Abrasives, Abrasion, and Polishing

1/79

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

80 Terms

finishing is to put a final surface on; the _____ of ____ prior to ____

the refinement of form prior to polishing

polishing is to make ___ and ____ by _____

smooth and glossy usually by abrasion

what casting technique can you use for indirect restorations? process?

lost-wax casting technique; via spruing, investing, burnout

what are three types of investments contributing to surface roughness?

nodules, ridges / veins, or fins

what three factors contribute to a FINE surface roughness?

low W / P ratio (decreases investment adaptation or flow)

prolonged burnout (increases investment decomposition)

overheating alloy (increases investment decomposition)

a high W / P ratio ____ surface roughness

increases

what are the 13 steps of a streamlined direct restoration?

diagnostic

tissue management

isolation

decay removal

cavity prep

sectional matrix

lingual matrix

bonding

composite

place, shaping, blending, curing

finishing

polishing

procedure systems

define abrasion

wear or material loss from a surface as a result of scratching or other mechanical means

define the substrate and abrasive

substrate is ABRADED (passive)

abrasive CAUSES wear (active)

what is the first type of dental abrasion procedure?

two body abrasion;

abrasive particles are tightly bonded to the abrasive instrument that is removing material from the substrate surface

what is the second type of dental abrasion procedure?

three body abrasion;

involves the use of non-bonded abrasives, particles are free to translate and rotate between two surfaces

what is the third type of dental abrasion procedure?

airborne particle abrasion;

abrasive particles are propelled (sandblasted) against a substrate by air pressure to remove surface material

what factors affect the rate of abrasion?

hardness between abrasive and substrate

abrasive particle size

abrasive particle shape

speed & pressure

lubrication

the hardness between the abrasive and the substrate is the …

relative hardness of minerals using a Mohs scale (1812) which indicates the resistance to scratching of one material by another

what does the Mohs Hardness Test compare?

compares the resistance of a mineral by scratching with ten reference minerals known as the Mohs Scale Materials

what are the 10 Mohs Scale Materials? Hardness increases 1 - 10.

Talc

Gypsum

Calcite

Fluorite

Apatite

Orthoclase

Quartz

Topaz

Corundum

Diamond

The Gecko Couldn’t Fight Against One Quail, Too Catty, Damn!

how is the Mohs Hardness Scale determined?

by scratching the surface of the tile with different minerals and subjectively assigning a “Mohs” number

how is pumice created? Mohs number?

super-heated, highly pressurized rock ejected from a volcano, 6

what is another test to determine the hardness between the abrasive and the substrate?

indentation hardness test for surface hardness;

surface hardness (Brinell, Knoop, Vickers hardness tests)

what does the indentation hardness tests determine?

the size or depth of the indentation and the amount of force are used to calculate a hardness value

WHAT ARE THE FIVE FACTORS AFFECTING RATE OF ABRASION?

hardness between abrasive and substrate

abrasive particle size

abrasive particle shape

speed & pressure

lubrication

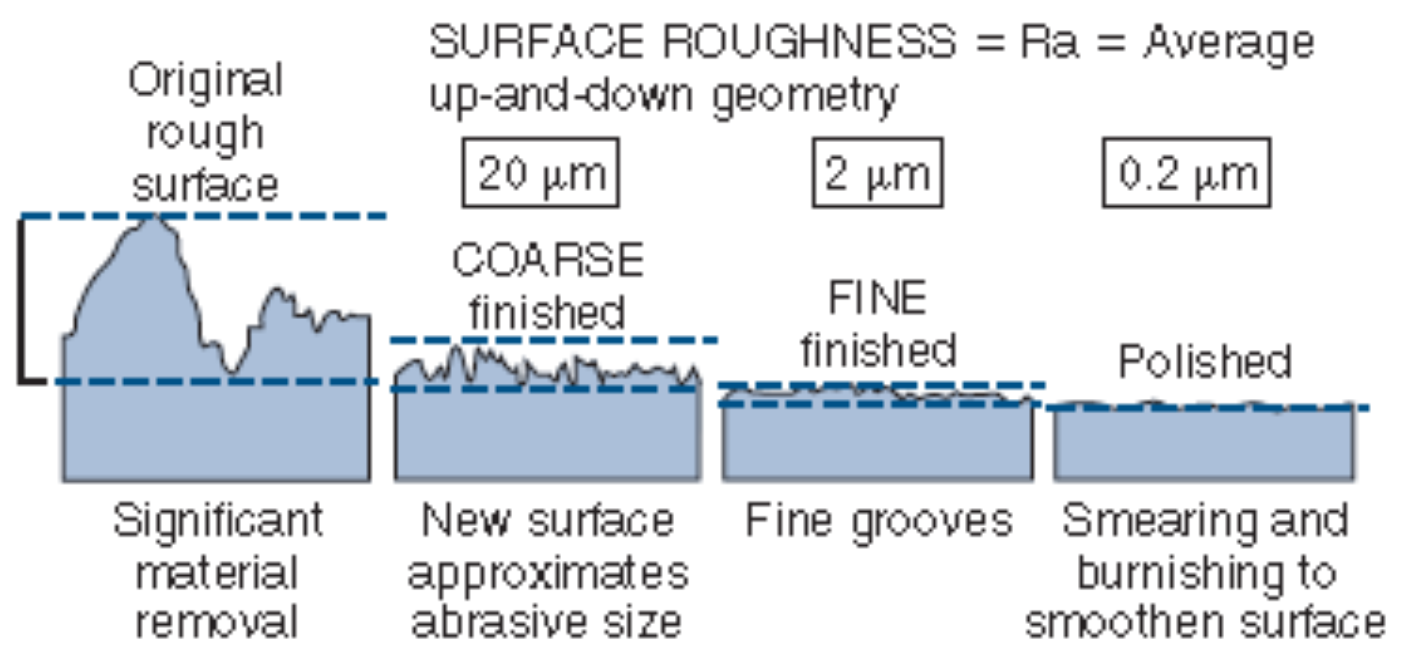

how does the particle size of the abrasive affect abrasion?

for the same applied pressure, larger particles leave larger scratches in the substrate and smaller particles leave smaller scratches

what are the four different sizes of abrasive particles?

superfine (<10 um)

fine (10-20 um)

medium (20-100 um)

coarse (100-500 um)

how does the particle shape of the abrasive affect abrasion?

a sharp particle (pointy) produces deeper abrasion than a rounder (blunt) particle under the same applied force

how does abrasive speed & pressure affect abrasion?

deeper and wider scratches are produced with increasing force.

equivalent sized scratches can be produced by different sized particles if you vary the applied pressure.

how does lubrication affect abrasion?

it reduces heat build up and helps wash away debris to prevent clogging of the abrasive instrument.

ex: oil in an engine to stop metal to metal contact

when does the most efficient abrasion occur?

when the difference in hardness between the abrasive and substrate is LARGER

what is the step-down approach to finishing and polishing?

gross reduction using diamond or carbide burs

finish (refinement of substrate surface)

polish (make smooth and glossy)

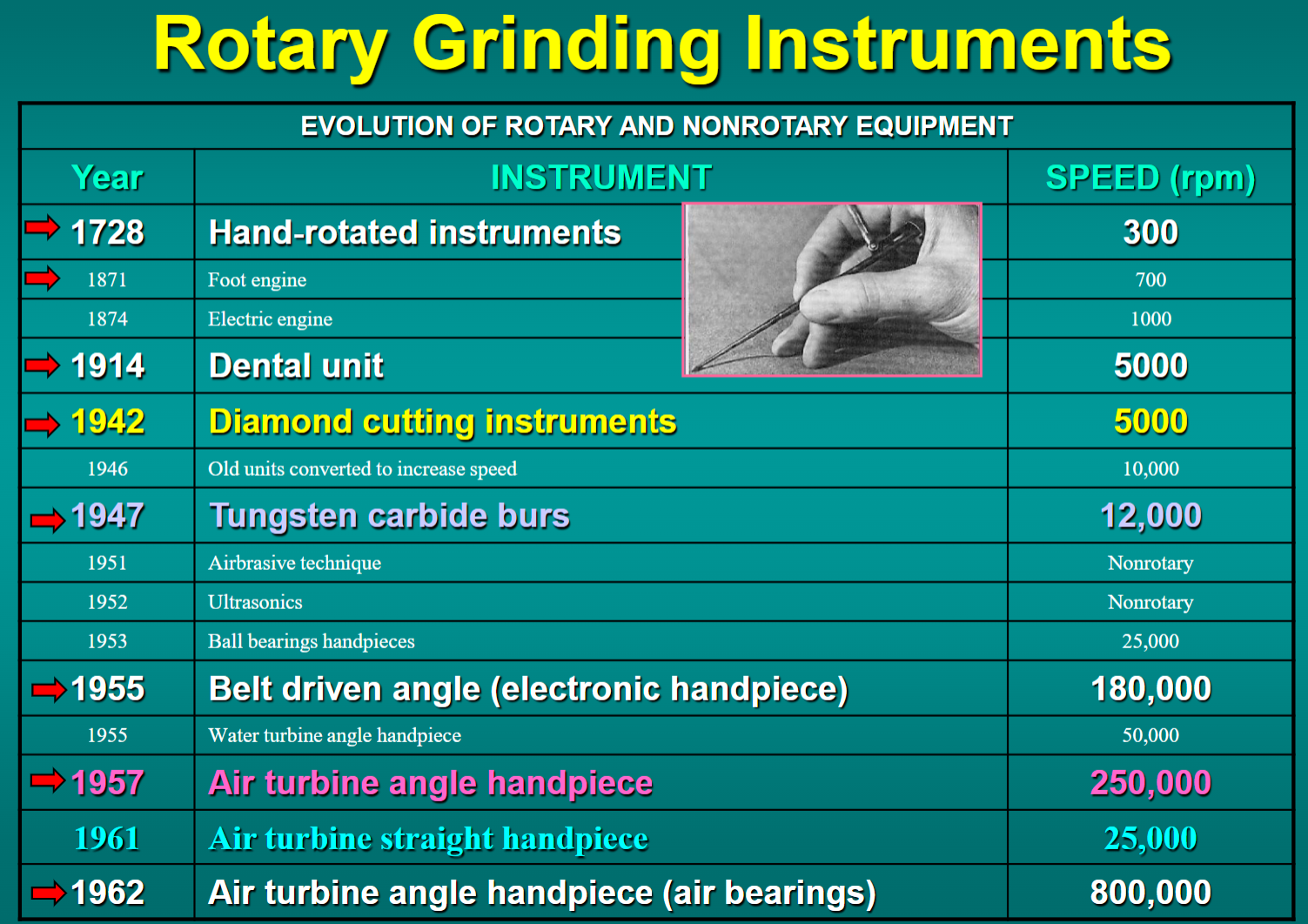

rotary grinding instruments!

what are the three speed ranges of rotary grinding instruments?

low speed <20K rpm

medium speed 20K - 200K rpm

high speed >200K rpm

the high speed handpiece utilizes what?

it is air-driven; air turbine

balance between speed and torque, faster and consistent cutting and grinding

what type of handpieces are electric vs air-driven?

electric = 100K - 200K rpm (medium speed), greater initial cost, 60 watts

air-driven = 400K rpm (high speed), louder sound, high pitched, 20 watts

what are five types of finishing and polishing instruments?

carbide burs

diamond burs

dental stones

rubber wheels

disks & strips

what are the three basic parts of a dental bur?

shank, neck, head

shanks can very to accommodate either contra-angle or straight handpieces

shanks can be friction grip (high speed) or latch type (high or low)

what type of shank and cutting blade are used for CARBIDE burs?

bur shank is stainless steel

cutting blade is tungsten carbide

carbide burs are available in a variety of shapes that can be used for ____ and ____

contouring & finishing

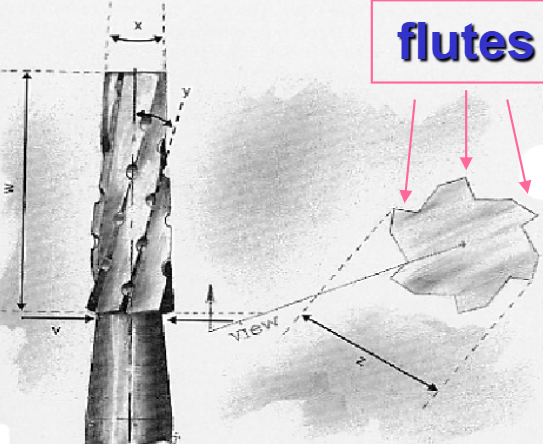

the most commonly used burs range from ___ to ____ ____ blades which can be straight or twisted

range from 8 to 30 fluted blades which can be straight or twisted

what is the difference between straight and spiral blade design?

straight blade design have one blade on tooth, spiral blade design have multiple blades on tooth

READ THRU THE 13 STEPS OF STREAMLINED DIRECT RESTORATIONS

READ THRU THE 13 STEPS OF STREAMLINED DIRECT RESTORATIONS

finishing diamond instruments are used to __ , __ , and __ composites or porcelain

contour, adjust, and smooth

what is the structure of a diamond bur?

shank: stainless steel

abrasive: powdered diamond with a metallic bonding material that holds the powder onto the shank

what is the bur shank and bur cutting end of a diamond bur?

bur shank is stainless steel

bur cutting end is stainless steel w diamond particles cemented

diamond burs also come in disk form, what is the structure of the disk?

stainless steel metal disk with diamond particles cemented

three considerations with diamond particle use

usually applied in sequence, starting with coarser and progressing to a finer grit

diamond burs used WITH water spray

other polishing instruments (ex: rubber) will usually follow the use of diamond

carbide burs are better for ____, the produce lower heat, and have more _____ for cutting

better for end-cutting, produce lower heat, have more blade edges

diamond burs are more effective for ____, ____, and __

1) tooth preparation

2) beveling enamel margins

3) enameloplasty

carbide vs diamond bur $$$

$ 1 vs $$$ 3

5 recommendations for cutting

use contra-angle handpiece to cut

use air-water coolant system

use higher-operating speed >200K

use light pressure

use carbide or diamond bur

what are the procedures for finishing & polishing?

original rough surface

1) gross reduction & contouring

2) finishing

3) initial polishing

4) final polishing

final smooth restoration

what do dental stones consist of?

consist of abrasive particle that have been sintered together or bound with an organic resin to form a cohesive mass

available in fine, medium, and coarse grades

stones are used for ___ and ____ when ___ abrasion is needed

used for contouring & finishing when maximum abrasion is needed

three examples of dental stones include

silicon carbide (carborundum)

aluminum oxide

diamond

what are rubber wheels used for?

fine grinding to remove coarse scratches from rough grinding

how are rubber wheels made?

made by molding the fine abrasives (AlO, SiC, CrO) into a rubber matrix

what are rubber polishers used for?

adjusting and polishing acrylic material

come with variety of shapes since they are flexible to reach more tooth surfaces

when using rubber polishers…

use light pressure! (avoid friction heat because it can be deleterious to the restoration, rubber, and tooth)

why are polishing strips useful?

particularly useful in finishing and polishing interproximal areas

what is the peak-to-valley height?

the scratches. we want to reduce this height 9and active SA of restoration) with proper polishing.

finishing and polishing sequence! woohoo!

if the polished surface is DULL,

the scratches are GREATER THAN 0.5 um

if the polished surface is SHINY,

the scratches are LESS THAN 0.5 um (500 nm vis light)

the tongue can feel scratches. when can the Pt feel rough? smooth?

scratches GREATER than 20 um deep are ROUGH

scratches LESS than 2 um deep are SMOOTH

what is the importance of coolants?

control frictional heat at cutting site (vital tissue)

what are the three most common types of coolant?

air, water, & air-water spray

when does an air coolant work?

used when visibility is a problem

used with low speed and light intermittent application

when do you use water coolant?

it is very effective, but clouds visibility

if cutting is continuous though, the water might be deflected

why is air-water spray the most common type of coolant?

maximizes visibility, lubricates and cleans which increases cutting efficiency and instrument life

dental prophylaxis paste should be carefully chosen and applied to _______ without ______

applied to remove exogenous stains and particles

without damaging tooth structure or adj. restoration

why is dentifrice/toothpaste used?

used to remove debris and residual stains from teeth and for polishing the tooth surface and restoration

abrasivity values for dentifrice products are reported as

abrasivity index (AI)

what is the abrasivity index (AI) a measure of?

the amount of material abraded from a dentin surface in a given time period

higher AI means more wear in a set amount of time

when you polish amalgam, use ____

copious amounts of coolant

key polishing concepts and tips

work from larger grit to smaller grit

coarse - medium - fine - superfine

use slower and optimal speed

light pressure

5 characteristics of a well polished restoration

maximize esthetic appearance

resist staining & plaque formation

minimize soft tissue irritation

decrease wear on opposing dentition

increase durability and service life

how are disks made?

made by a stiff plastic or paper backing coated with abrasive particles

what are disks used for?

used for gross reduction, contouring, finishing, and polishing

Enhance Finishing (aluminum oxide) and PoGo Polishing (diamond) systems are designed to

finish and polish all types of composite restoration surfaces

what is a flute?

what is the rake angle?

the angle made between the rake face and the line connecting the edge to the axis of the bur