Materials Part C - Powder metallurgy

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

19 Terms

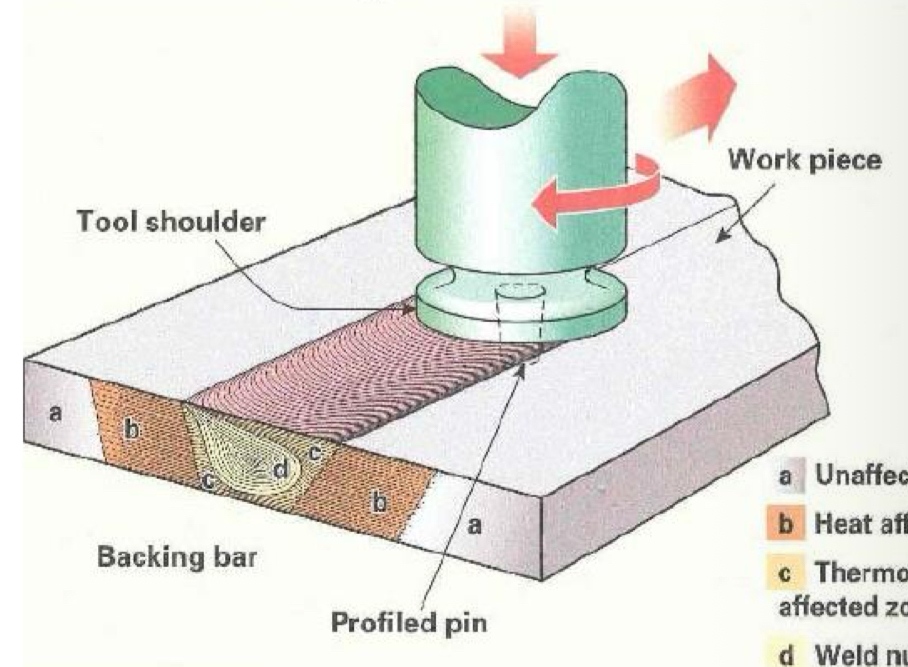

How is friction stir welding done?

Rotating tool with flat face is pressed ontop of mating edge and draw across seam while spinning so soften and join the metals.

What are the advantages behind friction stir welding?

Excellent mechanical properties

No porosity or distortion

Non consumable tool can be used for many operations

Can be used for on the spot repair work

What are the disadvantages behind friction stir welding?

Expensive equipment

Very difficult to apply to some materials.

What are some applications for friction stir welding?

Shipbuilding and marine structures

Wings, fuel tanks

train bodies, railway tankers, container bodies

What are the main manufacturing processes in powder metallurgy?

Additive layer manufacturing

Metal Injection moulding

Hot isostatic pressing

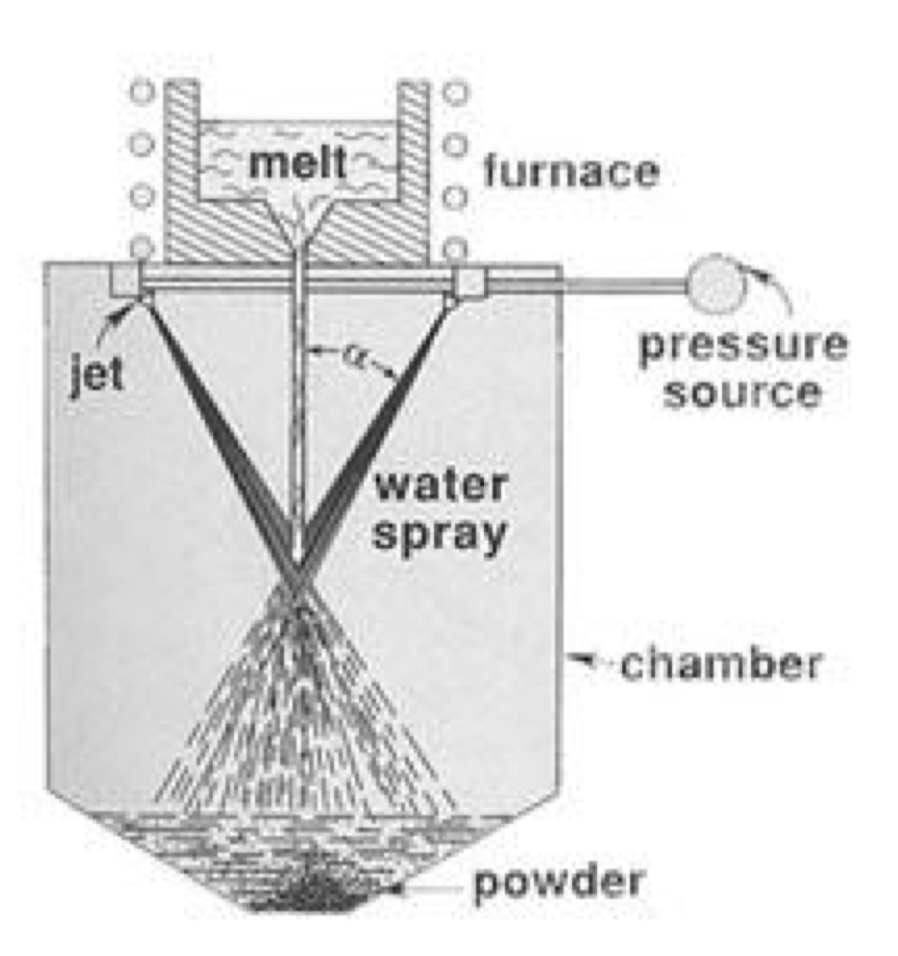

How is the metal powder created?

Through a repaid solidification process where a liquid stream of metal is blasted with an inert gas or water.

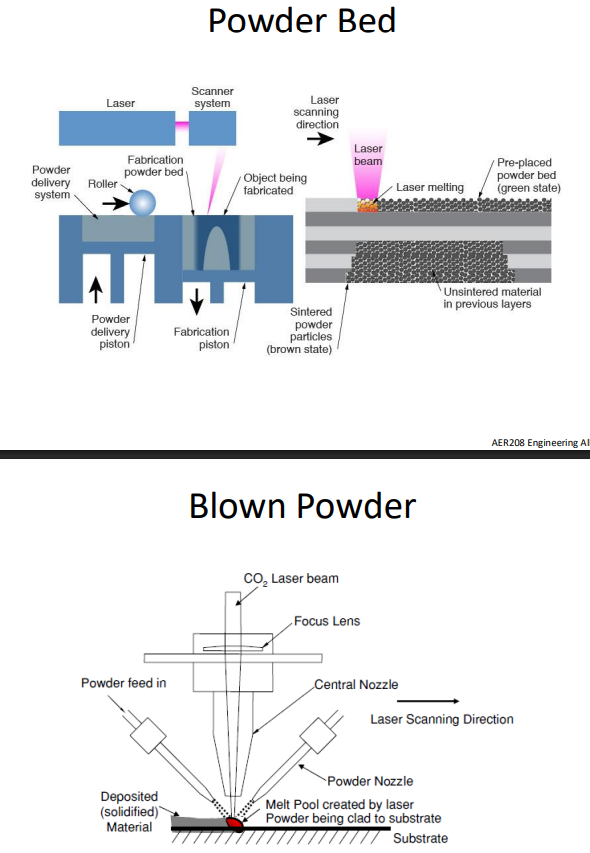

What are the 2 types of powder additive layer manufacture?

Blown powder

C02 laser is used to melt layers of powder in place are they blown in by several nozzles

Powder bed

Powder is inserted layer by layer and a laser passes over each layer solidifying the powder in area where it is needed.

What are some drawbacks behind this method of manufacturing (laser systems specifically)?

Since heating is very localised, surrounding powder is cold leading to residual stress in the part

Thin walls are almost impossible

What are other limitation with additive style manufacture?

Creation of overhangs is difficult leading to wasted support material.

Cant have enclosed space for powder bed manufacture since void will be full of loose powder.

What are the advantages of using electron beam instead?

Preheating occurs on every layer

This leaves the part annealed with no residual stress

Fatigue properties are therefore much better than cast parts and comparable to forged

What are the overall advantages to additive manufacture processes?

Shorter lead time therefore designs can be iterated faster

Less wasted material

Allows for more creative freedom when making parts

Can use difficult to machine alloys

What are 2 other powder metal processing routes?

Metal injection moulding

Hot Isostatic Pressing

What are the main stages involved in metal injection moulding?

Metal powder and binder is mixed

Binder metal mix is heated and forced into mould

Part is then placed in oven and heated further to remove binder

Part is placed in even hotter oven and fed with highly pressurised noble gas to compress and sinter final part

This is done to remove porosity left from the binder.

What are some considerations when looking at metal injection moulding of a part?

Powder need to be of high quality (spherical and fine)

Binder - Secret formula

Careful handling of debinded part (high porosity)

Sintering - Correct atmosphere and temperature are required

Part shrinkage

What are advantages to metal injection moulding?

Offers high flexibility for chemistry and geometry

Much lower energy footprint per part than casting

What are some limitations for metal injection moulding?

Carbon pickup

Powders for specialty alloys are very expensive

What are key advantages of hot isostatic pressing?

Consolidation of materials in solid state

Minimises segregation of heavy atoms (happens in melt routes)

Smaller grain size than sintering

Heals porosity of castings

What are some key considerations of hot isostatic pressing?

Capsule needs to be manufactured

Efficient at transferring pressure

Joinable

Low cost

Design of part needs to be carefully considered and process needs to be simulated

Removal of mould requires strong acids and is a lengthy process

Give key conclusions to HIP?

Costly

Complex

Low volume

Shape and surface quality is excellent