Module 1 & 2: Quality Control & Quality Assurance

1/86

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

87 Terms

Quality

Totality of characteristics or features of a product that bear on its capacity to satisfy stated or implied needs

Quality Assurance

Sum total of the organized arrangements made w/ the object of ensuring that products will be consistently of the quality required by their intended

Good Manufacturing Practice (GMP)

Ensure that production consistently produced & controlled according to quality standards & marketing authorization (from FDA)

Quality Control

Part of GMP concerned with sampling, specifications & testing, & with the organization, documentation & release procedures which ensures that the relevant & necessary tests are intact & in fact carried out & that materials are not released

QA Department Function

Assures policies are followed inept to economic issues associated with manufacturing & distribution of product

Cooperate with regulatory agencies & final authority for product acceptance or rejection

QA Department Function

Helps to identify & prepare necessary SOP’s relative to control of quality

Personnel

Procedure

Equipment

Premises

Environment

Package

Starting Materials

Validate Processes

Factors Affecting Quality Products (8)

Monograph

A document which specifies all the tests to be conducted on a particular material or product, the procedure and/or appropriate references containing the details of the procedure and expected results

Validated by researchers

Certificate of Analysis

A document containing the result of all tests conducted on a particular material or product to show compliance or non-compliance with established standards or specifications approved by responsible personnel

Absolute Error

Relative Error

2 Types of Error

Absolute Error

Distinction between quantities of measured value and actual value

Indeterminate (uncontrollable causes)

Determinate (identifiable systematic errors or bias)

2 Types of Absolute Error

Indeterminate

random errors

slight variations in a series of observations made by the same observer

intangible, elimination by analyst is hard

difficult to detect

difference of judgment of analyst

Determinate

Errors by analyst

methodological errors

instrumental error

Accuracy

Closeness of the data to true value

Precision

Closeness of data

Specificity

Assess unequivocally the analyte in the presence of components that may be expected to be present

Sensitivity

Refers to the ability of a test to detect very small amounts of a target analyte (the minimum detectable concentration)

Robustness

Measure of capacity to be unaffected by small but deliberate variations in method & provides indication of its reliability during normal usage

Measurability

Seriousness or Gravity

Nature

3 Category of Defects

Variable Defect

Attribute Defect

2 Defects under Measurability

Variable Defect

Can be measured directly by instruments

Confiable

Attribute Defect

Cannot be measured directly by instruments

Non confiable

Critical Defect

Major Defect

Minor Defect

3 Defects under Seriousness and Gravity

Critical Defect

May endanger life or property & may render the product non-functional (Absence of Warning)

Major Defect

May affect the function of the object, & therefore, may render the product useless. (Crack in a Bottle)

Minor Defect

Does not endanger life or property but remains a defect. (Slight deviation of the color of the label from the color standards)

Ex: packaging

Ocular Defect

Internal Defect

Performance Defect

3 Defects under Nature

Ocular Defect

Visible (Foreign particulate contamination)

Internal Defect

Not seen although present (Subpotent Drug Product)

Performance Defect

Defect in function (Suppository that does not melt at body temperature)

Materials

Variation between suppliers of same substance

Variation between batches from same suppliers

Variation within a batch

Machines

Variation equipment for the same process

Difference in adjustment of equipment

Aging & improper care

Methods

Inexact procedure

Inadequate procedures

Negligence

Men

Improper working conditions

Inadequate training, & understanding

Dishonesty, fatigue & carelessness

Confidence Interval

range of value around an actual result w/ which true value is expected

Significance Test

compare individual values or set of values for significant differences.

Null Hypothesis there is no significant differences

Alternate Hypothesis

One Tailed

there is a significant difference & indicates what is the dissimilarities or variations

Two Tailed

there is a significant difference but doesn’t indicate the dissimilarities or any variations.

Quality Control Testing Of Pharmaceutical Dosage Forms

sum of all processes done to ensure that product possesses, ensuring its efficacy & safety.

Packaging

Identity Test

Limit Test

Potency Test

Dosage- Form Specific Test

General Test Classifications (5)

Assumptions

Sampled using an appropriate sampling plan; Representative of the lot being tested

Packaging Material type Special Properties

Example: transparent, collapsible, easy to drain Integrity

Example: tightness, leak-free

Physical Properties

Gross physical appearance

Example: color, occurrence, odor, consistency, dimensions

Potency Test

determine conformance of dosage form to label claim

Instrumental Methods

Chemical Methods

Biological Methods

Methods Under Potency Test

Sampling

comprises the operations designed to select a portion of a pharmaceutical product (for definition, see glossary) for a defined purpose. The sampling procedure should be appropriate to the purpose of sampling, to the type of controls intended to be applied to the samples and to the material to be sampled. The procedure should be described in writing

n plan

p plan

r plan

Sampling Plans and Techniques for Starting Material (3)

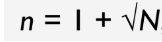

n plan

when the material to be sampled is considered uniform and is supplied from a recognized source

Samples can be withdrawn from any part of the container (usually from the top layer)

Formula of n plan

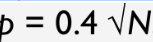

p plan

when the material to be sampled is considered uniform and is supplied from a recognized source and the main purpose is to test for identity

Formula of p plan

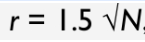

r plan

when the material is suspected to be nonuniform and/or is received from a source that is not well known

used for herbal medicinal products used as starting materials.

Formula of r plan

Acceptable Quality Limit (AQL)

Sampling Plans and Techniques for Finished Products

AQL

The quality level that is the worst tolerable over the course of many inspections

used to determine how many units should be inspected and how many defects are acceptable during the inspection

Statistical Quality Control

the monitoring of quality by the application of statistical methods in all stages of production

Attribute Chart

Variable Chart

Two basic Quality Control Charts

Attribute Chart

a chart when makes use of discrete data classifying the number of item conforming & the number of items failing to conform to any specified requirements

Example: P chart and C chart

Variable Chart

a chart using actual records of numerical measurement on a full continuous scale such as meter, grams, liter.

Example: X and R charts

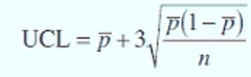

Formula of UCL

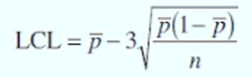

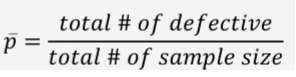

Formula of LCL

Formula of Center Line

Raw Materials Quality Control (RMQC)

In Process Quality Control

Finished Product Quality Control

3 Main Areas of Quality Control

Identity Test

Purity Test

Limit Test

Physical Test

Special Test

5 Tests Under RMQC

In Process Quality Control

These are checks that are carried out before the manufacturing process is completed

monitoring and if necessary, adaption of the manufacturing process to comply with the specifications

Primary Moisture Content 31-35%

Adequacy of Wetness

Shape

Final Moisture Content : 0.5-1%

Angle of Repose

Porosity (Pores)

Bulk Density

Tapped Density

Carr’s Index

Hausner’s Ratio

Particle Size Distribution

Thickness

Hardness

Tests Under In Process Quality Control (13)

Picking & Sticking

Capping, Chipping, and Lamination

High moisture: & ; Low moisture: , ,

Angle of Repose

A constant 3D angle assumed by a cone-like pile of material

Porosity (Pores)

measurement of the void or empty spaces of a material and is defined as the ratio between the volume of voids and the total volume

Bulk Density

the density of a large volume of porous material powder including the pore spaces within the material particles in the measurement volume

Tapped Density

an increased bulk density attained after mechanically tapping a container containing the powder sample. The tapped density is obtained by mechanically tapping a graduated measuring cylinder or vessel containing the powder sample

Carr’s Index

Index of compressibility

Indication of the compressibility of a powder

Hausner’s Ratio

measure of flowability

Stroke Monsato

test of strength

Friability Test

Hardness

Thickness

Disintegration Test

Dissolution Test

Uniformity of dosage units

6 Tests For Solid Dosage Forms

Bacterial Endotoxin Test

Particulate Matter

Pyrogen Test

Clarity Test

Safety Test

Sterility Test

Leaker’s Test

7 Tests For Parenterals

Microbial content

Stability

Sedimentation value

Redispersibility

Rheological properties

Electrophoretic Analysis

Particle Size determination

7 Tests For Non-Sterile Products

Microbial content

Spreadability

Viscosity

3 Tests For Semi-solid

Stability

Capacity of drug to remain within specifications

Established to assure identity, strength, quality, & purity

Acceptable Stability

Time in storage and use in which a particular formulation in a container remains within physical, chemical, toxilogical, and bioavailability specifications.

Expiration Date

Time in which the preparation will remain stable when stored under recommended conditions

Too Early

Too Late

Type 1 Alpha Error :

Type 2 Beta Error:

Harmful Events

Decrease in therapeutic activity of preparation to below some arbitrary content

Appearance of toxic substances formed as degradation

Stability Studies

Conducted within a span of 6 months

10 tabs

18 tabs

24 tabs

50 tabs

No. of samples

Appearance, Hardness, Thickness, Weight, Moisture = tabs

Disintegration = tabs

Dissolution = tabs

Friability = tabs

2 ½ years or 13 months

Ideal Shelf Life