Abrasives, Abrasion and Polishing

1/103

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

104 Terms

Mechanical Properties

Characteristics of dental materials that determine their performance under stress.

Polymerization

The process of reacting monomer molecules together to form polymer chains.

Hydrocolloid Impression Materials

Materials that form gels when mixed with water, used for dental impressions.

Elastomeric Impression Materials

Flexible materials that record tooth and gum structures when set.

Lost-Wax Casting Technique

A method for creating dental restorations where a wax pattern is melted away.

Surface Roughness

The texture of a surface, determined by small-scale deviations or irregularities.

Finishing

The refinement of a surface prior to polishing, ensuring proper fit and shape.

Polishing

The process of making a surface smooth and glossy by abrasion.

Abrasive Index (AI)

A measure of the amount of material abraded from a dental surface in a specified time.

Dental Cements

Materials used to bond or affix dental restorations to tooth structures.

Mechanical Testing

A method to evaluate the properties of a material under various mechanical loads.

Diamond Burs

Dental tools embedded with diamond particles used for cutting and polishing.

Air-Water Spray Coolants

A mixture of air and water used to reduce heat during dental procedures.

What kind of prosthesis is finishing?

Interim

What kind of prosthesis is polishing?

Definitive

State the steps of a direct restoration

Diagnostic

Tissue Management

Isolation

Decay Removal

Cavity Preparation

Sectional Matrix

Lingual Matrix

Bonding

Composite

Placing, Shaping, Blending and Curing

Finishing

Polishing

Procedure systems

Define Abrasion

Wear or material loss from a surface as a result of scratching or other mechanical means

What is a substrate in dental abrasion

Material being abraded

What is abrasive?

Material that causes wear

What is two-body abrasion?

Abrasive particles are tightly bonded to the abrasive instrument that is removing material from the substrate surface

What is three-body abrasion?

Involves the use of non-bonded abrasives, abrasive particles are free to translate and rotate between two surfaces

What is airborne particle abrasion?

Abrasive particles are propelled (sandblasted) against a substrate by air pressure to remove surface material

What are some factors that affect the rate of abrasion?

Hardness between the abrasive and the substrate

Particle size of abrasive

Particle shape of abrasive

speed & pressure

lubrication

What is the hardness between the abrasive and the substrate?

Relative hardness of minerals using a scale

What does the Mohs values indicate?

The resistance to scratching of one material by another

What is the Mohs Hardness Test?

This test compares the resistance of a mineral by scratching with ten reference minerals known as the Mohs Scale Materials

What is the Mohs Hardness Scale

It is determined by scratching the surface of the tile with different minerals and subjectively assigning a “Mohs” number

When/how is pumice created?

When super-heated, highly pressurized rock is violently ejected from a volcano

What is the hardness of pumice?

6

What is the hardness of dentin and hard gold alloy?

3-4

What is the hardness of enamel?

5-6

What is the indentation hardness test?

The size or the depth of the indentation and the amount of force used to calculate a hardness value

What is the particle size of superfine abrasive?

<10 micrometers

What is the particle size of fine abrasive?

10-20 micrometers

What is the particle size of medium abrasive?

20-100 micrometers

What is the particle size of coarse abrasive?

100-500 micrometers

For the same applied pressure, larger particles

leave larger scratches in the substrate

For the same applied pressure, smaller particles

leave smaller scratches in the substrate

A sharp particle produces

Deeper abrasion than rounder particle under the same applied force

Equivalent sized scratches can be produced by different sizes of particles by

Varying the applied pressure

What is the purpose of lubrication?

To reduce heat build up, and to wash away debris to prevent clogging of the abrasive instrument

What stops metal to metal contact and reduces wear in engines

Oil or maintenance as a lubricant

What is the rotational speed of a low speed rotary grinding instrument?

< 20,000 rpm

What is the rotational speed of a medium speed rotary grinding instrument?

20,000 to 200,000 rpm

What is the rotational speed of a high speed rotary grinding instrument?

> 200,000 rpm

What is an air turbine?

Balance between speed and torque, faster and consistent cutting and grinding

Air driven handpieces have a faster bur speed, but are also

High-pitched (lounder sound)

Name some finishing and polishing instruments

Carbide burs

Diamond burs

Dental stones

Rubber wheels

Disks and strips

What are the three basic parts of carbide and diamond burs?

The shank, the neck, and the head

This portion of the bur can vary to accommodate contra-angled or straight handpieces

The shank

What are the two difference types of shanks?

Friction (high speed), and Latch-type for slow speed

What material are bur shanks made of?

stainless steel

What material are cutting blades made of?

Tungsten carbide

What are carbide burs used for

Contouring and finishing

This is how mnay fluted blades you can see on a carbide bur

8-30 either straight or twisted

What is the straight blade design?

One blade on toothW

What is the spiral blade design?

Several blades on tooth

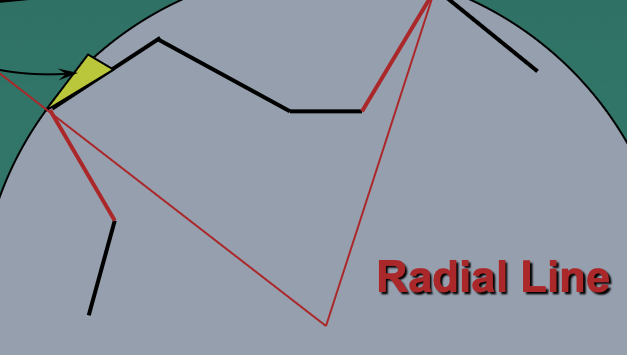

What are the components of a carbide bur blade design?

Clearance Face

Rake Faces

Rake Angle

Radical Line

Direction of Rotation

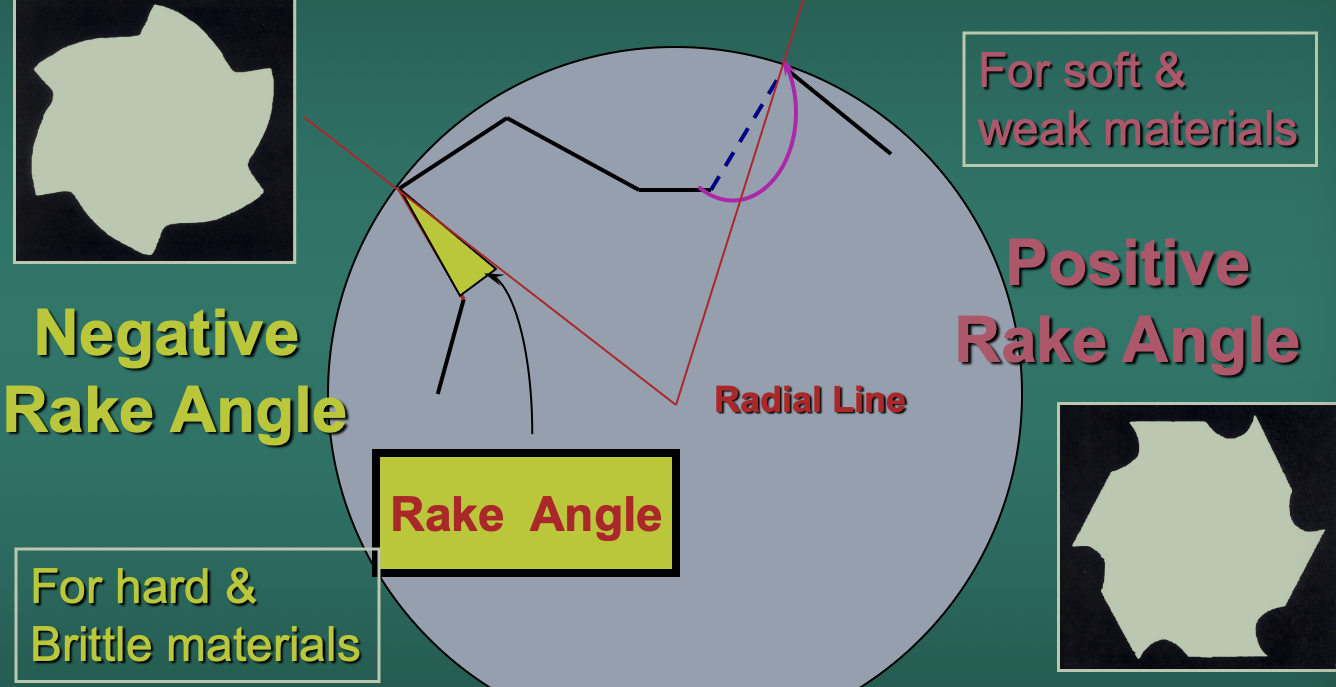

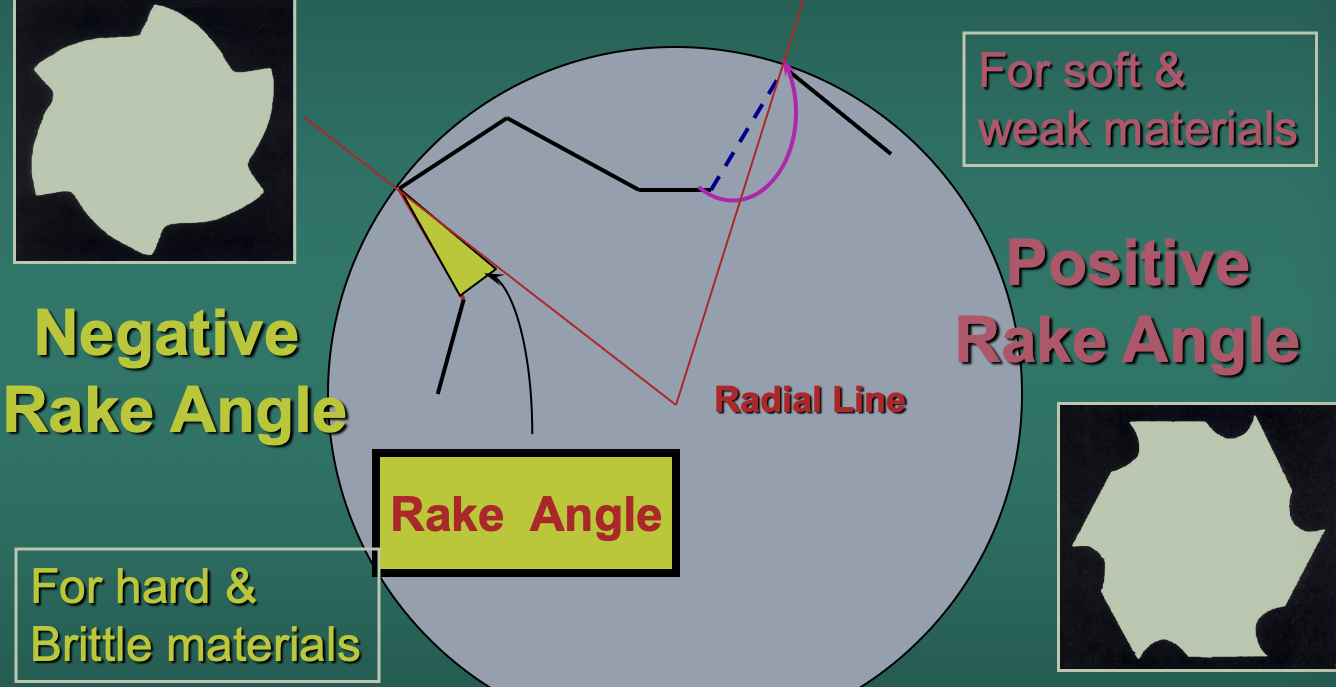

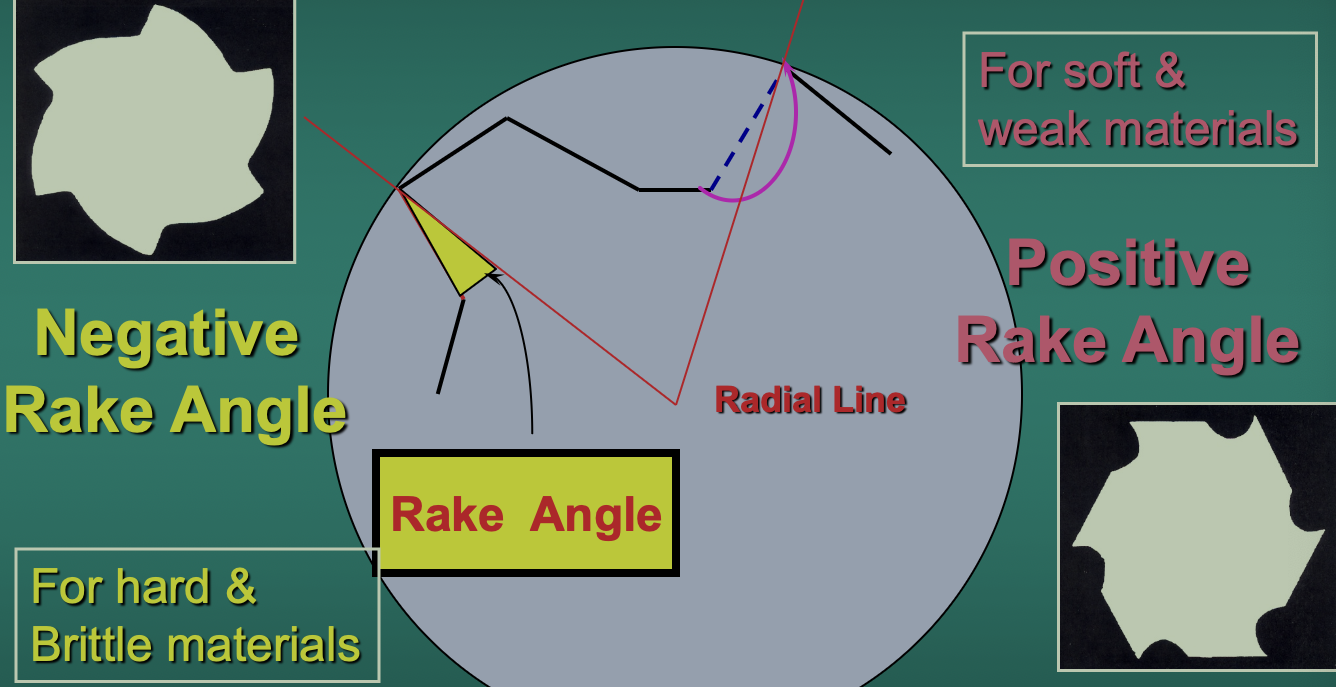

What is the rake angle

The angle made between the rake face and the line connecting the edge to the axis of the bur

What is a negative rake angle?

The radial line lies behind the rake face and entirely within the blade

What is a positive rake angle?

The radius lies outside the blade, the rake angle is positive

What does a large rake angle mean?

Lower strength of cutting edge

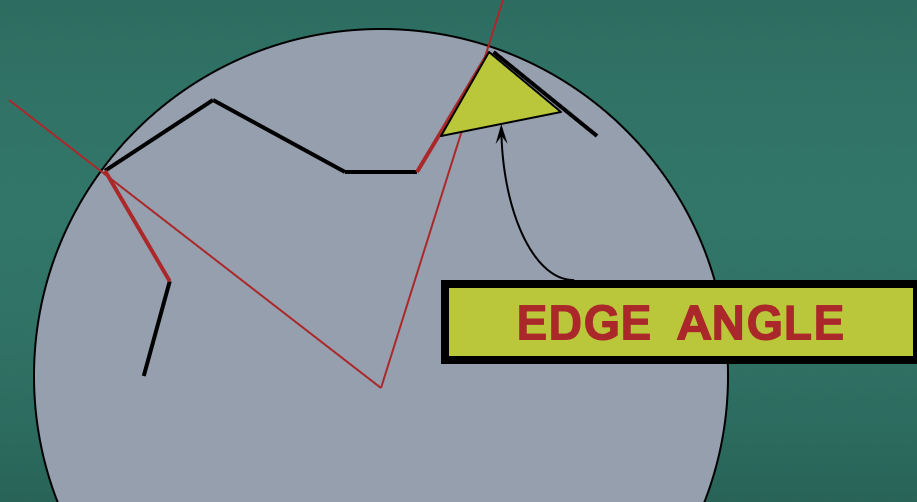

What is the edge angle?

The internal angle at the edge formed by the two faces of the bur blade, it is related to the resistance of the blade to fracture

What is a clearance angle?

The angle between the clearance face immediately behind the edge and a tangent to the path of rotation

What are the purposes of the clearance angle?

To eliminate rubbing friction of the clearance face of the blade against the new tooth surface

To provide a stop to prevent the bur edge from digging into the tooth structure excessively

To provide adequate clearance space for the chips formed ahead of the following blade

What is a rake angle?

Cutting edge strength

What is an edge angle?

Blade strength

What is a clearance angle

Provide a stop and space

What are diamond instruments used for?

Finishing diamonds are used to contour, adjust, and smooth composites or porcelain

What is a diamond bur?

A stainless steel shank

Powered diamond abrasive

DiA metallic bonding material that holds the diamond powder onto the shank

Diamond burs should always be utilized with

water spray

Other polishing instruments, such as rubber polishing instruments or pastes, will usually

follow the use of diamonds

What are carbide burs better for?

End-cutting, produce lower heat, and have more blade edges for cutting

What are diamond burs better for?

More effective for tooth preparation, beveling enamel margins and enameloplasty

Name some cutting recommendations

Using a (contra-angle) handpiece

air-water coolant system

high-operating speed

light pressure

a carbide bur or diamond bur

What are dental stones?

Abrasive particles that have been sintered together or bound with an organic resin to form a cohesive mass

What are dental stones used for?

Contouring and finishing restorations, where maximum abrasion is needed

What are the types of dental stones

Silicon Carbide

Aluminum Oxide

Diamond Stone

What are rubber wheels used for

Fine grinding to remove coarse scratches from rough grinding

How are rubber wheels made?

By molding the fine abrasives (aluminum oxide, silicon carbide, and chromium oxide) in a rubber matrix

What are rubber polishers used for?

Adjusting and polishing acrylic material

What are point shape instruments used for

Occlusal fine finishing and polishing

What can happen if you apply heavy pressure when using rubber polishing instruments?

They can produce excessive friction heat

How is heat dangerous in rubber polishing?

It can be deleterious to the restoration, rubber instrument and to the tooth itself

What are disks made of?

A stiff plastic or paper backing coated with abrasive particles

What are disks used for?

Gross reduction, contouring, finishing, and polishing restorations

What are enhance finishing and PoGo Polishing systems designed for

To finish and polish all types of composite restoration surfaces

What are enhance aluminum oxide finishers (disks, cups, and points) used for?

For preparing composite for their final polish

What are PoGo diamond polishers used for?

Single-use resin polishing devices designed for the final polishing of all accessible composite resin restorations

What are polishing strips useful for

In finishing and polishing interproximal areas

Polishing of a surface relies on

Using sequentially smaller and smaller abrasives

Larger abrasive particles do what?

Remove large amounts of material from the substrate

Smaller particles do what?

Smooth out the roughness produced by larger particles

What does proper polishing do?

Reduces peak-to-valley height and active surface area of the restoration

What is required to control frictional heat at the cutting site

Coolants

Name some types of coolants

Air, water, and air-water spray

When visibility is a problem, what should be used?

Air coolant

Air coolants are used:

at high cutting speeds, less heat is produced, air coolant combined with lower speed and light intermittent application

Water is used as a coolant when?

In controlling temperature increase

Visibility is not an issue in which type of coolant?

Air-water spray