MODELS & DIES

1/42

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

43 Terms

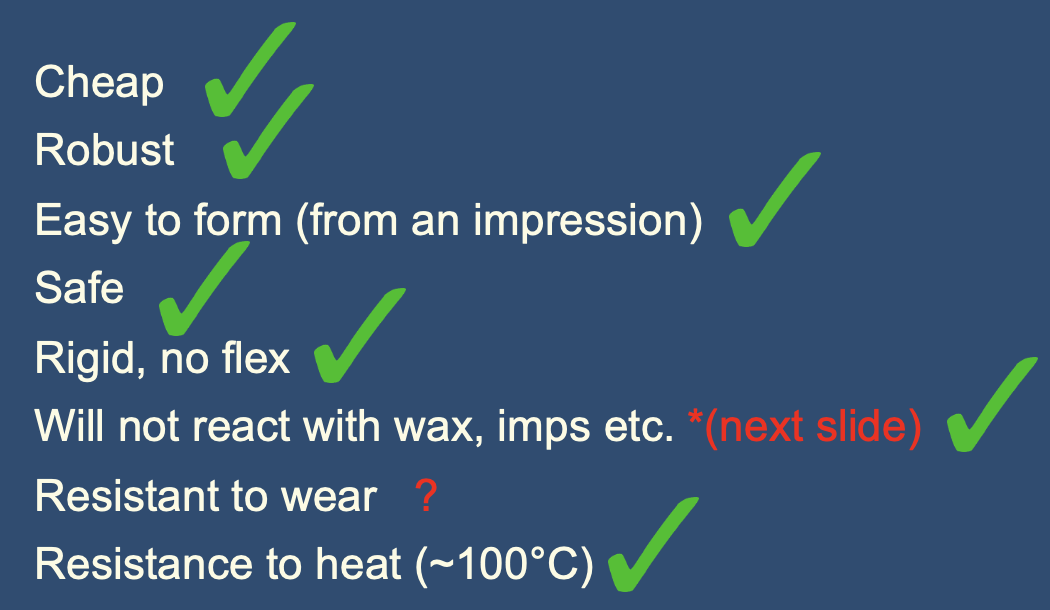

what properties/ characteristics would be required for a dental modelling material

cheap

easy to form (from an impression)

safe during handling and if swallowed

robust

rigid, no flexion or deformation

will not chemically react with water, wax, impressions etc.

resistant to wear (apppliances will be made to fit the model and will need to be repeatedly tried on)

resistant to heat (approx. 100°C)

what are the categories of modelling materials

plastics/ polymers

organic

clay

plaster (most common)

which criteria of ideal features of dental modelling materials does plaster of Paris/ Gypsum not meet

what material DOES react with plaster

agar

how can the reaction between agar and plaster be prevented

alum solution can be used as a barrier

what are the uses of plaster of Paris/ Gypsum

models and dies

impression material

moulds for denture construction

binder in refractory investments for casting

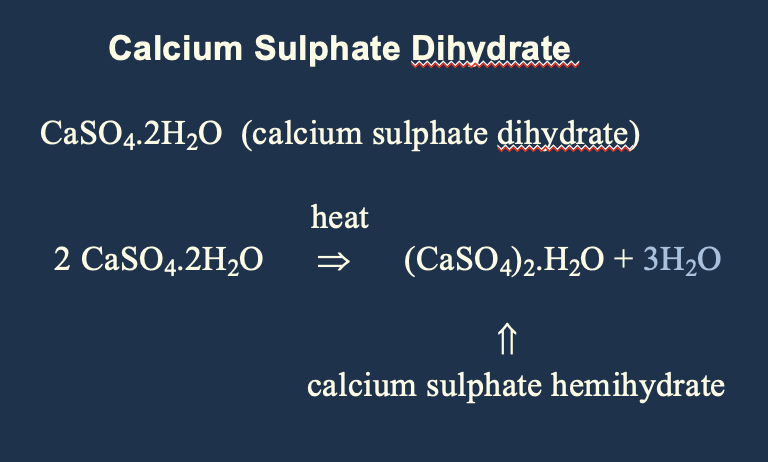

what is Plaster of Paris

gypsum is a natural mineral that is mined

quarries of Montmartre district of Paris produce burnt gypsum

this dehydrated gypsum became known as Plaster of Paris

upon addition of water, plaster of Paris becomes regular gypsum (dihydrate) again, causing the material to harden or set

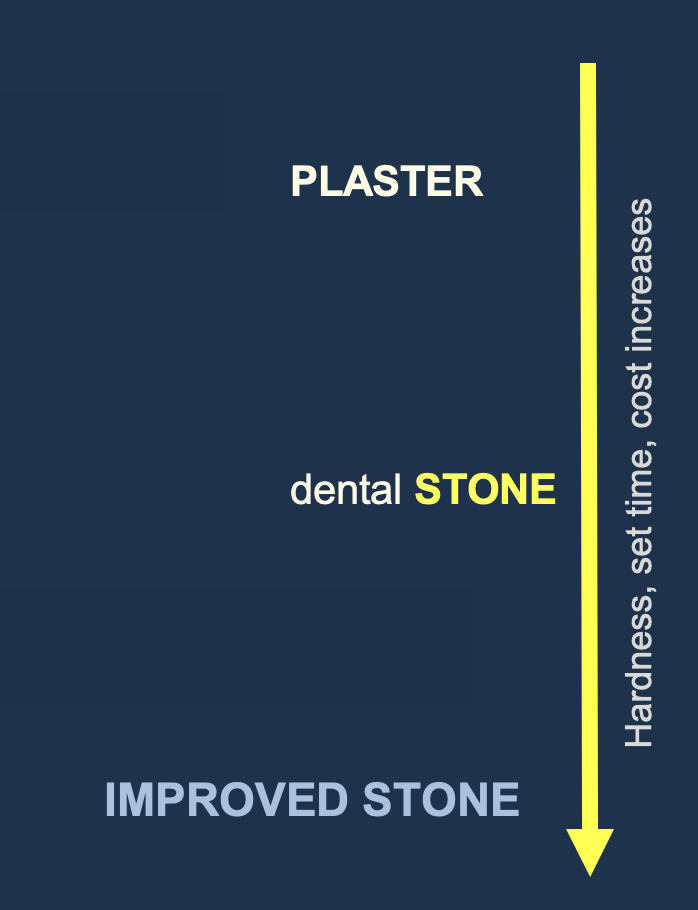

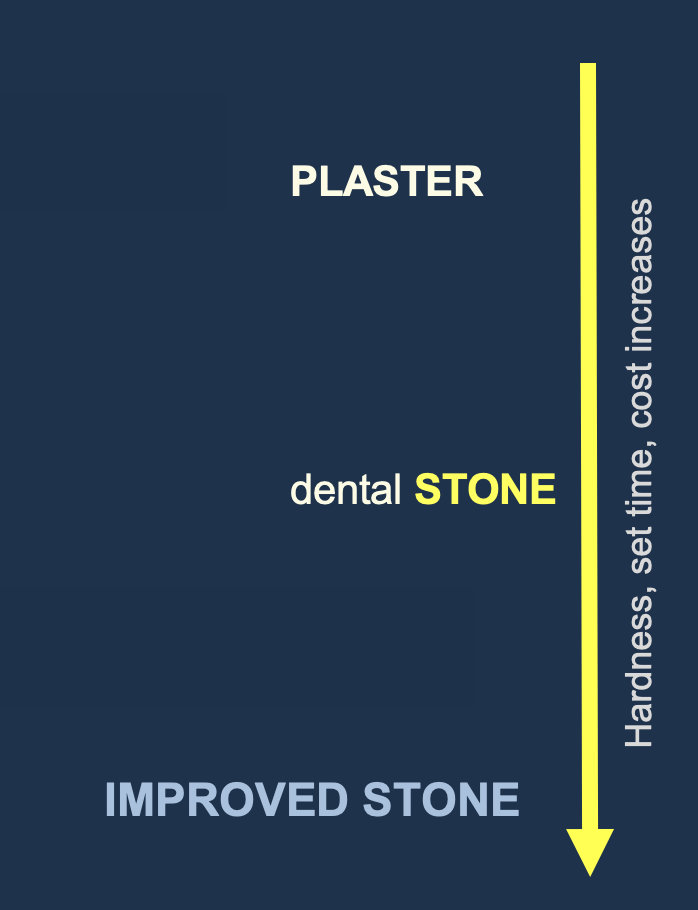

what pathways does gypsum from the ground go through to become dehydrated to form the end material

open kettle at 110-120°C

pressure vessel at approx. 125°C

in the presence of deflocculants (CaCl2 and MgCl)

outline open kettle at 110-120°C

makes calcium sulphate beta-hemihydrate

beta hemi-hydrate produces large porous particles

» plaster of Paris

outline pressure vessel at approx. 125°C

calcium sulphate alpha-hemihydrate in pressure vessel - this drives more water out of the gypsum

produces small dense particles

» dental stone (buttery yellow colour)

outline in the presence of deflocculants (CaCl2 and MgCl)

calcium sulphate alpha-demihydrate

add deflocculants which allows material to flow over each other so the material does not clump up

produces very small dense particles

» improved stone (white colour)

what is improved stone used to make

crown and bridge

define model VS die

model: the whole mouth

die: a tooth (a section of the model), removable to be worked on

what are the types of Gypsum products

current ISO Standard for Dental Gypsum Products identifies 5 types of materials:

Type 1 Dental plaster for impression

Type 2 Dental plaster for model

Type 3 Dental stone, die, model

Type 4 Dental stone, die, high strength, low expansion

Type 5 Dental stone, die, high strength, high expansion

key information about dental plaster

cheapest

referred to as the ‘beta’ form

in the lab: white powder

working time = 3-4 mins

initial setting time = 5-10 mins

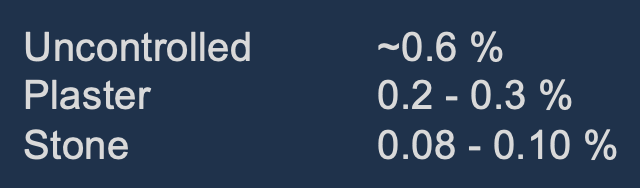

slight expansion on setting of 0.2-0.3%

exothermic setting reaction, cool once set

softest but quickest setting

rarely used on its own as a model (mostly mixed with dental stone)

used as denture moulds

what kind of behaviour does plaster display

thixotropic behaviour

key information about dental stone

referred to as the ‘alpha’ form

often called Kaffir-D but use stone or KD

in the lab: yellow powder

working time = 3-4 mins

initial setting time = 5-20 mins

slight expansion on setting of 0.08-0.1%

exothermic setting reaction, cool once set

stronger than Plaster of Paris

often used for ‘everyday’ dental models (mixed 50/50 with dental plaster to reduce cost and setting time)

what is the ratio of dental stone and water that is mixed

1:!

key information about improved stone

a lot more expensive

referred to as the ‘alpha-modified’ form

‘die-stone’

in the lab: coloured powder e.g. blue

finer, more regular particles

working time = 5 mins

initial setting time = 20+ mins

even less expansion on setting of 0.05-0.07%

it is harder than Plaster of Paris but takes longer to set

significantly higher cost

usually vacuum mixed

used where accuracy and wear resistance is critical e.g. crown and bridge models

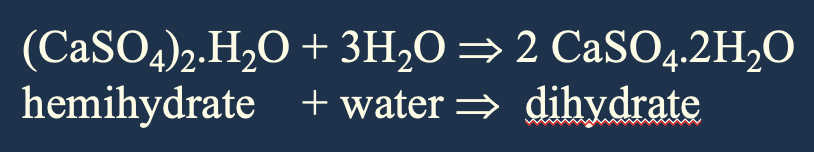

chemistry of plaster

reversible reaction

setting process for plaster

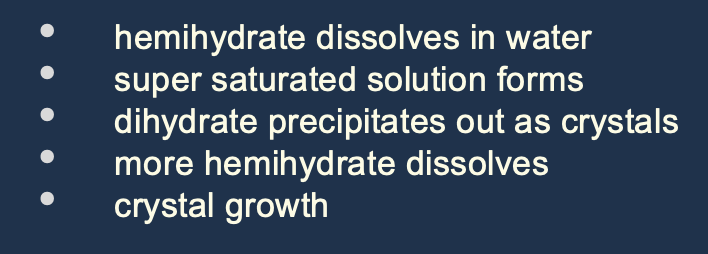

what are the stages of the setting reaction of plaster

how does plaster harden into a solid

spherulites of gypsum crystals expand, aggregate and impinge during the exothermic reaction when plaster is mixed with water

how can the setting time of plaster be increased

if you need more time for plaster to set you mix it thinner

this means the crystals have further to grow to impinge on each other so the plaster takes longer to set

what is a disadvantage of mixing the plaster thinner

as the crystals get bigger they get more fragile

therefore material that takes longer to set is also softer

expansion of plaster percentages

what can reduce the setting expansion of plaster

accelerators and retarders

anti-expansion agents

what are bonus properties of plaster

easy to trim or grind with a scalpel/ knife

can be coloured (appealing shades)

sticks to itself so models can be added to and modified

when making plaster moulds, how can you prevent plaster from bonding to itself

use an alginate-based separating liquid

paint it on the plaster and wait for it to dry

what is the water:powder ratio for plaster VS stone

plaster: 50ml water per 100g powder

stone: 20-35ml water per 100g powder

why does stone need less water than plaster

because the powder is ground finer than plaster

what does spatulation refer to and how does it affect setting time

spatulation: how long you are mixing for

over spatulating decreases setting time (sets faster) because you start to break the crystals that have started to form

this increases the nucleation sites so more crystals will form quicker

how does water temperature affect setting time

colder water = longer to set

give examples of retarders

borax

potassium citrate

sodium chloride (large amounts)

give examples of accelerators

potassium sulphate solution

gypsum powder (adds new centres of nucleation)

sodium chloride (small amounts, causes pink spots on material)

what is the typical composition of a dental plaster

powder:

calcium sulphate beta-hemihydrate (CaSO4)2·H2O

borax (slows the setting rate)

potassium sulphate (reduces expansion)

liquid:

water

what other tests would have shown a greater difference between plaster and stone

wear resistance test (scratching surface)

surface hardness (indentation test)

three-point bend

what are other model materials

‘Rhino Rock’ polymer

3D printed models

digital models

outline Rhino Rock

polymeric model material

cures within 30 mins

dimensionally stable

zero expansion

strong and impact resistant - will not chip

white, opaque

can be 3D scanned

what are disadvantages of Rhino Rock

expensive

dangerous to skin

outline digital models

intra-oral scanning offers the opportunity for digital capture, design and manufacture

no properties to work around

only a file to store