lecture 2 scada

1/73

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

74 Terms

SCADA

supervisory control and data acquisition

It is a type of software application program for process control.

SCADA

a central control system which consists of controllers network interfaces, input/output, communication equipment, and software.

SCADA

used to monitor

and control the equipment in the industrial process which includes

manufacturing, production, development, and fabrication.

SCADA systems

The infrastructural

processes include

gas and oil distribution

electrical power

water distribution

Public utilities include

bus traffic system

airport

takes the

reading of the meters and checks the status of sensors in regular intervals so

that it requires minimal interference of humans.

SCADA system

reads the measured flow and level, and send the setpoints to the PLCs

SCADA system

t/f: Before the

concept of SCADA was introduced in the

mid-20th century, many manufacturing

floors, industrial plants, and remote sites

relied on personnel to manually control and

monitor equipment via push buttons and

analog dials.

true

to provide some level of supervisory control

without having to send people to remote locations to interact with each

device, Industrial organizations

started to utilize

relays

timers

In the early ____, computers were first developed and used for industrial

control purposes.

1950s

In the 1960s, _______ was established for monitoring, which allowed for

automated communications to transmit measurements and other data from

remotes sites to monitoring equipment.

telemetry

The term “SCADA” was coined in the

early ____, and the rise of microprocessors and PLCs during that decade

increased enterprises’ ability to monitor and control automated processes

more than ever before.

1970s

Supervisory control and data acquisition (SCADA) is a system of

software and hardware elements that allows industrial organizations to:

Control industrial processes locally or at remote locations.

Monitor, gather, and process real-time data.

Directly interact with devices such as sensors, valves, pumps, motors, and more through human-machine interface (HMI) software.

Record events into a log file.

used to gather data from sensors and

instruments located in remote areas.

SCADA system

gathers the information (like a

leak on a pipeline occurred) and transfers the information back to the system

while giving the alerts that leakage has occurred and displays the information

in a logical and organized fashion.

SCADA system

crucial for industrial

organizations since they help to maintain efficiency, process data for smarter

decisions, and communicate system issues to help mitigate downtime.

SCADA system

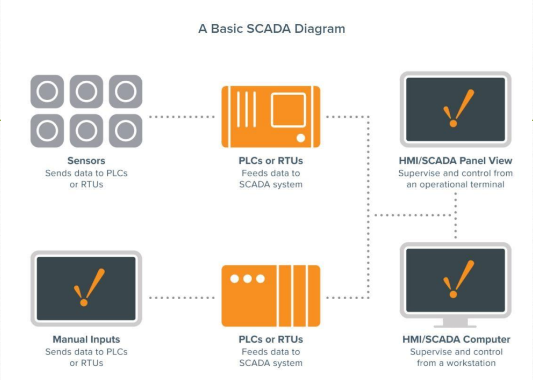

a basic SCADA diagram

The SCADA system can be classified into two parts:

client layer

data server layer

layer which caters for the man-machine interaction.

Client layer

layer which handles most of the process data activities.

Data server layer

a centralized system that monitors and

controls the entire area.

SCADA system

t/f: pure software package that is positioned on

top of the hardware.

true

gathers data on the process and

sends the commands control to the process.

supervisory system

RTU.

remote terminal unit

t/f: The SCADA is a remote terminal unit

true

t/f: Most control actions are automatically

performed by RTUs or PLCs.

true

consists of the programmable logic

converter which can be set to specific requirement.

RTU

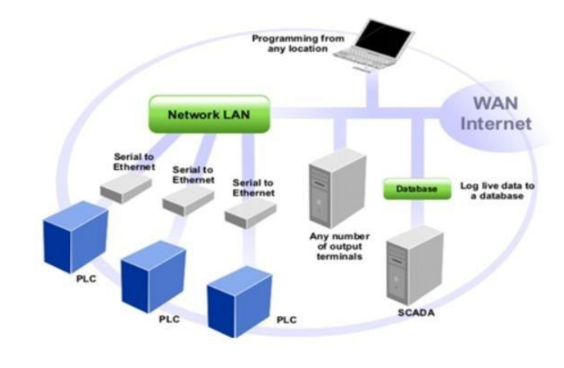

basic SCADA architecture

programmable logic controllers (PLCs)

remote terminal units (RTUs).

microcomputers that communicate with an array of

objects such as factory machines, HMIs, sensors, and end devices, and then route the

information from those objects to computers with SCADA software.

PLCs and RTUs

processes, distributes, and displays the data, helping operators and other employees analyze

the data and make important decisions.

SCADA software

allows operators to change the set point for the

flow, and enable alarm conditions in case of loss of flow and high

temperature, and the condition is displayed and recorded.

SCADA system

monitors the overall performance of the loop.

SCADA

system

a centralized system to communicate with both wired and wireless

technology to Client devices.

SCADA

system

can run

completely all kinds of the industrial process.

SCADA system controls

refers to the servers and it is composed of a single PC.

SCADA station

communicate with devices in the field through process controllers like

PLCs or RTUs.

data servers

connected to the data servers either directly or via

networks or buses.

PLCs

SCADA system utilizes 2 networks

WAN

LAN

consist of internet protocols used for communication between the master

station and devices.

WAN and LAN

convert the sensor signals to digital data and sends digital data to

the master.

RTUs

Hardware Architecture:

t/f: Most of the servers are used for multitasking and real-time database.

true

responsible for data gathering and handling.

servers

to provide trending, diagnostic data, and manage information

such as scheduled maintenance procedures, logistic information, detailed

schematics for a particular sensor or machine, and expert-system troubleshooting

guides.

software program

t/f: the operator can see a schematic representation of the plant

being controlled.

true

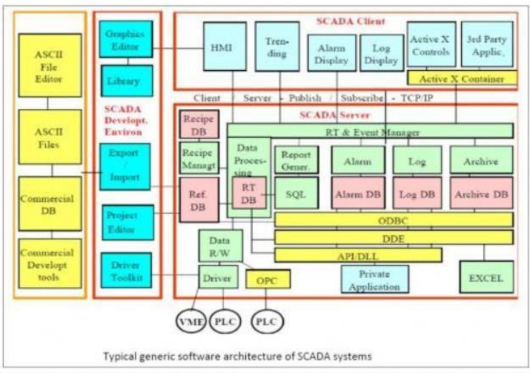

Software Architecture:

SCADA system performs four functions:

Data Acquisitions

Data Communication

Information/Data presentation

Monitoring/Control

These functions are performed by

sensors

RTUs

controller

communication network.

used to collect the important information

sensors

used to send this information to the controller and display the status of the

system.

RTUs

According to the status of the system, the user can give the command

to other system components. This operation is done by the

communication network

consists of thousands

of components and sensors.

The real-time system

It is very

important to know the status of particular

components and sensors.

Data Acquisitions

t/f: The SCADA system uses a wired network to communicate between users

and devices.

true

Sensor and relays are not able to communicate with the

network protocols so ____ used to communicate sensors and net work

interfaces.

RTUs

It connect to sensors in the process, converting sensor signals to digital

data and sending digital data to the supervisory system.

Remote Terminal Units (RTUs)

It is used as field devices because they are more economical,

versatile, flexible, and configurable than special-purpose RTUs.

Programmable Logic Controller (PLCs)

The SCADA system uses the ____________ to provide all of the information gathered from the various sensors.

human-machine interface (HMI)

provides access to multiple

control units which can be PLCs and RTUs.

HMI

provides the graphical

presentation of the system.

HMI

it is an important part of the HMI that is activated

according to the predefined values.

alarm system

t/f: The SCADA system uses different switches to operate each device

and displays the status of the control area.

true

it is implemented to work automatically

without human intervention but in critical situations, it is handled by

manpower.

SCADA system

SCADA systems are the

backbone of many modern industries, including:

energy

food and beverage

manufacturing

oil and gas

power

recycling

transportation

water and waste water

t/f: Effective SCADA systems can result in significant

savings of time and money.

true

scada system applications

Power generation, transmission, and distribution

Water distribution and reservoir system

Public buildings like electrical heating and cooling system.

Generators and turbines and Traffic light control system

scada system advantages

provides onboard mechanical and graphical information

easily expandable. We can add a set of control units ands ensors according to the requirement.

ability to operate critical situations.

allow real-time data from the plant floor to be

accessed from anywhere in the world.

Modern SCADA systems

t/f: Without SCADA software, it would be

extremely difficult if not impossible to gather sufficient data for consistently well-informed decisions.

true

most modern SCADA designer applications have

_______ capabilities that allow users to design

applications relatively easily, even if they don't have extensive knowledge of

software development.

rapid application development (RAD)