8. Foams, gels and the colloidal glass transition

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

Types of foam (shape)

Spherical foams:

It has more continuous phase

Example shaving foam

Polyhedrical foams:

It has thin continuous phase

Example beer foam

Spherical foams might transfer to polyhedrical

Types of foam (stability)

Transient foams:

A foam that is not stable tends to collapse quickly

Examples: detergents, beer, champagne

Stable foams

A foam that is stable doesn’t tend to collapse quickly

Examples: styrofoam, bread etc. (since continuous phase is a solid)

Foams

• Associative liquids → interface with air → needs stabilization by surface active molecules

• Surface costs energy! (high surface energy)

• Gas is hydrophobic since there is low inter-molecular interaction

• Pure liquids do not foam

• Creation of foams

– Whipping/vigorous stirring

– Through small pores

– In situ (gas generation)

Stability of foams

The stability of foams is affected by

Draining

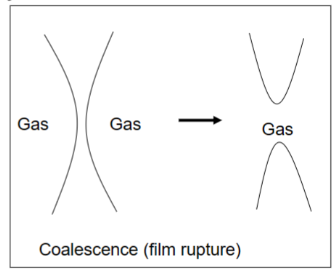

Coalescence

Disproportionation

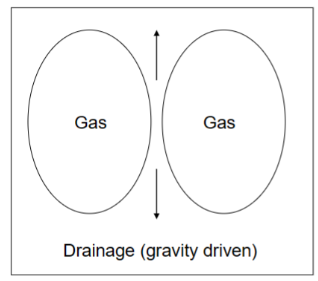

Drainage

liquid between bubbles will drain because of gravity

Fast without surface film (adsorbed layer of surfactant)

Slower with surface film

Rate of drainage depends on the viscosity of the liquid phase (by increasing viscosity (adding thickening agent)→ draining rate will decrease) - for example maräng

Coalescence can occur

Presence of solid particles

Presence of spreading oils destabilizes aqueous interfaces

Coalesence in presence of solid particles

Penetrating particles destabilize → rupture of interface

Typically particles that are not wetted by the liquid phase

Non-penetrating particles stabilize → increase in viscosity of the liquid phase

Coalence in presence of spreading oils destabilizes aqueous interfaces

Spreading along the interface occurs if: γwater/air > γoil/water + γoil/air

Air/water interface collapses

Thick adsorbed layers are more stabilizing → more resistant to deformation.

Large bubbles are less stable against coalescence → more easily deformed

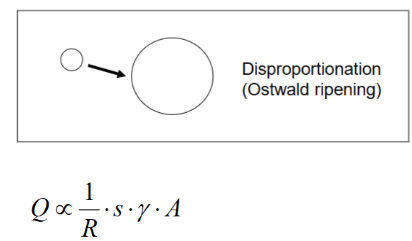

Disproportionation (Ostwald ripening)

Small bubbles “disappear” and large bubbles grow

Driven by the Laplace pressure.

Individual gas molecules dissolve from small bubbles and diffuse to large bubbles.

R=bubble radius

s=solubility of gas

γ=surface tension

A=area of film (per volume gas phase)

Gel formation

• A gel is a system with a considerable yield value (overcome yield value → to make it flow)

• Requires a continuous 3D-network of polymers or particles

Viscous flow can be very low

• Relaxation from one state to another can be very slow

– The time for observing viscous flow can be very long

– Very viscous ”liquids” can appear solid (depending on how long observe it)

Types of gels

• Particle gels

• Polymer gels

• Lamellar structures of surfactants and lipids (cosmetic products like creams → incorporates into the skin)

Polymer gels can form by being

– Covalently linked

– Linked through physical interaction:

• Ion bridges

• Hydrophobic interaction

• Partial crystallization

• Helix formation

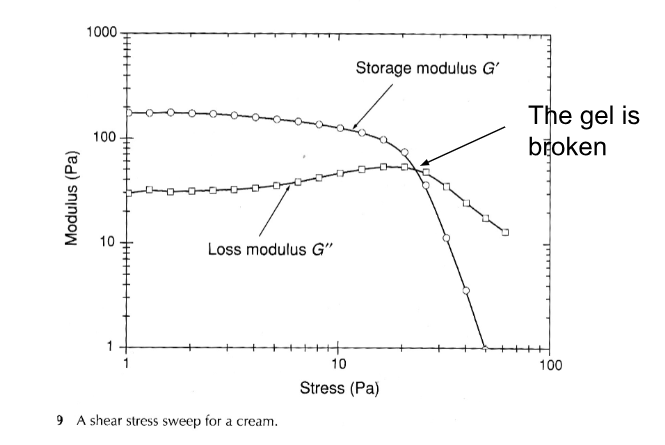

Viscoelasticity for gels

G’= ”in phase” shear modulus = storage modulus = elastic response=”solid-like” contribution.

G’’=”out of phase” shear modulus = loss modulus = viscous response=”liquid-like” contribution.

A characteristic of gels is that G’ > G’’ at low deformation

Colloidal glass

It is formed when colloidal particles are densely packed in a suspension to the point where they form a disordered, amorphous solid-like structure.

Transition from liquid to solid doesn’t depend on temperature and instead occurs at different volume fractions depending on:

• Attractive interaction

• Repulsive interaction

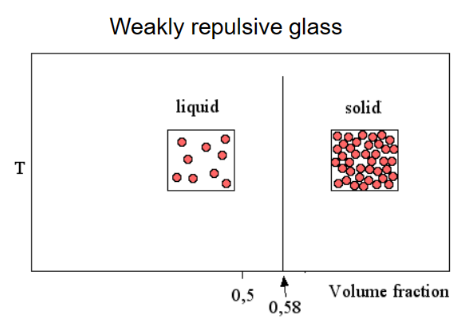

Repulsive glass

Repulsive forces between particles will lead to a transition at higher particle volume fraction. They are forced together even though there is repulsion between them, since there is no more space. It occurs around φg≈0.58

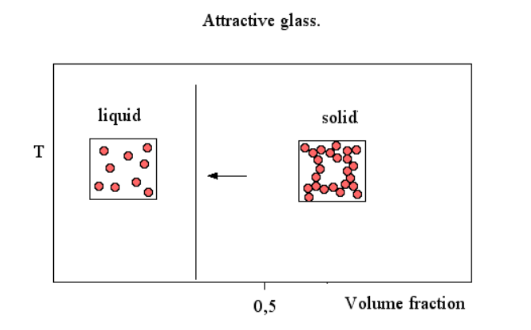

Attractive glass

Attractive forces between particles will lead to a transition at lower particle volume fraction, since it flocculates

Cage effect

One particle is caged by other particles. Occurs for repulsive glass

Long range repulsion compared to short range repulsion

Long range repulsion in a dispersion shifts the colloidal glass transition to a lower volume fraction compared to short range repulsion.