Propulsions II

1/178

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

179 Terms

What is the source for lubricants

Petroleum

What does the process for lubricants begin with

Crude petroleum

Crude is pulled out of the ground and is put in a chamber. It turns into a gas and when it cools below its boiling point heavy stuff at the bottom and light stuff at the top. It is then separated into gasoline, jet fuel, heating oil, lubricating oil

Lubricant definition

Substance with greasy properties used to reduce friction, prevent rust and corrosion on metalica surfaces

How are lubricants classified

Animal, Mineral, Vegetable, and Synthetic

Animal lubricants

Doesn’t produce a lot of heat, highly stable at normal temps

Produces fatty acids at high temps - not good for internal combustion engine

Vegetable lubricants

Not used because they wear away steel by loosening the bonds of iron on the surface (oxidizes when exposed to air)

Has a lower coefficient of friction than most mineral oils

Mineral lubricants

Used on most aircraft engines, chemically stable at high temps

Perform well at low temps

Classified as solid, semisolid, and fluid

Solid Mineral Lubricants

Don’t dissipate heat rapidly enough for high speed machines

Used in a powdered form (talc and graphite)

Semisolid Mineral Lubricants

Very heavy oils (grease)

Not good for continuous operation because the mix varies in consistency

Fluid Mineral Lubricants (oils)

Principle lubricants used in internal combustion engines because they can be pumped and sprayed easily

Fluids

Absorb and dissipate heat quickly

Provides good cushioning

Animal and Vegetable lubricants

Unstable at high temps

Perform poorly at low temps

Mineral Based lubricants

Stable at moderately high temps

Perform well at low temps

Used for reciprocating engines

Synthetic Lubricant

Developed because of the high temperature in aircraft engines

Not made from natural crude oil or are highly modified

Used in turbine engines

Do not evaporate easily, do not break down easily, do not produce coke or other deposits

Lubricating Oil properties

Flash point

Viscosity

Pour Points

Chemical stability

Flashpoint

Temperature at which the oil gets to a point where enough vapor comes off of it that it can ignite

Quick burn

Aircraft oils must have a high flash point because they operate at high temp

Engine operating temperature determines what

Type of oil grade to use

Fire point

Temperature enough vapor coming off the oil oil boiling enough vapor that a CONTINUOUS FLAME can occur over the oil

CONTINUOUS FLAME fiyuhhhh

50-60*F higher than the flashpoint

If used aircraft oil is tested and has a low flash point this means

There is dilluted fuel in the oil

A low fire point means

There is a lot of fuel in the oil

Viscosity

Fluid friction of the oil

High viscosity means its thick

Low viscosity means its thin

The flow of oil is referenced to its

Pour point which indicates the fluidity of oil at low temperatures

Pour point (the pee pee)

Lowest temperatures at which the oil will flow

Why is it important that oil be moving freely

So that the engine will start and can be pumped under colder conditions

Low viscosity oils - colder weather - (thinner)

Higher viscosity oils - warmer weather (thicker)

What is the goal with oil?

Use the lowest viscosity for operating at high temperatures

This ensures a thin film over all moving parts

Oil dilution

Fuel is added to the oil to circulate more readily in cold conditions

Disadvantages out weight advantages so now multigrade oil is used

(Oil dilution) What happens when the aircraft reaches normal operating temps

The fuel is burned off and the oil returns to original characteristics

Chemical stability is starbility against

oxidation (rusting), thermal crackng, and coking (solid product waste), must resist becoming emulsified (mixed with water)

Oil oxidizes at which temps

High

Oil should have

Minimum coefficient of friction

Maximum adhesion to the lubricated surfaces

Good oiliness characteristics

Adequate film strength

Why is lubrication needed

To reduce wear

To reduce power loss of engine from friction

3 types of friction

Sliding- surfaces sliding over eachother

Rolling- surfaces rolling over each other

Wiping- continually changing load on a contacting surface (between gear teeth)

4 factors needed for lubrication

Movement of 2 surfaces on one another

Condition and material of surfaces

Nature of contact movement

Load carried by surfaces

Oil is used not only for lubrication but also

In hydraulic systems,

To lubricate moving parts outside of the engine (prop reduction gear)

6 specific functions of engine oil

Reduce friction (lubricates)

Cools things (coolant)

Seals combustion chambers (sealant)

Cleans engine (cleanser)

Prevents corrosion (protector)

Acts as a cushion (buffer)

Straight mineral oil

Used primarily for break in period for most 4 cycle aviation engines,

Only has one additive

Ashless dispersant oil

Has dispersants that suspend contaminants

“Ashless” comes from additives that leave no ash when burned

Using this means less oil is consumed- Tends to stay cleaner

Grade of oil

Measured by an oils viscosity

Grade to be used in engine is determined by- operating temp and operating speeds

Single grade

industry standard

Flows slowly in colder weather (excessive wear and damage, poor lubrication- too thick)

Reacts poorly to temp change (too hot- gets too thin, too cold- gets too thick)

Multi viscosity oils

Used when needed for quick and easy flow at low temps

Also called multigrade oils

What is the purpose of a lubrication system?

Supply oil to the engine at the correct pressure and volume to provide adequate lubrication and cooling for all parts of the engine subject to friction

What is needed from each part of the lubrication system?

Oil tank - Must have adequate capacity

Oil pump - Volume and pressure must be good

Oil cooler - Oil must be cooled properly

What are the three different types of lubrication systems used on aircraft

Pressure lubrication system - Most aircraft use this or a combination of it and splaish/spray

Splash lubrication system

Spray lubrication system

Describe the pressure lubrication system (before manifold)

A mechanical pump is used to supply oil under pressure

Oil flows into the inlet side of the pump from the oil sump

The inlet is high enough on the sump so no sediment is drawn in

The pump forces oil into a manifold

Describe the pressure lubrication system (after manifold)

The oil manifold distributes to the crankshaft bearings

Oil flows from the crankshaft main bearings through to the connecting rod bearings

Oil for the camshaft comes straight from the oil manifold and flows out through the camshaft to the bearings and cams

Engine cylinder surfaces and piston pins are lubricated via a spray system

What are the components of lubrication systems?

Pressure oil pump, oil pressure relief valve, oil reservoir, oil pressure gauge, oil temperature gage, oil filter, piping and connections, oil cooler

Pressure oil pump

Either gear type or vane type

The pump can deliver more oil to the engine then required. This is so as the engine wear down there are greater clearances and more oil can fill those gaps

Replace the pump when oil pressure is not achieved within 30sec of engine startup

Oil pressure relief valve

Control and limit the lubricating oil pressure

Design consists of an oil pressure relief valve that is a plunger and spring

Oil reservoir

Must be enough oil to supply the engine at max operating temperature

Heating the engine thins out the oil so you need more

Oil supply is broken into usable and unusable oil

Oil pressure and temp gage

Pressure gage - Located where the oil enters the crankcase

Temp gage - Located in the oil inlet line or passage between the pressure pump and engine system

What type of oil filter system do most aircraft have?

Full flow type oil system - All of the oil is filtered

Partial flow type oil system - Only 10% of the oil filtered, this is on older aircraft

Filters may be simple screens which may or may not be disposable

What is the best place to to inspect for internal engine wear

Oil filter

Oil lines

Orange on the outside is a fire sleeve that protects the oil on the inside from excess heat

Subject to vibration- flexible lines

Little vibration- rigid lines

Oil cooler

Forces oil to follow through passages back and forth in cooler which have ram air passing through the.

Oil is going up and down in a S shape while the air is going in between the S

Open and closes based on oil temp

Wet sump system

Gravity returns it back for you

Not for aerobatic flight

Sprays against the back of the pistons and then goes down to the reservoir by gravity

Dry sump system

Supply line in the resivor in the bottom gets pumped up to the rest of the engine

Flexible weighted internal hose can still pump even in inverted flight

Return line takes the rest of that oil through a cooler back to the reservoir

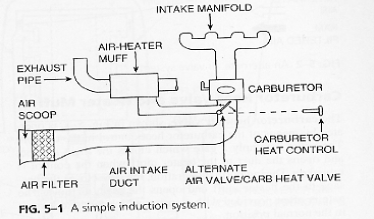

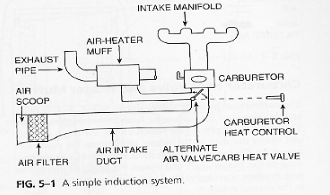

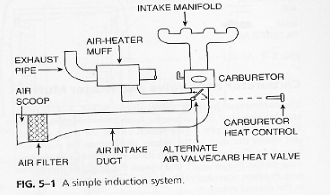

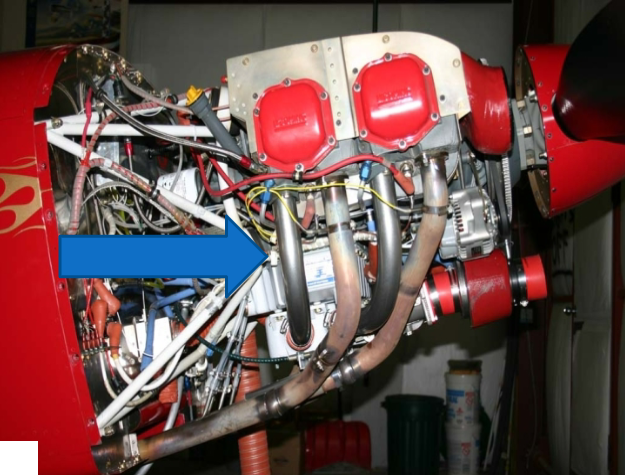

Complete induction system

Three sections

Air scoop and duct leading to carburetor

Carburetor or air control section

Intake manifold and pipes

Air scoop and ducting section has 4 parts

Air scoop

Air filter

Alternate air valve

Carburetor heat air valve or heater muff

Air scoop

Opening facing airstream

Scoop receives ram air- usually augmented by the prop slipstream

Compression adds to the total weight of air received making it supercharged

Air filter

Installed at or near air scoop

Remove dirt, sand and abrasive particles before going into the engine

Reduce air pressure somewhat because they slow down the air

How any types of air filters are there

3

Foam soaked with oil

Paper - at 500 hours replace the filter because people were keeping them until they had massive holes

Alternate air valve

Allows air to get to the engine if filter or other parts become clogged

Either unfiltered warm from the engine or outside cold air

What are the functions of the alternate air valve

Counter carb ice

Use in heavy rain situations

Carburetor heat air valve and heater muff

Operated from cockpit

Heater muff is a shroud placed around exhaust pipe

Prolonged use of carb heat causes what

Prolonged use of carburetor heat may also cause detonation especially at high power settings

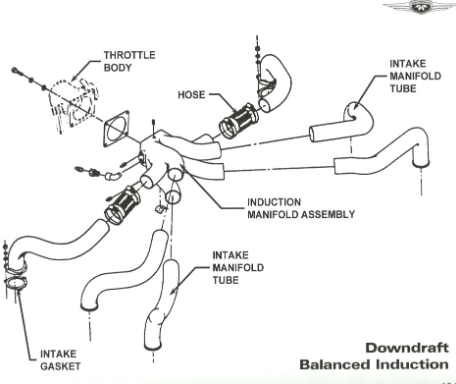

Intake manifolds

Sends the pressurized fuel-air mixture into cylinders

One pipe per cylinder

Sometimes the intake manifold piping will extend to the oil sump which cools the oil slightly and to increase the temperature of the charge for better vaporization of fuel

Downdraft and updraft induction

Updraft induction - Air goes from the bottom to the cylinder

Downdraft induction - Air goes from the top down to the cylinder

Manifold absolute pressure

Is below atmospheric in unsupercharged engines

Induction system icing

Can cut off flow of the fuel-air ratio

Three types of induction system icing:

Impact ice

Fuel evaporation ice

Throttle ice

Supercharger

A supercharger is an air compressor used to force more air into the combustion chamber of an internal combustion engine that can be achieved with standard atmospheric pressure

Considered supercharged when MAP is over 30Hg

Superchargers consist of

A centrifugal compressor connected to the air intake

Compressor can be driven by gearing from crankshaft and exhaust gasses (turbine)

What is a turbocharger

A supercharger that is turbine driven

What is the difference between a turbine and an impeller

Turbine- rotating device that is turned by an outside force such as air or water flowing past it to transform energy into power or to drive a compressor

Impeller- A rotating device used to force air or water in a desired direction under pressure can be the main rotor of a radial compressor which increases the velocity of the air being pumped

Engine normalizer

Raise the pressure in an engine but not above 30 Hg to compensate for the decreased air density

Capacity of supercharger depends on

Size of impeller

The speed its rotating

Manifold absolute pressure

Pressure in the intake manifold of an engine

In a normally aspirated engine MAP is less than atmospheric pressure due to friction loss within induction system

At what altitude can you use a supercharger with an engine with a high compression ratio

5000 or higher or else you fuckin die (detonation or preignition)

What does higher octane fuel allow for

Greater super charging (common fucking sense) (u cant put 100LL in a damn 737)

What is the purpose of supercharging

To increase the MAP above atmospheric pressure

Increasing MAP increases power output in 2 ways

Increases weight of charge delivered to engine cylinders

Increases compression pressure

What is the difference between a internal and external supercharger

The difference is where the supercharger is located in the engine system

EXTERNAL (turbocharger) - JESS WAKE THE FUCK UP ITS BEFORE THE CARB. The dense air wants to take more fuel, receives its power from the engine exhaust

Internal - After the carburetor

Turbo vs Turbosupercharger

If the air only compresses only to 30Hg then its called a turbocharger, if higher than 30Hg than its a turbosupercharger

Waste gate

Where exhaust gases are diverted to the turbochargers

The degree to which is open determines the degree of turbocharging

Turbochargers can deliver excess power up until

Their critical altitude

After critical altitude the charger will no longer deliver full power for which it was designed

Turbocharger limitations

Max and min engine RPM

Max MAP

Max Cylinder head temp

Range for carb inlet air temp

Turbocharger lubrication is accomplished at

Lower pressure than standard for an engine

whats the upper deck pressure of these zyns in my mouth

100

Deck pressure

Pressure between the discharge of the compressor and engine throttle valve

Maintains 28-30 Hg in a normalized engine or higher for boosted engine

Manifold pressure

Pressure after the throttle valve

What does a density controller do

Limits MAX MAP to prevent over boost and limiting deck pressure when aircraft is below engines critical altitude

Differential pressure controller

Regulates the waste gate position maintains preset differential across throttle usually 2-3 in

Variable pressure controller

Takes place of density and differential pressure controllers and controls both max MAP and regulates the differential

Often has a cam follower to preset for throttle setting

Over-boost control valve

Spring operated valve in the intake that opens when pressure gets too high

Overboost

When MAP exceeds the limits at which the engine was tested and certified by the FAA

Overshoot

Occurs when the automatic controls do not respond quickly enough to stop the inertia of the turbocharger speed increase with a rapid throttle increase (use small throttle movements)

Bootstrapping

Could be from a sticky or stuck waste gate

Basically because its sticky the controller sends too much oil pressure and then when there’s too much it sends less basically chasing its tail because the waste gate is stuck

What is turbine inlet temperature TIT?

Measurement of the EGT at the turbocharger turbine inlet

Why is excessive heat harmful in a reciprocating engine

Overheating - Fuel/air mixture is too hot, and you won’t get as good combustion, preignition or detonation may occur

Weakens and shortens the life of the engine - Parts may also warp and the engine may seize

Impairs lubrication - The viscosity of the oil is reduced

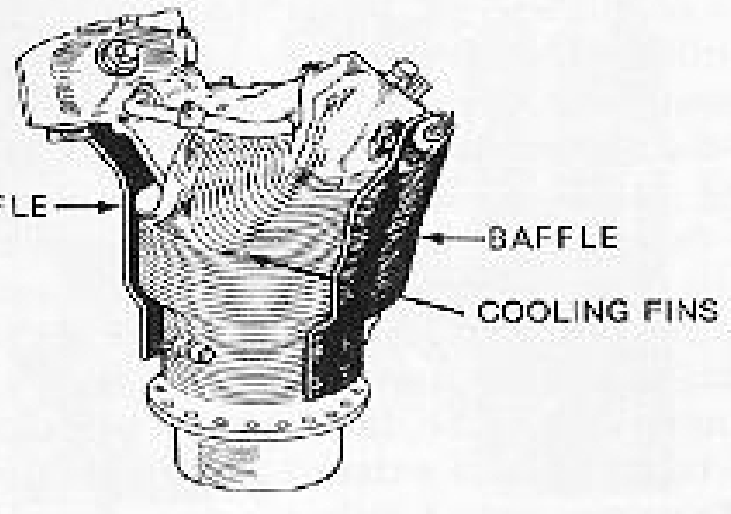

How is cooling achieved in an air-cooled engine?

Engines that are air cooled use thin fins that extend from the cylinder wall/head, as air flows over the fins excess heat is absorbed via conduction

Some cylinders use deflector baffles which are used to direct the flow of air for max cooling

Proper installation of the baffles is essential otherwise hot spots will occur

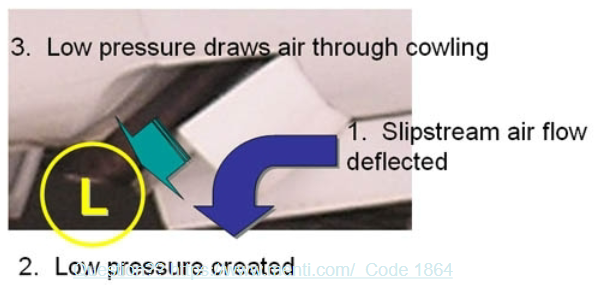

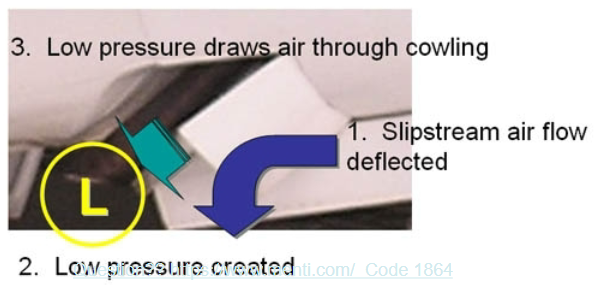

How else are engines air cooled?

Cowl flaps

Manual or automatic

Creates low pressure which draws air through the cowling

The majority of cooling is still tied to what?

Exhaust gasses venting out correctly