Aircraft Materials, Hardware and processes

1/78

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

79 Terms

If dye penetrant inspection indications are not sharp and clear, the most probable cause is that the part

was not thoroughly washed before the developer was applied.

Which tool is used to find the center of a shaft or other cylindrical work?

Combination set.

Generally speaking, bolt grip lengths should be

equal to the thickness of the material which is fastened together.

Liquid penetrant inspection methods may be used on which of the following?

Ferrous and nonferrous metals and nonporous plastics.

What aluminum alloy designations indicate that the metal has received no hardening or tempering treatment?

3003-F.

Why should an aircaft maintenance technician be familiar with weld nomenclature.

In order to gain familiarity with the welding technique, filler material, and temperature range used.

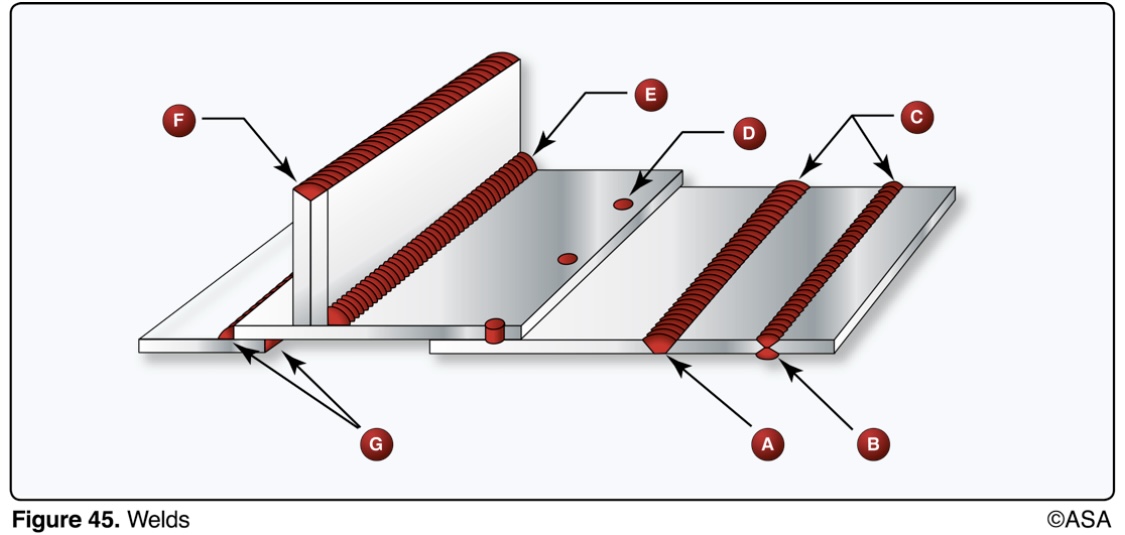

(Refer to Figure 45.) What type weld is shown at B?

Double butt.

One way a part may be demagnetized after magnetic particle inspection is by

slowly moving the part out of an ac magnetic field of sufficient strength.

Which material cannot be heat treated repeatedly without harmful effects?

Clad aluminum alloy.

In the four-digit aluminum index system number 2024, the first digit indicates

the major alloying element.

In performing a dye penetrant inspection, the developer

acts as a blotter to produce a visible indication.

The aluminum code number 1100 identifies what type of aluminum?

99 percent commercially pure aluminum.

What is generally used in the construction of aircraft exhaust collectors, stacks, and manifolds?

Stainless steel.

Holes and a few projecting globules are found in a weld. What action should be taken?

Remove all the old weld, and reweld the joint.

Which of the following statements is true?

An aircraft part may be demagnetized by subjecting it to a magnetizing force from alternating current that is gradually reduced in strength.

Aircraft bolts are usually manufactured with a

class 3 fit for the threads.

(Refer to Figure 43.) Identify the clevis bolt illustrated.

3

Which of the following defects are not acceptable for metal lines?

Dents in straight section that are 20% of tube diameter.

Alclad is a metal consisting of

pure aluminum surface layers on an aluminum alloy core.

When the specific torque value for nuts is not given, where can the recommended torque value be found?

AC 43.13-1.

What defects will be detected by magnetizing a part using continuous longitudinal magnetization with a cable?

Defects perpendicular to the long axis of the part.

Why is steel tempered after being hardened?

To relieve its internal stresses and reduce its brittleness.

On a fillet weld, the penetration requirement includes what percentage(s) of the base metal thickness?

25 to 50 percent.

Which of the following methods may be suitable to use to detect cracks open to the surface in aluminum forgings and castings?

Dye penetrant inspection and eddy current inspection.

A bolt with an X inside a triangle on the head is classified as an

NAS close tolerance bolt.

Which statement regarding aircraft bolts is correct?

In general, bolt grip lengths should equal the material thickness.

Which of the following describe the effects of annealing steel and aluminum alloys?

Decreasing internal stresses and softening of the metal.

Unless otherwise specified or required, aircraft bolts should be installed so that the bolthead is

upward, or in a forward direction

A part which is being prepared for dye penetrant inspection should be cleaned with

a volatile petroleum-base solvent.

Which heat-treating operation would be performed when the surface of the metal is changed chemically by introducing a high carbide or nitride content?

Case hardening.

Which tool can be used to measure the alignment of a rotor shaft or the plane of rotation of a disc?

Dial indicator.

When a fiber or nylon insert-type self-locking nut can be threaded on a bolt or stud through the insert with only the fingers, it should be

rejected.

A fiber-type, self-locking nut must never be used on an aircraft if the bolt is

subject to rotation.

Under magnetic particle inspection, a part will be identified as having a fatigue crack under which condition?

The discontinuity is found in a highly stressed area of the part.

The reheating of a heat treated metal, such as with a welding torch

can significantly alter a metal's properties in the reheated area.

In examining and evaluating a welded joint, a mechanic should be familiar with

likely ambient exposure conditions and intended use of the part, along with type of weld and original part material composition.

Select a characteristic of a good gas weld.

The weld should taper off smoothly into the base metal.

Which of the following materials may be inspected using the magnetic particle inspection method?

Iron alloys.

In magnetic particle inspection, a flaw that is perpendicular to the magnetic field flux lines generally causes

a large disruption in the magnetic field.

Which heat-treating process of metal produces a hard, wear-resistant surface over a strong, tough core?

Case hardening.

A particular component is attached to the aircraft structure by the use of an aircraft bolt and a castle tension nut combination. If the cotter pin hole does not align within the recommended torque range, the acceptable practice is to

change washers and try again.

Self-locking nuts may be used on aircraft provided that

the bolt or nut is not subject to rotation.

Which of the following occurs when a mechanical force such as rolling, hammering, or bending is repeatedly applied to most metals at room temperature?

The metals become strain or work hardened or cold worked.

The core material of Alclad 2024-T4 is

heat-treated aluminum alloy, and the surface material is commercially pure aluminum.

Magnetic particle inspection is used primarily to detect

flaws on or near the surface.

The pattern for an inclusion is a magnetic particle buildup forming

parallel lines.

Normalizing is a process of heat treating

iron-base metals only.

When checking an item with the magnetic particle inspection method, circular and longitudinal magnetization should be used to

reveal all possible defects.

Which statement relating to the residual magnetizing inspection method is true?

It may be used with steels which have been heat treated for stressed applications.

Which is an acceptable safety device for a castle nut when installed on secondary structures?

Cotter pin.

What two types of indicating mediums are available for magnetic particle inspection?

Wet and dry process materials.

(Refer to Figure 44.) Select the illustration which depicts a cold weld.

2

What method of magnetic particle inspection is used most often to inspect aircraft parts for invisible cracks and other defects?

Continuous.

Which condition indicates a part has cooled too quickly after being welded?

Cracking adjacent to the weld.

Circular magnetization of a part can be used to detect which defects?

Defects parallel to the long axis of the part.

When installing a castle nut, start alignment with the cotter pin hole at the

minimum recommended torque plus friction drag torque.

How is the locking feature of the fiber-type locknut obtained?

By the use of an unthreaded fiber locking insert.

Aircraft bolts with a cross or asterisk marked on the bolthead are

standard steel bolts.

What metal has special short-time heat properties and is used in the construction of aircraft firewalls?

Titanium alloy.

To detect a minute crack using dye penetrant inspection usually requires

a longer-than-normal penetrating time.

Which of the following factors are considered essential knowledge for X-ray exposure?

Material thickness and density and the type of defect to be detected.

(Refer to Figure 45.) What type weld is shown at A?

Butt.

What is descriptive of the annealing process of steel during and after it has been annealed?

Slow cooling; low strength.

When used in close proximity to magnetic compasses, cotter pins are made of what material?

Corrosion resisting steel.

What type of corrosion may attack the grain boundaries of aluminum alloys when the heat treatment process has been improperly accomplished?

Intergranular.

The Society of Automotive Engineers (SAE) and the American Iron and Steel Institute use a numerical index system to identify the composition of various steels. In the number '4130' designating chromium molybdenum steel, the first digit indicates the

basic alloying element.

(Refer to Figure 45.) What type weld is shown at G?

Lap.

Torque values for aircraft bolts normally consider

the threads to be clean and dry.

One characteristic of a good weld is that no oxide should be formed on the base metal at a distance from the weld of more than

1/2 inch.

How is a clevis bolt used with a fork-end cable terminal secured?

With a shear nut tightened to a snug fit, but with no strain imposed on the fork and safetied with a cotter pin.

(Refer to Figure 44.) Identify the weld caused by an excessive amount of acetylene.

3

Which of the bolthead code markings shown identifies an AN corrosion resistant steel bolt?

3

The testing medium that is generally used in magnetic particle inspection utilizes a ferromagnetic material that has

high permeability and low retentivity.

The advantages of HI-LOK(tm) fasteners include

light weight, high fatigue resistance, high strength, and inability to be over-torqued.

A bolt with a single raised dash on the head is classified as an

AN corrosion-resistant steel bolt.

Which type crack can be detected by magnetic particle inspection using either circular or longitudinal magnetization?

45°.

Which of the following is a main determinant of the dwell time to use when conducting a dye or fluorescent penetrant inspection?

To relieve internal stresses developed within the base metal.

Why is it considered good practice to normalize a part after welding?

To relieve internal stresses developed within the base metal.

Where is an AN clevis bolt used in an airplane?

Only for shear load applications.