Welding

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

20 Terms

What is welding?

The process of joining multiple parts through melting

Done because it is hard to make a whole thing out of a single piece

How to weld

Parts heated at high temps, parts cool, they fuse together

Early Welding

Iron, silver and gold were welded for jewelry and weapons

Simple terms

welding is melting a filler metal to deposit onto or join a work peice.

Electric current between a workpiece and filler metal cause a temp gradient

filler metal melts to form a bead that is deposited on the workpiece or joins multiple parts

shielding gas surrounds the weld pool to prevent oxidation of the cooled metal

Common types

Arc, MIG (metal inert gas), Tungsten (tungsten inert gas), Automated laser beam

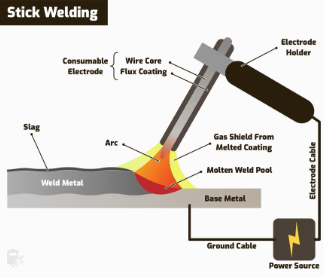

How it works - Arc Welding

uses a power source, torch and electrode.

Power source is connected to the torch and workpiece and provides an electric current between them

Torch is loaded with an electrode

The electrode has a wire made off the desired filler material and a flux coating providing a gas shield for the weld pool.

When the power source is applied, heat between the torch and workpiece melts the electrode.

Flux melts to provide a gas shield for the weld pool

flux cools to form slag (non ferrous by product of weld pool that must be removed

Arc Welding

Advantage - easiest cheapest welding process, can be applied to contaminated materials, almost anything can be arc welded

Disadvantages - poor weld quality, post processing is required to remove slag, heat also causes distortion and problems with thin materials

Applications - construction, ship building, general fabrication

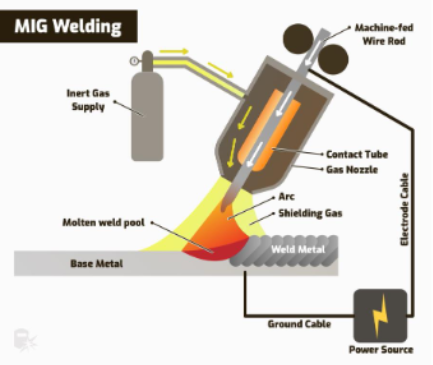

MIG (metal inert gas) welding How it works

Power source is connected to the torch and workpiece and provides an electric current between them

Torch now contains a machine-fed wire rod that is electrically charged by the power source

The torch has an gas around it fed by bottle of inert gas

When the power source is applied heat between the torch and workpiece melts the rod

continous supply of inert gas provides a gas sheild for the weld pool

MIG Advantages and disadvantages

Advantages- easy process, provides clean welds (no slag), continous wire feed meaning no electrode replacement

Disadvantages - wind or air can easily impact gas, materials cannot have contaminants

TIG (tungsten inert gas) welding

Power source connected to the torch and workpeice to provide electric current

Torch now contains a fixed tungsten electrode that is electrically charged

torch has an outer housing fed by pressurized bottle of inert gas

Welder must now hand feed the welding rod into the weld pool (lots of skill)

When the power source is applied, heat between then torch and workpeice melts the hand fed rod

Contunous supplu of inert gas provides gas sheild

TIG Pros and Cons

Pros: Highest quality, precision of the welding process, better heat control meaning less distortion and ability to weld thinner materials, provides prettiest and cleanest welds

Cons: High operator skill required, expensive equipment and electrodes

Automated Welding

Laser beam provides a concentrated heat source

Filler metal is applied through a powder or wire feeder

Robotic head containg laser and material supply is moved over the workpiece in patterns (coded)

Weld material is deposited along the weld path to form the desired geometry

Vision systems are often used to customize weld paths to individual components

Automated Welding advantages and disadvantages

Advantages- ultimate control over size, shape and heat input of welds, computerized control can consistently achieve complex geometries

Disadvantages- very expensive process requiring specialized equipment and software, variations in input must be accounted for by vision systems or programs

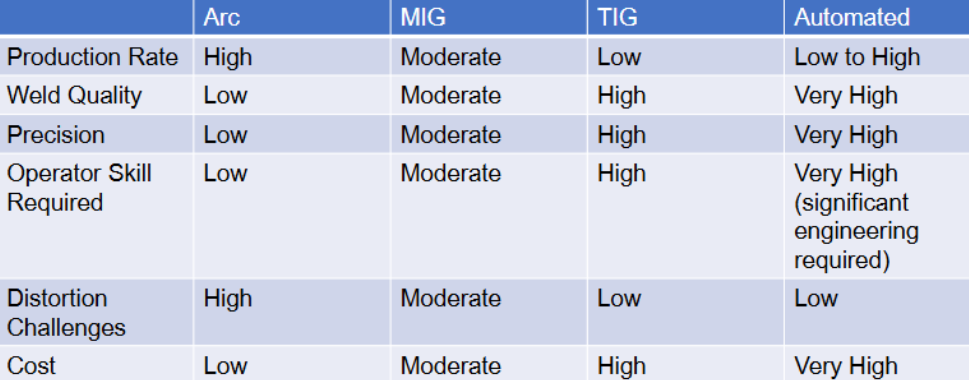

Welding comparison

Welding Materials

Certain materials are easy to weld (mild steel) and others are very difficult (superalloys)

Weldability is related to carbon content, more carbon means more strength, less ductility, less weldability.

Nickle based super alloys are difficult to weld w/o cracking

General rule: Stronger materials, harder to weld

Techniques for Weldability

Heat treat the components before welding, to get rid of stresses and soften

Head during welding to reduce the thermal gradient between base and welding region

Use special filler wires with ductility- increasing compounds (boron and silicone)

Reduce heat input or size of welds.

Welding Distortion

This happens when the workpiece changes shape or size during welding, can be cause by heat input or cooling after,

Distortion affects dimensional requirements and is a major downside to welding design

Techniques for minimizing distortion

Jigs or fixtures- constrain the part during welding

Order of welds- choose weld sequence appropriately

Heat treatment- Relieve welding stresses before unclamping parts

Straightening- Use jigs or fixtures to reshape the parts after welding

Welding Alternatives - Brazing

A method fusing pieces together using another material

Advantages- low temp, doesnt distort, dissimilar materials can be joined

Disadvantages- produces a much weaker joint then welding, can contaminate

Welding Alternatives- Adhesives

Substance applied to seperate surfaces to join them togerther firmly

Advantages: no heat, no distortion or cracking

Disadvantages: Limited temp range, delamination voids the bond, health and saftey concerns.