Test 2

5.0(3)

Card Sorting

1/91

Earn XP

Description and Tags

Last updated 4:37 PM on 2/28/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

92 Terms

1

New cards

**High stiffness and strength**

can be alloyed for high rigidity, strength, and hardness

2

New cards

**Toughness**

capacity to absorb energy better than other classes of materials

3

New cards

**Good electrical conductivity**

metals are conductors

4

New cards

**Good thermal conductivity**

conduct head better than ceramics or polymers

5

New cards

**Cost**

the price of steel is very competitive with other engineering materials

6

New cards

**Cast metal**

starting form is a casting

7

New cards

**Wrought** metal

the metal has been worked or can be worked after casting

8

New cards

**Powdered** metal

starting form is very small powders for conversion into parts using powder metallurgy techniques

9

New cards

**Ferrous**

Those based on iron, steels, cast irons

10

New cards

**Nonferrous**

all other metals, aluminum, magnesium, copper, nickel, titanium, zinc, lead, tin, gold, silver

11

New cards

Alloy

a mixture or compound of two or more elements, at least one of which is metallic

12

New cards

The phase of Iron at room temperature

alpha, α, called ferrite

13

New cards

What does ferrite transform to as temperature rises?

Ferrite, alpha, to austenite, gamma, to delta

14

New cards

Steel

an iron-carbon alloy containing from 0.02% to 2.1% carbon

15

New cards

Cast iron

an iron-carbon alloy containing from 2.1% to about 4% or 5% carbon

16

New cards

**Ductile iron**

is formed by special melting and pouring treatment of gray cast iron

17

New cards

**Malleable iron**

is formed by heat treatment of white cast iron

18

New cards

THIS IS START OF CH 6 ASSIGNMENT

IGNORE

19

New cards

What are some of the general properties that distinguish metals from ceramics and polymers?

Typical metallic properties include: high strength and stiffness, good electrical and thermal conductivity, and higher density than ceramics or polymers

20

New cards

What are the two major groups of metals? Define them.

Ferrous metals, which are based on iron; and nonferrous, which includes all others.

21

New cards

What is a solid solution in the context of alloys?

A solid solution is an alloy in which one of the metallic elements is dissolved in another to form a single phase.

22

New cards

Distinguish between a substitutional solid solution and an interstitial solid solution.

A substitutional solid solution is where the atoms of the dissolved element replace atoms of the solution element in the lattice structure of the metal. An interstitial solid solution is where the dissolved atoms are small and fit into the vacant spaces (the interstices) in the lattice structure of the solvent metal.

23

New cards

What is an intermediate phase in the context of alloys?

An intermediate phase is an alloy formed when the solubility limit of the base metal in the mixture is exceeded and a new phase, such as a metallic compound (e.g., Fe3C) or intermetallic compound (e.g., Mg2Pb) is formed.

24

New cards

What is the range of carbon percentages that defines an iron‑carbon alloy as a steel?

The carbon content ranges from 0.02% to 2.11%.

25

New cards

What is the range of carbon percentages that defines an iron‑carbon alloy as cast iron?

The carbon content ranges from 2.11% to about 5%.

26

New cards

Identify some of the common alloying elements other than carbon in low alloy steels.

The common alloying elements in low alloy steel are Cr, Mn, Mo, Ni, and V. at least two

27

New cards

What is the predominant alloying element in all of the stainless steels?

Chromium

28

New cards

Besides high carbon content, what other alloying element is characteristic of the cast irons?

Silicon

29

New cards

Identify some of the properties for which aluminum is noted?

Aluminum is noted for its low density, high electrical and thermal conductivity, formability, good corrosion resistance due to the formation of a tough oxide film on its surface, and ability to be alloyed and strengthened to achieve good strength‑to‑weight ratios.

30

New cards

What are some of the noteworthy properties of magnesium?

Magnesium is noted for its very low density (lightest of the structural metals), propensity to oxidize (which can cause problems in processing), and low strength; however, it can be alloyed and strengthened by methods similar to those used for aluminum alloys to achieve respectable strength‑to‑weight ratios

31

New cards

What is the most important engineering property of copper that determines most of its applications?

Its high electrical conductivity (low resistivity).

32

New cards

What elements are traditionally alloyed with copper to form (a) bronze and (b) brass?

The elements are (a) tin and (b) zinc, respectively.

33

New cards

What are some of the important applications of nickel?

The important applications of Ni are (1) as an alloying ingredient in steel, e.g., stainless steel; (2) for plating of steel to resist corrosion; and (3) to form nickel‑based alloys noted for high‑temperature performance and corrosion resistance

34

New cards

35

New cards

What are the noteworthy properties of titanium?

Titanium is noted for its high strength‑to‑weight ratio, corrosion resistance (due to the formation of a thin but tough oxide film), and high temperature strength.

36

New cards

Identify some of the important applications of zinc.

The important applications of Zn are (1) die castings ‑ zinc is an easy metal to cast; (2) as a coating in galvanized steel; (3) as an alloying element with copper to form brass.

37

New cards

What important alloy is formed from lead and tin?

Solder

38

New cards

What is so special about the superalloys? What distinguishes them from other alloys?

The superalloys are generally distinguished by their strength and resistance to corrosion and oxidation at elevated temperatures.

39

New cards

What are the three basic methods by which metals can be strengthened?

The three basic methods are (1) alloying to form solid solutions and two‑phase structures which are stronger than the elemental metals; (2) cold working, in which the strain‑hardened metal is stronger and harder than the unstrained metal; and (3) heat treatment ‑ most of the commercial heat treatments are designed to increase the strength of the metal.

40

New cards

THIS IS START OF CH 21 SLIDES

IGNORE

41

New cards

Machining

a material removal process in which a sharp cutting tool is used to mechanically cut away material so that the desired part geometry remains

42

New cards

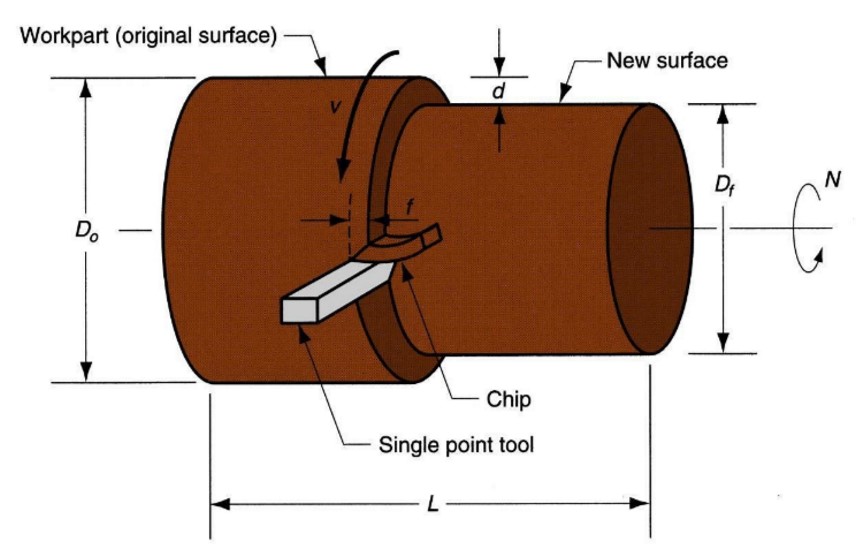

Turning

\

43

New cards

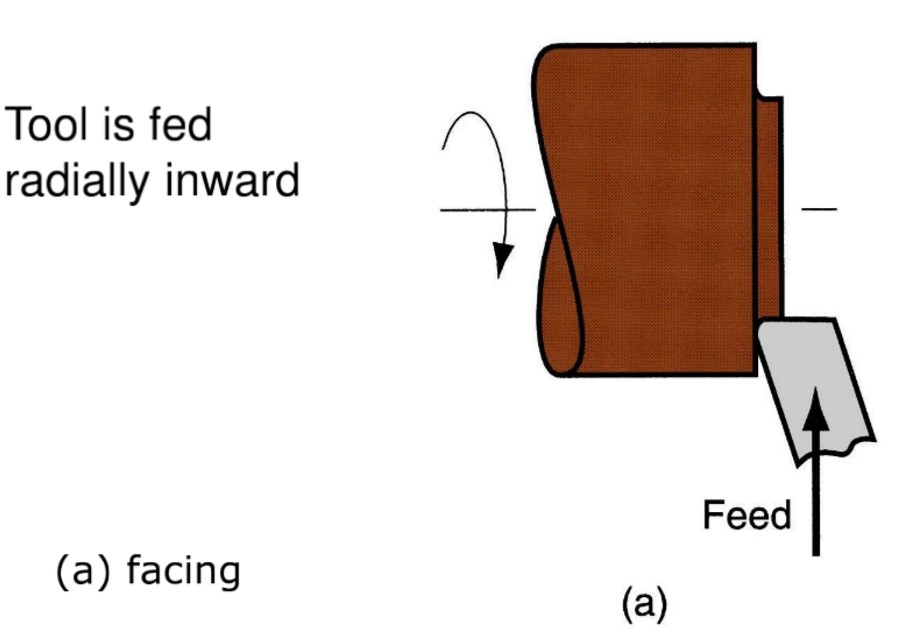

Facing

44

New cards

Contour Turning

instead of feeding tool parallel to axis of rotation, tool follows a contour that is other than straight, thus creating a contoured shape

45

New cards

Chamfering

cutting edge cuts an angle on the corner of the cylinder, former a chamfer

46

New cards

Cutoff

tool is fed radically into rotating work at some location to cut off end of part

47

New cards

threading

pointed form tool is fed linearly across surface of rotating work part parallel to axis of rotation at a large feed rate, thus creating threads

48

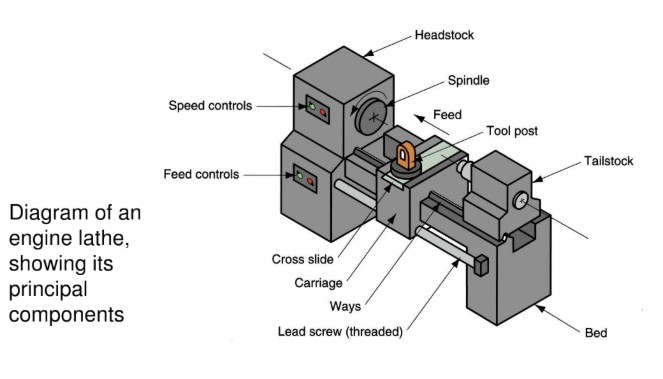

New cards

MANUAL LATHE

49

New cards

Reaming

50

New cards

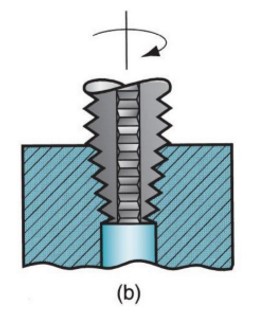

tapping

51

New cards

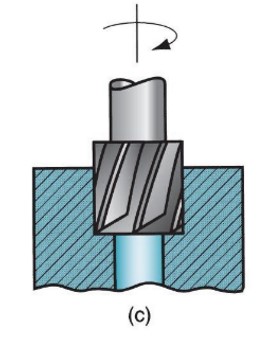

counterboring

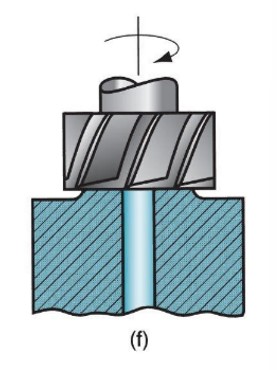

52

New cards

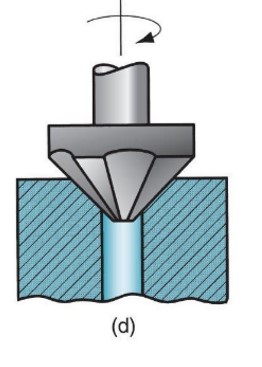

countersinking

53

New cards

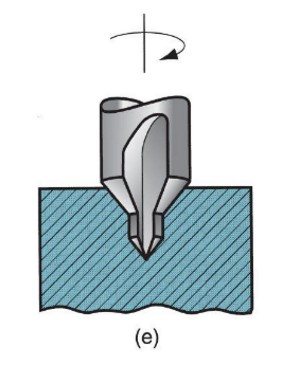

center drilling

54

New cards

spot facing

55

New cards

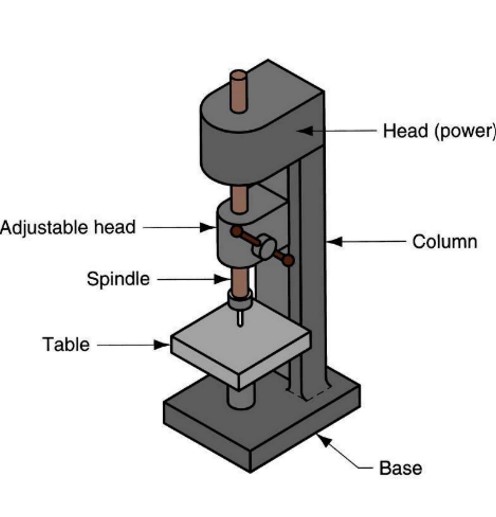

DRILL PRESS

56

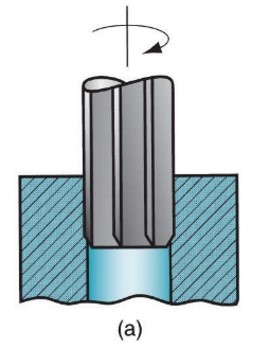

New cards

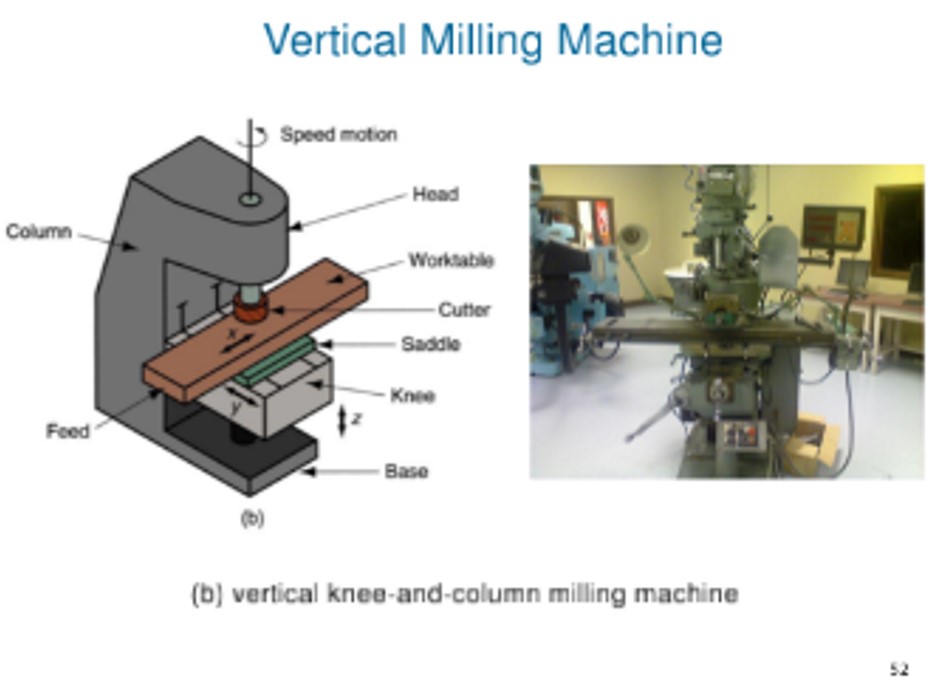

Vertical milling machine

57

New cards

THIS IS START OF CH 6 QUIZ

RECHECK ANSWERS

58

New cards

Sand casting is which of the following types:

expendable mold

59

New cards

The upper half of a sand casting mold is called which of the following:

cope

60

New cards

In foundry work, a runner is which one of the following:

channel in the mold leading from the downsprue to the main mold cavity

61

New cards

A riser in casting is NOT described by which of the following:

an insert in the casting that inhibits buoyancy of the core

62

New cards

Which one of the following casting processes is the most widely used:

sand casting

63

New cards

For which one of the following reasons is a green mold named:

moisture is contained in the mold

64

New cards

Shell molding is best described by which one of the following:

casting process in which the mold is a thin shell of sand binded by a thermosetting resin

65

New cards

Which of the following qualifies as a precision casting process:

investment casting

66

New cards

Which of the following metals would typically be cast in die casting

aluminum

67

New cards

A misrun is which one of the following defects in casting:

metal solidifies before filling the cavity

68

New cards

START OF CH 39 40

69

New cards

The manufacturing engineering department in an organization is best described as which one of the following:

technical staff function

70

New cards

Which of the following is NOT a usual responsibility of the manufacturing engineering department?

marketing the product

71

New cards

Which of the following is considered a basic process, as opposed to a secondary process?

impression die forging

72

New cards

Which of the following would be considered a secondary process, as opposed to a basic process?

machining a metal casting

73

New cards

In a make or buy situation, the decision should always be to purchase the component if the vendor ’s quoted price is less than the in-house estimated cost of the component:

False

74

New cards

Which of the following is an operation to enhance physical properties?

annealing

75

New cards

A route sheet is a document whose principal function is which one of the following?

specifies the process plan

76

New cards

Which one of the following types of computer-aided process planning relies on parts classification and coding in group technology?

retrieval CAPP

77

New cards

Start of Jeopardy

jeopardy

78

New cards

For what is aluminum not noted

poor corrosion resistance. Has good corrosion resistance

79

New cards

CHECK PHOTOS

80

New cards

RANGE OF CARBON PERCENTAGES

81

New cards

the distance the tool advances into or along the workpiece each time the tool point passes a certain position in its travel over the surface is called

Feed

82

New cards

Ch 21 quiz

ch 21 quiz

83

New cards

In a turning operation, the change in diameter of the workpart is equal to which one of the following:

2 x depth of cut

84

New cards

A lathe can be used to perform which of the following machining operations:

boring

85

New cards

A facing operation is normally performed on which one of the following machine tools:

lathe

86

New cards

Knurling is performed on a lathe, but it is a metal forming operation rather than a metal removal operation:

true

87

New cards

Which one of the following cutting tools cannot be used on a turret lathe:

broach

88

New cards

Which one of the following turning machines permits very long bar stock to be used:

screw machine

89

New cards

Reaming is used for which of the following functions:

enlarge a drilled hole

90

New cards

End milling is most similar to which one of the following:

face milling

91

New cards

A planing operation is best described by which one of the following:

a workpart moves linearly past a single-point tool

92

New cards

A broaching operation is best described by which one of the following:

a tool with multiple teeth moves linearly past a stationary workpart