Chemistry-Corrosion

1/26

Earn XP

Description and Tags

Redox

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

27 Terms

Corrosion

When an uncombined metal decomposes into one of its more stable compound

Condition/ requirement for corrosion

Metal surface free from protective films e.g paint/oil

Suitable oxidising agent present

something high on the SRP table

Solution containing ions for conducting charge

Chemical formula for rust

Fe2O3.H2o

Products of corrosion

Soluble products

Sparingly soluble products

Soluble products

readily dissolve and washed away leaving holes or pits in the metal

Sparingly soluble products

Form layers which are not washed away

2 types

Coherent coatings - stay in one piece to form a continuous coating on the metal surface (Zn&Al in air) This stops further corrosion i.e protective coatings such as Al2o3 on Al (uniform coating of Al2o3 on Al)

Incoherent coatings - flaky powdery or peel off the metal surface e.g the oxidation of Fe2+. Corrosion can occur below this layer

Al and Mg are _________

Strong reducing agents with high oxidation potential value, so in the presence of suitable oxidising agent such as o2 in the presence of h2o, these metals readily undergoes oxidation to produce Al3+ and Mg2+ respectively

Instead of corrosion use ______

Oxidation of metal

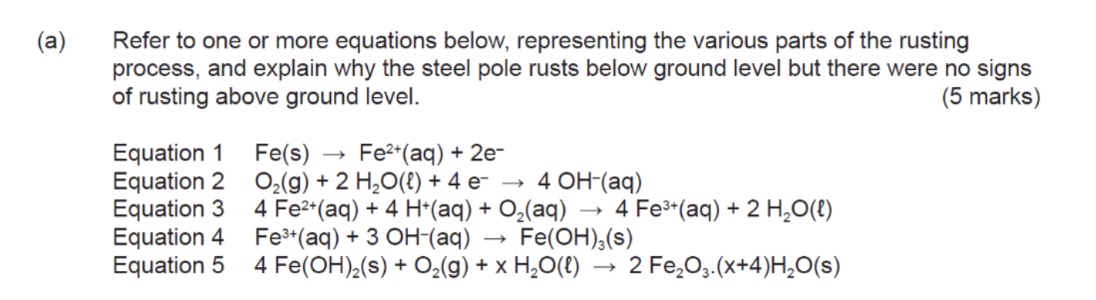

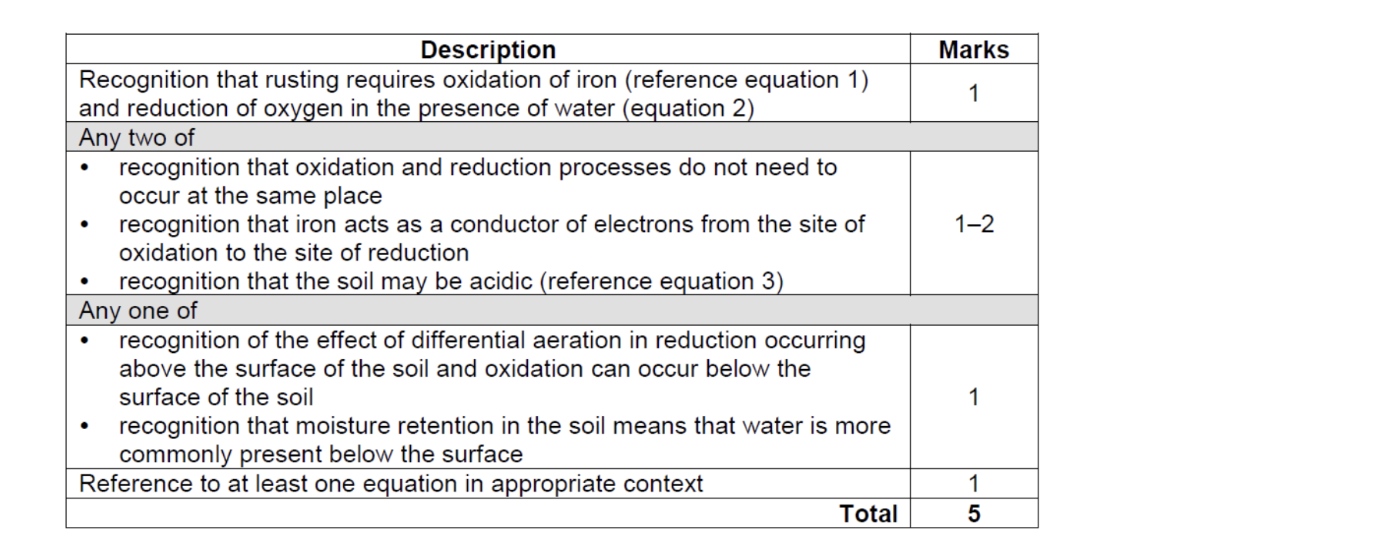

Formation of rust requires____?

iron

oxygen

presence of water

Rust is composed of ___? Chemical formula

hydrated iron(III) oxide - Fe2o3.nH2o

Initial oxidation of iron equations

Oxidation of iron at the anodic site

Reduction of o2 in acidic or non acidic conditions

Precipitation of Fe(OH)2

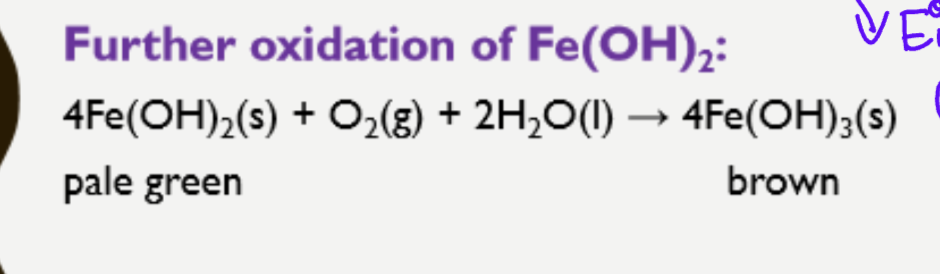

Further reduction of Fe(OH)2

Dehydration of Fe(OH)3

Prevention of corrosion

Surface protection

Plating with metal that has a lower oxidation potential

Sacrificial anodes

Cathodic protection

Surface protection

prevents o2 or h2o from being in direct contact with iron

Less reactive

Weaker reductant/ reducing agent

Plating with a weaker reductant than Fe

weaker reductant has lower oxidation potential and does not get oxidised easily

a scratch on the surface will lead to an increase in the rate of oxidation than uncoated Fe

Sacrificial anode

Galvanising (plating with zn)

connecting the iron to a piece of metal that is a stronger reductant than iron

Can be easily replaced after consumed using a wire

Ships hull/ buried pipes

Why isn’t Na, Ba, Ca or K used as a sacrificial anode

Oxidise too rapidly, depleting themselves before effectively protecting the metal structure

Sacrficial anode definition

it is a piece of metal that is connected to Fe that has higher oxidation potential than the metal being protected from oxidation and so oxidises in preference to the metal being protected

iron/steel to be protected, connected by a conducting wire to a stronger reductant than Fe

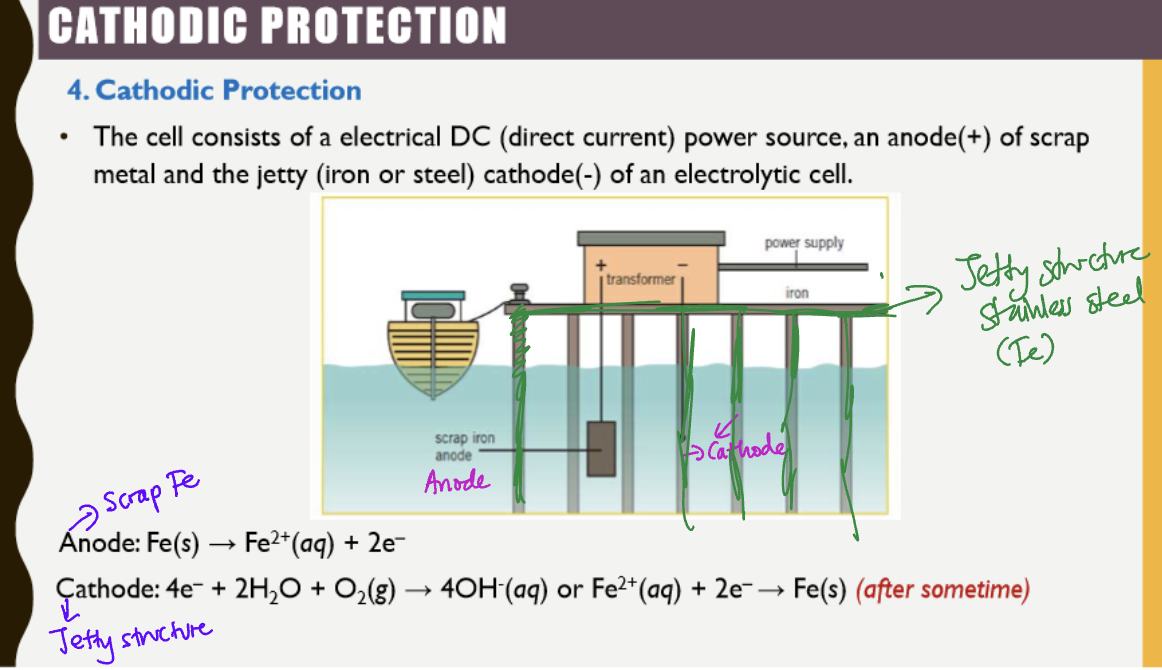

Cathodic protection requirements

electrical DC current power source

Anode of scrap metal (+ve)

Jetty (cathode of electrolytic cell)

Cathodic protection

Fe structure is connected to the negative terminal of the power supply making it the cathode in an electrochemical cell preventing the oxidation of Fe in jetty structure

at cathode, O2 is reduced in the presence of h2o and forms OH-

iron scrap is connected to the +ve terminal of the power supply made as anode

Acts as an electrolytic cell

Non-spontaneous reaction

Iron scrap

refers to discarded iron metals like old railways

What would happen if a lower oxidation potential than Fe was used for cathodic protection?

Higher voltage will be required to provide a potential difference in the electrode potential value

If higher voltage not used

the iron to be protected will undergo oxidation at a faster rate due to positive p.d in electrical potential

the purpose of a conducting wire during sacrificial anode

to provide a path for electron flow

Cathodic protection equations