Productivity and Quality Leadership Test 1

1/60

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

61 Terms

Q: What is productivity?

A: Productivity = Outputs ÷ Inputs

Q: What is value in Lean terms?

A: What the customer wants and is willing to pay for

Q: What is waste in Lean terms?

keeping the value, elimitating the waste

Q: What are the 7 types of waste? (TIMWOOD)

A:

1.. Transportation

2. InventoryMotion

3. Waiting

4. Overproduction

5. Over-processing

6. Defects

Transportation Waste

Movement of product (people can be viewed as product)

Inventory Waste

Excess inventory = BAD or having too much of anything too soon

Motion Waste

Movement of people that does not add value

Waiting Waste

Waiting for anything

Over production waste

making too much or making too soon

Over processing Waste

Part of process we shouldnt do; unnessary to satisfiy customer

Defect Waste

Not doing something right the first time

Q: What are the main Lean Tools?

A: Poka-yoke, Visual Management, 5S, Preventive Maintenance, Just-in-Time (JIT)

Q: What is the goal of Poka-yoke?

A: Prevent mistakes from becoming defects and stop defects from moving further in the process

Q: What are the three levels of Poka-yoke?

Detection, Facilitation, Prevention

Detection Poka Yoke

Catch errors at the source or next step

EX: weighed packages to catch wrong packages

Facilitation Poka Yoke

Make the wrong action difficult

Ex: Golf ball on string in garage so you can park fulling in

Prevention Poka Yoke

Design so that defects are impossible

EX Deisal nozzzle will not fit in regular car

Q: What is the purpose of Visual Management?

A: To clearly convey information so status and priorities are obvious at a glance

Q: Benefits of Visual Management?

A: Reduces need to ask/discuss, eliminates interpretation, shows status, identifies priorities

Q: What is 5S used for?

A: Organizing the workplace to make it more efficient

What are the 5s

1. Sort

2. Set

3. Shine

4. Standardize

5. Sustain

Sort

Keep only what you need

Set

A place for everything

Shine

Keep it clean and inspect

Standardize

All similar processes

Sustain

Make it a habit

Q: What does JIT (Just-in-Time) mean?

A: The right part, at the right time, in the right amount

Q: What does Kanban signal?

A: To produce or stop producing, To move items to consuming location, To place an order

Q: What is the purpose of Preventive Maintenance (PM)?

A: Detect defects early, prevent breakdowns, and plan downtime to avoid costs

Q: What do processes do?

A: Transform inputs into outputs — it's how we do things

Q: What do all processes include?

A: Activities that add value and activities that don't

Q: What is value?

A: What the customer wants and is willing to pay for

Q: What is waste?

A: Anything and everything else besides value

Q: What is a Value Stream Map (VSM)?

A: An extension of a process map that examines and quantifies every step in the process

Q: What does a VSM differentiate?

A: Value-added vs. non-value-added activities

Q: What do you quantify in a VSM?

A: Value, waste, and outputs (time, distance, cycle time, people, equipment, materials)

How to create a VSM?

Observe the current state of the process map

Q: What is a typical representation of value vs. non-value activities?

A: Value-added is usually much smaller than non-value-added

Q: What are two common diagram types used with process mapping?

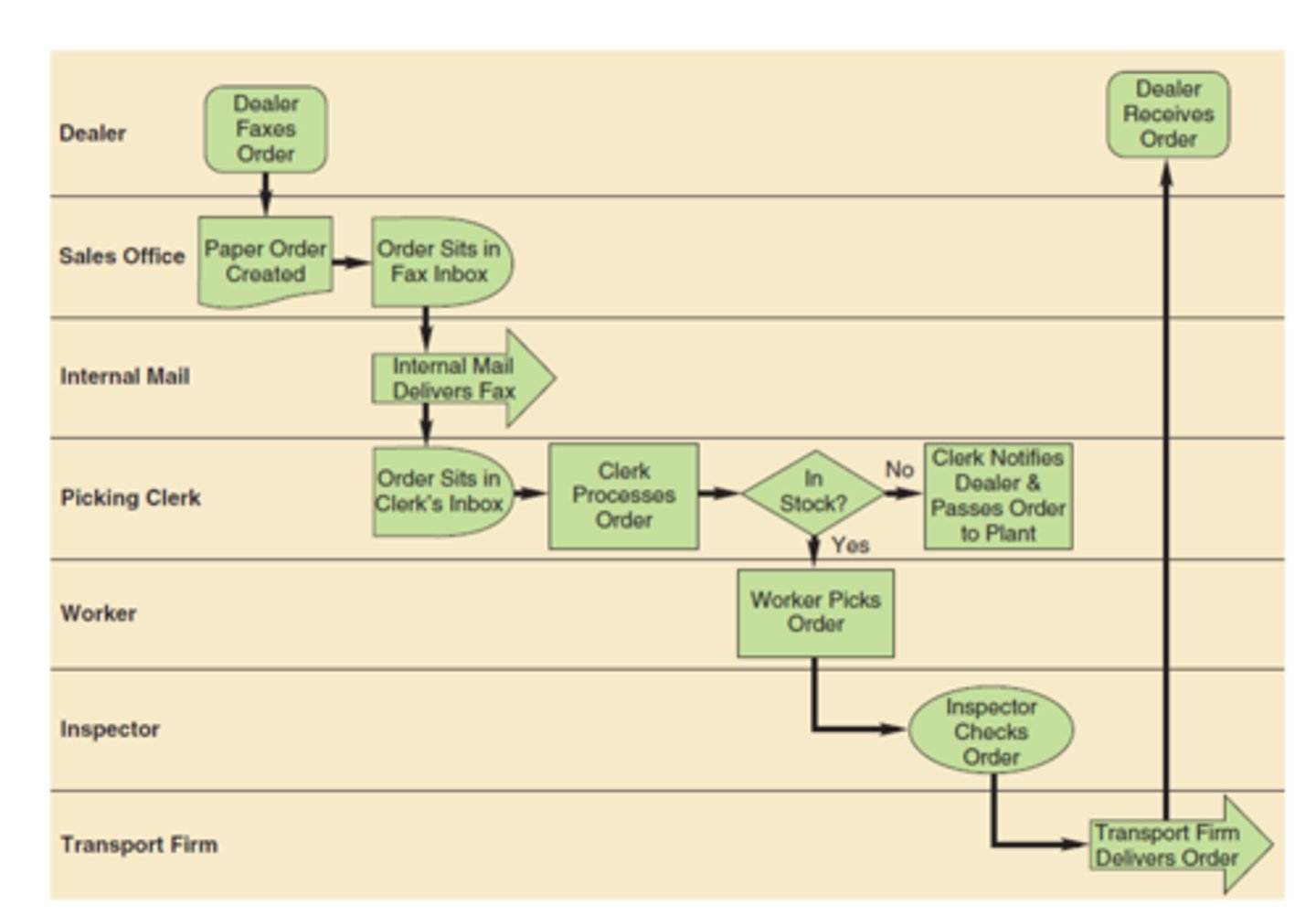

A: Spaghetti diagram and Swimlane diagram

Spaghetti Diagram

visual creation of actual flow

Swim Lane Diagram

shows participants responsibilities for a certain part of the process

Q: Who developed the quality and productivity methods used in Six Sigma?

A: Edwards Deming

Q: What did Deming emphasize about quality?

A: Lower costs and better quality at the same time

Q: What does DMAIC stand for?

A: Define, Measure, Analyze, Improve, Control

Q: What happens in the Define phase?

A: Define the goal and measure of success (MoS); create a project charter

Q: What happens in the Measure phase?

A: Gather data (observations, surveys, interviews, company data) to establish current state and baseline for MoS

Q: What happens in the Analyze phase?

A: Use data visualization (charts, Pareto, benchmarks, best practices) to find root causes

Q: What happens in the Improve phase?

A: Develop solutions and present them visually; create steps for how to implement changes

Q: What happens in the Control phase?

A: Evaluate whether changes improved the MoS and create systems to sustain improvements

Q: What is a MoS (Measure of Success)?

A: A way to measure whether improvements achieved the defined goal

Profit

Revenue - Expenses

(P+Q) - (Vc-Fc)

Quality Tools

1. Process Map

2. Checksheet

3. Histogram

4. Pareto Diagram

5. Scatter Diagram

6. Cause-and-effect Diagram

7. Run Chart

Process Map

A picture of a process. Identifies the sequence of activities or the flow of materials and information in a process

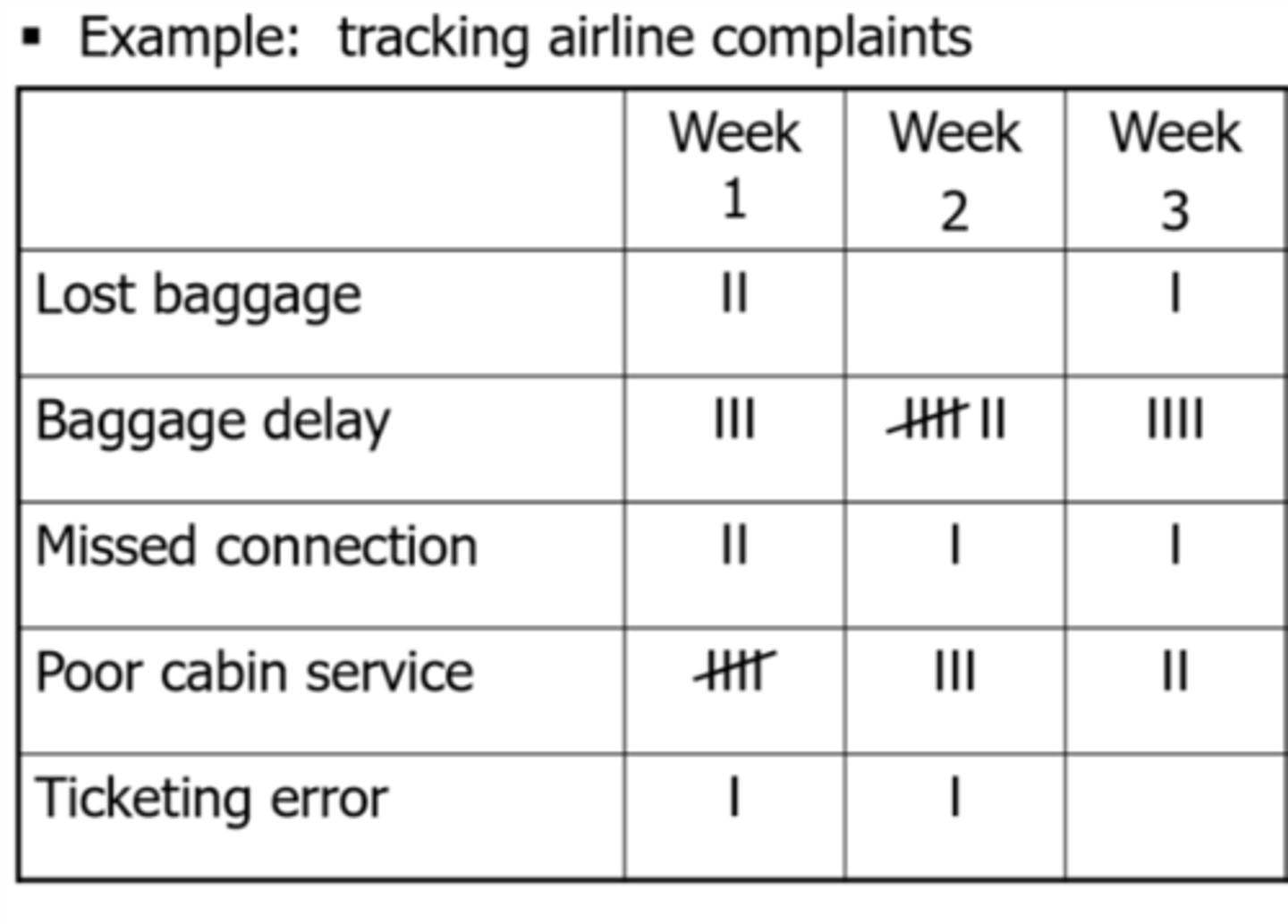

Checksheet

Ensures consistency of data collected. Spot problems. NOT THE SAME AS A CHECKLIST; STARTS OUT EMPTY

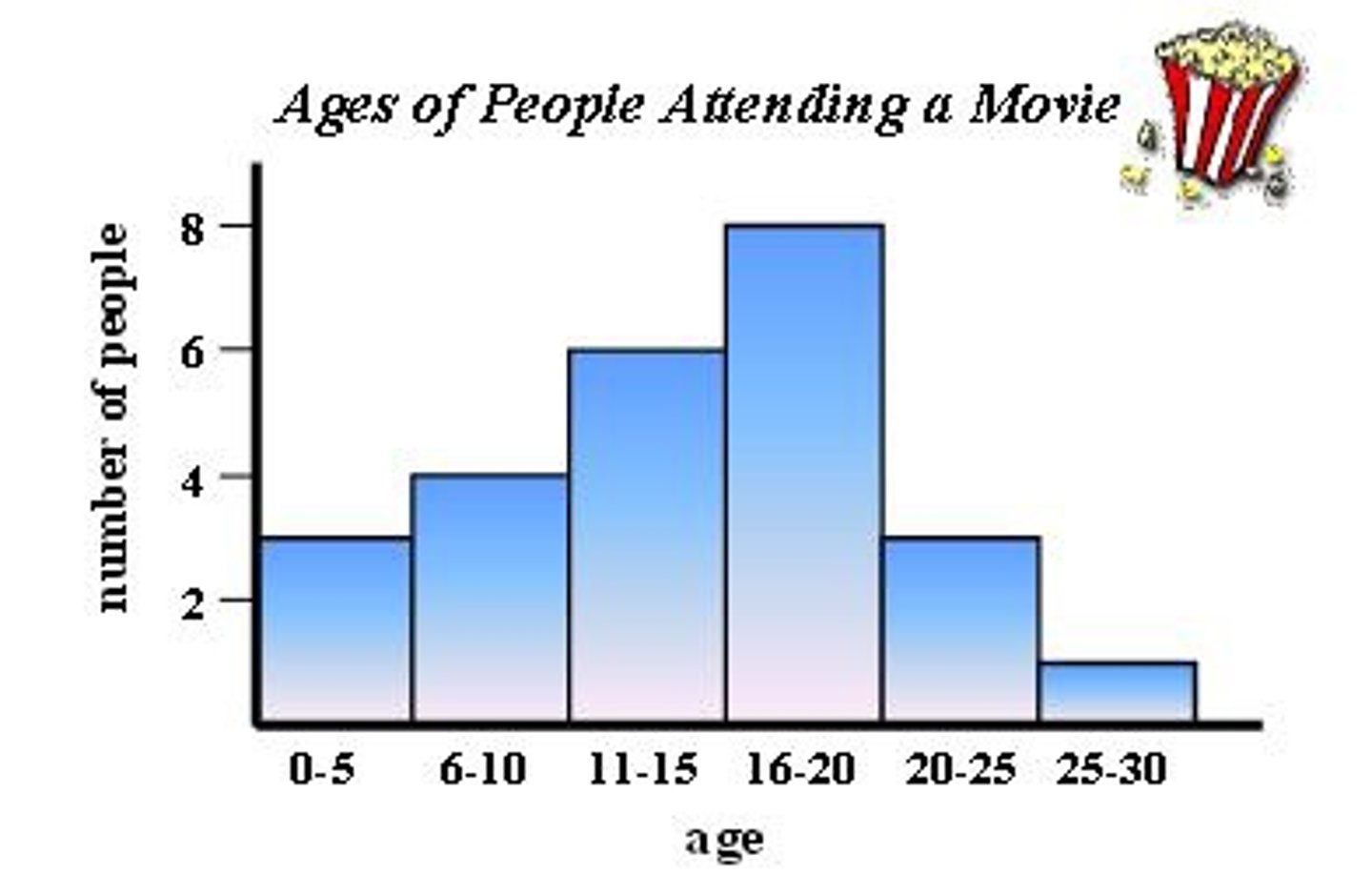

Histogram

Picture of data. Allows us to see patters or trends that are difficult to see in tables or numbers; measures frequency of occurence

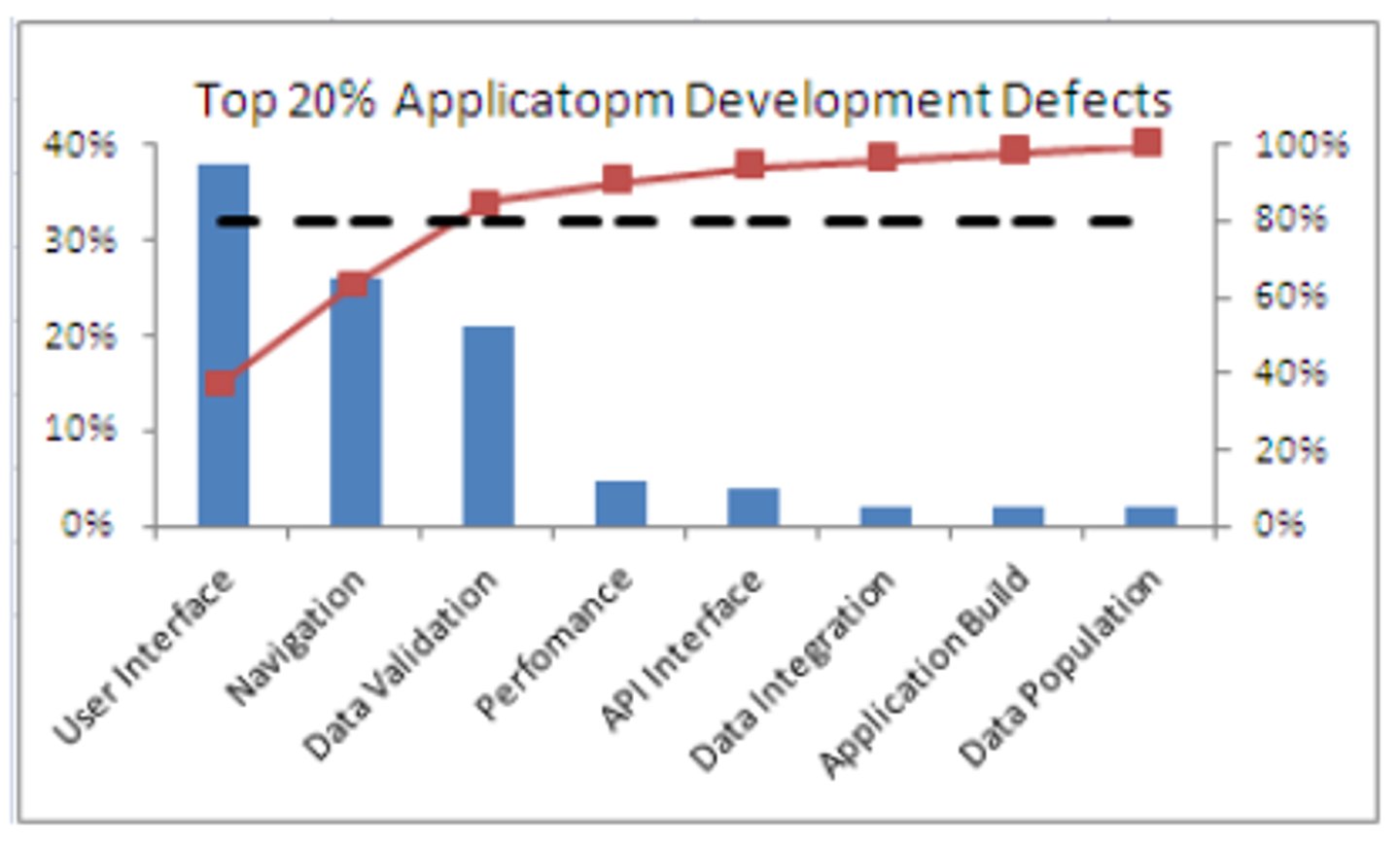

Pareto Diagram

Type of histogram

Shows data from the largest frequency to the smallest (80/20 Rule). Identifies PRIORITY

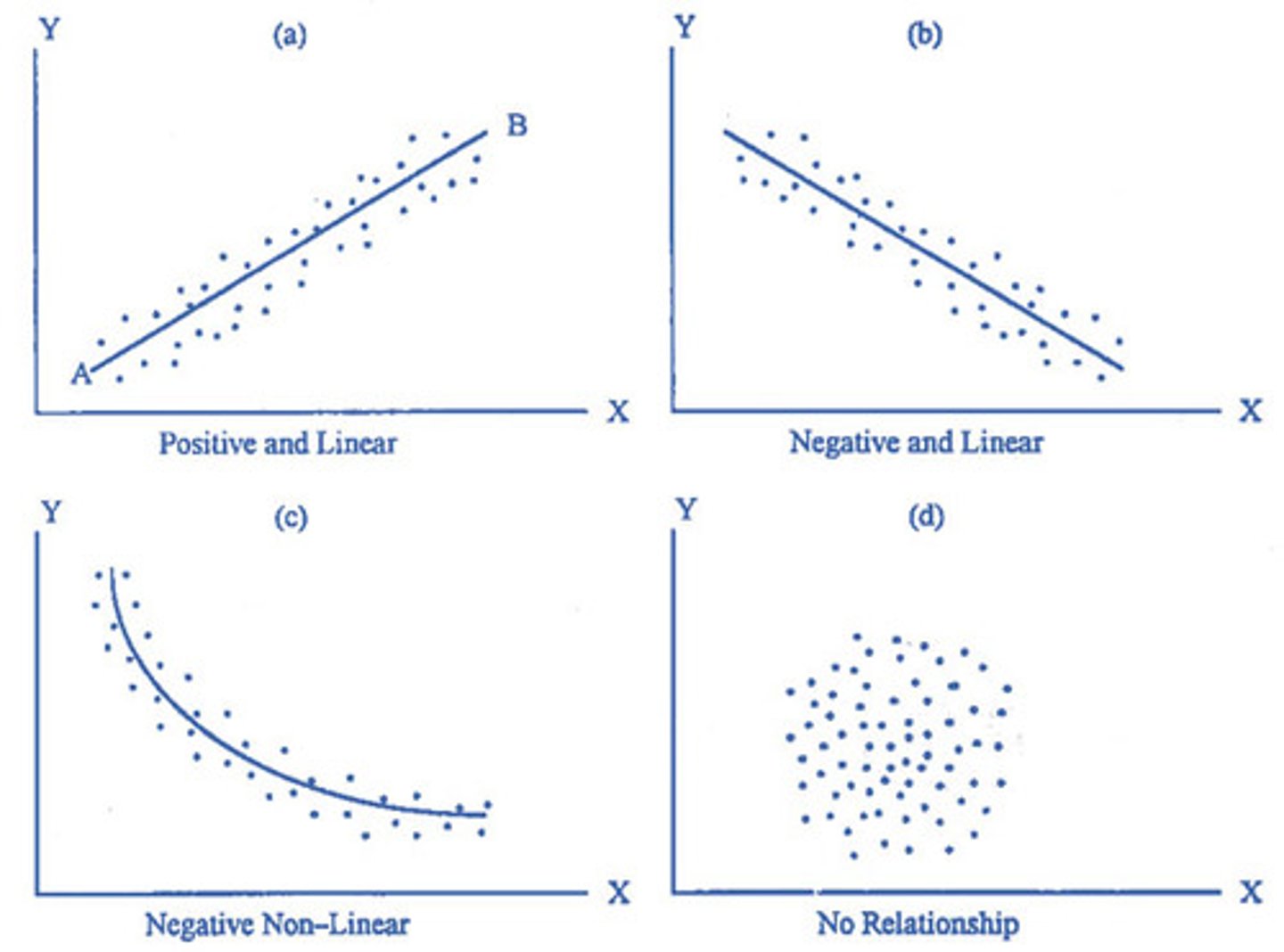

Scatter Diagram

Identifies possible relationships between two different sets of variables. A DISPLAY OF WHAT HAPPENS TO ONE VARIABLE WHEN ANOTHER CHANGES; shows coorelation BUT NOT CAUSATION

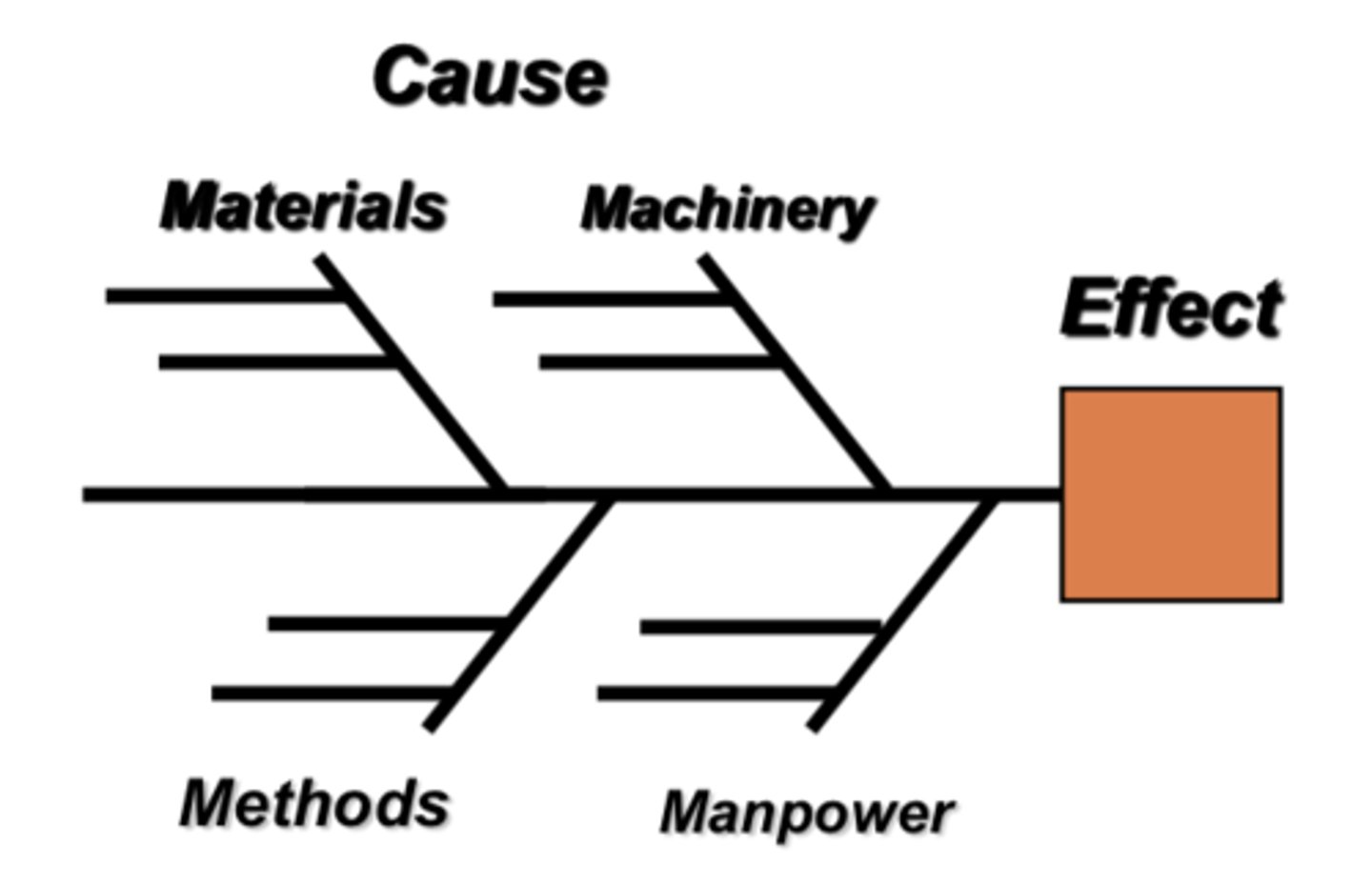

Cause and Effect Diagram (fish bone chart) (5Ms)

Identifies all possible causes of a specific problem

What are the 5 M's in aCause and Effect (Fish bone) Chart?

1. Machine

2. Materials

3. Man

4. Mother Natrue

5. Method

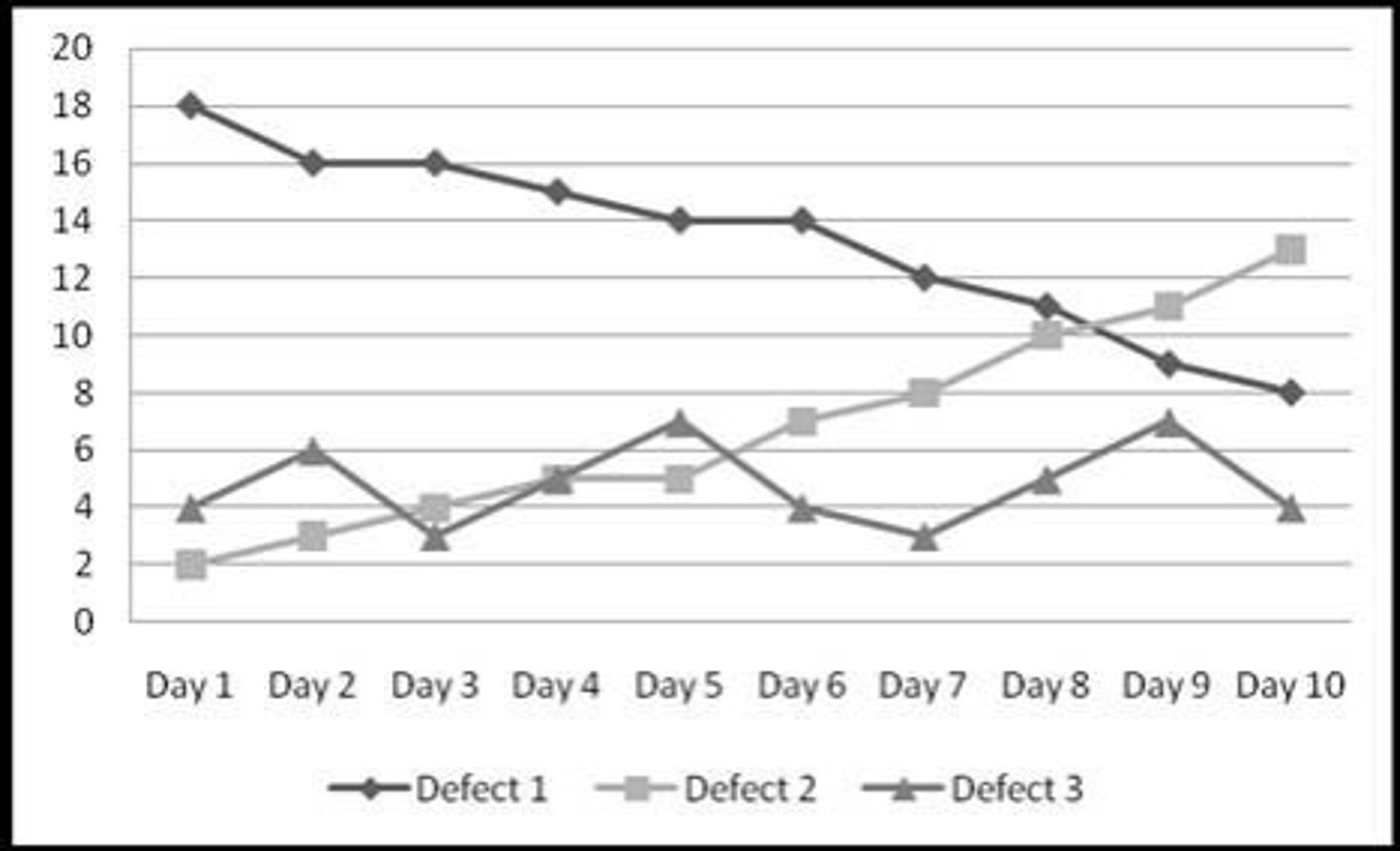

Run Chart

Displays data in the time sequence in which it occurred. helpful in spotting IMPACT OF CHANGE CAN NOT SHOW AVERAGE DATA)

Pareto principle

Establishes priority