part 8: MICROMERITICS

1/99

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

100 Terms

Micromeritics

Science of small particles and the study of particle size distribution

Micrometer (micron)

Nanometer (nm)

The unit of particle size used most frequently is

Particle size and size distribution

Particle volume

Particle number

Particle shape

Particle surface area

The following are the five fundamental properties of powders from which other properties can be derived:

Packing geometry

Porosity

Density

Bulkiness

Flow property

Derived properties of powders

Optical Microscopy

Sieving Method

Sedimentation Method

Automated Particle Counter

Methods of Particle Size Determination

Optical Microscopy

Most popular and most accurate method of particle size determination

0.2 mcm - 100 mcm

Range of analysis of Optical Microscopy

SEM

TEM

These may be used in measuring very small particle size

TEM

May be used in measuring very small particle size, but 3D imaging is required

Direct observation of the shape and size of particles

Aggregation of particles can be detected

The field can be projected and a photograph can be taken

Easy to handle (Simple and Economic)

Advantages of Optical Microscopy

Diameter is obtained from only 2D of the particle (length and breadth); No estimation of depth (thickness)

Slow, tedious and time-consuming method

Disadvantages of Optical Microscopy

Feret’s diameter

Martin’s diameter

Projected area diameter

Expressions of Diameter

Feret’s diameter

Distance between pairs of parallel tangents to the projected outline of the particle in some fixed direction

Martin’s diameter

Diameter measured from the length of the particle at the point that divides a particle into two equal projected areas

Projected area diameter

Diameter of a circle having the same area as the projected area of the particle resting in stable position

Screening

Sieving method is also known as?

Sieving Method

Range of analysis: 50 um to 1500 um; although preferred size > 75 um

Range of analysis 40 um to 9500 um (Ansel Reference)

It consists of a series of standard sieves

National Bureau of Standards

Standard sieves are calibrated by

Mesh number or Mesh count

Number of square openings per linear inch

smaller openings

High mesh number =

large openings

Low mesh number =

Specially useful for weight distribution

Inexpensive

Very simple method

Advantages of Sieving Method

Sample should be dried every time

Induction of attrition during shaking – may cause reduction of particle size

Very small particles cannot be used because of surface and electrostatic forces

Disadvantages of Sieving Method

Sedimentation Method

Used for evaluation of suspensions, emulsions and determination of molecular weight of polymers

Range of analysis: 0.8 to 300 um

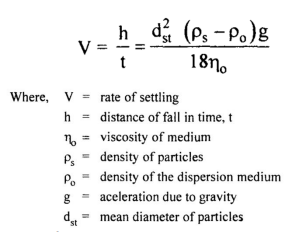

Based on Stoke’s law

Used for evaluation of suspensions, emulsions and determination of molecular

Stoke’s Law

Andreasen pipet or apparatus

Instrument used in Sedimentation Method

Coulter counter

Single particle optical counter (HIAC ROYCO particle counter)

Automated Particle Counter

Coulter counter

Principle: Electric resistance

↑Electric resistance = ↑Particle volume = ↑Particle size

Single particle optical counter (HIAC ROYCO particle counter)

Principle: Light blockage

↓ Transmitted light = ↑ Light blockage = ↑ Particle size

Their main use is to COUNT PARTICLES rather than size them

Stoke’s Law

What law is followed by SEDIMENTATION method

a. Boyle’s Law

b. Charle’s Law

c. Gay Lussac’s Law

d. Stoke’s Law

Void fraction

Porosity is also known as?

Porosity

Measure of the void volume in a powder material

Porosity

Represents the fraction of the powder volume that is occupied by the voids

Intraparticle space or voids

Space within the particle

Interparticle space or voids

Space between the particle

Closest or rhombohedral packing

Loosest or cubic packing

There are two ideal packing arrangements for the powder beds of uniform sized spheres

True volume (Vp)

Granule volume (Vg)

Bulk volume (Vb)

Types of Volume

True volume (Vp)

Volume of the solid particles EXCLUDING both INTRA and INTER PARTICULATE VOIDS

Granule volume (Vg)

True volume of particle with INTRAPARTICLE SPACE or VOIDS

Vg= Vp + Intraparticle space

Formula of Granule volume (Vg)

Vb= Vg + Interparticle space

Vb = Vp + Intraparticle + Interparticle space

Formula of Bulk volume (Vb)

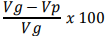

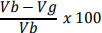

ε Intraparticle

ε Interparticle

ε Total

Types of Porosity

ε Intraparticle

ε Interparticle

ε Total

Closest or rhombohedral packing

Bigger interparticle space

Loosest or cubic packing

Smaller interparticle space

Vg = 0.4mL

Vb = 2 mL

Interspace porosity = 80%

Total porosity = 85%

Compute for the following Granule volume, Bulk volume, Interspace porosity, Intraspace porosity and Total porosity.

Volume of particle=0.3 mL

Intraparticle space= 0.1 mL

Spaces between particles= 1.6 mL

note: refer to handouts for the solutions! 🙂

Density

Mass per unit volume

True density (ρ)

Granule density (ρg)

Bulk density (ρb)

Types of Density

Formula of True density (ρ)

Formula of Granule density (ρg)

Formula of Bulk density (ρb)

True density (ρ)

Type of Density that is determined using Helium Densiometer

Granule density (ρg)

Type of Density that is determined using Liquid Displacement Method

Bulk density (ρb)

Type of Density that is determined using Graduated Cylinder Method

Bulkiness or Specific Bulk Volume

What is the reciprocal of Bulk density?

Bulkiness or Specific Bulk Volume

Determines the size of container

Low particle size

High bulkiness = _____ particle size

Flow property

Plays an important role in the manufacturing of tablets or capsules

Particle size

Shape

Porosity and density

Surface texture

Surface force

Temperature

Flow properties depends on the:

High particle size

Smooth surface

High density

Low internal porosity

Low electrostatic charges

Spherical shape

Low temperature

Characteristics of powder with GOOD FLOWABILITY

Angle of Repose

Compressibility Index

Characterization of Powder Flow

Angle of Repose

Maximum angle possible between the surface of a pile powder and horizontal plane

Formula of Angle of Repose

< 25

Angle of Repose (degrees) of Excellent Flow

25-30

Angle of Repose (degrees) of Good Flow

30-40

Angle of Repose (degrees) of Poor Flow

> 40

Angle of Repose (degrees) of Very Poor Flow

Glidant

Addition of _________ is necessary to improve flow property

25-30

Angle of Repose (degrees) of Excellent Flow

31-35

Angle of Repose (degrees) of Good Flow

36-40

Angle of Repose (degrees) of Fair - aid not needed Flow

41-45

Angle of Repose (degrees) of Possible - may hang up Flow

46-55

Angle of Repose (degrees) of Poor - must agitate, vibrate Flow

> 66

Angle of Repose (degrees) of Very, very poor Flow

Compressibility

Ability to decrease in volume under pressure

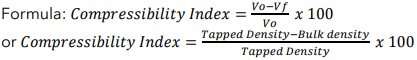

Carr’s Compressibility Index

This index measures the tendency of a powder to consolidate

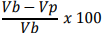

Formula of Carr’s Compressibility Index

Percent

Unit of Carr’s Compressibility Index

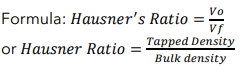

Formula of Hausner Ratio

Unitless

Unit of Hausner Ratio

≤ 10

Compressibility index (%) of Excellent Flow

11-15

Compressibility index (%) of Good Flow

16-20

Compressibility index (%) of Fair Flow

21-25

Compressibility index (%) of Passable Flow

26-31

Compressibility index (%) of Poor Flow

32-37

Compressibility index (%) of Very poor Flow

> 38

Compressibility index (%) of Very, very poor Flow

1.00-1.11

Hausner Ratio of Excellent Flow

1.12-1.18

Hausner Ratio of Good Flow

1.19-1.25

Hausner Ratio of Fair Flow

1.26-1.34

Hausner Ratio of Passable Flow

1.35-1.45

Hausner Ratio of Poor Flow

1.46-1.59

Hausner Ratio of Very poor Flow

> 1.60

Hausner Ratio of Very, very poor Flow

Carr’s Index = 23.08%

Hausner Ratio = 1.3

A powder was poured in a graduated cylinder and was noted to have a volume of 65 mL. It was allowed to compress by tapping the cylinder n the table counter. The initial volume was reduced by 15 mL.

Determine the Carrs index and Hausner Ratio

note: refer to handouts for solutions! 🙂

30.96°

A sample powder was made to flow from a funnel suspended @ a height of 20 cm. A powder cone of 1.2 cm from the surface was made as well as a spread of 4 cm in diameter.

Determine the angle repose of the powder

note: refer to handouts for solutions! 🙂

Inversely proportional

Relationship of Compressibility and Flowability

a. Directly proportional

b. Inversely proportional

c. NOTA

Angle of Repose

Simplest method to express flowability

a. Angle of Repose

b. Carrs Compressibility Index

c. Hausner Ratio

d. NOTA