MET 3100 (Applied Physical Metallurgy) - Chapter 3

1/36

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

37 Terms

Tensile Strength

The maximum stress a material can withstand when stretched or pulled before breaking.

What is Tensile Strength considered in Metals, Ceramics, and Polymers?

Metals - The point when noticeable necking begins

Ceramics - The point at which crack propagation starts

Polymers - Polymer backbones are aligned and about to break at this point

Mechanical Properties of Materials

They reflect the relationship between its response or deformation to an applied load or force.

Some examples are strength, hardness, ductility, and stiffness

Compressive Strength

The capacity of a material to resist deformation under compression.

Elasticity

The ability of a material to return to its original shape after being stretched or compressed.

Plasticity

The ability of a material to undergo permanent deformation without breaking when subjected to stress.

Hardness

Resistance to indentation or abrasion.

Ductility

The ability of a material to be stretched into a wire without breaking.

Brittleness

The tendency of a material to break or shatter without significant deformation when subjected to stress.

Toughness

The ability to absorb energy and deform plastically before fracturing.

Malleability

The ability of a material to be hammered or rolled into thin sheets without breaking.

Fatigue Strength

The maximum stress a material can withstand for a number of cycles without failing.

Creep Resistance

The ability of a material to resist deformation under sustained load over time, especially at high temperatures.

Young's Modulus (Elastic Modulus)

A measure of stiffness or rigidity, indicating how much a material deforms under stress.

Poisson's Ratio

The ratio of transverse strain to axial strain when a material is stretched or compressed.

Fracture Toughness

The ability of a material containing a crack to resist fracture.

Shear Strength

The maximum stress a material can withstand in a direction parallel to its surface without sliding.

Impact Strength

The ability of a material to resist shock or sudden force without fracturing.

Solids deform when they are subject to ___ (can be tensile, compressive, or shear)?

Load

Tension Tests

The most common mechanical stress strain tests which are used to ascertain (determine) several mechanical properties of materials; tested material is deformed - usually to a fracture, with gradually increasing uniaxial tensile load applied along the length of the material

The resulting output of the test is the load / force vs. elongation

Tensile Test Machine

Designed to elongate the testing material at a constant rate, and to continuously and simultaneously measure the instantaneous applied load, and the resulting elongations.

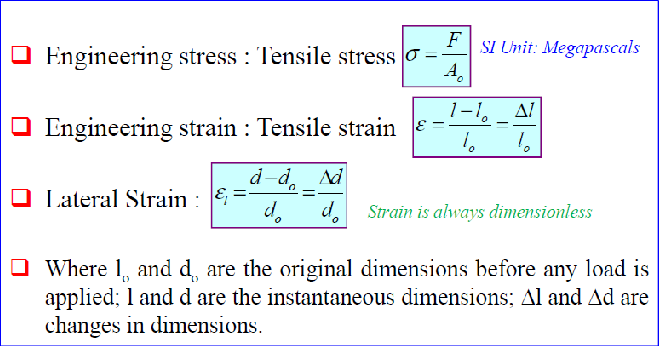

Engineering Stress, Engineering Strain, and Lateral Strain (equations)

Compression Tests

This test is conducted in a manner similar to the tensile test, but the force applied is compressive.

By convention, compressive forces are taken as NEGATIVE , which yields a negative stress. Furthermore, L(o) is > L(i)

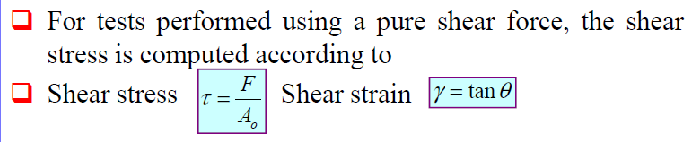

Shear Tests (shear stress, and shear strain equations)

F, is the load or force imposed - parallel - to the upper and lower faces of the tested material, each of which has an area of “A(o)”. The shear straiin (gamma) is defined as the tangent of the strain angle (theta)

Torsion

___ is a form of pure shear in which a material is twisted about its longitudinal axis, producing rotational motion (torque).

Torsional Test (conventions)

Shear stress (tau) is a function of the applied torque (T - tau), and shear strain is related to the angle of the twist (phi)

Elastic Deformation

Deformation in which stress and strain are proportional; non-permanent, and reversible deformation

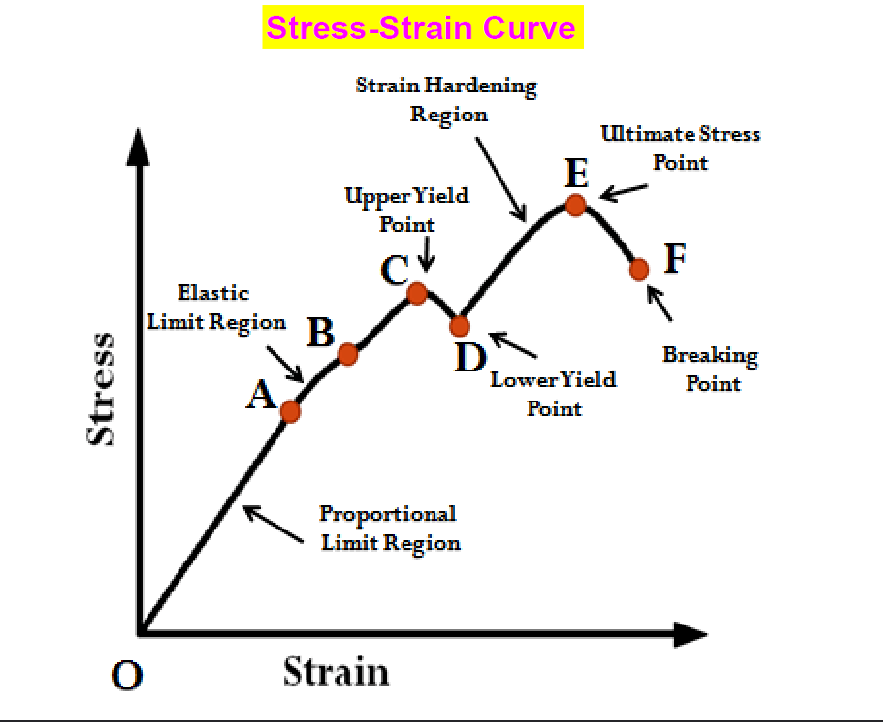

What is the Stress-Strain Curve?

A graph derived from measuring load (stress) versus extension (strain) for a sample material

IMPORTANT TO REMEMBER: What do the different points and regions on the Stress-Strain Curve represent?

A: The Proportional Limit Region - the region on the curve where stress and strain are equal, meaning it behaves elastically

B: Elastic Limit Region - the region on the curve where the material can undergo deformation, and still return to its original shape, after stress is removed

C: Upper Yield Point - Marks the max load required to initiate permanent elastic deformation

D: Lower Yield Point - The lowest point of stress on a material’s stress-strain curve after the upper yield point

D-E: Strain Hardening Region - The portion along the S-S Curve where the material undergoes plastic deformation under increasing stress

E: Ultimate Stress Point - The absolute maximum tensile stress a material can withstand before it begins to fracture

F: Breaking Point - The point where the material physically breaks apart into two smaller pieces

What is the Modulus of Elasticity, or Young’s Modulus

The slope of the linear segment of the stress-strain curve, which corresponds to the modulus of elasticity (E). It can be thought of as the stiffness, or resistance of elastic deformation, of a given material

For materials showing nonlinear elasticity … what can be used to determine the material’s modulus of elasticity?

Either tangent or secant modulus can be used. Tangent modulus is taken as the derivative of the curve some specific instance of stress, whereas Secant modulus represents the slope of a secant drawn from the origin to some given point of the curve

What is Plastic Deformation?

Permanent deformation in the absence of external constraints. At the atomic level, corresponds to the breaking of atomic bonds with original atom neighbors and then reforming bonds with new neighbors

What are the three Tensile Properties?

Yielding - the beginning of plastic deformation

Proportional Limit - The point at which there is a deviation from the straight line ‘elastic’ regime

Yield Strength - Stress at which noticeable plastic deformation has occurred. The magnitude of yield strength is a measure of a materials resistance to plastic deformation.

Percent Elongation (%EL)

The percentage of plastic strain at fracture. Calculated as

(L(f) - L(o)) / L(o)

Toughness

The energy required to break a unit volume of material - the integral of the material’s stress-strain curve

Resilience, U( r )

The capacity of a material to absorb energy when it is deformed elastically, and then, upon unloading, to have this energy recovered

Hardness

Resistance to permanently indenting the surface