Powder Metallurgy | Quizlet

1/13

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

14 Terms

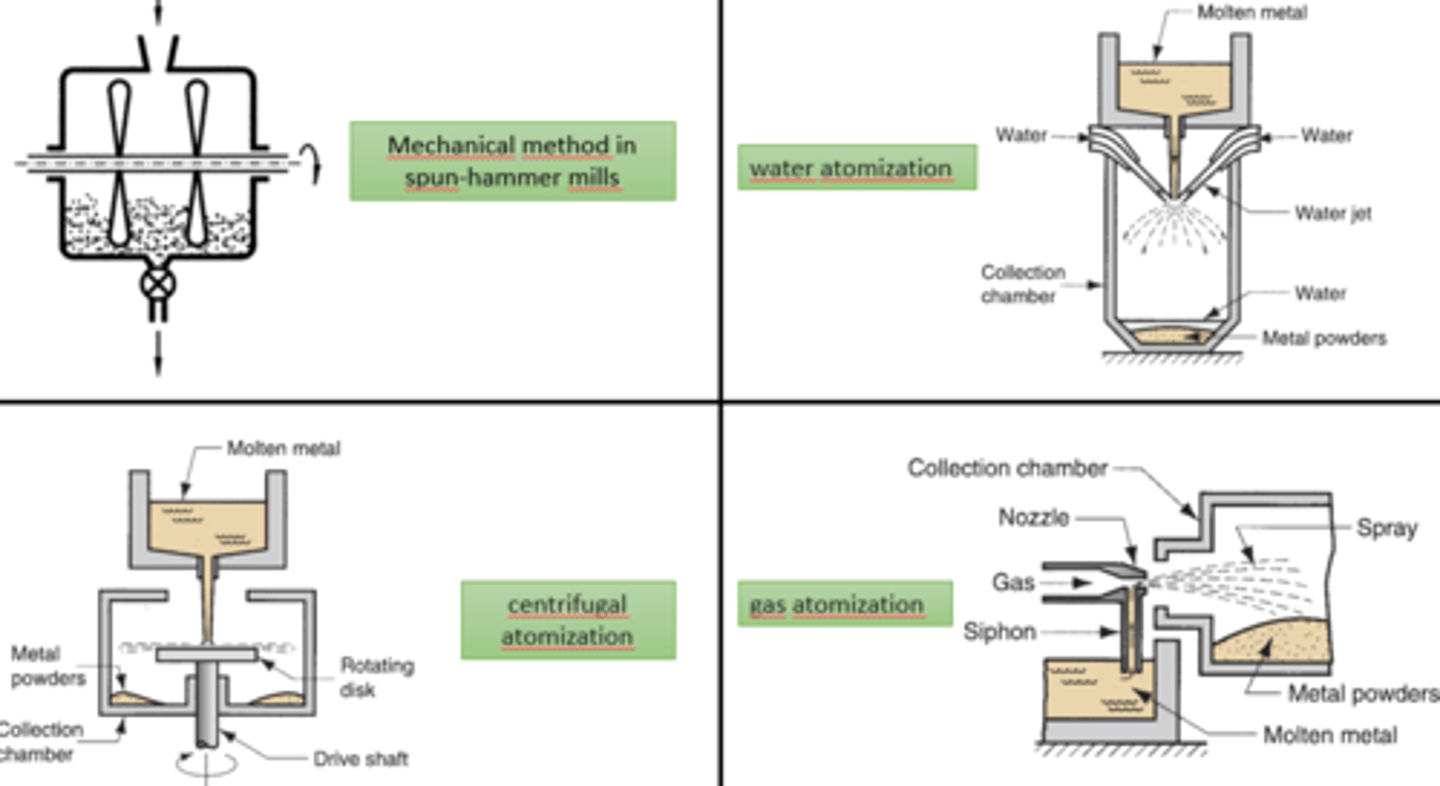

Powders fabrication

Sedimentation

which involves measuring the rate at which particles settle in a fluid

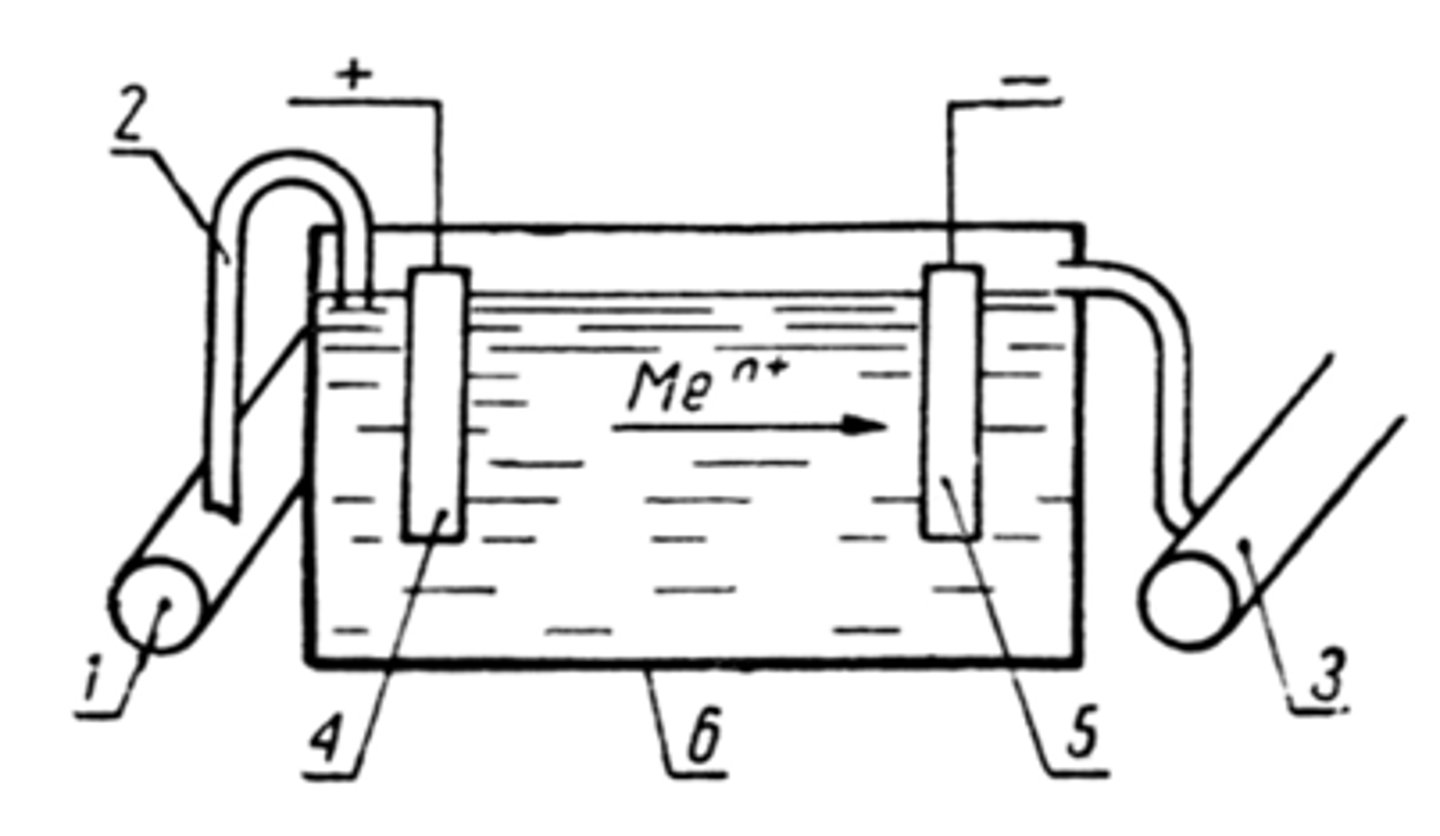

electrolysis

• In electrolysis, an electrolytic cell is set up in which the source of the desired metal is the anode. The anode is slowly dissolved under an applied voltage, transported through the electrolyte, and deposited on the cathode. The deposit is removed, washed, and dried to yield a metallic powder of very high purity. The technique is used for producing powders of beryllium, copper, iron, silver, tantalum, and titanium.

• In short, the process uses electricity to move metal atom by atom from an impure source (the anode) to a new location (the cathode), leaving the impurities behind.

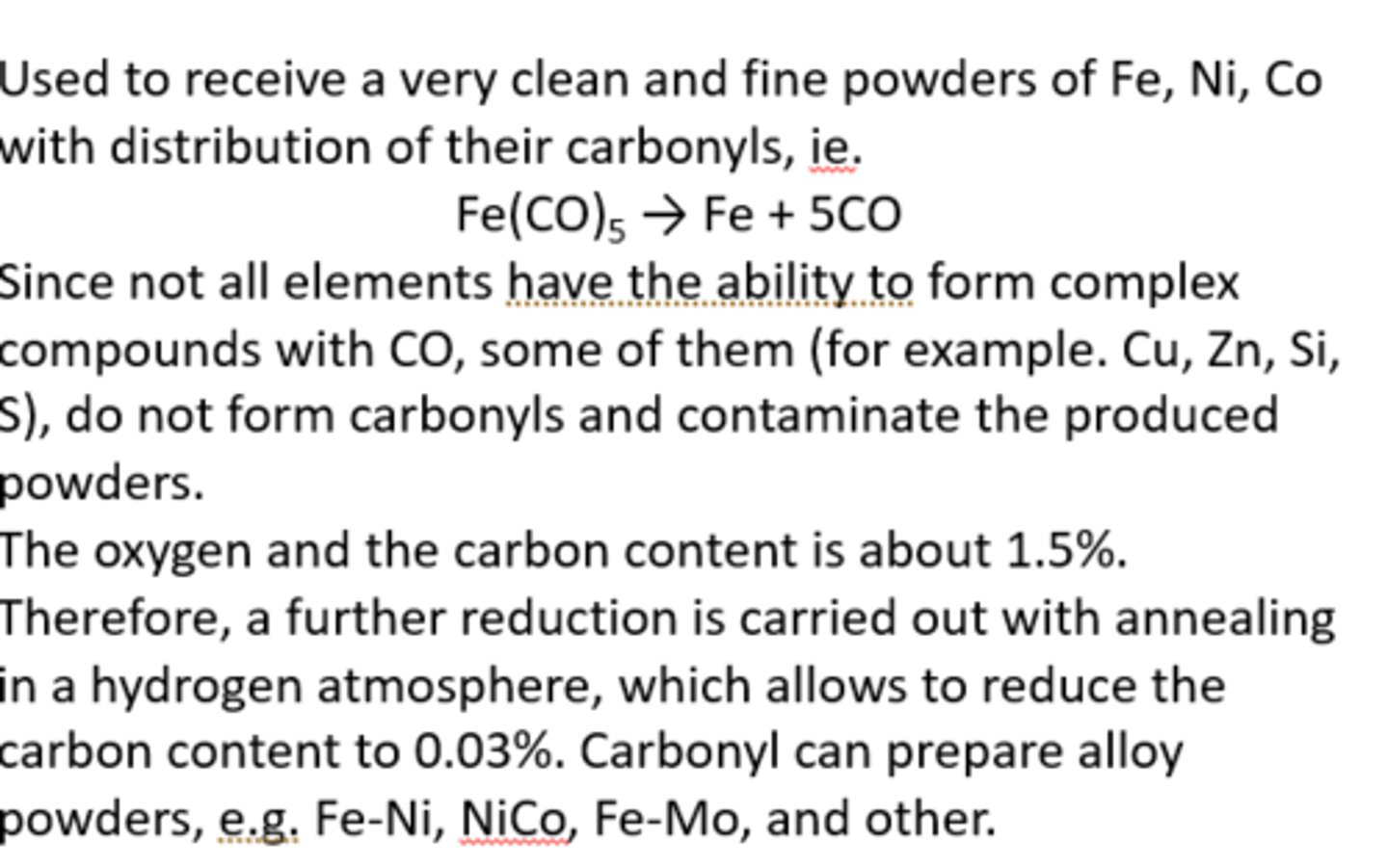

Mond process (carbonyl method)

Particle shapes

The shape of the particles is determined by how they are fabricated, not the type of material.

Screening

Particle size usually is measured by screening—that is, by passing the metal powder through screens (sieves) of various mesh sizes.

Light scattering

1.from a laser that illuminates a sample consisting of particles suspended in a liquid medium. The particles cause the light to be scattered, and a detector then digitizes the signals and computes the particle-size distribution.

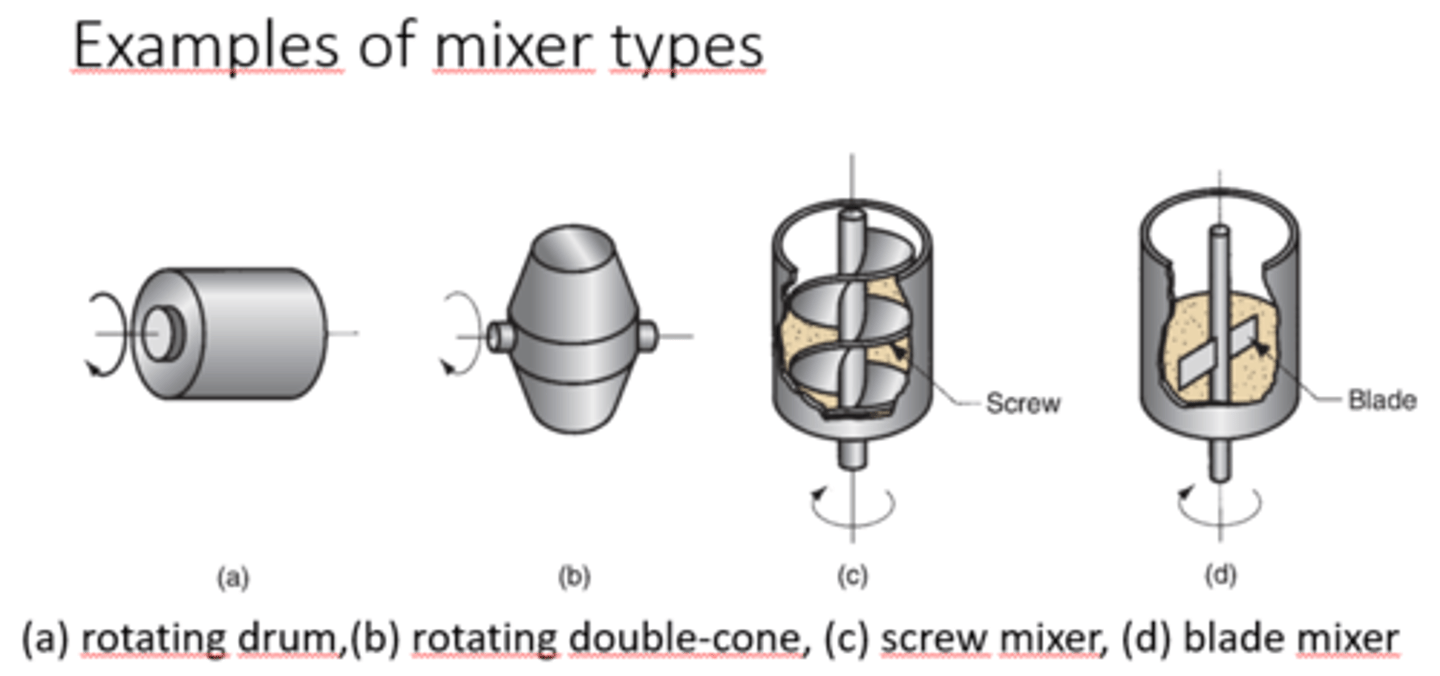

Powder mixing

Preparation of powders for compaction include mixing:

• Base powder

• Lubricants, such as stearates of zinc and aluminum, wax, paraffine, graphite, in small amounts to reduce friction between particles and at the die wall during compaction

• Binders, which are required in some cases to achieve adequate strength in the pressed but unsintered part

• Deflocculants, which inhibit agglomeration of powders for better flow characteristics.

Mixing time is typically 20 – 60 minutes.

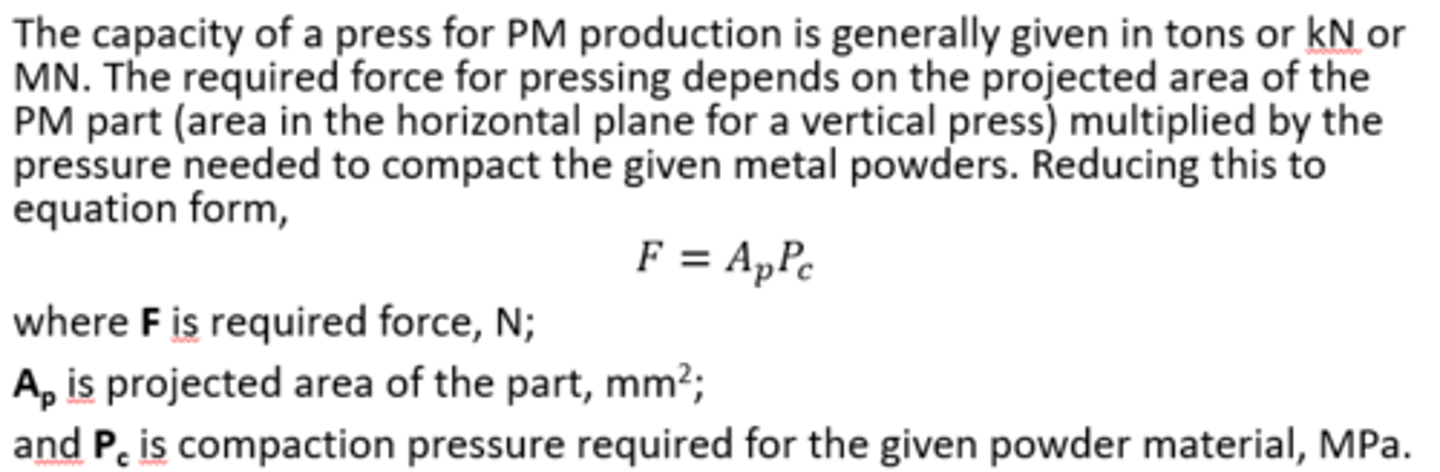

Matrix compression

• In compaction, high pressure is applied to the powders to form them into the required shape. The conventional compaction method is pressing, in which opposing punches squeeze the powders contained in a die.

• Compaction pressures typically range from 70 MPa for aluminium powders to 700 MPa for iron and steel powders.

green compact

• The work part after pressing is called a green compact, the word green meaning not yet fully processed. As a result of pressing, the density of the part, called the green density, is much greater than the starting bulk density.

• The green strength of the part when pressed is adequate for handling but far less than that achieved after sintering.

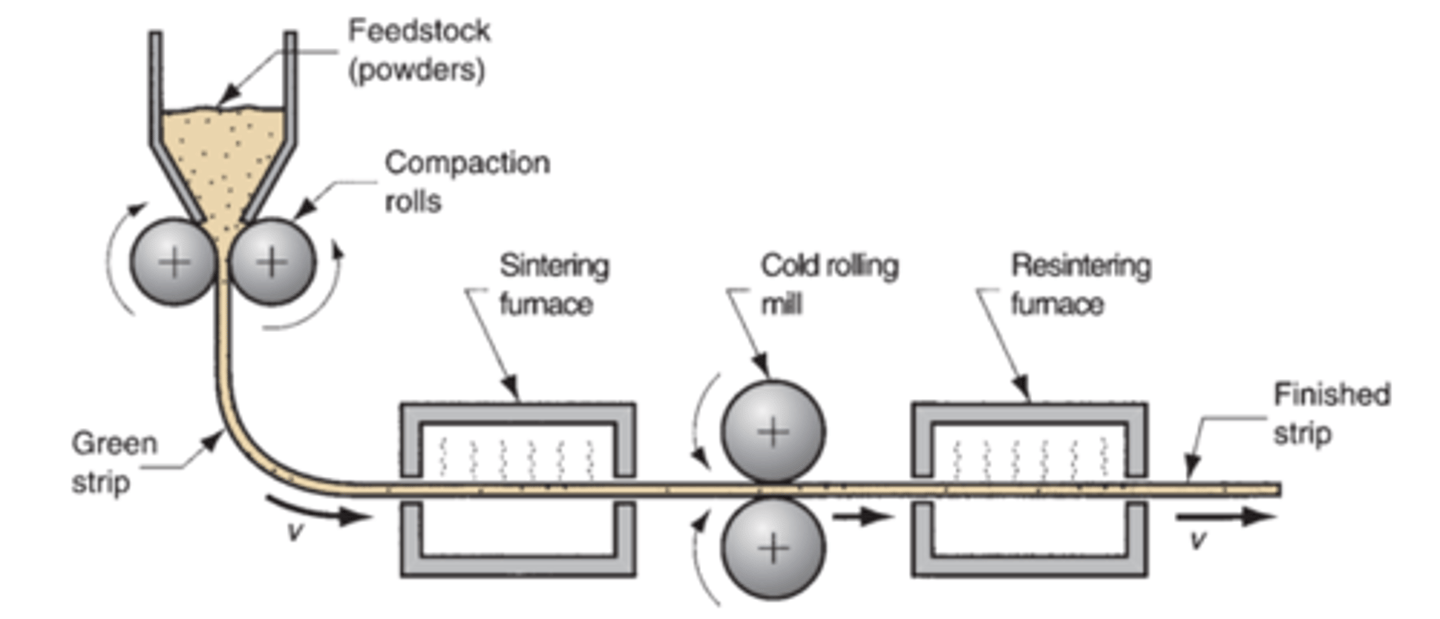

Powder rolling

• Powders can be compressed in a rolling mill operation to form metal strip stock. The process is usually set up to run continuously or semicontinuously. The metallic powders are compacted between rolls into a green strip that is fed directly into a sintering furnace.

• Powder rolling allow to fabricate both uniform and bimetallic strips.

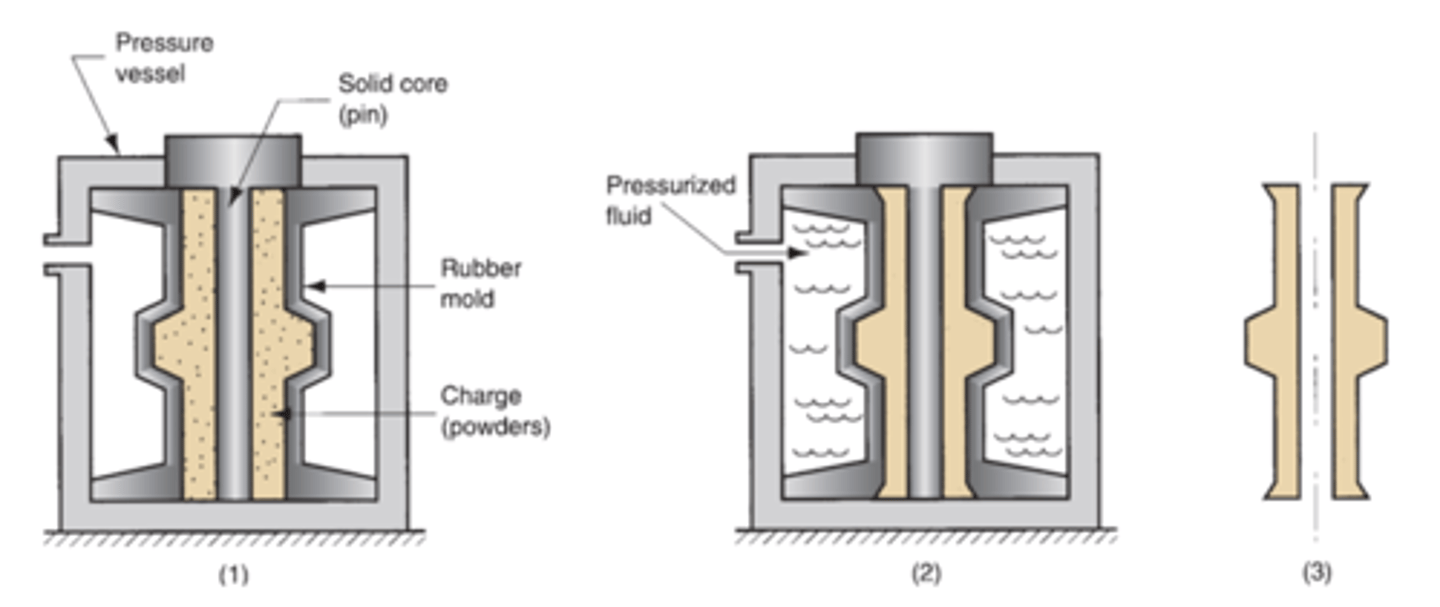

Isostatic pressing

In isostatic pressing, pressure is applied from all directions against the powders that are contained in a flexible mold; hydraulic pressure is used to achieve compaction. Isostatic pressing takes two alternative forms: cold isostatic pressing (CIP) and hot isostatic pressing (HIP).

The main advantages of isostatic pressing are the following:

1.Because of the uniformity of pressure from all directions and the absence of die-wall friction, it produces fully dense compacts of practically uniform grain structure and density (hence, isotropic properties), irrespective of part shape.

2.HIP is capable of handling much larger parts than those in other compacting processes.

The limitations of HIP are as follows:

1.Wider dimensional tolerances than those obtained in other compacting processes.

2.Higher equipment cost and production time than are required by other processes.

3.Applicability only to relatively small production quantities, typically less than 10,000 parts per year.

Powder injection molding (PIM)

Injection molding is closely associated with the plastics industry. The same basic process can be applied to form parts of metal or ceramic powders, the difference being that the starting polymer contains a high content of particulate matter, typically from 50% to 85% by volume.

The steps in PIM proceed as follows:

1.Metallic powders are mixed with an appropriate binder.

2.Granular pellets are formed from the mixture.

3.The pellets are heated to molding temperature, injected into a mold cavity, and the part is cooled and removed from the mold.

4.The part is processed to remove the binder using any of several thermal or solvent techniques.

5.The part is sintered.

6.Secondary operations are performed as appropriate.

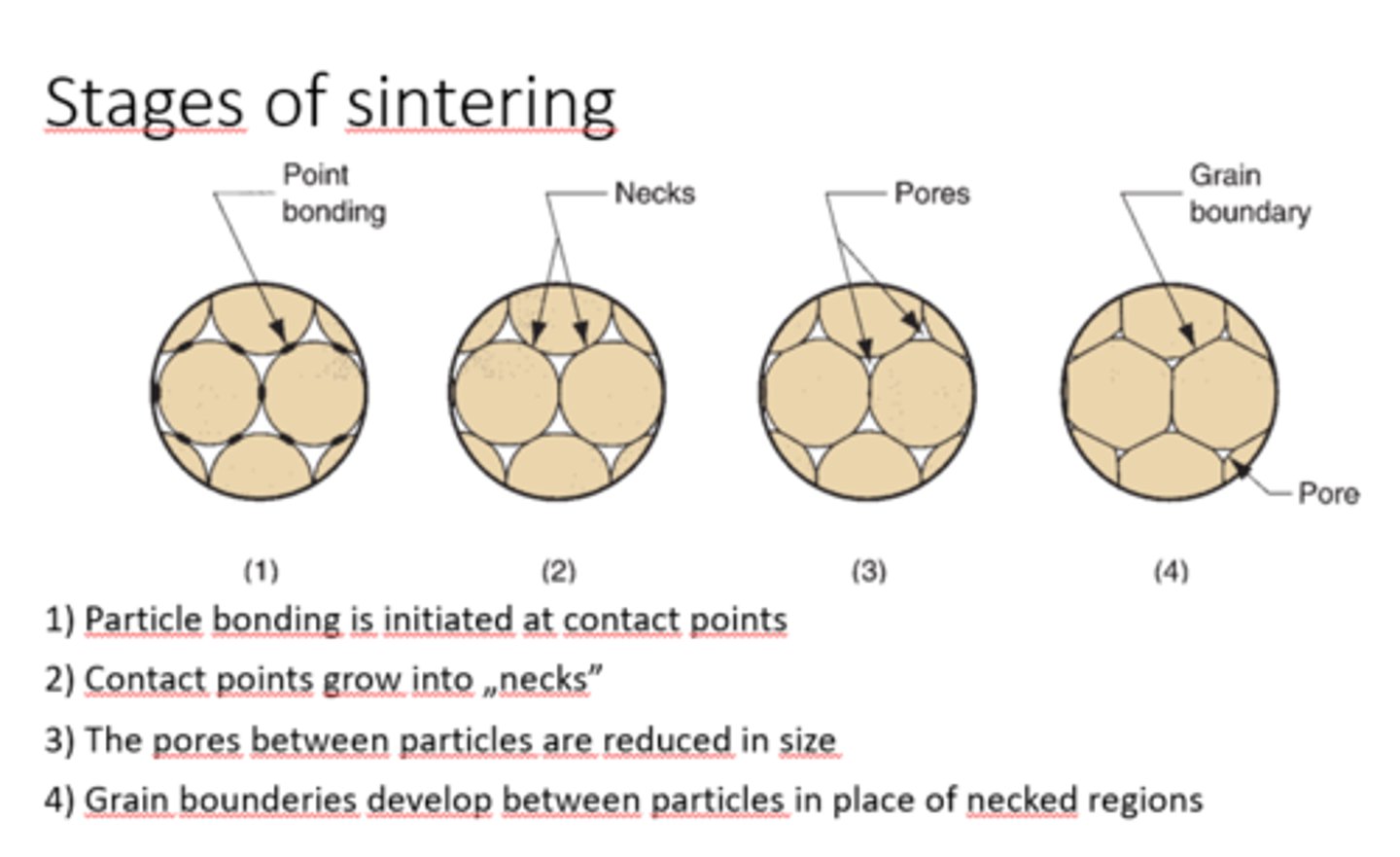

Sintering

Sintering is the process whereby green compacts are heated in a controlled-atmosphere furnace to a temperature below the melting point but sufficiently high to allow bonding (fusion) of the individual particles