Operations Management: 5.1, 5.2, 5.4, 5.5

1/48

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

49 Terms

What is operations management

Operations Management involves the planning, organising, coordinating and controlling of all activities involved in the transformation of inputs into outputs. It plays an important role in the business’s success.

The aim of operations management (operational targets)

Operational targets:

Effectiveness of operations

Consistently producing products in the;

Right qualities

Right specifications

Efficiency of operations

Producing and delivering products in a cost-efficent manner

Sustainability of operations

Meeting the company’s and the government’s sustainability targets and requirements

Job production

A labour-intensive manufacturing method that involves making customized, one-off, and unique goods or services that meet the specific needs of a specific customer.

Each product is completed before the next is started

Advantages of Job Production

Higher customer satisfaction as products are made specifically for them.

Possible higher prices.

High quality due to skilled workers (USP).

Higher employee motivation due to changing requirements.

Low inventory costs: No need to stockpile finished goods (made-to-order).

Direct interaction with customers fosters brand loyalty.

Disadvantages of Job Production

Labour-intensive, so higher labour costs.

Time-consuming and product-specific decisions must be made → less potential for automation.

Fewer economies of scale due to low output over time.

Possible cash flow challenges as each order is unique and will thus have different costs involved

Batch production

Involves producing a set of identical products

Each batch is fully completed before production switches to another batch.

Each batch may have slightly different specifications

Advantages of Batch Production:

More variety within a given product.

More customers are satisfied overall.

Some flexibility to change the product between batches.

Lower unit costs → more economies of scale as more products are made at once.

If there is a high demand, the business can satisfy it, meaning more profit in absolute terms

Mass production

Involves large-scale production of a standardized product using production-line technology, making it heavily automated

Advantages of Mass Production:

Economies of scale (high volume).

High labour efficiency (workers specialize in one job).

Consistent brand image (standardized products).

Lower labour costs (low labour intensity).

Fewer issues due to lack of motivation.

Disadvantages of Mass Production

High initial set-up costs (machinery purchases).

Lower employee motivation (specialization → repetitive tasks).

Difficult to offer different product choices to consumers.

Higher storage costs (high volume of products).

Disadvantages of Mass/Flow Production

High set-up costs (must buy production line machinery).

Lower employee motivation due to repetitive tasks.

More difficult to offer different product choices to consumers.

Higher storage costs due to higher production volume

Higher costs for mass marketing / above the line promotion

Mass customization

Uses technology to produce a variety of models on the same production line.

Combines high production volume (mass production) with flexibility to tailor products to customer demands (e.g., car configuration)

Advantages of Mass Customization

Potentially higher pricing due to higher customization and general uniqueness of each product

Economies of scale through high production volume

Higher customer satisfaction

Disadvantages of Mass Customization

Heavy investment in technology (capital-intensive).

High set-up costs.

Choosing the Most Appropriate Production Method Depends On

The best method depends on:

Demand for the product (size of the market):

High volume → mass production.

Low volume → job/batch production.

Demand for customization vs. standardization.

Financial considerations:

Initial capital expenditure.

Source of finance.

Ongoing production costs.

Marketing considerations:

Pricing and profitability.

Product positioning (quality vs. standardization, USP, personalized product).

Operations considerations:

Loss of operational flexibility.

Economies of scale.

Technical capabilities (R&D and worker skills).

Problems of Changing Production Methods

Demand factors:

Total market volume and consistency of demand.

Financial constraints:

Capital investment and ongoing costs.

Marketing challenges:

Aligning product positioning with new method.

Operational disruptions:

Loss of flexibility, scaling issues, or skill gaps.

5.4 Location

Location

Refers to the geographical position of the business.

Factors that affect the location of a business (Quantitative)

Cost of rent/mortgage.

Labour costs

Government policies,

Distance to market

How far from customers

Distance to inputs.

Availability of government grants and incentives

Factors that affect the location of a business (Qualitative)

External economies of scale

Infrastructure

Potential employees

Near suppliers.

Political and legal factors.

E.g. Maximum working hours.

Brand image

location of competition

Space for expansion

Quality of life in an area

How attractive is the area

Facilities quality

Standard of living

Ways of reorganizing production both nationally & internationally [AO3]

Offshoring

Refers to when a business relocates part or all of its functions and processes to another country

the part of the business might stay internally or go to an external company

Advantages of Offshoring

Lower costs

Labour costs

Import costs

Government tax advantages

Potentially access specialized labour

Leads to higher production quality,

decision-making-factors

Less strict regulation on

Health and safety

Environmental protection.

Employee rights

Can be closer to market where products are sold

Can lead to better market research thus better decision-making

Disadvantages of Offshoring

Culture/language barriers

Can lead to misunderstandings

Or misinterpretation of the task.

Lower quality output

Or lower productivity.

Increased transportation costs.

As finished goods may have to be transported back

Negative brand image

If employees are not treated well (ethically)

If the environment is damaged in the process

Redundancy of home country workers.

As jobs are moved overseas.

Bad PR for the company

Demotivation of remaining workers

Loss of control over quality

Outsourcing

Refers to when a business subcontracts a process, such as packaging or manufacturing, to another business or organization.

The business buys the service from another company rather than doing it internally

(Can be onshore or offshore)

Advantages of Outsourcing

Business can focus on core functions.

Increases efficiency and productivity

Can lead to lower costs

The outsourced business may have specialized equipment that the business would not invest in given operations.

Quick increase in capacity,

without needing internal methods of growth.

Cost advantage

Disadvantages of Outsourcing

Loss of control

The business loses control over the operation methods used for that specific function

Can lead to lower customer satisfaction due to declining quality.

Redundancy after outsourcing

Can lead to negative publicity as the business may be seen as unethical.

Also lead to resistance from existing workforce

The outsourcing supplier may not deliver according to business's needs

Deliver on time so other operations are not held up

Could cause internal diseconomies of scale.

Working conditions of other producer

Negative brand image affect brand image of business which is outsourcing its functions

Unethical practices of producer

Insourcing

Refers to when a business transfers a previously outsourced function back to the organization's own resources

Advantages of Insourcing

Assurance of quality

Methods and standards can be better overseen and changed by the business.

Cheaper than paying the outsourced organization

Disadvantages of Insourcing

May cause short term reduction in cash flow

Purchasing specialist/ required equipment

May distract the business from its core Function

Must recruit and train employees to work in that part of the business

Must oversee quality.

Can negatively impact cash

takes Longer to generate revenue.

5.5 Break-Even Analysis

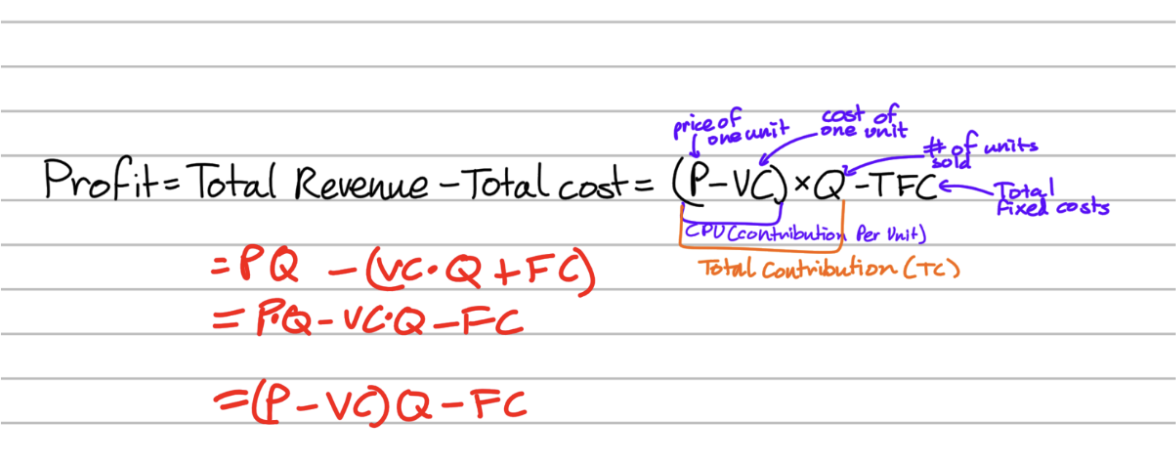

Governing Equation for Break-Even Analysis

Contribution per unit

CPU (Contribution Per Unit)

The amount of money a business makes from selling each unit of a product after covering variable costs.

CPU = Price - Variable cost

Total Contribution

The total amount of money which contributes to the fixed costs

The total profit after selling all units of production and covering variable costs

TC=CPUxQuantity = (Price-Variable cost)x Quantity

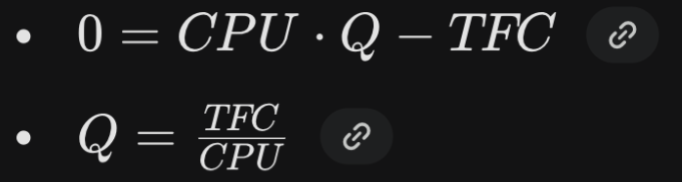

Break-even quantity

The level of output or production at which a business's sales generate just enough revenue to cover all costs

No profit or loss is made at this point.

0 = Total Revenue - Total Costs

Solve for Break-even quantity (BEQ)

Solve for Break-Even Revenue

Revenue = Price Quantity

Break-even Revenue = Price Break-Even Quantity

Break-Even Point

The point where the total revenue and total costs are equal

Target Profit

The amount of profit that a business aims to earn within a given time period

This is usually given and you will have to solve for

Quantity

Price

Target Profit output (Q)

The quantity of sales required to reach the firm's target profit

Set Q as unknown

Target price

The price of a product per unit in order to reach the firm's target profit

Set price as unknown

Break-even price

A special case of target price where the target profit equals , namely when the business breaks even

Margin of safety

The difference between how much a business sells and its BEQ

Steps for drawing a break-even chart

X axis is "Sales quantity (product)"

Y-axis is "Costs and revenues (currency)"

Step 1: Calculate BEQ & B-E Revenue

Step 2:

Make x-axis range 2x or 1.5x BEQ

Make y-axis range 2x or 1.5x BE Revenue

Step 3: Draw total fixed cost line

Step 4: Add Break-even point on chant (BEQ, BE-Revenue)

Step 5: Draw total Revenue line connecting (0,0) to BEP

Step 6: Draw total cost line from TFC to BEP

Step 7: Title and labels:

Break-even chart for xxx

Axes (see above)

Label BEP, BEQ, BE- Revenue

Step 8: Add arrows & a dotted line for margin of safety.

Effect of price on the profit and margin of safety

Increase in price

Profit = (Price -Variable cost)x Quantity-Fixed cost

Revenue = Price x Quantity

BEQ ↓ CPU ↑ Margin of safety ↑

Margin of Safety increases because the BEP is at a lower quantity

Decrease in price

Opposite of above

Effect of fixed costs on the profit and margin of safety

Increase in fixed costs.

TC = FC + VC

TC shifts upwards (y-int)

CPU stays the same

Profit margin.

GPM stays the same

BEQ ↑ Margin of safely ↓

Effect of Variable cost per unit on profit and margin of safety

Increase in variable cost:

TC = FC + Q x VC

TC will pivot upwards.

CPU ↓

CPU= Price-Variable costs

Profit margin ↓

BEQ ↑

Margin of Sales ↓

Profit ↓

Decrease

Opposite of above

Advantages of Break-Even Analysis

Visual and easy to interpret

Provides guidelines

Will the business make a profit?

How close to a loss is the business

Facilitates Scenario Analysis

profit under different.

at situations

Check

Can be of value in supporting a business's application for a bank loan

Disadvantages of Break-Even Analysis

Costs and prices change frequently

Break even analysis may not be realistic

Costs and Revenues are not usually Straight lines

Total Revenue line does not consider demand

TC: Economies of scale may exist

Assumes all stock is sold