Amorphous solid dispersions

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

21 Terms

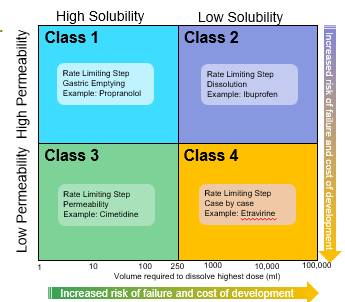

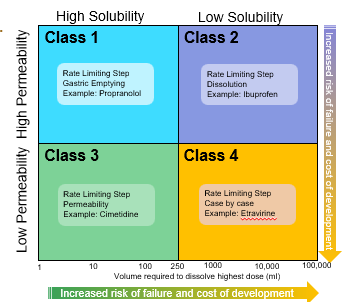

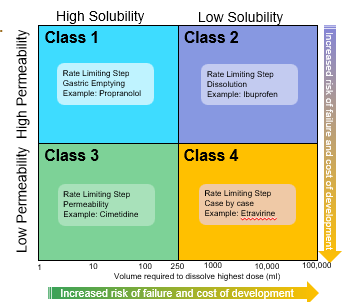

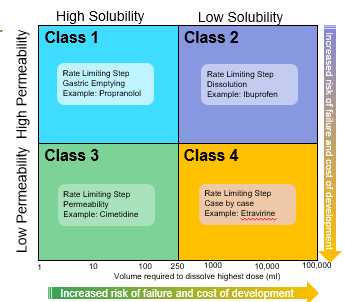

From a delivery perspective drugs for oral delivery need to display:

adequate solubility and dissolution properties

adequate absorption through the gut (eg. permeability)

The bioavailability of a drug: class 1

is determined only by delivery of the drug solution to the intestine

Formulation independent

Rate Limiting Step: Gastric Emptying

The bioavailability of a drug: class 2

Rate limiting step: drug solubility/dissolution

Formulation dependent

The bioavailability of a drug: class 3

Rete limiting step: intestinal permeability

Dependent on barrier properties

The bioavailability of a drug: class 4

Rate limiting step: solubility /dissolution and intestinal permeability

Formulation and barrier properties dependent

Oral Formulation approaches for poorly water soluble compounds → rank: Conventional → Non-Conventional : Risk and complexity

Salt formulation/ particle size reduction

Self-Emulsifying Drug Delivery Systems (SEDDS)/ Complexes

Nanoparticles/ Crystalline solid dispersions

Amorphous drug and Amorphous Solid Dispersions

Particle size reduction

Increases dissolution because for a given solute mass there is more surface area exposed to the solvent. Can work well for BCS Class 2 (low sol, high permeability)

SEDDS (Self-Emulsifying Drug Delivery Systems)

Stable mixtures of oil, surfactant, co-surfactant and drug that spontaneously form fine oil in water emulsions (down to 50nm in size) on exposure to water. Formulated in capsule form

Complexes

Entrapping poorly soluble drug within a soluble structure can be used to increase bioavailability

Nanoparticles

increased surface to volume ratio dissolves more quickly

Specialised nano-milling using surfactants to stabilise the nanoparticles can increase bioavailability.

Crystalline Solid Dispersions

Small ordered particles of drug are stabilised in a solid water-soluble polymer matrix

Amorphous drug and Amorphous Solid Dispersions

Disrupt ordered crystalline state to form a disordered amorphous state.

Solid now dissolutes much more rapidly.

Drug can also be molecularly dispersed and stabilised in a solid water-soluble polymer matrix. Often known as a Solid Solution.

What influences physical stability of amorphous materials and solid dispersions?

Glass transition temperature (Tg)

What is the Glass transition temperature (Tg)?

is a physical transition that takes place in amorphous materials, from a brittle to a rubbery state.

The lower the Tg…

the less stable the amorphous material may be

Main manufacturing methods for solid dispersions

Solvent based methods

Heat based methods

Solvent based methods:

Spray drying

Rapid solvent evaporation.

Needs acceptable solubility of drug in low boiling solvent required.

Heat based methods

Hot melt extrusion

Temp. and shear can cause degradation

No solvent required

Melting point < 200 °C required

Why the amorphous form of a poorly soluble drug is an important formulation strategy to bring such drugs to market.

Curial for poorly soluble drugs

Micro and Nanoscale analysis of spray dried solid

Small piece cut using an ion beam in the microscope

high-powered transmission electron microscope (TEM)

TEM of slice shows no structure, so drug is well dispersed in the polymer (no crystals)

At high temperatures drug starts to separate out and crystalize. Spectral amylases confirms that the dark spots are drug (contain Bromine)