Intro to Occlusion Exam 1 [Alginate and Gypsum]

1/81

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

82 Terms

Occlusion

The static relationship between the incising or masticating surfaces of the maxillary or mandibular teeth or tooth analogues

Articulation

The static and dynamic contact relationship between the occlusal surfaces of the teeth during function

Alginate is an

irreversible hydrocolloid

Alginate is a commonly used material for the ________ of hard and soft tissue

registration (impression)

Uses of Alginate:

Study casts

Preliminary casts for making custom trays

Definitive removable partial denture impressions

Alginate: SOL-GEL reaction

Sol: Suspension of dispersion of larger particle in a solvent

Gel: A colloidal system in which solid and liquid phases are continuous

Alginic acid

Mucous derived from seaweed is rich in alginic acid, which is a copolymer of

- anhydro-B-D-Mannuronic acid

- anhydro-B-L-Guluronic acid

Insoluble in water except when it is in its salt form (chelated with Na or K)

Alginic acid must be in ___ form to dissolve in water

salt form (chelated with Na, K)

When the salt form of Alginic acid mixes with water, a

viscous sol is formed which acts to create a supporting matrix or scaffold

The chelated for of Alginic acid =

Potassium alginate

Setting reaction:

Calcium sulfate + Potassium alginate = Insoluble calcium alginate

Potassium alginate

Alginic acid in salt form so that it is soluble in water to for a sol

Function:

- Soluble alginate

Weight percentage

- 15

Calcium sulfate

Calcium sulfate is the reactor:

- Provides calcium ions to the alginate scaffold

Function:

- Reactor

Weight percentage

- 16

Filler particles

Diatomaceous earth and Zinc oxide are your fillers

Diatomaceous earth

Acts as a filler

- Increases strength and stiffness

- Smoother texture

- Firm surface

Function:

- Filler particles

Weight percent:

- 60

zinc oxide

Also a filler

Function:

- Filler particles

Weight percent

- 4

Potassium titanium fluoride

Helps accelerate the setting of stone once poured

- Creates a hard, dense surface

Function:

- Gypsum hardener

Weight percent:

- 3

Sodium phoshate

The potassium ions in the alginate scaffold are replaced with calcium very rapidly

Sodium phosphate acts as a retarder and defers this reaction, so that the working time is sufficient

Function:

- Retarder

Weight percent

- 2

Setting reaction: described

Potassium alginate with water forms a viscous Sol scaffold

Calcium ions replace the potassium ions to cross link and stabilize the scaffold

The production of insoluble calcium alginate is too rapid for practical use- so we must

add a retarder to slow this down and give us more working time

We use sodium phosphate:

- Phosphate ions preferentially consumes calcium

Elastic recovery

How well an impression material is able to maintain its original shape after it is taken out of the patients mouth

Alginate has _____ elastic recovery

poor

Other materials are better suited for elastic recovery

Alginate's flexibility is ____ compared to other impression materials

better

Reproduction limit

Have a groove that is 25 microns thick, and you impress that groove with your impression material. If you are able to accurately replicate that 25 micron groove then you have a good ability to replicate what you need.

Alginates Reproduction limit compared to other impression materials is

Poor

Alginates tear strength compared to other impression materials

Poor

Advantages of Alginate

Non toxic

Accurate

Inexpensive

Easy to manipulate

Disadvantages of Alginate

Non-correctable

Give clinically overextended borders

Compresses soft tissue

Must pour immediately

Can react (etch) the gypsum cast

EFFECT: Grainy material

Improper mixing

Excessive gelation

Water/Powder ratio too low

EFFECT: Tearing

Premature removal from the mouth

Moisture contamination

Prolonged mixing

EFFECT: Bubbles

Air incorporation during mixing

Moisture or debris on tissue

EFFECT: Distortion

Impression not poured immediately

Moving the tray during gelation

Premature/improper removal from the mouth

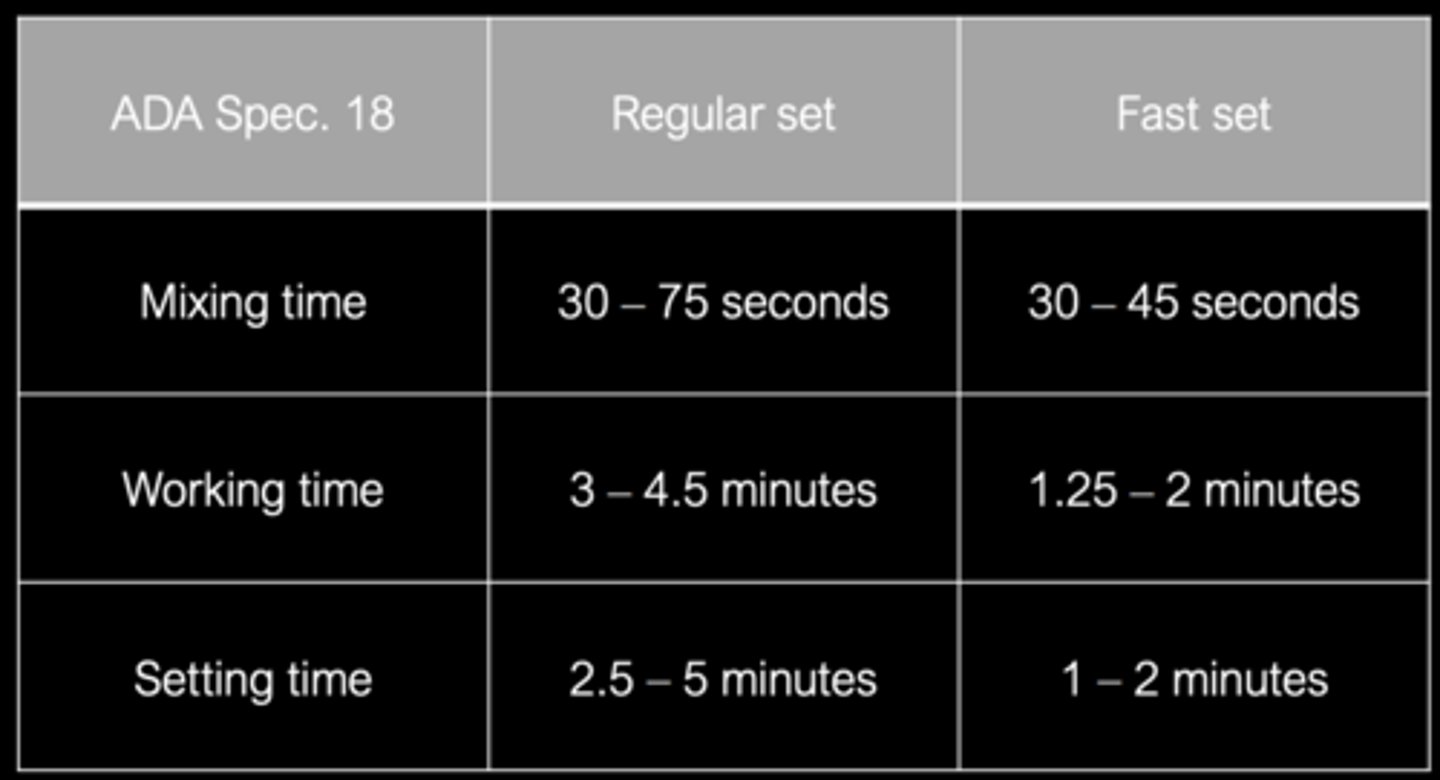

ADA Standards

Not on study guide

Alginate impressions should be poured within ___ to avoid syneresis and imbibition

12 minutes

Syneresis

Calcium organizes the water in the "sol" scaffold as it turns to "gel"

Squeezes water out

Continue to lose water after alginate sets

Limit its effect on dimensional stability by pouring impression immediately after removal from mouth

TIP:

Syneresis = Shriveled (both start with S)

Imbibition

Gel state can absorb water

Also causes dimensional change

Similar to osmosis

TIP:

ImBIBition

(wear a BIB when you eat which makes you bigger)

Handling rules

Use distilled water

Use room temperature water

Mix proper amount of time

Remove with a snap

Store in a sealed plastic bag

Pour within 12 minutes

WHY THE RULES: Distilled water

Hardness range

WHY THE RULES: Room temp water

Setting time changes

WHY THE RULES: Mix proper amount of time

Otherwise grainy

WHY THE RULES: Remove with snap

Elastic recovery, compressive and tear strength all improved

WHY THE RULES: Store in sealed plastic bag

100% relative humidity

WHY THE RULES: pour within 12 minutes

Avoid syneresis

Changing water:powder ratio

Changes consistency

Strength (thicker = stronger)

Working and setting time (thicker = faster)

Flow (thicker= more voids and less detail for teeth)

Soft tissue displacement (thicker = pushes lips and cheeks more)

Changing water: powder ration

More thick means

more powder

Gypsum uses

Impression plasters

Model stones

Die materials

Binder for silica investments

Gypsum is composed of

calcium sulfate and water

Gypsum can exist in

dihydrate and hemihydrate forms

Gympsum is typically mined as the

dihydrate

Calcination

Heating process performed by the manufacturer to create a hemihydrate powder form of the product

This hemihydrate form is what we use in dentistry

The _____ form is what we use in dentistry

Hemihydrate

Type I

Impression plaster

Type II

Model plaster

Type III

Dental stone

Type IV

High strength stone

Type V

High strength and high expansion stone

All type of Gypsum classification

have the same chemical formation

Physical properties of Gypsum classifications are derived from how the

water is driven off in the calcination reaction

What type of gypsum classification do we use in the lab to pour our cast

Type III

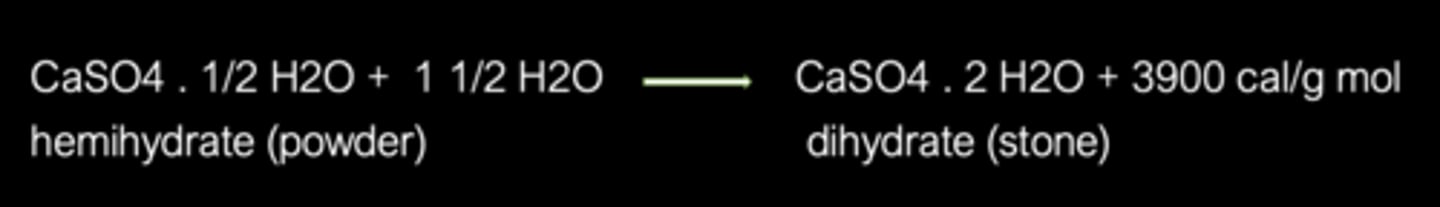

Calcination: reaction

CaSO4 , 2H2O (Mined dihydrate) --> CaSO4 , 1/2 H2O (Hemihydrate powder)

Hemihydrate can be classified based on the physical form of the actual powder particles

Beta-hemihydrate

Alpha- hemihydrate

Modified alpha-hemihydrate

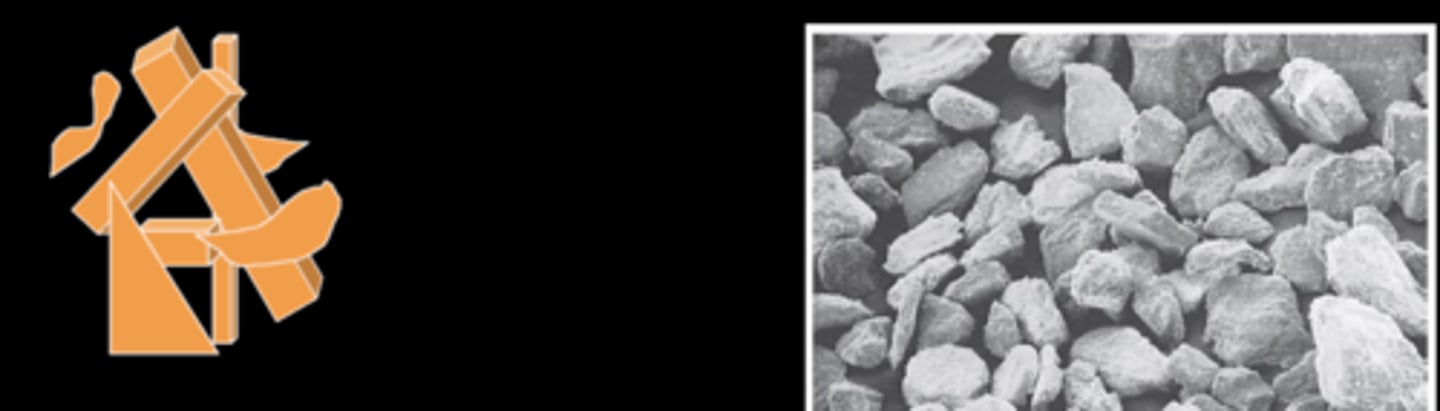

Beta-hemihydrate

Plaster

Rough and irregular particle shapes

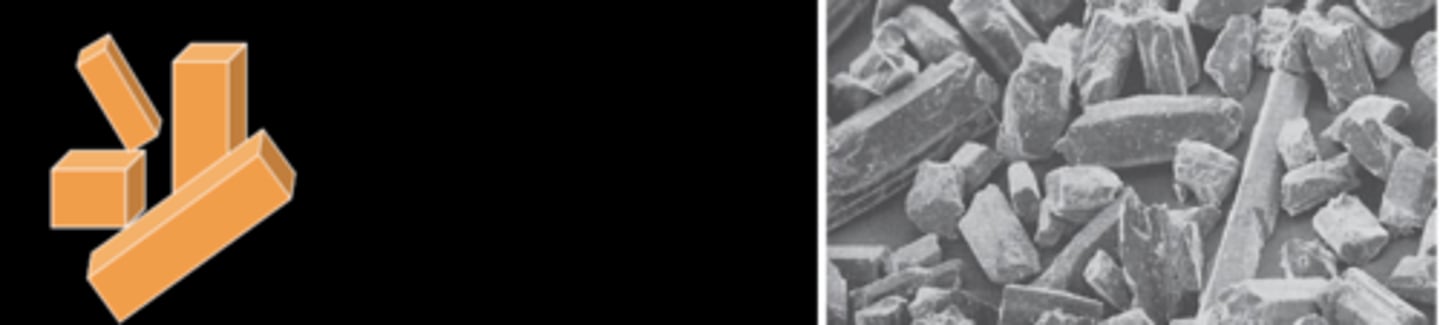

Alpha-hemihydrate

Stone

Uniform, dense particle

Modified alpha-hemihydrate

Die stone

Shorter and thicker particles

Type I: Impression plaster

Type II: Model Plaster

Beta-Hemihydrate

Type III: Dental Stone

Alpha-Hemihydrate

Type IV: High-strength stone

Type V: High-strength, high expansion stone

Modified Alpha-Hemihydrate

Manufacturing a processes of dehydration: Type II Plasters

Open kettle heating around 110-120 degrees celcius

Results in predominantly irregular shaped particles (Beta-hemihydrate)

Manufacturing a processes of dehydration: Type III Dental stones

Dehydration under pressure in the presence of water vapor to control the rate of water loss

Creates a more uniform particle shape (alpha-hemihydrate)

Manufacturing a processes of dehydration: Type IV and V die stones

Dehydration in the presence of 30% CaCl2

Milling of the final product is then performed to create a very uniform sized particle

All gypsum products set by

the same reaction

Chemically, 100g of hemihydrate requires only _____ mL water to form the dihydrate form

18.61

Derived primarily from the shape and form of the hemihydrate particles in the powder

The more uniform the particle size, the

less water is need to "Wet" the particles and thus the more dense, less porous the set mass

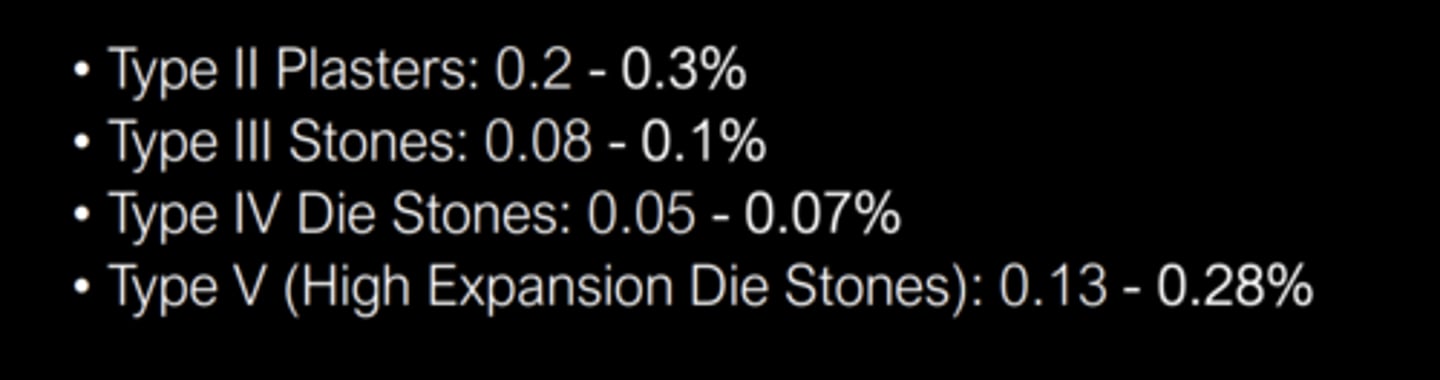

Setting expansion

All gypsum materials demonstrate some linear expansion upon setting

Compressive strength

Strength values increase from plasters to the die stones

Depends on the water/powder ration

Controlling setting time

Performed during manufacturing and clinically

Chemical modifiers like accelerators and retarders can be added by manufacturers to control setting time

Chemical modifiers: Accelerators

Potassium sulfate

Calcium sulfate dihydrate

Sodium chloride acts as an accelerator but also increases expansion

Chemical modifiers: Retarder

Borax

Controlling setting time Clinical modification

Adding slurry water (water saturated with fine gypsum particles) to accelerate setting

Changing the water/powder ratio- the high the ratio the more delayed the setting

Spatulation

water temperature

contamination

Spatulation

Mixing increases the number of nucleation sites, accelerating the setting reaction

Water temperature

Elevated temperature increases ion mobility which tends to offset the change in solubility

Contamination

Colloidal solutions block the expansion of the calcium sulfate dihydrate crystals leading to a soft porous surface to the stone

RINSE RINSE RINSE