M&PII: Processes Quiz 4

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

20 Terms

Reaction Injection Molding Benefits

Large, Durable, lightweight parts at a low tooling cost.

Smooth paintable finishes straight from the mold.

Reaction Injection Molding Disadvantages

Not Ideal for high volume production

Non-recyclable and can release VOCs

Reaction Injection Molding Alternative Process

Injection molding is similar with a higher tooling cost but with tighter tolerances.

Reaction Injection Molding Tolerances

0.005" to 0.10"

Reaction Injection Molding Product

Airplane Overhead Bins

Selective Laser Sintering Benefits

Design freedom with no support structures required -Because the unsintered powder acts as a support medium, SLS allows for complex internal geometries, interlocking parts, undercuts and assemblies printed in one piece.

Strong functional end-use parts comparable to injection-moulded plastics SLS parts (typically nylon PA12/PA11) - offer good mechanical strength, impact and environmental resistance — making them viable for production parts, not just prototypes.

Selective Laser Sintering Disadvantages

Surface roughness and finish require post-processing ( matte, somewhat grainy, and may need media blasting, tumbling or coating to meet aesthetic or smoothness requirements.

Higher cost, limited material variety and dimensional challenges While no tooling is required, the machines, powder materials and preparation are more expensive compared to simpler 3D-printing or moulding methods. Also, parts may exhibit shrinkage, warping or dimensional offsets due to thermal effects.

Selective Laser Sintering Alternative Process

FDM instead:

When budget is the primary concern.

For large, low-stress prototypes where fine detail and surface finish are less important.

When material options (e.g. flexible or specialty filaments) are more critical than precision.

Selective Laser Sintering Tolerances

±0.010" (±0.25 mm) for the first inch

±0.002" (±0.05 mm) per additional inch

Dimensional accuracy: approximately ±0.3% overall

Selective Laser Sintering Product

Camera Tripod

Metal Injection Molding Product

Pistol trigger

Metal Injection Molding Benefits

Can produce small, intricate metal parts with internal details that would be impossible or extremely costly to machine on a CNC.

Achieves near-wrought material strength and density while maintaining the high-volume, low-cost efficiency of plastic injection molding.

Metal Injection Molding Disadvantages

High upfront tooling and equipment costs make it too expensive for low production volumes (compared to machining or additive manufacturing).

Sintering shrinkage (~15-20%) puts a limit on part size, and can introduce distortion, reducing dimensional accuracy on larger components.

Metal Injection Molding Alternative Process

Die Casting or Powder Metallurgy (PM)

Metal Injection Molding Tolerances

+/-0.002in

Ceramic Injection Molding Benefits

Complex Geometries

(produces intricate shapes that are often difficult or impossible to machine through other processes

Supports thin walls, micro-features, and internal channels)

High Precision

Tight tolerances and excellent dimensional accuracy

Ceramic Injection Molding Disadvantages

High initial cost

Can have shrinkage and defects

Ceramic Injection Molding Alternative Process

Metal Injection Molding

CIM & MIM are nearly identical, with the key difference being

the use of ceramic powder versus metal powder

Ceramic Injection Molding Tolernaces

± 0.008 inches

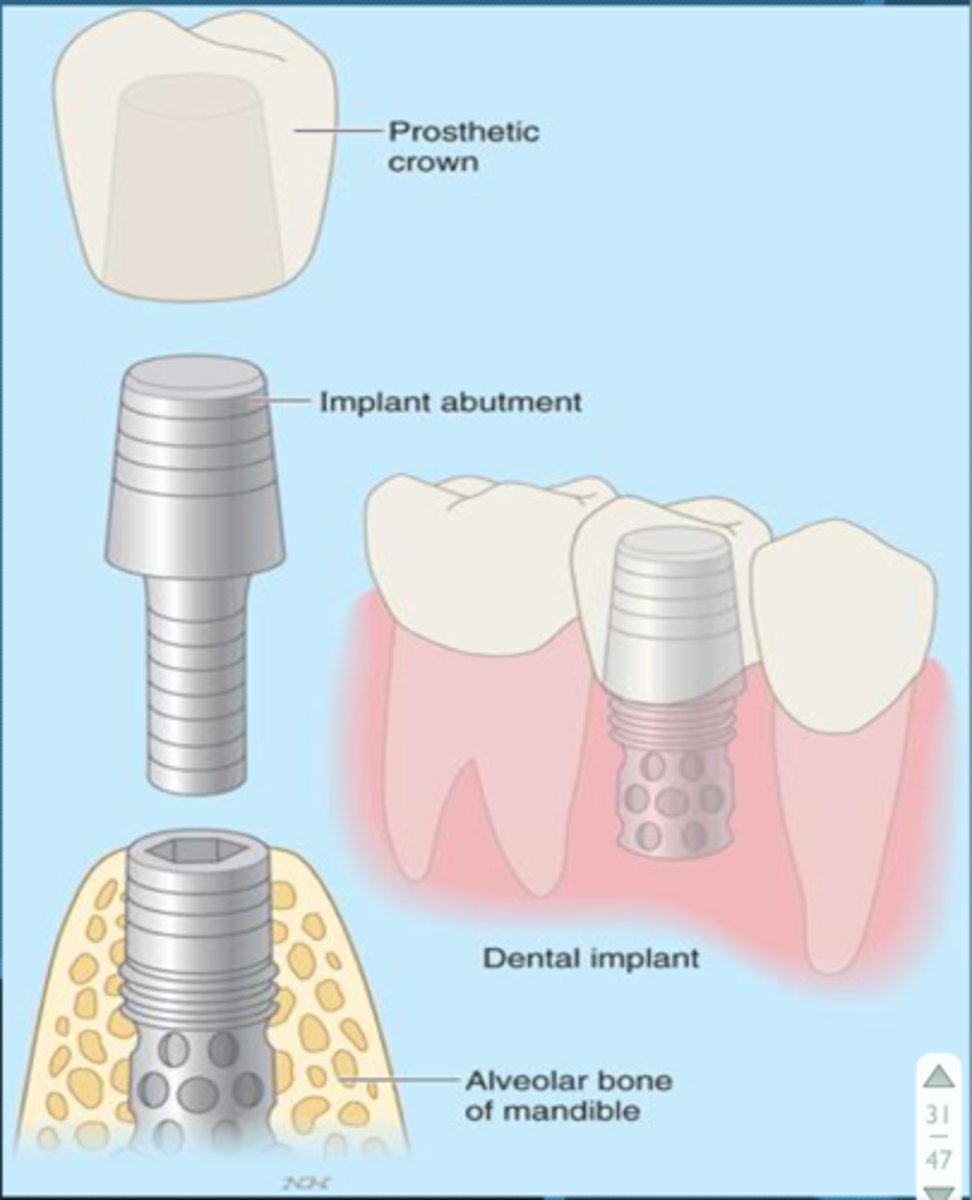

Ceramic Injection Molding Product

Dental Implants