5. RMGIC (done)

1/24

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

25 Terms

Definition of RMGIC

a hybrid of glass ionomers (a glass powder) and composite resin and

thus contain a liquid of acid-base that contains polymerizable components attached to polyacrylic acid

Composition of RMGIC

glass ionomer cement (typically a fluoroaluminosilicate glass) as the main component.

resin monomers (2-hydroxyethyl methacrylate (HEMA), bisphenol A-glycidyl methacrylate (Bis-GMA) + Initiators.

a liquid phase containing polyacrylic acid (a polycarboxylic acid) and water.

Essentially combining the properties of a conventional glass ionomer cement with the added polymerization capabilities of a resin monomer that improving mechanical strength and setting characteristics compared to standard glass ionomers.

Composition of RMGIC Powder:

consists of an ion leachable glass and initiators for chemical/light-curing

The liquid contains four ingredients

Bis-GMA; enables polymerization reaction.

Poly acrylic acid: reacts with the ion-leachable glass to allow acid-base reaction.

HEMA: hydrophilic methacrylate allows both the resin and the base components to coexist in an aqueous solution and takes part in the polymerization reactions

Water: allows ionization of the acid component so that the acid-base reaction can occur.

activator and initiator of RMGIC of chemically polymerized variant

hydrogen peroxide as the initiator

ascorbic acid as the activator.

activator and initiator of RMGIC of light activated variant

camphorquinones is used as visible light photochemical initiator

sodium p-toluene sulphinate as the activator

role of HEMA

to polymerize the materials and positively enhance the bond strength to tooth structure, to enhance penetration of adhesive to dentine and as a

cosolvent and monomer.

Water is responsible for

calcium and aluminum cation transportation to the polyacid

If there is not enough water the reaction will stop resulting in crazing (cracks)

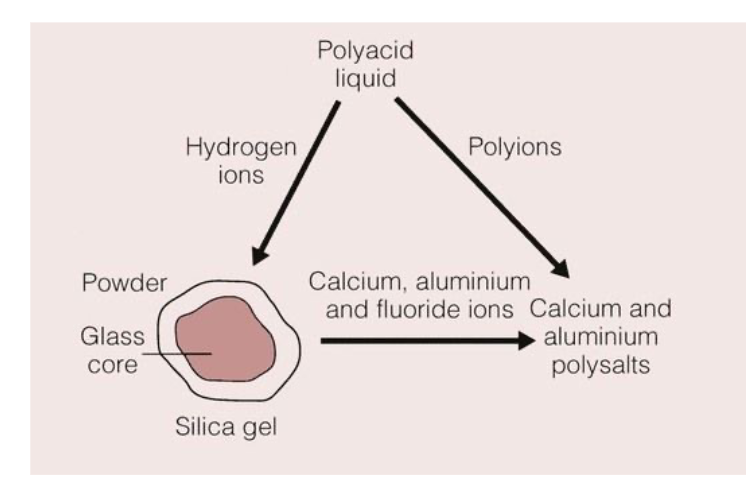

Acid-Base Reaction in conventional GIC

Fluoro alumino silicate glass (base) + Poly acrylic acid = calcium and aluminum poly salt hydrogel.

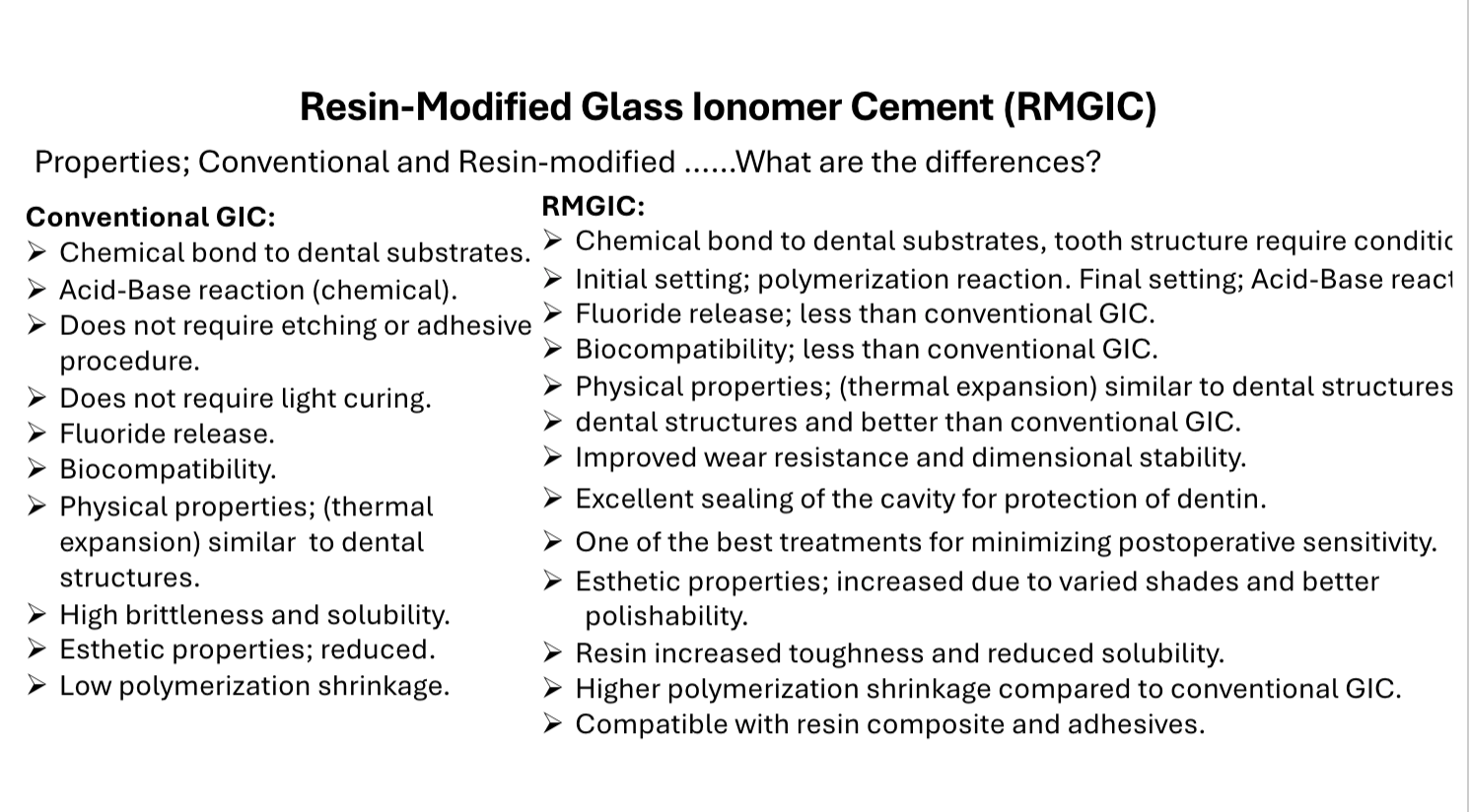

Conventional GIC properties

a bulk placement restorative material (no need for incremental placement)

able to bond directly to dentine and enamel.

polyacrylate ions either react with the apatite structure (displacing calcium and phosphate ions, and creating an intermediate layer of polyacrylate, phosphate and calcium ions), or bond directly to the calcium in the apatite

fluoride ions in the set ionomer structure do not take part in the setting reaction, they are released into the surrounding environment via an ion exchange process.

glass ionomers can also absorb salivary fluoride and act as fluoride reservoirs capable of releasing the ions which may have the potential to inhibit caries formation.

RMGIC properties

the acid-base reaction is much slower giving a longer working time because the HEMA replaced some of the water content and water is

an essential component of the acid-base reaction.

Acid-base; 7 to 10 minutes but gelation is very slow and the reaction may continuous for weeks or even months

Polymerization reaction

the polymerization of the HEMA to poly HEMA. This will be completed in less than one minute (much faster than acid-base reaction).

Free radical or photochemical polymerization process is similar to that used in composite resins.

adhesion to tooth structure:

Bonding of RMGIC to tooth structure is due to dual mechanism of adhesion.

As for the conventional GIC the mechanism of adhesion is thought to be based on a ion exchange mechanism where the poly alkenoic acid softens and infiltrates the hydroxyapatite structure, displaces calcium and phosphate ions to form adsorption layer of calcium and aluminum phosphates and poly acrylates at the glass ionomer-hydroxyapatite interface

adhesion to tooth structure For resin-based adhesives:

micromechanical bonding occurs with chemical bonding

Shear bond strength of RMGIC to dentine is significantly higher than that of the conventional GIC.

various adhesive systems used and they are visible light-cured liquids which are composed of HEMA, ethanol, photo initiators and a modified poly acrylic acid.

Resin-Modified Glass Ionomer Cement (RMGIC) Commercially available primers:

Fuji dentine conditioner (GC)

Vitremer primer (3M ESPE).

Nano ionomer primer (3 M ESPE)

Resin-Modified Glass Ionomer Cement (RMGIC) Adhesion to composite resin:

ability to directly bond to resin composites.

RMGIC produce a catalyst rich air-inhibited layer which can polymerize with the composite, making them useful in glass ionomer/ composite laminate restoration.

GIC cannot bind directly to the composite $

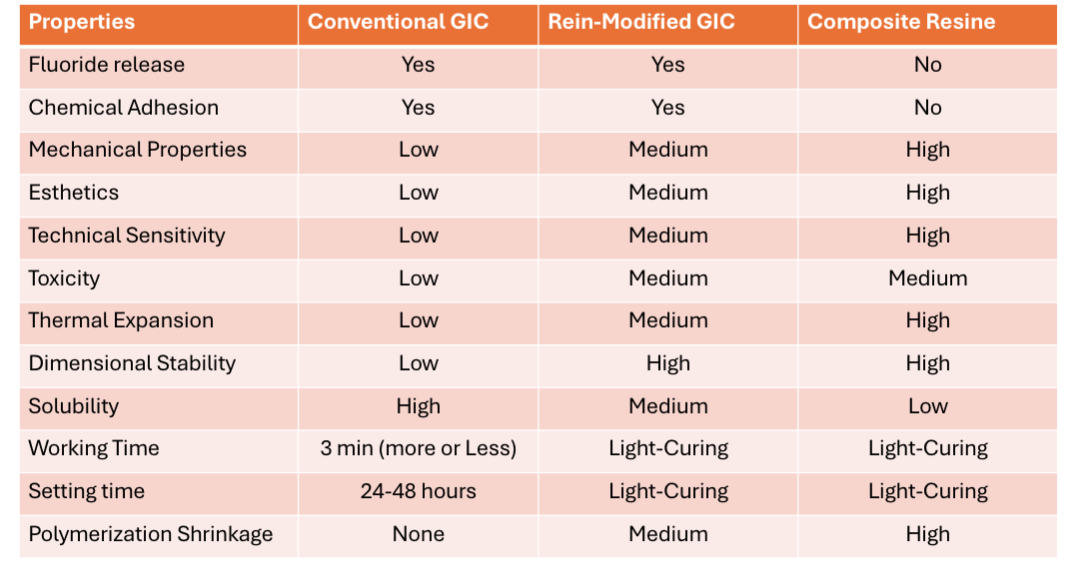

RMGIC vs GIC *know

Bounding of nano RMGIC to tooth structure:

RMGI) bonding involves a hybrid mechanism combining chemical adhesion and micro-mechanical interlocking.

relies on a dual-setting reaction—acid-base and polymerisation.

RMGICs micromechanically bond to dentine through infiltration of the collagen network previously exposed by using a 10% polyacrylic acid pre-treatment, in combination with chemical bonding obtained by ionic interaction of carboxyl groups from the acid with calcium ions of remaining

HAP crystals within the partially demineralized dentin and enamel.

Nano-filled RMGICs demonstrated a similar bonding mechanism with minimal infiltration of resin tags into dentin indicating more ionic bonding with tooth rather than micromechanical retention.

Development and available brands of RMGIC:

The most widely used is the Nano-Filled Resin-Modified Glass Ionomer Cements

Unlike conventional GICs that consist of a glass powder and a polyacid solution, resin modified GICs also have:

A polymer resin component, which sets by a self-activated (chemically cured) or light- activated polymerization reaction.

These “hybrid” materials are combining the mechanical properties of a resin composite with the anti-carious potential of GICs.

RMGICs not only release fluoride but they also have flexural strength superior to conventional GICs, as well as lower solubility.

Early RMGIC products showed slight expansion due to water sorption after 24 h of placement. However, newer formulations have overcome this problem.

When compared to resin composites, conventional RMGICs still possess reduced mechanical properties including brittleness and inferior strength along with aesthetics.

Resin-Modified Glass Ionomer Cement (RMGIC); available forms

Powder/Liquid

Pre proportioned

Encapsulated

Paste/Paste systems

Applications of RMGIC:

Pit and fissure sealant.

Liner and/or base.

Luting agent.

Intermediate restorations.

Final restorations in deciduous teeth.

Final restoration of class V in permanent teeth.

ATR ?

Resin-Modified Glass Ionomer Cement (RMGIC) steps

tooth conditioning:

Apply a conditioning gel (polyacrylic acid) to the cavity walls for a specified time to enhance bonding. Rinse thoroughly and gently dry the cavity. WHY????Mixing the RMGIC:

Follow manufacturer instructions for mixing the liquid and powder components of the RMGIC. Mix thoroughly to achieve a homogenous mixture.Placement in the cavity:

Quickly transfer the mixed RMGIC to the cavity using a suitable instrument, ensuring the material reaches all corners.

Fill the cavity from the base upwards to minimize air bubbles then light cure.Adaptation:

Use a dental condenser to pack the RMGIC firmly against the cavity walls, ensuring proper adaptation.

Shape the material to the desired contour using appropriate instruments.Setting and final finishing:

Ø Allow the RMGIC to set according to the manufacturer's guidelines.

Ø Once set, remove any excess material with a sharp instrument.

Ø Polish the restoration to a smooth surface using polishing discs or strips.

Important points to remember:

Moisture control:

RMGIC is sensitive to moisture during the setting process, so ensure the cavity is properly dried before

placing the material.Matrix bands:

In some cases, a matrix band may be used to help shape the restoration, especially on proximal

surfaces.Light curing:

While not all RMGICs require light curing, some formulations may benefit from light activation to

accelerate setting.

Preparation and application of RMGIC:

Remove the RMGIC capsule from its packaging.

Tap the RMGIC capsule on its base to loosen the glass particles.

Activate the RMGIC capsule by firmly depressing the colored plunger on the bottom of the capsule against the countertop and holding it down for 2 seconds. Make sure the plunger is flush with the main body of the capsule to avoid an inadequate mixing of the powder and liquid contained in the capsule.

Triturate (mix) the capsule for 10 seconds in the capsule mixer.

Place the capsule into the applicator gun and click two to three times to push the material into the tip.

Discard the first part, insert the material into the cavity starting with the deepest corner and go up.

KNOW THIS TAble