ME215 Exam 2

1/107

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

108 Terms

Heat Treatment

processes of controlled heating and cooling to purposefully alter a material's structure and properties

Full Annealing - Hypoeutectoid

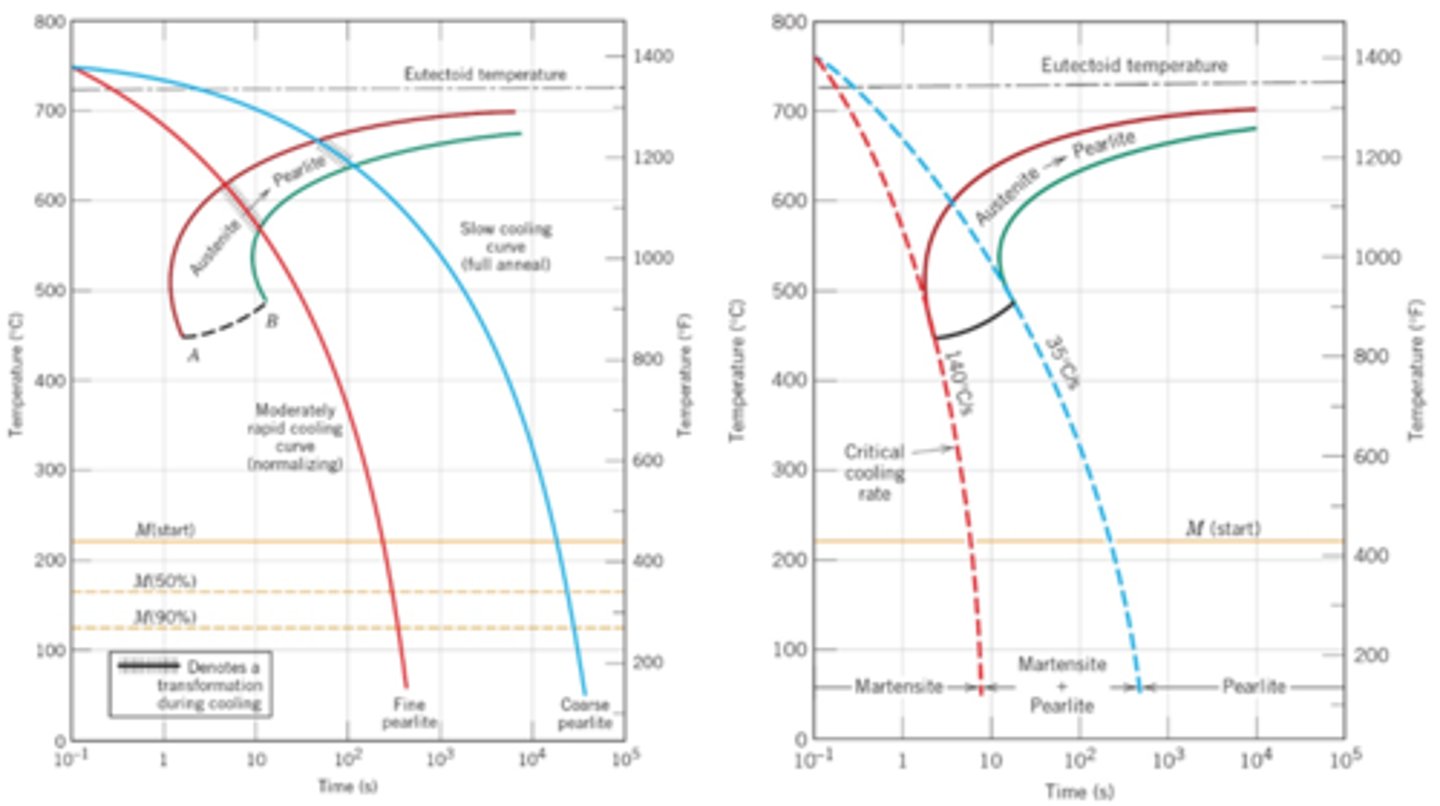

Time and energy consuming Process of heating and slowly cooling material to remove internal stresses and toughen it, resulting in coarse pearlite and excess ferrite, resulting in soft and ductile steel

Full Annealing - Hypereutectoid

Time and energy consuming Process of heating and slowly cooling material to remove internal stresses and toughen it, resulting in coarse pearlite and excess cementite

Normalizing

Process of heating steel to temperature higher than annealing and then cooling with uncontrolled air. More cost effective than annealing and properties will vary between surface and interior due to different cooling rates

Process Anneal

Recrystallization is induced after a material has been cold worked to reduce strain hardening effects. Induces a change in grain size, shape, and distribution

Stress-relief anneal

Reduces residual stresses in casting, welded assemblies, and cold-formed products, slow cooled

Spheroidization

Objective is to produce a structure in which all of the cementite is in the form of small spheroids or globules dispersed throughout a ferrite matrix

Solid-solution strengthening

Base metal dissolves other atoms as substitutional solutions or interstitial solutions

Strain hardening

Increases strength by plastic deformation

Grain size refinement

Metals with smaller grains tend to be stronger

Precipitation hardening ( or age hardening)

Strength is obtained from a nonequilibrium structure produced from heat treatment. most effective mechanism to strengthen nonferrous metals. heating, quenching, aging

Dispersion hardening

When two or more phases exist, Dispersing second-phase particles through a base material

Phase transformations

Heated to form a single phase at an elevated temperature

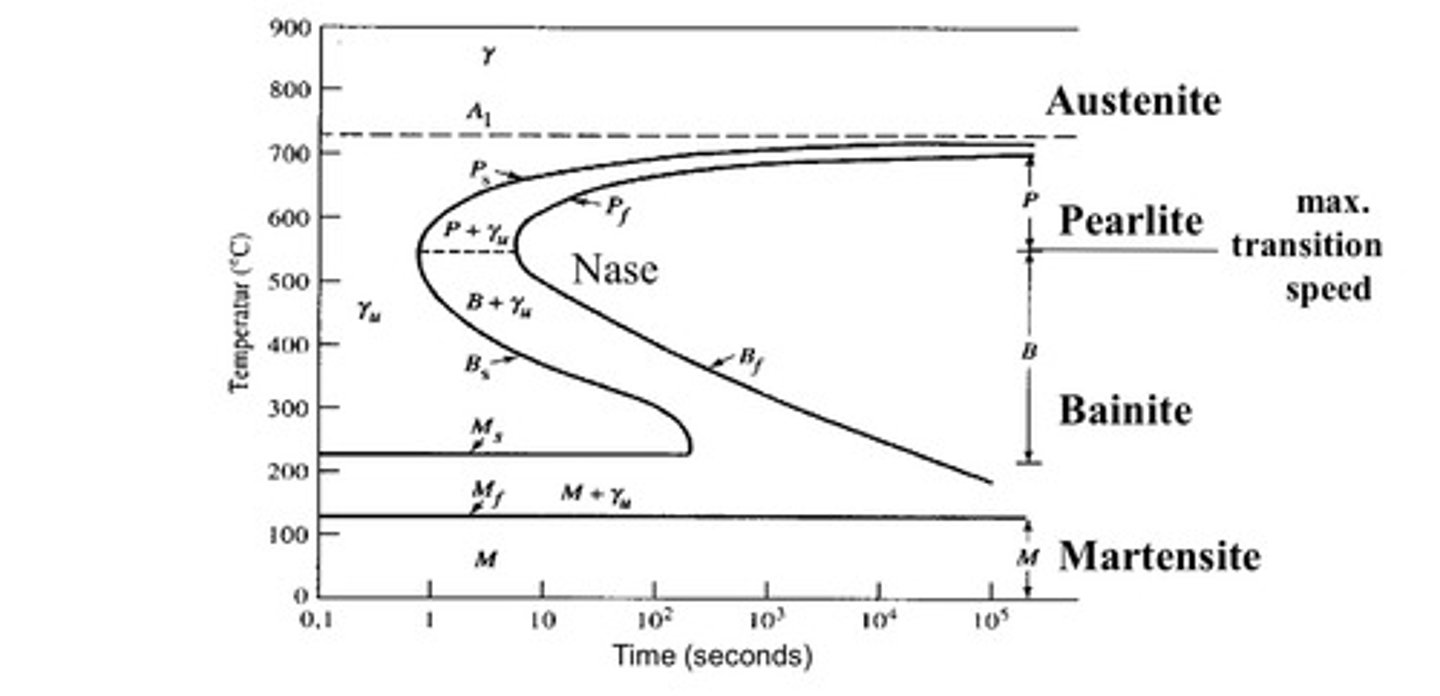

TTT (Time-Temperature-Transformation) Diagram

assume that the properties of instantaneous heating followed by constant temperature transformation match reality

Martensite

very hard, strong, but brittle. lacks the toughness and ductility for engineering applications

CCT Diagram

show a more accurate picture of the transformations

Jominy test

test used to evaluate hardenability, an austenitized steel bar is quenched atone end only thus producing a range of cooling rates

Hardenability Considerations

The greater a material's hardenability, the easier it is for a material to be slow cooled. Slow cooling reduces the probability of quench-cracking

Quenchants

he medium in which a material is quenched (rapid cooling of material at elevated temperature)

Formation of the vapor jacket

1st stage of quenching. Thin gaseous layer between the metal and the liquid during cooling

Nucleate boiling phase

2nd stage of quenching. Produces rapid rates of cooling down to the boiling point of the quenchant

Conduction and convection

3rd stage of quenching. Slower cooling from the boiling point to room temperature

Water

effective quenching medium because of its high heat of vaporization and relatively high boiling point

Brine (salt water)

Similar to water. Rapid cooling occurs because the salt nucleates bubbles. Corrosion problems may exist

Oil

utilized if slower quenching rates are desired. may cause water contamination, smoke, fumes, etc. More expensive than water or brine quenchants

Residual stresses

Stresses that exist in a part independent of an applied stress. Most parts being heat treated experience nonuniform temperatures during cooling or quenching can lead to this

Ways to prevent quench cracking and residual stresses

More uniform cross-sectional area

Generous fillets

Radiused corners

Smooth transitions

Adding additional holes

Ausforming

Material is heated to form austenite and then quenched to a temperature in the ``bay''between pearlite and bainite, maintaining the austenite. One may then deform the material, and then temper it to increase ductility.

case hardening

Methods to produce properties that vary throughout the material, i.e., hard surface, soft core

Flame hardening

Uses an oxy-acetylene flame to raise the surface temperature to reform austenite

Induction hardening

Steel part is placed inside a conductor coil and alternating current is used to change the surface of the steel . Rate and depth of heating can be controlled. Ideal for round bars and cylindrical parts

Laser beam hardening

Produces hardened surfaces . Absorptive coatings (zinc or manganese phosphate) are applied to the steel to increase efficiency

Electron beam hardening

Heat source is a beam of high-energy electrons

Carburizing

diffusion of carbon into FCC austenite steel at elevated temperatures

gas carburizing

hot gas containing carbon surround the part

pack carburizing

he steel is surrounded by a solid (charcoal for example) that contains carbon

liquid carburizing

the steel is placed in a molten bath with carbon

Nitriding

hardens the surfaces by producing alloy nitrides in special steels that contain nitride-forming elements typically heated in a dissociated ammonia

Ionitriding

plasma process that places parts in an evacuated furnace and treats them with direct current potential. Low pressure nitrogen is then introduced into the furnace and becomes ionized

Ion carburizing

similar to ionitriding except that methane is introduced instead of nitrogen

Carbonitriding

where both nitrogen and carbon are introduced

Steel

Mostly used by automotive industries

Plain Carbon Steel

Theoretically, steel is an alloy of only iron and carbon, but steel contains other elements in detectable amounts. Strength is primarily a function of carbon content

Low Carbon Steels

have less than 0.20% carbon and have good formability

Medium Carbon Steels

have between 0.20% and 0.50% carbon . Best balance of properties . High toughness and ductility are good with respect to the levels of strength and hardness

High carbon steels

have more than 0.50% carbon. Toughness and formability are low, but hardness and wear resistance are high

Carbon steels

have high strength, high stiffness, and reasonable toughness. Rust easily and require surface protection

Aluminum

Alloying element in nitriding steels

Bismuth

Improves machinability

Boron

Powerful hardenability agent

Chromium

Increase of hardenability, corrosion resistance,

Copper

Corrosion resistance, improved machinability

Lead

Improved machinability

Manganese

Prevents brittleness, increases hardenability

Molybdenum

Inhibits grain growth

Nickel

Toughener, Corrosion resistance

Silicon

Increases strength, spring steels

Sulfur

Free-machining properties

Titanium

Reduces martensitic harness in chromium stels

Tungsten

Hardness at high temperatures

Vanadium

Increases strength while retaining ductility, Prmotes fine grain structure

AISI-SAE Classification System

First number indicates the major alloying elements

Second number designates a subgrouping within the major alloy system

Last two digits indicate the carbon percentage

High-strength low-alloy (HSLA)

Provide increased strength to weight ratio

Modest increase in cost

Available in sheet, strip, plate, structural shapes, and bars

High yield strength, good weldability, and good corrosion resistance

Microalloyed Steels

are between carbon steels and alloy grades with respect to cost and performance

offer maximum strength with minimum carbon

Preserves weldability, machinability, and formability

Energy savings can be substantial

Advanced High-Strength Steels (AHSS)

Enable the stamping or hydroforming of complex parts

Higher strength provides improved fatigue resistance

Dual-phase steels can absorb more energy, meaning they are better for crash resistance in automotive applications

Free-Machining Steels

Machine readily and form small chips when cut

The smaller the chips reduce friction on the cutting tool which reduces the amount of energy required (reduces tool wear)

Maraging steels

Used when extremely high strength is required

Typically also have high toughness

Steels for High-Temperature Service

Plain-carbon steels should not be used for temperatures in excess of 250°C

Tend to be low-carbon materials

Ferritic stainless steel

Limited ductility, Poor toughness, Readily weldable, Cheapest

Martensitic stainless steels

Increased strength, More carbon content, less chromium , Less corrosion resistant but more expensive than ferritic

Water-hardening tool steels (W)

Least expensive method for small parts that are not subjected to extreme temperatures

Cold-work steels (O,A)

Larger parts that must be hardened

Oil or air quenched grades

Shock resisting tool steels (S)

Offers high toughness for impact applications

High speed tool steels

Used for cutting tools where strength and hardness are needed at high temperatures

Hot-work steels (H)

Provide strength and hardness during high temperature applications

Plastic mold steels (P)

Meets requirements of zinc die and plastic injection molding

Special purpose tool steels (L,F)

Extreme toughness, extreme wear resistance

Casting process

Material is melted

Heated to proper temperature

Treated to modify its chemical makeup

Solidifies

Advantages of Casting

Complex shapes, hollow sections or cavities, large parts, mold materials

Parting line

Separates the cope and drag

Draft

Angle or taper on a pattern that allows for easy removal of the casting from the mold

Casting

Process and product when molten metal is poured and solidified

Casting Defects

Gas porosity, Shrinkage

Chill Zone

Rapid nucleation that occurs when the molten metal comes

into contact with the cold walls of the mold

Columnar Zone

Rapid growth perpendicular to the casting surface

Equiaxed Zone

crystals in the interior of the casting, spherical randomly oriented crystals

Shrinkage

Shrinkage of liquid as it

cools from the solidification

temperature

Solidification shrinkage as

the liquid turns into solid

Solid metal contraction as

the solidified metal cools to

room temperature

Risers

Reservoirs of liquid metal that feed extra metal to the mold to compensate for shrinkage

Blind Riser

contained entirely within the mold cavity

Live Riser

Receive the last hot metal that enters the mold and generally do so at a time when the metal in the mold cavity has already begun to solidify.

Sand Casting

a metal casting process characterized by using sand as the mold material.

Requirements of sand used in casting

Refractoriness

Cohesiveness

Permeability

Collapsability

Dump-Box Shell Molding

Flip

Complex internal cavities can be produced with

cores

Die Casting

Similar to permanent mold casting except that the metal is injected into the mold under high pressure.

Centrifugal Casting

inertial forces of rotation or spinning are used to distribute the molten metal into the mold cavity

Powder metallurgy

Metal processing technology in which parts are produced from metallic powders

Basic Process of Powder Metallurgy

Powder manufacture

Mixing or blending

Compacting

Sintering

Isostatic compaction

when extremely complex shapes are desired, the powder is generally encapsulated in a flexible mold and immersed in a pressurized gas or liquid process

Sintering

a process whereby particles are heated to the point that they fuse together at their borders but do not clump into one solid mass