typical reactioms

-x

polar c-x bond

nucleophilic substituion

elimination

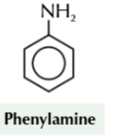

amine functional group,properties and typical reactioms

-N-

lone pair on nitrogen can act as a base or nucleophile

neutralisation

nucleophilic substitution

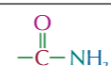

amide functional group

nitrile functional group,properties and typical reactioms

electron deficient carbon centre

reduction,hydrolysis

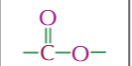

ester unctional group,properties and typical reactioms

electron deficient carbon centre

hydrolysis

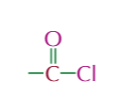

acyl chloride functional group,properties and typical reactioms

electron deficient carbon centre

nucleophilic substitution

condesation

friedal crafts acylation

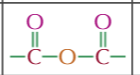

acid anyhdride functional group,properties and typical reactioms

electron deficient carbon centre

esterification

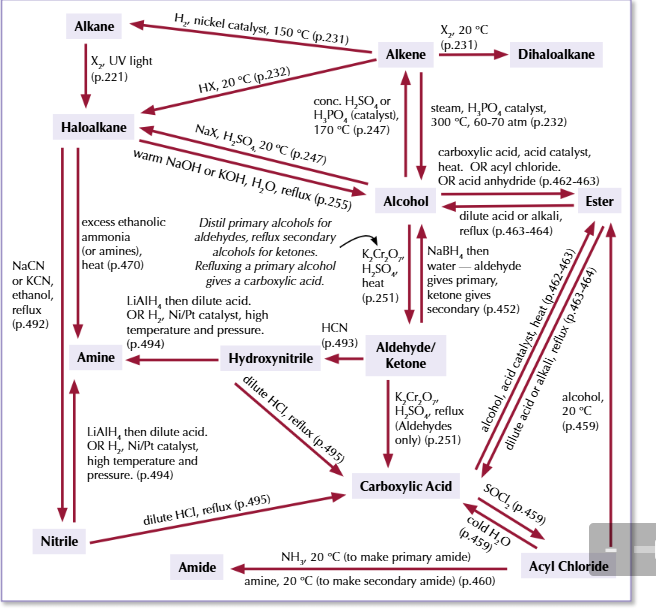

alevel syntehsis routes for aliphatic compounds

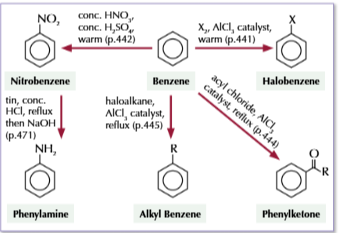

alevel syntehsis routes for benzene

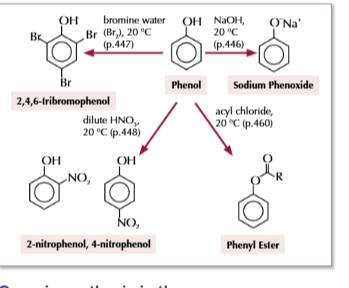

alevel syntehsis routes for henol

alkane to haloalkane

X2

UV light

haloalkane to amine

excess ethanolic ammonia

heat

haloalkane to nitrile

NaCN or KCN

ethanol

reflux

haloalkane to alcohol

warm NaOH or KOH

H2O

reflux

alcohol to haloalkane

NaX

H2SO4

20C

alcohol to ester

carboxylic acid,acid catalyst,heat

or acyl chloride

or acid anhydride

ester to alcohol

dilute acid or alkali

reflux

alcohol to alkene

conc H2SO4 or H3PO4

170C

alkene to alcohol

steam

H3PO4 catalystt

300C

60-70 atm

alkene to dihaloalkane

X2

20C

alkene to alkane

H2

nickel catalyst

150C

Alkene to haloalkane

HX

20C

alcohol to aldehyde/ketone

Acidified pottasium dichromate

distil primary alcohols to aldehydes

reflux secondary alcohols to ketones

aldehyde/ketone to alcohol

NaBH4 with water

aldehyde gives primary

ketone gives secondary

aldehyde/ketone to hydroxy nitrile

HCN

aldehyde to carboxylic acid

acidified pottasium dichromate reflux

hydroxynitrile to amine

LiAlH4 then dilute acid

or H2 Nickle catalyst high temp and pressure

hydroxy nitrile to carboxylic acid

dilute HCL

reflux

nitrile to carboxylic acid

dilute HCl

reflux

carboxylic acid to ester

alcohol

acid catalsyt

heat

ester to carboxylic acid

dilute acid or alkali

reflux

carboxylic acid to acyl chloride

SOCl2

acyl chloride to carboxylic acid

cold H2O

acyl chloride to ester

alcohol

20

acyly chloride to amide

NH3 20C to make primary

amine 20 to make secondary

benzene to nitrobenzene

conc HNO3

conc H2SO4

warm

phenyl amine

nitrobenzene to phenylamine

tin

conc HCL

reflux then NaOH

benzene to alkly benzene

haloalkane

AlCl3 catalyst

reflux

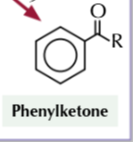

phenyl ketone

benzene to phenyl ketone

acyl chloride

AlCl3 ctalyst

reflux

benzene to halobenzene

phenol to 2,4,6-tribromophenol

bromien water Br2

20C

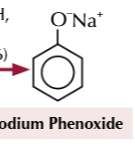

phenol to sodium phenoxide

NaOH

20C

sodium phenoxide

phenol to 2-nitrophenol or 4-nitrophenol

dilute HNO3

20C

phenol to phenyl ester

acyl chlirde

20C

phenyl ester