HW1: Turning,Milling & Drilling Processes

5.0(1)

Card Sorting

1/26

There's no tags or description

Looks like no tags are added yet.

Study Analytics

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

27 Terms

1

New cards

Lathe Turning

A metal cutting process used for the generation of cylindrical surfaces. Normally the workspace is rotated on a spindle and the tool is fed into it radially, axially, or both ways simultaneously, to produce the desired surface

2

New cards

Work holding methods

“Held in a chuck”

“Held in a collet”

“Held between Centers”

“Held in a collet”

“Held between Centers”

3

New cards

Held in a chuck

When a workpiece is _________, it is clamped in a rotary chuck containing 3 or 4 jaws for security

4

New cards

Held in a collet

When a workpiece is ______, it is held in precision cylindrical bushings

5

New cards

Held between centers

When a workpiece is_______, it is supported between 2 pointed mandrels.

\-Used for long slender pieces

\-Used for long slender pieces

6

New cards

True

T or F: All standard tool holders are designed to cut with the cutting edge or point located on the center line of the machine and workspace

7

New cards

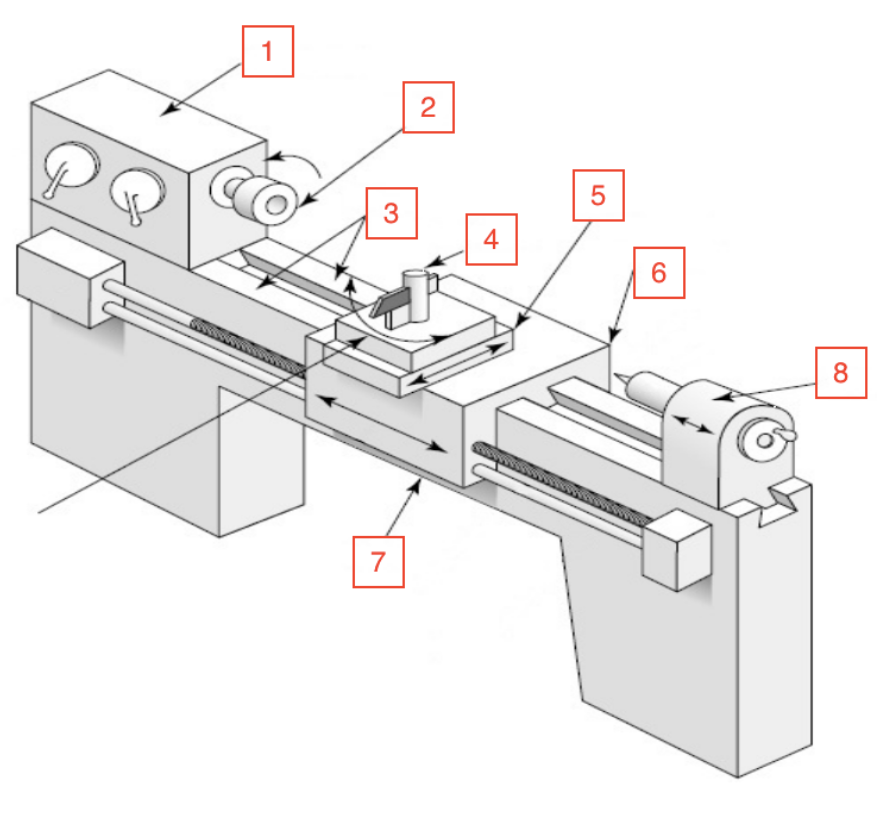

Name all of the Locations

1-Headstock

2-Spindle

3-Ways

4-Tool Post

5-Cross Slide

6-Carriage

7-Bed

8-Tailstock

2-Spindle

3-Ways

4-Tool Post

5-Cross Slide

6-Carriage

7-Bed

8-Tailstock

8

New cards

Turret Lathe

Engine Lathe

Engine Lathe

Two Different Types of Lathe

9

New cards

Turret Lathe

Represents First step towards high production turning machines

Replaces the tail stock and tool post compound assembly with tool-holding turrets

Includes “skill of the worker”, inexperienced workers can reproduce identical parts

Higher production needs

Replaces the tail stock and tool post compound assembly with tool-holding turrets

Includes “skill of the worker”, inexperienced workers can reproduce identical parts

Higher production needs

10

New cards

Engine Lathe

Lower production needs

Skilled operator and requires time to produce identical parts

Skilled operator and requires time to produce identical parts

11

New cards

Milling

A process of generating machined surfaces by progressively removing a predetermined amount of material or stock from the work piece which is advanced at a relatively slow rate of movement or feed to a milling cutter rotating at a comparatively high speed

12

New cards

End Milling

The use of the end and periphery of the cutting tool to create a shoulder or pocket

13

New cards

Face Milling

The use of the end or tip of the cutting tool to create a flat work piece surface

14

New cards

High speed steel

From what material are most solid milling cutters and drills made?

15

New cards

Vise

What is the most common type of work holding device for a milling machine?

16

New cards

True

T or F: Drilling accounts for the majority of holes produced in industry today

17

New cards

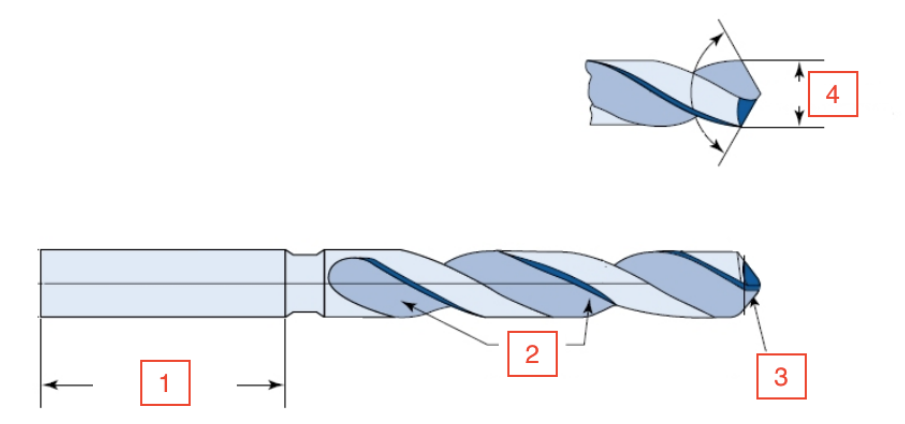

Name of the components of the drill

1-Shank Length

2-Flutes

3-Lip

4-Drill diameter

2-Flutes

3-Lip

4-Drill diameter

18

New cards

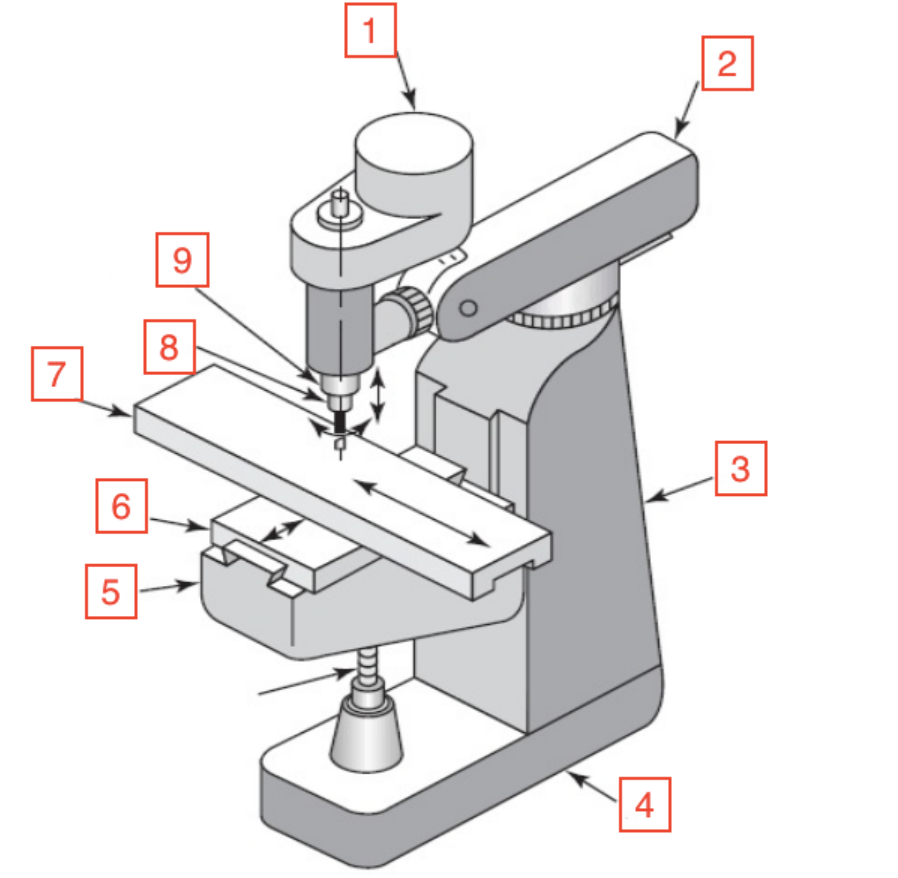

Name of the components of the Mill

1-Motor

2-Overarm

3-Column

4-Base

5-Knee

6-Sadde

7-Table

8-Spindle

9-Quill

2-Overarm

3-Column

4-Base

5-Knee

6-Sadde

7-Table

8-Spindle

9-Quill

19

New cards

Facing

Surfaces are typically positioned perpendicular to the axis of the workpiece in the “___” operation.

\-Dominated by racial feed

\-Dominated by racial feed

20

New cards

Knurling

In an operation known as “_____,” a regular cross-hatched pattern is produced in work surfaces through metal forming

21

New cards

Turning

The generation of any cylindrical surface with a single point tool is referred to as “______.” In this operation, the direction of the feeding motion is predominately axial with respect to the machine spindle.

22

New cards

Chamfering

For a “_____” operation, a tool cuts the corner of a cylinder at an angle

23

New cards

Threading

During a “_____” operation, external or internal threads are achieved by feeding a pointed tool linearly across the outside or inside surface of a rotating part

24

New cards

Drilling

In the “_____” process, a hole is produced by feeding a drill into a rotating workpiece along its axis

25

New cards

Boring

A single point tool is def linearly and parallel to the axis of a workpiece to enlarge a hole made by a previous process in the operation known as “_____”

26

New cards

Parting

For a “_____” operation, the end of a part is cut off by feeding a tool radially into a rotating workpiece at a particular location along its length

27

New cards

Profiling

In a “______” operation, both modes of tool feed are simultaneously desired to create tapered and contoured surfaces