EGN 3365 Exam 2

5.0(2)

Card Sorting

1/76

Earn XP

Description and Tags

Last updated 4:29 PM on 3/9/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

77 Terms

1

New cards

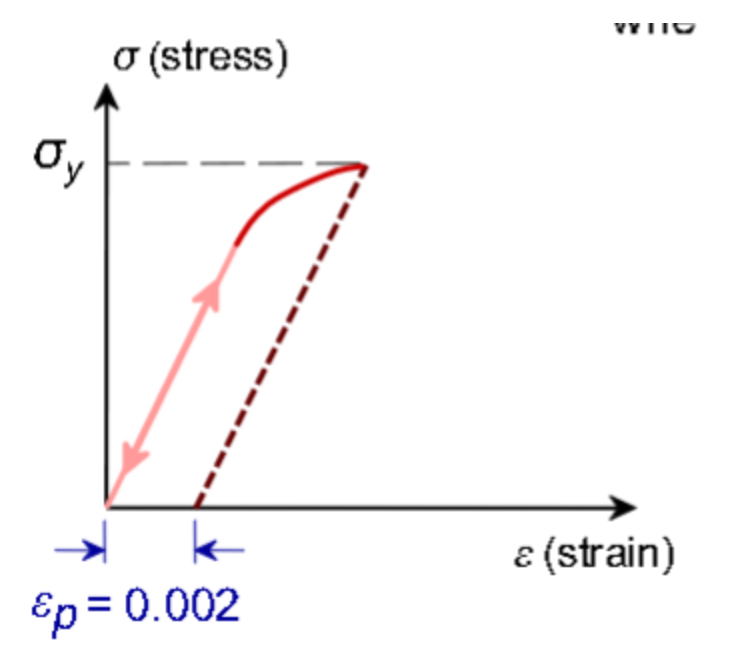

The given stress-strain graph represents?

Elastic then plastic deformation

2

New cards

What does the figure represent?

Simple compression

3

New cards

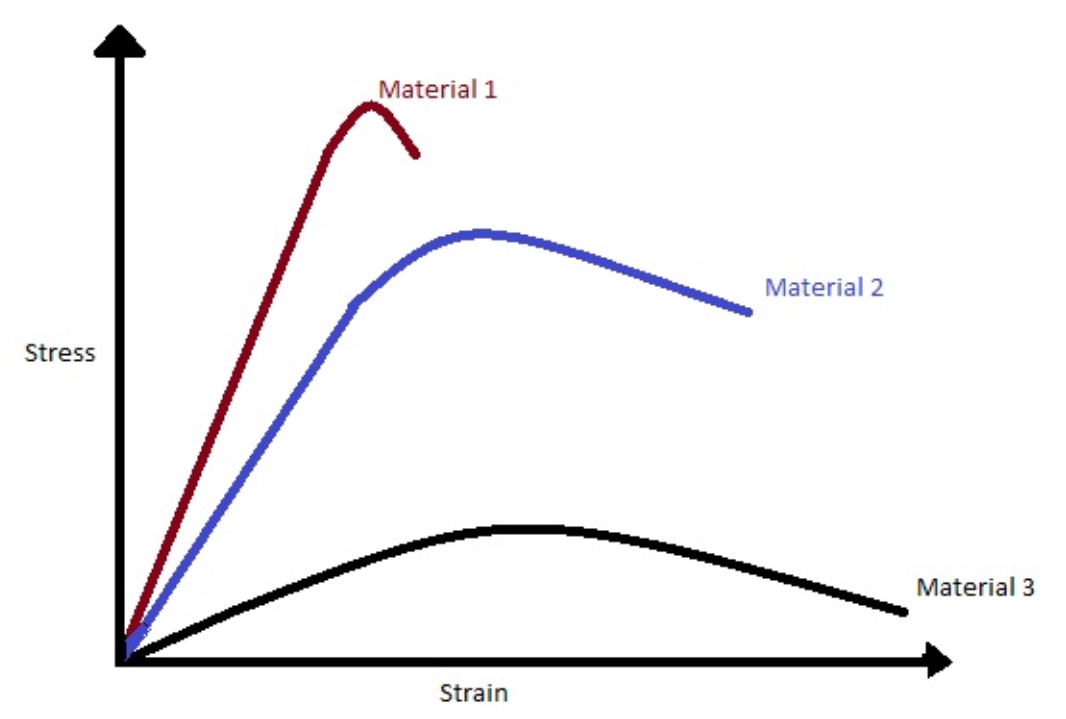

Which material has the highest toughness?

Material 2

4

New cards

For an engineering strain of 1, calculate percentage elongation (ductility) of the specimen?

100

5

New cards

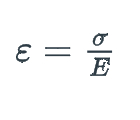

A specimen of copper having a rectangular cross-section 15.2 mm X 19.1 mm is pulled in tension with 44,500 N force, producing only elastic deformation. Calculate the resulting strain. ( Elastic modulus of copper = 110 GPa)

1\.39 x 10^-3

6

New cards

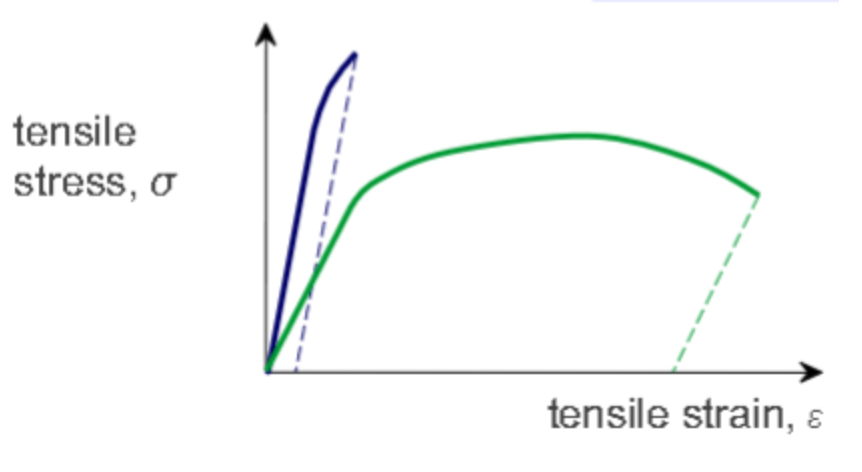

Ductility is the amount of plastic deformation at failure.

From the given graph below, determine which line represent a material with high ductility and which line represent a material with low ductility.

From the given graph below, determine which line represent a material with high ductility and which line represent a material with low ductility.

Blue line: Low ductility.

Green line: High ductility.

Green line: High ductility.

7

New cards

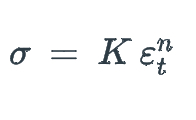

For some metal alloy, the true stress of 345 MPa produces a plastic true strain of 0.02. How much does a specimen of this material elongate when true stress of 415 MPa is applied if the original length is 500 mm? Assume a value of 0.22 for the strain-hardening exponent, n.

23\.7mm

8

New cards

Poisson's ratio for metals, ceramics and polymers is in the range:

0\.15 < v

9

New cards

Deformation of a sample to an engineering strain of 2 means that the sample is ___________ its original length.

A. Half

B. Twice

C. Three times

D. 2% longer than

A. Half

B. Twice

C. Three times

D. 2% longer than

Three times

10

New cards

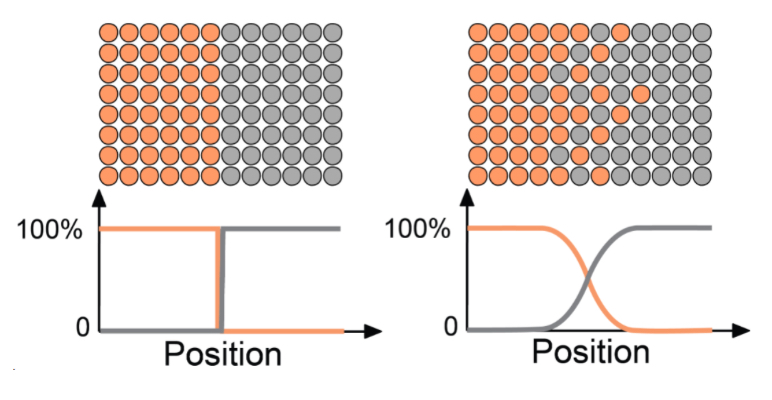

What best describes the figure?

A. Not an example of diffusion

B. Left: before diffusion, right: after diffusion

C. Left: after diffusion, right: before diffusion

D. None of the above

A. Not an example of diffusion

B. Left: before diffusion, right: after diffusion

C. Left: after diffusion, right: before diffusion

D. None of the above

Left: before diffusion; right: after diffusion

11

New cards

What is diffusion

Mass transport by atomic motion

12

New cards

Atoms tend to _____________ from regions of _____________ concentration to regions of _____________ concentration.

Migrate, high, low

13

New cards

What is self-diffusion?

Migration of host atoms in pure metals

14

New cards

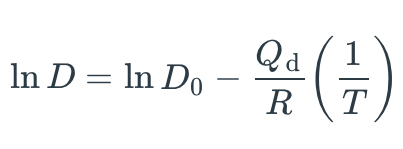

What is the derivation of the equation relating the diffusion coefficients at two temperatures T1 and T2, given that:

D₂ = D₁exp \[-Qd/R(1/T2-1/T2)\]

15

New cards

At 300°C the diffusion coefficient and activation energy for Cu in Si are

D₁ (300°C) = 7.8 × 10⁻⁻¹¹ m²/s

Qd = 41.5 kJ/mol

Compute the diffusion coefficient D₂ at 400°C.

D₁ (300°C) = 7.8 × 10⁻⁻¹¹ m²/s

Qd = 41.5 kJ/mol

Compute the diffusion coefficient D₂ at 400°C.

28\.46 × 10⁻⁻¹¹ m²/s

16

New cards

Non-steady state diffusion is a function of:

Time and position

17

New cards

Fick’s first law of diffusion is applicable to

Steady state diffusion

18

New cards

What’s Fick’s second law of diffusion?

dC/dt = D d²C/dx²

19

New cards

What's Fick’s first law of diffusion?

J = −D dC/dx

20

New cards

What’s the relationship between the diffusion coefficient and temperature?

Increases with increasing temp

21

New cards

What is interdiffusion?

Diffusion of atoms of one material into another material

22

New cards

Diffusion rate of vacancy diffusion depends on

Number of vacancies, activation energy

23

New cards

interstitial diffusion

smaller atoms diffuse between adjacent atoms, faster than vacancy diffusion

24

New cards

Case hardening is an example of _________ diffusion

Interstitial

25

New cards

case hardening

outer surface is hardened by diffusing carbon atoms into surface

26

New cards

Doping

adding impurities to a semiconductor to increase conductivity

27

New cards

Process of doping

1. P rich layers on surface

2. Heat it

3. Doped semiconductor regions

28

New cards

Diffusion is faster for

open crystal structures, materials with secondary bonding, smaller diffusing atoms, lower density materials

29

New cards

Tensile load (pulling)

If a specimen is being elongated or extended

30

New cards

Compressive load (pushing)

Specimen is compressed or contracted

31

New cards

Deformation

Change in dimension

32

New cards

shear forces

Parallel to cross sectional area

33

New cards

Plastic deformation

permanent change in shape by bending and folding

34

New cards

Elastic deformation

material returns to original state when stress is removed

35

New cards

Common states of stress

Simple tension, torsion, simple compression, bi-axial tension, hydrostatic compression

36

New cards

Yield strength

point where the material begins to plastically deform

37

New cards

Toughness

the ability of a material to resist fracture

38

New cards

Hardness

resistance to localized surface deformation and compressive stresses

39

New cards

Resilience

Ability of a material to store energy

40

New cards

Ductility

amount of plastic deformation at failure

41

New cards

Engineering stress

tensile, shear

42

New cards

Engineering strain

tensile, lateral, shear

43

New cards

Percent elongation

the total percent increase in length of a specimen during the tensile test

44

New cards

Dislocation

A defect where atoms are misaligned around it

45

New cards

Edge dislocation

extra half plane of atoms inserted into a crystal structure

46

New cards

Dislocation line

The line where dislocations happen

47

New cards

Screw dislocation

lattice plane shifts similar to a spiral staircase

48

New cards

Burgers vector

measure of lattice distortion

49

New cards

Twin boundary

a reflection of atom positions across the twin plane

50

New cards

Solidification

Result of casting molten material

51

New cards

Grain boundaries

Regions between grains (crystals)

52

New cards

Point defects

vacancy, interstitial atoms, substitutional atoms

53

New cards

Vacancies are

vacant atomic sites

54

New cards

Dislocations move when

Stresses are applied

55

New cards

A catalyst \____________ the rate is a chemical reaction without being consumed

Increases

56

New cards

Dislocation types include

Edge, screw, and mixed

57

New cards

two diffusion mechanisms

vacancy and interstitial

58

New cards

The applied mechanical force is normalized to

Stress

59

New cards

The degree of deformation is normalized to

strain

60

New cards

Elastic deformation is

nonpermanent and reversible

61

New cards

Plastic deformation is

permanent and nonrecoverable

62

New cards

Stiffness

a material's resistance to elastic deformation

63

New cards

Strength

A materials resistance to plastic deformation

64

New cards

In an optical microscope, grain boundaries appear as white lines after the surface is prepared by etching. T/F

false

65

New cards

According for Fick’s first law, the concentration of diffusing species is a function of both time and position. T/F

false

66

New cards

D_interstitial << D_substitutional

T/F

T/F

false

67

New cards

In edge dislocation, burger’s vector is perpendicular to dislocation line. T/F

true

68

New cards

Diffusion coefficient _________ with increasing temperature

increases

69

New cards

What are the interfacial defects?

twin boundaries, grain boundaries, stacking faults

70

New cards

I can observe individual atoms using an optical microscope. T/F

false

71

New cards

What’s an example to processing using diffusion

case hardening

72

New cards

Interstitial diffusion is more rapid than vacancy diffusion. T/F

true

73

New cards

Equiaxed grains are

Roughly the same dimension in all directions

74

New cards

Columnar grains are

grains elongated in one direction

75

New cards

Rate of diffusion is __________ of time

independent

76

New cards

Diffusion is ____________ of time

dependent

77

New cards

What are the 5 interfacial defects?

external surfaces, phase boundaries, optical boundaries, twin boundaries, stacking faults