3. Fatigue failure

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

18 Terms

Definition of fatigue failure

Failure of material under cyclical load (load that varies over time)

Stress level fatigue occur

can occur below yield stress

Dangers of fatigue stress

no warning →no deformation, necking

sudden, catastrophic fracture

4 Methods where crack appear

manufacturing defects

fatigue processes

corrosion

creep

Types of fatigue failure (in terms of cycle and presence of cracks)

Cycle:

Low cycle fatigue

low no. of cycle

occur above σy

High cycle fatigue

million cycles to fail

occur below σy

Crack:

1. Crack-free

Pre-existing cracks - non destructive testing method used to spot cracks)

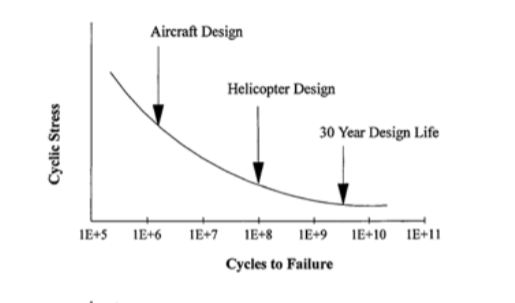

High cycle load cyclic stress-no. of cycle relationship (Stress-number (SN) curve)

for crack-free specimen

for any cyclic load, follow SN curve of σm (mean stress)

Benefit for SN curve

material comparison

early design estimate

high cycle fatigue regime

Limitations of SN curve

remaining life of cracked component

crack growth behaviour

high scatter in experiemental data

long test required

most of lifetime used to initate defect

IGNORES CRACK SIZE

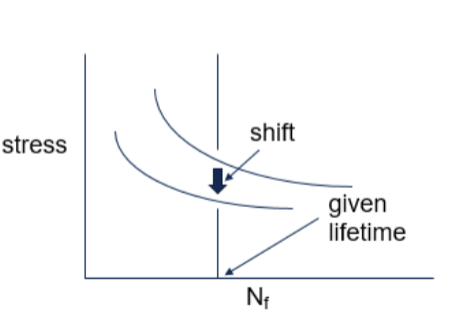

Method to solve limitation of SN curve

find one curve for certain stress value

shift curve up and down for different stress

estimate but useful

**

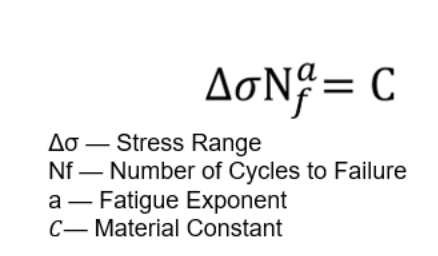

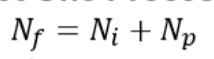

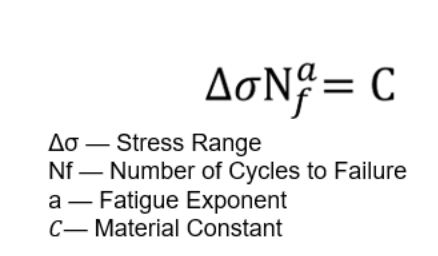

Calculation of fatigue life (by number of cycle)

Ni: crack initiation

Np: crack propagation

depends on crack size & stress intensity range

Definition of Paris Law

rate of fatigue crack growth

relate crack growth to range of stress intensity factor

occur AFTER crack propagation

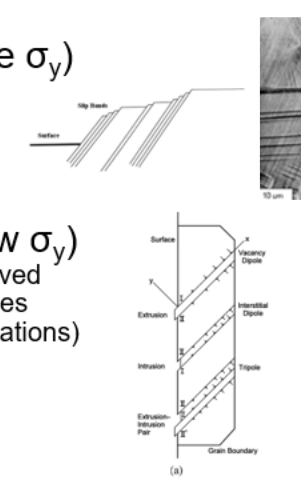

Methods to form defect(crack initiation) (Low vs high cycle)

Low:

plasticity causes slip steps on surface

act as stress concetrator to start fatigue

High:

no gross plasticity but homogeneties in atomic level raise local stress and initiate fatigue

Design method to reduce fatigue

reduce section stress (raise cross-section)

remove stress concentrators(add fillers, welding)

Environmental method to cope with fatigue

consider corrosion-fatigue relationship

Surface treatment to cope with fatigue

locally harden surface as crack usually initates there

case hardening, work hardening, shot peening (locally inducing elastic compressive stresses)

3 ways material is used to cope with fatigue

remove porosity ( at source or via hot working)

employ 2 phases (to deflect crack path)

employ composites(blunt crack as it propagates)

Maintenance method to cope with fatigue

employ non-destructive method(NDE) to detect cracking

repair, remove replace or review