Topic 11: Corrosion

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

the deterioration of the material resulting from chemical attack by its environment

what is corrosion

electro → movement of electrons, chemical → changes in chemical composition

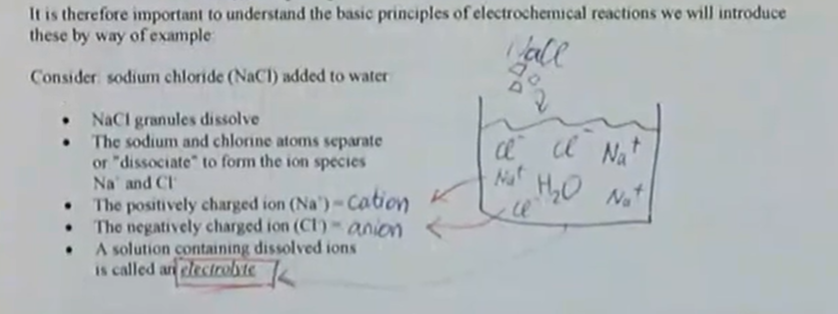

consider sodium chloride added to water:

→ NaCl granules dissolve

→ the sodium and chlorine atoms separate or “dissociate” to form the ion species Na+ and Cl-

→ the positively charged ion (Na+) = cation

→ the negatively charged ion (Cl-) = anion

→ a solution containing dissolved ions is called an electrolyte

describe the electrochenical process of corrosion

reaction by which metals form cations that go into aqueous solution (water based), i.e. reaction by which metal corrodes

called the anodic reaction

the location where this reaction takes place is called the anode

the electrons generated in this reaction remain in the metal

what is an oxidation reaction

reaction where a metal or non-metal cation accepts electrons

called the cathodic reaction

the location where this reaction takes place is called the cathode

this reaction consumes electrons

what is a reduction reaction

at the same time

at the same rate

what time and rate must oxidation and reduction reaction occurs at

2H+ (aq) + 2e- (aq) → H2(g)

what is the reaction for corrosion occurring in acidic solutions (containing H+ ions) and no metal ions

O2(g) + 4H+(aq) + 4e-(aq) → 2H2O(l)

what is the reaction for corrosion occurring in an oxidising acidic solution with no metal ions

O2(g) + 2H2O(l) + 4e- (aq) → 4OH-(aq)

what is the reaction for corrosion occurring in a neutral or alkaline solution with no metal ions

if a piece of iron is left outside it will undergo uniform corrosion and form ‘rust’

in this case, water from rain or condensation, which contains some dissolved oxygen from the air, sits on the surface

the anodic corrosion reaction that occurs at microscopic local anodes is:

→ 2Fe(s) → 2Fe2+ (aq) + 4e-the cathodic reaction that occurs at a microscopic local cathode is:

→ O2(g) + H2O(l) + 4e- (aq) → 4OH- (aq)the overall reaction in this case is the sum of these:

→ 2Fe(s) + O2(g) + 2H2O(l) → 2Fe2+(aq) + 4OH-(aq)if the surface is allowed to dry, the ferrous hydroxide dehydrates to form ferric oxide, Fe2O3:

→ 2Fe(OH)2 (aq) → Fe2O3 . 3H2O — rust

describe the rusting of iron

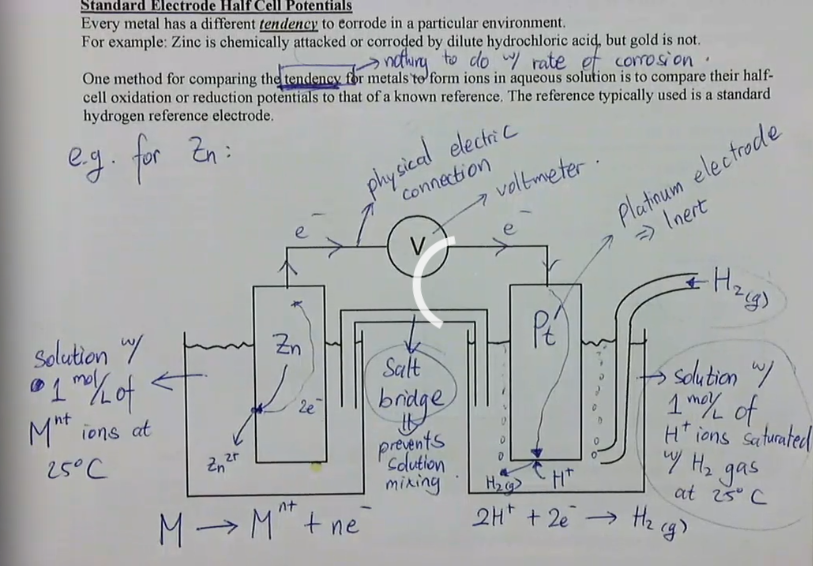

Every metal has a different tendency to corrode in a particular environment.

For example: Zinc is chemically attacked or corroded by dilute hydrochloric acid, but gold is not.

One method for comparing the tendency for metals to form ions in aqueous solution is to compare their halfcell oxidation or reduction potentials to that of a known reference. The reference typically used is a standard hydrogen reference electrode.

Platinum is the standard hydrogen reference electrode

draw the electrodes used in electrolysis

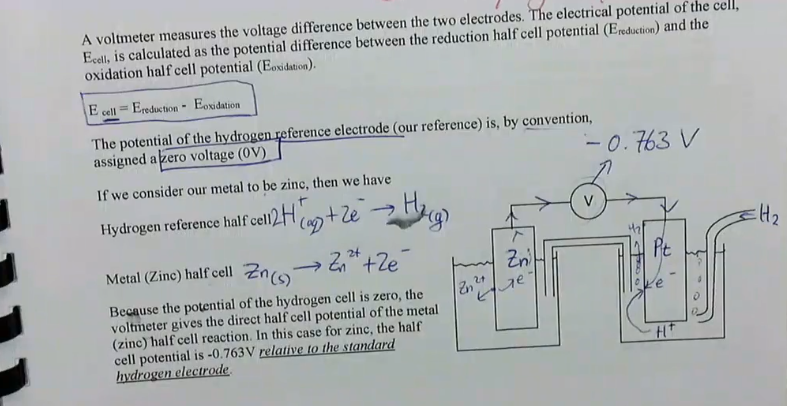

Ecell = Ereduction - Eoxidation

the potential of the hydrogen reference electrode is by convention assigned a zero voltage (0V

metals which are more reactive than hydrogen are assigned negative potentials

if we connect the metal to the hydrogen reference electrode without a voltmeter, these metals are oxidised to ions and hydrogen ions are reduced to form hydrogen gas

the reaction with the more negative electropotential → will be oxidised

the reaction with the most positive electrode potential → will be reduced

how is the half-cell potential calculated

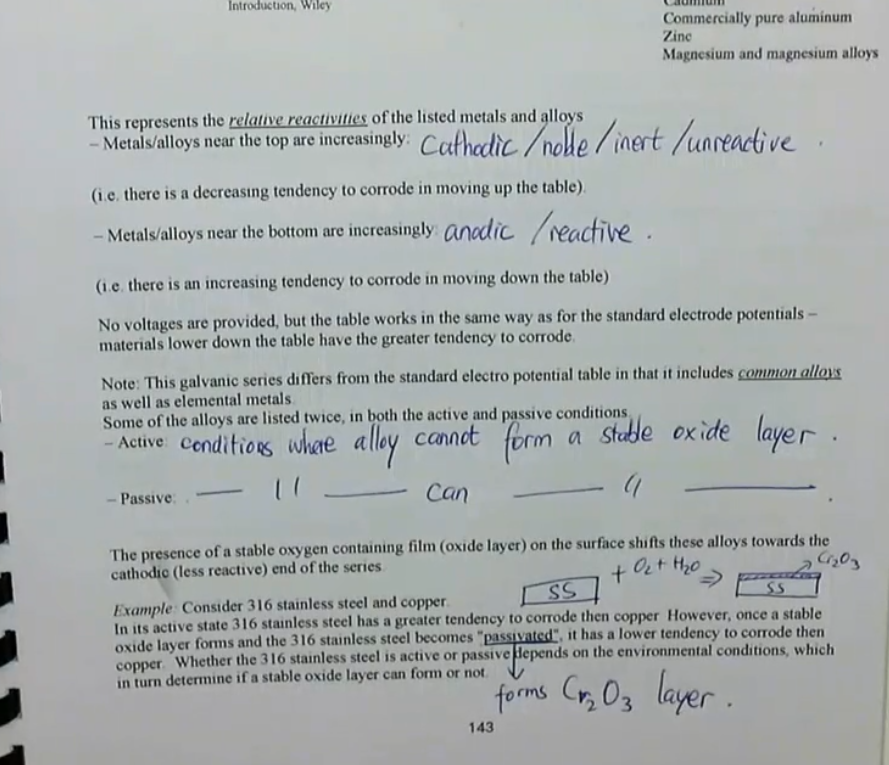

the galvanic series represents the relative reactivities of the listed metals and alloys

metals/alloys near the top are cathodic/noble/inert/unreactive

i.e. there is a decreasing tendency to corrode in moving up the table

metals/alloys near the bottom are increasingly anodic/reactive

i.e. there is an increasing tendency to corrode in moving down the table

no voltages are provided, but the table works in the same way as for the standard electrode potentials — materials lower down the table have the greater tendency to corrode

this galvanic series differs from the standard electro potential table in that it includes common alloys as well as elemental metals

some of the alloys are listed twice, in both active and passive conditions

active: conditions where alloy cannot form a stable oxide layer

passive: conditions where alloy can form a stable oxide layer

the presence of a stable oxygen containing film (oxide layer) on the surface shifts these alloys towards the cathodic (less reactive) end of the series

galvanic series

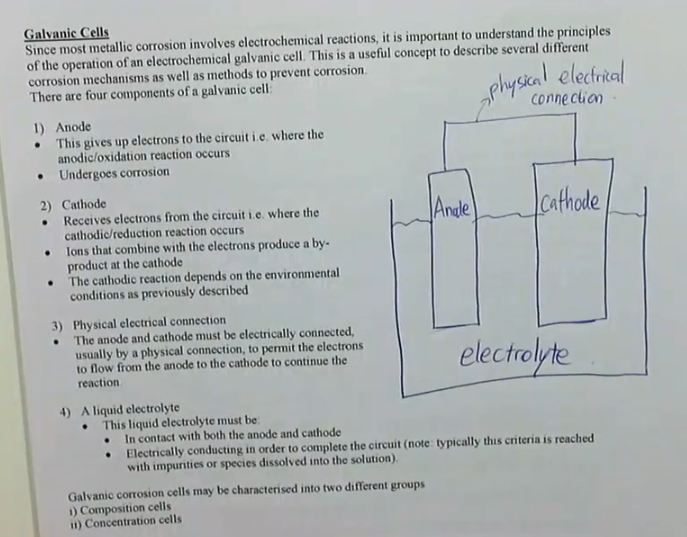

since most metallic corrosion involves electrochemical reactions, it is importat to under the principles of the operation of an electrochemical galvanic cell, this is a useful concept to describe several different corrosion mechanics as well as methods to prevent corrosion

there are four components of a galvanic cell

1. anode

this gives up electrons to the circuit, i.e. where the anodic/oxidation reaction occurs

undergoes corrosion

2. cathode

receives electrons from the circuit, i.e. where the cathode/reduction reaction occurs

ions that combine with the electrons produce a by-product at the cathode

the cathodic reaction depends on the environmental conditions as previously described

3. physical electrical connection

the anode and cathode must be electrically connected, usually by a physical connection to permit the electrons to flow from the anode to the cathode to continue the reaction

4. a liquid electrolyte

this liquid electrolyte must be:

in contact with both the anode and cathode

electrically conducting in order to complete the circuit (note: typically this criteria is reached with impurities or species dissolved into the solution)

galvanic corrosion cells may be characterised into two different groups:

composition cells

concentration cells

galvanic cells

a composition cell may be established between and two dissimilar metals

in each case the metal lower on the standard electrode potential (or galvanic series) table acts as the anode and undergoes corrosion

the further apart the two metals are, the greater the potential/tendency for corrosion to occur

during corrosion the metal atoms at the anode go into solution and release electrons

the cathode is protected from corrosion in this process

typically, if either metal were exposed to the electrolyte by itself, it would corrode, but at a comparatively slow rate — they would undergo general corrosion

the danger comes when they are coupled together i a galvanic cell — the corrosion rate of the anode metal in this case is much greater than its rate of general corrosion

in addition, the cathode material is protected from undergoing corrosion by this process

what are composition cells

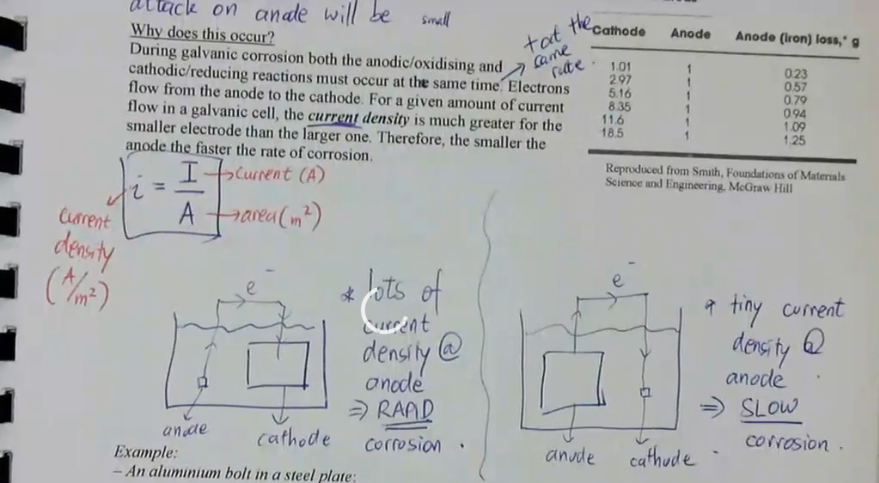

the other factor that controls galvanic corrosion is the relative size of the anode and cathode

if the anode is small relative to the cathode:

attack on anode will be large

if the anode is large relative to the cathode:

attack on anode will be small

why does this occur:

during galvanic corrosion both the anodic/oxidising and cathodic/reducing reactions must occur at the same time and at the same rate

electrons flow from the anode to the cathode

for a given amount of current flow in a galvanic cell, the current density is much greater for the smaller electrode than the larger one

therefore, the smaller the anode, the faster the rate of corrosion

current density equation: i = I/A (current/area), measured in A/m²

how does area effect corrosion

the amount of metal removed from the anode by corrosion can be determined by Faraday’s equation

m = (I x t x M)/(n x F)

m = mass in grams of metal lost

I = corrosion current in amps

t = time in seconds

M = atomic mass of the metal (g/mol)

n = number of electrons exchanged in the anodic reaction

F = Faraday's number (96,500 C/mol or amp.sec/mol)

what is the rate of metal loss to corrosion (for uniform corrosion)

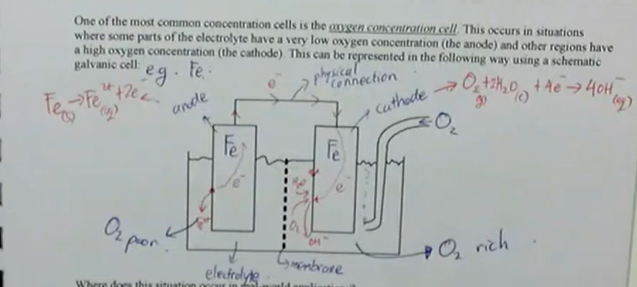

concentration cells develop due to differences in the concentration of the electrolyte, in this situation:

the metal in contact with the most concentrated solution will be the cathode (protected)

the metal in contact with the dilute solution will be the anode (will corrode)

one of the most common concentration cells is the oxygen concentration cell, this occurs in situations where some parts of the electrolyte have a very low oxygen concentration (the anode) and other regions have a high oxygen concentration (the cathode) — this can be represented in the follow way using a schematic galvanic cell

concentration cells

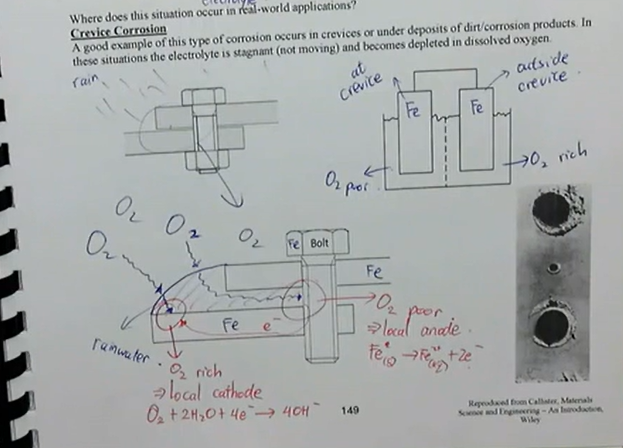

crevice corrosion is an example of a concentration cell

occurs in crevices or under deposits of dirt/corrosion products, in these situations the electrolyte is stagnant (not moving) and becomes depleted in dissolved oxygen

what is crevice corrosion

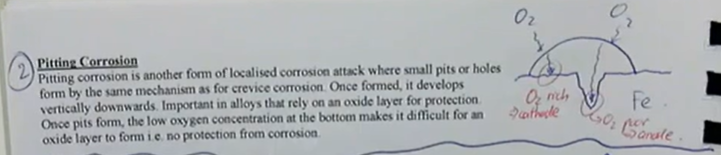

pitting corrosion is another form of localised corrosion attack where small pits or holes form by the same mechanism as for crevice corrosion

once formed, it develops vertically downwards

important in alloys that rely on an oxide layer for protection

once pits form, the low oxygen concentration at the bottom makes it difficult for an oxygen layer to form, i.e. no protection from corrosion

what is pitting corrosion

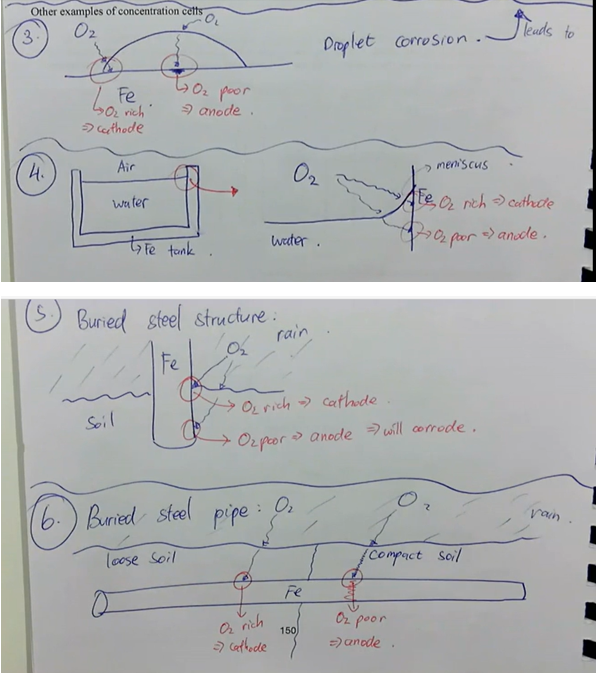

droplet corrosion → leads to pitting corrosion

water line corrosion

buried steel structure

buried steel pipe

what are other examples of concentration cells/corrosion

remove the electrolyte

design components so water does not sit for extended periods

clean surface deposits which may trap moisture near the surface

stagnant water forms O2 concentration cells

change materials so that the anodic material becomes cathodic

use of galvanising and sacrificial anodes

e.g. Zn-coating on steel

cathodic protection

cover the cathode to isolate it from the system

apply protective coatings

e.g. paint

passive layer (e.g. stainless steel)

electroplating (e.g. Sn-coated steel)

remove the electrical connection between the anode and cathode

use insulating materials between dissimilar materials

how do we prevent corrosion

corrosion of a metal, M, occurs by the generalised reaction

M(s) → Mn+ (aq) + ne-

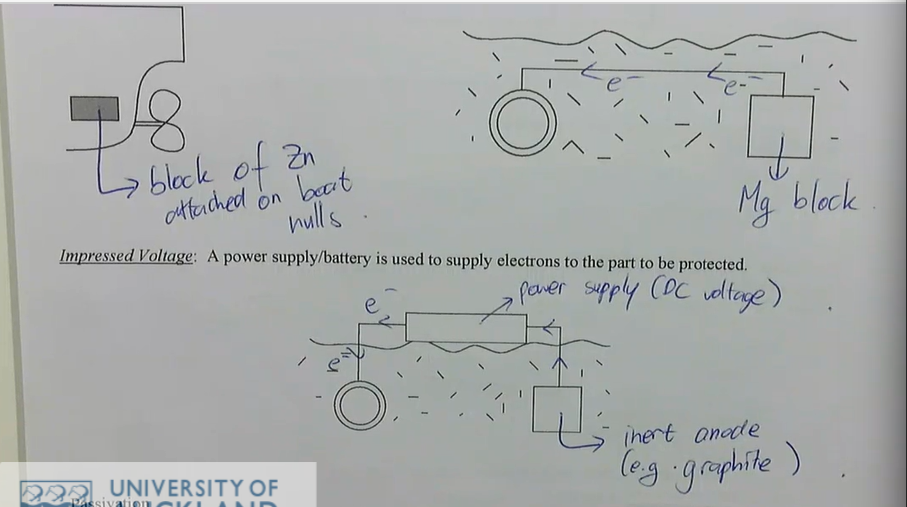

cathodic protection works by continuously supplying electrons to the metal to be protected, forcing it to be the cathode

there are two methods of supplying electrons to the metal:

sacrificial anode: a metal that is more reactive on the galvanic series is attached to the metal to be protected and acts as a sacrificial anode

as it corrodes it provides electrons to the metal to be protected

it must eventually be replaced

typically use magnesium or zinc as sacrificial anodes

examples: protection of buried pipes, ships, offshore drilling platform

impressed voltage: a power supply/battery is used to supply electrons to the part to be protected

cathodic protection