PKG 221 Test #1

1/54

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

55 Terms

Is glass a solid or liquid?

No - it is its own state of matter

What is the molecular structure of glass?

Amorphous, random

What is the melting point of glass?

As glass cools/heats, it gets “stiffer” or “more viscous” W

What are the main raw materials used in glass?

Silica (sand), limestone, soda ash

What is the purpose of limestone in glass?

Improves chemical durability

What is the purpose of soda ash in glass?

Reduces melting temperature

What would happen if sand was the only component in glass?

It would be harder to melt, harder to fine (get rid of bubbles), and more difficult to mold (high viscosity)

Why is cullet used?

It reduced energy usage

What is added to make yellow glass?

Iron Oxide

What is added to make green glass?

Chromium Oxide

What is added to make blue glass?

Cobalt oxide

What is added to make brown glass?

Carbon + sulfur + iron

Why would you make brown glass?

To protect the product from light

How do you make Flint (clear) glass?

Iron content imparts green color while selenium metal imparts pink or salmon color to create a gray color that appears clear to the human eye.

What does adding lead oxide do?

Very clear but soft glass

What does adding aluminum oxide do?

Adds hardness, durability & resistance to chemical attack

What does adding boron oxide do?

Thermal shock resistance (won’t crack bottle when you go from hot to cold)

What is natural glass?

Glass created by high heat events (like obsidian)

How has glass progressed throughout history?

Handblowing to semi-automatic to automatic

What does it mean to marver glass?

The “gather” of hot glass on the end of the blowpipe and blow small puffs to begin the formation of the “parison”.

What is annealing?

The process of heating a glass object to release the strain introduced in the forming process.

What is “cracking off"?

The technique of breaking off the blowpipe that has been used as a handle during the forming process.

What is a gob?

A specific amount of molten glass, which is eventually formed into a glass container.

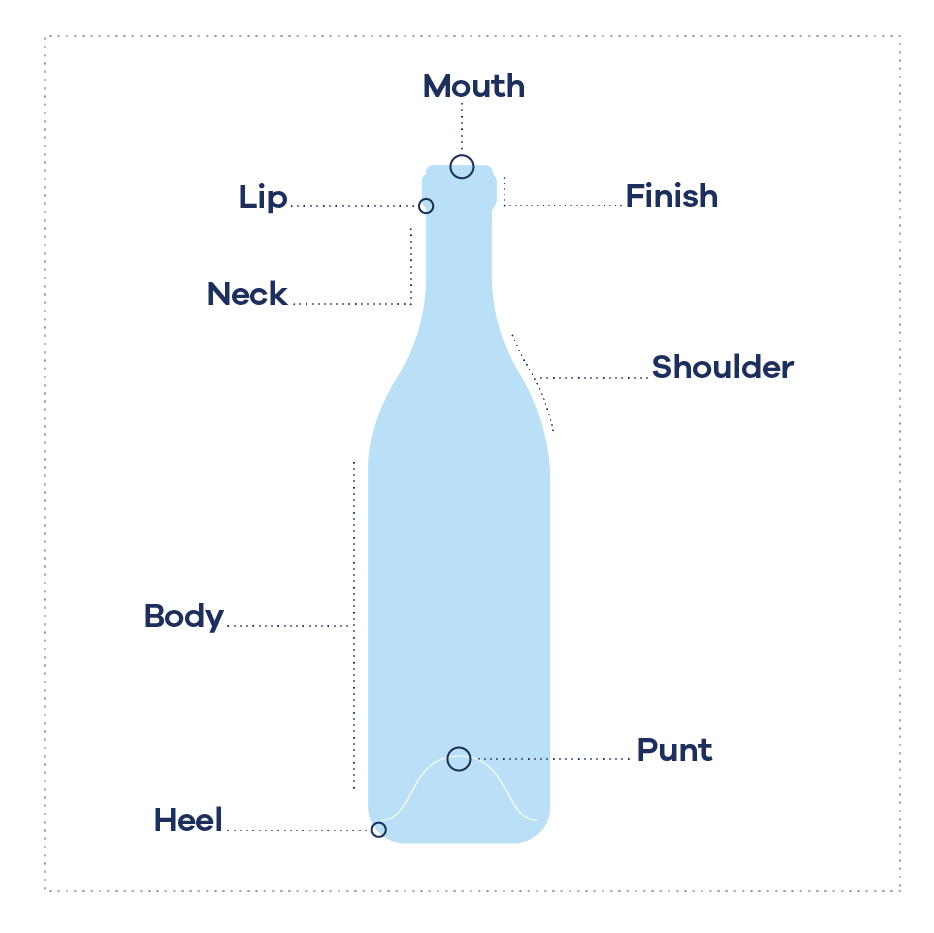

What is the shoulder, neck, and finish of a bottle?

What is the process for making a glass container?

Batch house > melting chamber > forehearth > feeder > forming machine > annealing lehr > inspection > load building

What happens in the batch house?

Raw materials storage, weigh material, mix material in batches

What happens in the melting chamber?

Melts raw material

What happens in the forehearth?

Channels glass & cools glass

What happens in the feeder?

Mixes glass, controls glass flow, shears/drops gob

What happens in the forming machine?

Creates containers

What happens in the annealing lehr?

Removes stress, reheats/slowly cools

What happens during inspection?

optically scans & automatically rejects

What happens during load building?

Pack for shipment

What is the difference between bottles & jars

Size

What is leaching?

When certain chemicals come out of the glass over time

What kind of product do we need to be concerned about leaching?

Medicine

What type of glass is used for pharmaceuticals?

USP Glass

What are vials?

Multi-use, small, round bottles, oversized rubber septum, syringe penetrates septum

What are ampoules?

Single use, extruded tubes, pinched on one end

What is the primary problem of the furnace?

Refractory materials are needed, zircon most common (most commonly run by natural gas)

What are the 3 stages of the melting process?

Melting, fining, and conditioning (reduces temp to make it consistent all the way through)

What is the goal of the melting process?

Convert batch materials into homogenous mixture suitable for forming

What is blow and blow process used for?

Large vessels >9.5” & heavy containers

What is the press and blow process used for?

9.5” or less & wide mouth jars

What is the narrow neck press and blow used for?

Less than or equal to 9.5” & 1.5” or less finish

What are the goals of surface treatments (hot & cool end coating)?

Preserve the strength of the glass containers & facilitate flow through glass manufacturer/customer filling line

What is striking?

When glass is reheated after the inspection process to make black glass

What are considerations for vertical pallet load?

Must design shoulder and heel for proper vertical loading (flat shoulder angles & large heel radii)

What are considerations for shipping cases?

Label indent, partition cells need to be large enough for insertion, corrugated needs to be designed with the right height and weight

What might a marketing group require?

An aesthetically pleasing packaging, unique shape, quality image, good size impression, adequate label area

What might a production group require?

A design that can be handled by automated/mechanical equipment, provides enough volume to meet specified label claim, and sufficient head space to allow product expansion due to temp changes

Why is bottle shape important?

Influences container strength: sphere is the strongest, cylinder is next strongest, rectangular is poorest

What is a critical defect?

Hazardous. to the user and makes the container unusable

What is a major defect?

reduces the usability of the container

What is a minor defect?

Do not affect the usability of the container but detract from its appearance or acceptability